Acerola cherry fruit powder and preparation method thereof

A technology of acerola fruit, acerola

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

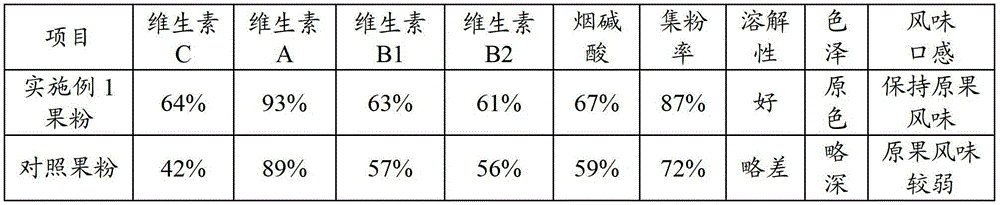

[0026] Embodiment 1: prepare acerola cherry fruit powder with preparation method of the present invention

[0027] Choose fruits with high maturity, plump and bright colors, and no rot and mildew. Rinse the acerola fruit, add 5% NaOH solution at 80°C, soak for about 2 minutes, remove it and put it in a container that can leak, control the water flow rate to rinse the acerola, then pour it into a glass container, and use a wooden stick Stirring, add appropriate amount of sodium sulfite to make SO 2 The content reaches 100mg / L, stir the mixture vigorously, and sieve to remove the acerola cherry seeds and peeled off peel.

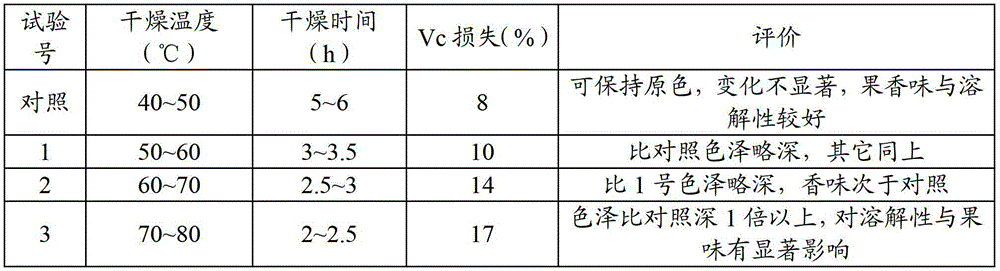

[0028] Send the coniferous cherry mixture into the pitted double-pass beater for beating (the first pass beater has a sieve diameter of 3 mm, and the second pass beater has a sieve diameter of 0.6 mm) to obtain acerola cherry pulp; the above-mentioned separated pulp Add 0.5% citric acid and 0.2% sodium chloride (ie deastringent solution) to the pulp, and tre...

Embodiment 2

[0031] Embodiment 2: prepare acerola cherry fruit powder with preparation method of the present invention

[0032] Choose fruits with high maturity, plump and bright colors, and no rot and mildew. Rinse the acerola fruit, add 5% NaOH solution at 80°C, soak for about 2 minutes, remove it and put it in a container that can leak, control the water flow rate to rinse the acerola, then pour it into a glass container, and use a wooden stick Stirring, add appropriate amount of sodium sulfite to make SO 2 The content reaches 100mg / L, stir the mixture vigorously, and sieve to remove the acerola cherry seeds and peeled off peel.

[0033] Send the coniferous cherry mixture into the pitted double-pass beater for beating (the first pass beater has a sieve diameter of 3 mm, and the second pass beater has a sieve diameter of 0.6 mm) to obtain acerola cherry pulp; the above-mentioned separated pulp Add 0.5% citric acid and 0.2% sodium chloride (ie deastringent solution) to the pulp, and tre...

Embodiment 3

[0036] Embodiment 3: prepare acerola cherry fruit powder with preparation method of the present invention

[0037] Choose fruits with high maturity, plump and bright colors, and no rot and mildew. Rinse the acerola fruit, add 5% NaOH solution at 80°C, soak for about 2 minutes, remove it and put it in a container that can leak, control the water flow rate to rinse the acerola, then pour it into a glass container, and use a wooden stick Stirring, add appropriate amount of sodium sulfite to make SO 2 The content reaches 100mg / L, stir the mixture vigorously, and sieve to remove the acerola cherry seeds and peeled off peel.

[0038] Send the coniferous cherry mixture into the pitted double-pass beater for beating (the first pass beater has a sieve diameter of 3 mm, and the second pass beater has a sieve diameter of 0.6 mm) to obtain acerola cherry pulp; the above-mentioned separated pulp Add 0.5% citric acid and 0.2% sodium chloride (ie deastringent solution) to the pulp, and tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com