Preparation method for radix puerariae lactobacillus effervescent tablet

A technology of kudzu root lactic acid bacteria and effervescent tablets, which is applied in the direction of lactobacillus, food preparation, streptococcus/lactococcus, etc., can solve the problems of high storage, transportation and sales costs, and achieve good product stability, easy absorption, and high comprehensive utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

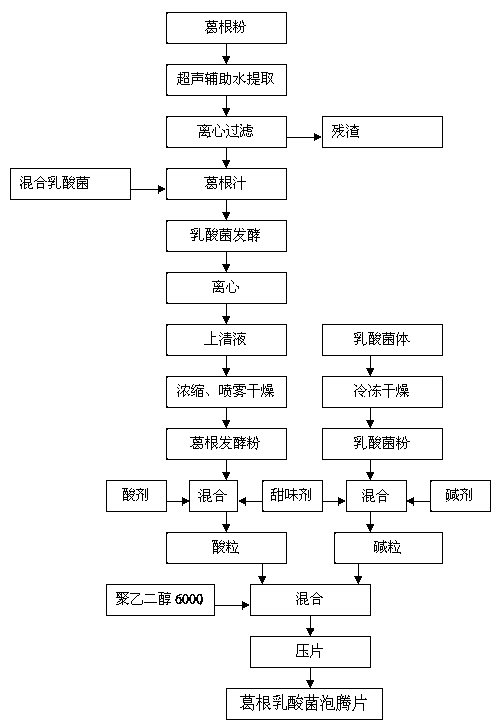

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of kudzu root juice: 1kg of kudzu root was pulverized to 80 mesh by dry method, and 2.4L tap water was added at 1w / cm 3 Under the ultrasonic power of 20℃, circulate extraction for 30min, centrifuge and filter, and sterilize the filtrate at 80℃ for 30min.

[0023] (2) Fermentation: Add mixed strains of Lactobacillus bulgaricus, Streptococcus thermophilus and Lactobacillus plantarum to Pueraria lobata juice, the ratio of each strain is 1:1:1, the amount of mixed strain is 3cfu, and the fermentation is kept at 37℃ for 72h , The total number of lactic acid bacteria in the fermentation broth reached 11cfu, pH 3.6, 0.5% reducing sugar and 2.3g / L flavonoid content.

[0024] (3) Filtration: After the fermentation, the fermentation broth is centrifuged and filtered at 5000 r / min for 15 minutes to obtain 1.6L of supernatant and 24g of lactic acid bacteria.

[0025] (4) Preparation of kudzu root baking powder: Concentrate the supernatant obtained in step (3), vacuum conce...

Embodiment 2

[0028] The process is the same as in Example 1.

[0029] Step (2): Lactobacillus bulgaricus, Streptococcus thermophilus and Lactobacillus plantarum mixed strains, the ratio of each strain is 1:1:2, the inoculation amount of the mixed strain is 3cfu, the fermentation temperature is 20℃, and the fermentation time It is 120h. The total number of lactic acid bacteria in the fermentation broth reached 8cfu, pH3.9, 0.2% reducing sugar and 2.1g / L flavonoid content.

[0030] Step (3): After the fermentation is finished, the fermentation broth is filtered by centrifugation at 8000 r / min for 5 min to obtain 1.4L of supernatant and 21g of lactic acid bacteria.

[0031] Step (4): vacuum concentration is carried out at a vacuum degree of 0.1 atmosphere to a solid content of 30%, and spray-dried to obtain 0.4 kg of kudzu root baking powder.

[0032] Step (5): The raw and auxiliary materials are composed of 21 g of lactic acid bacteria, 0.4 kg of kudzu root baking powder, 0.004 kg of strawberry fla...

Embodiment 3

[0034] The process is the same as in Example 1.

[0035] Step (2): Lactobacillus bulgaricus, Streptococcus thermophilus and Lactobacillus plantarum mixed strains, the ratio of each strain is 1:1:3, the inoculation amount of the mixed strain is 6cfu, the fermentation temperature is 40℃, and the fermentation time For 6h. The total number of lactic acid bacteria in the fermentation broth reached 8cfu, pH3.8, 1.3% reducing sugar and 2.1g / L flavonoid content.

[0036] Step (3): Centrifugation. Centrifuge at 3 000 r / min for 30 min to obtain 1.8 L of supernatant and 23 g of lactic acid bacteria.

[0037] Step (4): the Pueraria lobata fermentation broth is vacuum concentrated to a solid content of 60% under a vacuum degree of 0.4 atmospheres, and spray-dried to obtain 0.7 kg of Pueraria lobata fermentation powder.

[0038] Step (5): The composition of the raw and auxiliary materials is: 23 g of lactic acid bacteria, 0.7 kg of kudzu root baking powder, 0.56 kg of citric acid, 0.56 kg of baki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com