Waterborne epoxy graphene zinc anticorrosive coating and preparation method and application thereof

A technology of water-based epoxy and anti-corrosion coatings, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problem of reduced impact resistance and wear resistance, zinc powder sedimentation in zinc-rich paints, and changes in coating adhesion Poor and other problems, to achieve the effect of reducing content, improving adhesion, and improving shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The embodiment of the present invention also provides the preparation method of described waterborne epoxy graphene zinc anticorrosion coating, comprising:

[0039] mixing a water-based epoxy resin curing agent, a dispersant, an anti-sedimentation agent and a film-forming aid to form a mixture, and then mixing a graphene dispersion slurry, an extender pigment and zinc powder with the mixture to obtain component one;

[0040] Mix water-based epoxy emulsion, anti-flash rust agent, water and defoamer to obtain component 2;

[0041] The obtained component one and component two are uniformly mixed to form the waterborne epoxy graphene zinc anticorrosion coating.

[0042] In some embodiments, the preparation of component one specifically includes: mixing the water-based epoxy resin curing agent, dispersant, anti-sedimentation agent and film-forming aid, and dispersing at a speed of 400-600r / min for 5-10min to form a mixture, and then Add the graphene dispersion slurry into t...

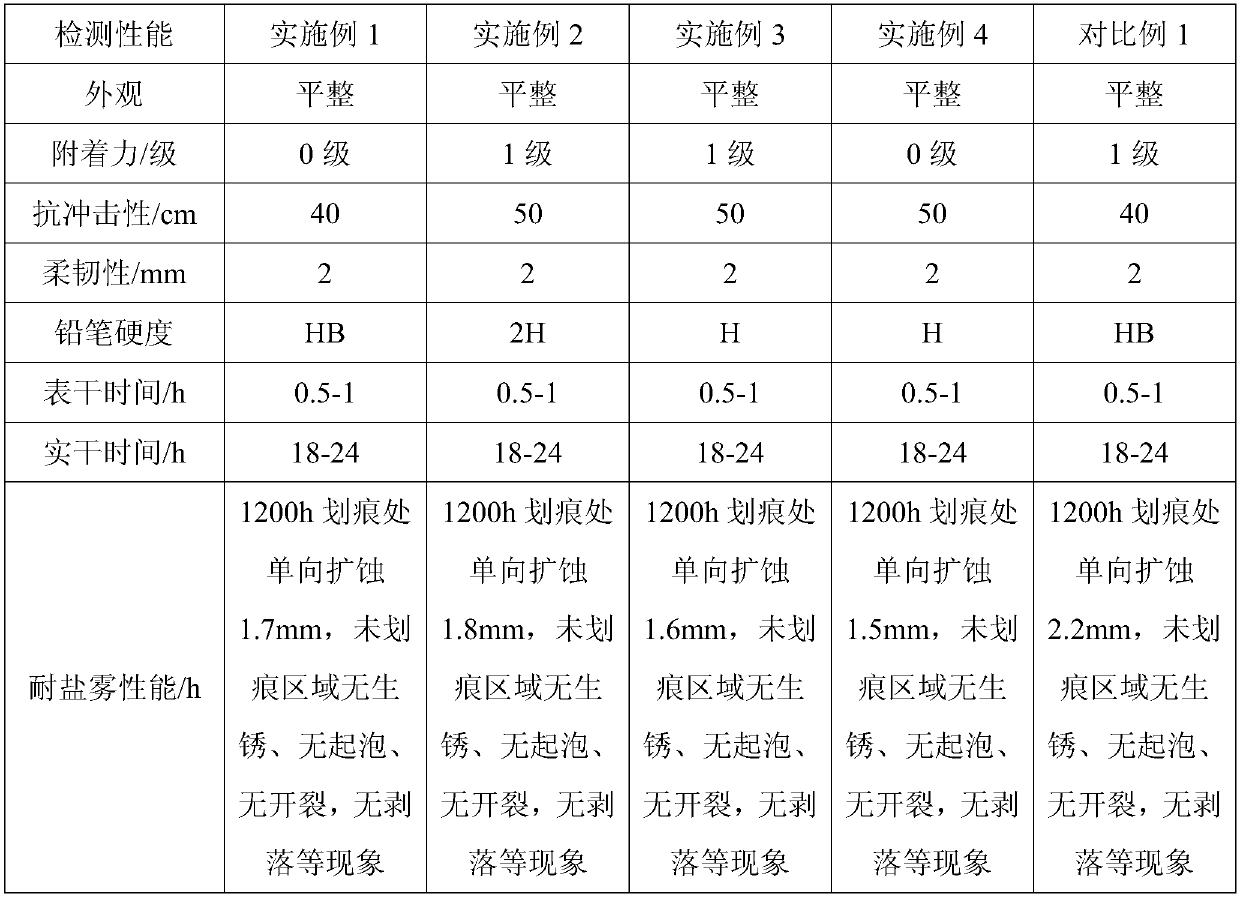

Embodiment 1

[0052] Put 5 parts of water-based epoxy curing agent, 0.5 parts of dispersant, 0.5 parts of fumed silica, 0.25 parts of polyamide wax, 0.25 parts of bentonite, and 1 part of propylene glycol methyl ether into the metal tank in sequence, and stir at 400-600r / min Disperse for about 10 minutes to obtain a semi-finished coating;

[0053] 0.2 parts of graphene, 2.3 parts of butyl glycol acetate, and 2 parts of propylene glycol methyl ether were stirred and mixed evenly, and then ultrasonically dispersed for 2 hours to obtain a graphene dispersion slurry;

[0054] Stir and disperse 4.5 parts of the above-mentioned graphene dispersion slurry at 800-1000r / min for about 5 minutes, add to the aforementioned semi-finished coating, and then add 2.5 parts of talc powder, 2.5 parts of mica powder, 5 parts of precipitated barium sulfate, and 40 parts of ordinary zinc powder and 2 parts of ultra-fine zinc powder, stirring and dispersing at a speed of 1000-2000r / min for about 20 minutes, the f...

Embodiment 2

[0059] Put 10 parts of water-based epoxy curing agent, 1 part of dispersant, 1.5 parts of fumed silica, 0.75 parts of polyamide wax, 0.75 parts of bentonite, and 3 parts of propylene glycol methyl ether into a metal tank in sequence, and stir at 400-600r / min Disperse for about 10 minutes to obtain a semi-finished coating;

[0060] 0.7 parts of graphene, 2.3 parts of butyl glycol acetate, and 2 parts of propylene glycol methyl ether were stirred and mixed evenly, and then ultrasonically dispersed for 2 hours to obtain a graphene dispersion slurry;

[0061] Stir and disperse 5 parts of the above-mentioned graphene dispersion slurry at 800-1000r / min for about 10 minutes, add to the aforementioned semi-finished coating, and then add 2.5 parts of talc powder, 2.5 parts of mica powder, 10 parts of precipitated barium sulfate, and 55 parts of ordinary zinc powder and 10 parts of ultrafine zinc powder, stirring and dispersing for about 20 minutes at a rotating speed of 1000-2000r / min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com