SnO2/modified carbon nanotube composite electric heating thin film and preparation method thereof

A technology of nanotube compounding and carbon modification, which is applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of high surface resistance of semiconductor electric heating films, inability to prepare high-temperature conductive films, and high cost of carbon-based electric heating films. Low cost, high hardness, and the effect of increasing carrier concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

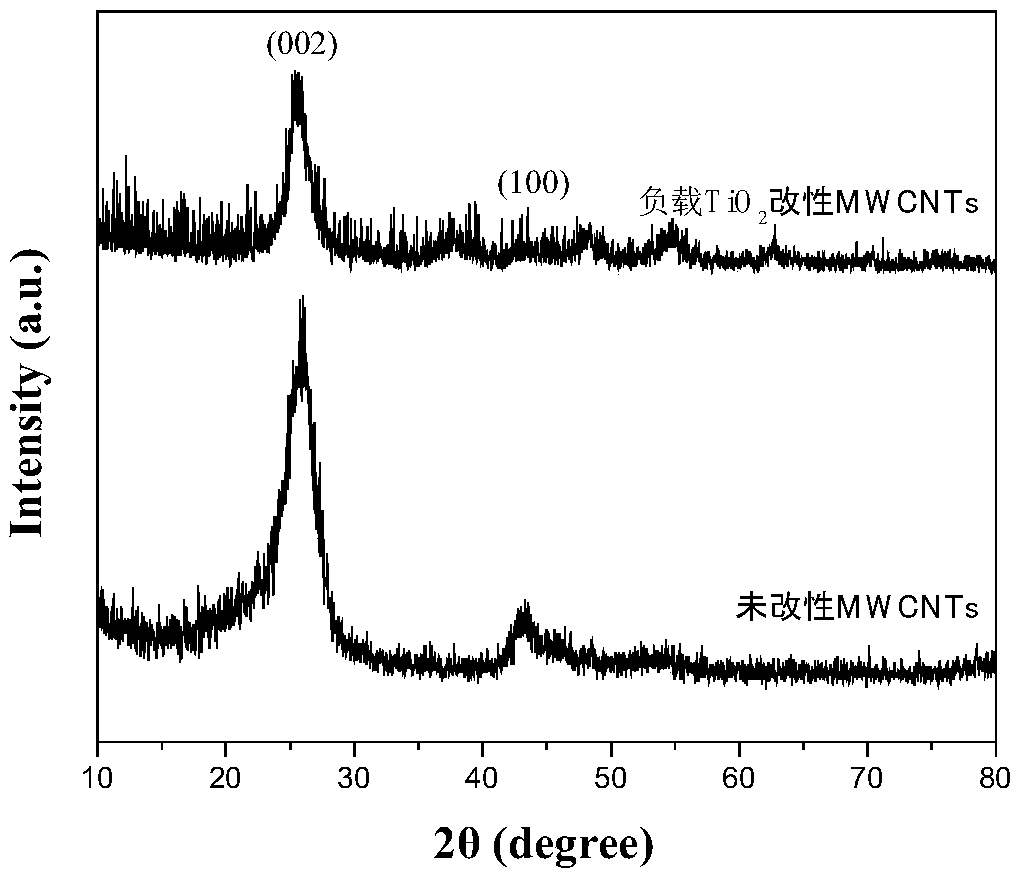

[0028] SnO of the present invention 2 / Modified carbon nanotube composite electrothermal film includes modified carbon nanotubes and SnO with a mass ratio of 0.005:1 2 . Among them, the modified carbon nanotubes are supported TiO 2 Multi-walled carbon nanotubes with a loading ratio of 1:1.

[0029] The preparation method of the electrothermal film comprises the following steps:

[0030] (1) Carbon nanotube impurity removal: take multi-walled carbon nanotubes and roast them in air at 400°C for 1 hour, then put them into 20% dilute nitric acid solution for 30 minutes of ultrasonication, let them stand for 6 hours, then filter and wash them with distilled water until they are neutral, then dry them. Grind and set aside. The present invention can effectively remove amorphous carbon impurities such as amorphous carbon by heating and oxidizing multi-walled carbon nanotubes in air, oxidizing dilute nitric acid and ultrasonically standing can remove remaining amorphous carbon, cat...

Embodiment 2

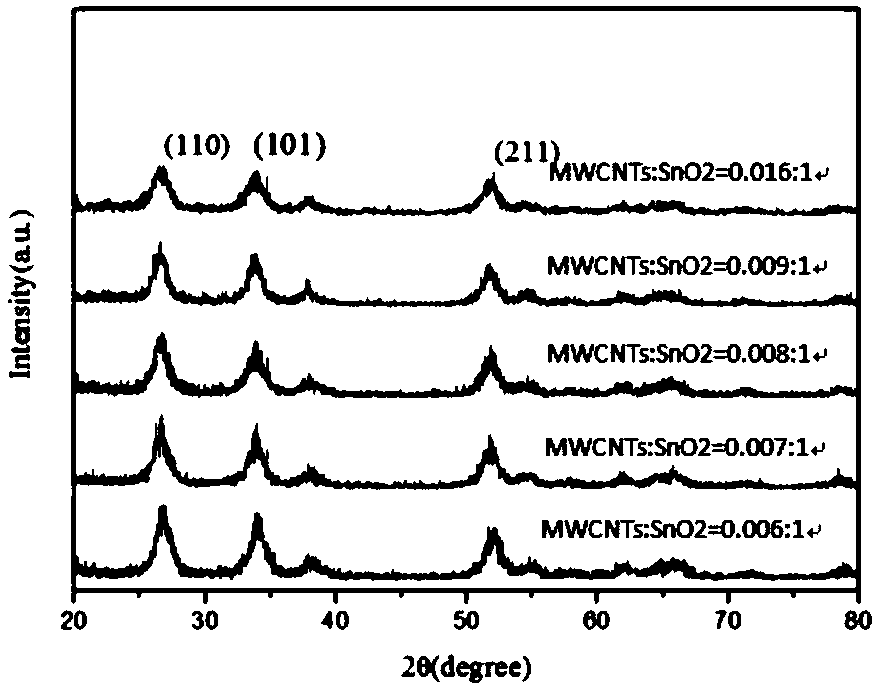

[0043] Design 5 groups of parallel experiments, basic steps are identical with embodiment 1, difference is the addition of carbon nanotube, it and SnO 2 The mass ratios are 0.006:1, 0.007:1, 0.008:1, 0.009:1 and 0.016:1, respectively.

[0044] The electrothermal film prepared in this embodiment was tested for performance, and the obtained results are shown in Table 2 below.

[0045] Table 2 The performance table of the electrothermal film prepared by embodiment 2

[0046]

[0047] Combining Table 2 and image 3 It can be seen that the electrothermal film prepared by the present invention has the advantages of high thermal efficiency, good chemical stability, etc., the sheet resistance is less than 100Ω / □, the emissivity reaches 0.9, and the electrothermal conversion efficiency is >90%, which can replace the traditional heating resistor and thermal efficiency is not high. Excellent heating element. When the content of carbon nanotubes is too much, due to their small size,...

Embodiment 3

[0076] Design group parallel experiments, the basic steps are the same as in Example 1, except that the concentration of tin element in the electrothermal film precursor solution is 0.4mol / L, 0.6mol / L, 0.8mol / L and 1mol / L respectively.

[0077] The electrothermal film prepared in Example 3 was tested for performance, and the obtained results are described in Table 6 below.

[0078] The performance table of the electrothermal thin film prepared in table 6 embodiment 3

[0079]

[0080] It can be seen from Table 6 that when the concentration of tin element in the electrothermal film precursor solution is 0.4-0.8mol / L, the prepared electrothermal film has the advantages of high thermal efficiency, good chemical stability, etc., the sheet resistance is less than 100Ω / □, and the emission The rate reaches 0.9, and the electrothermal conversion efficiency is >90%. If the concentration is low, lower than 0.4mol / L, the sample sprayed with the same solution will have less solute prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com