Water-based electronickelling sealing agent and preparation method thereof

A technology of electroplating nickel and sealing agent, applied in the field of water-based nickel electroplating sealer and preparation, can solve problems such as poor resistance to salt spray corrosion, achieve good sealing effect, enhance wettability, and improve resistance to salt spray corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

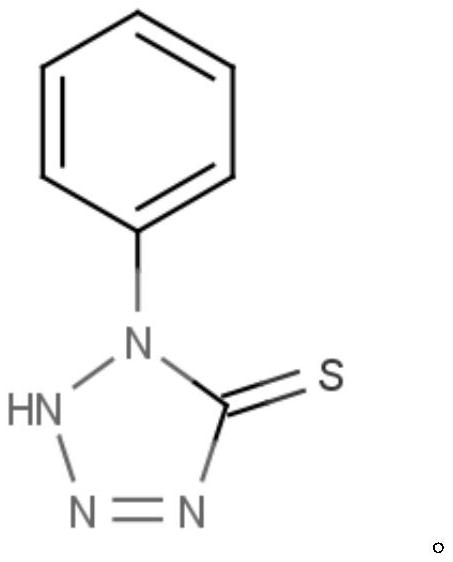

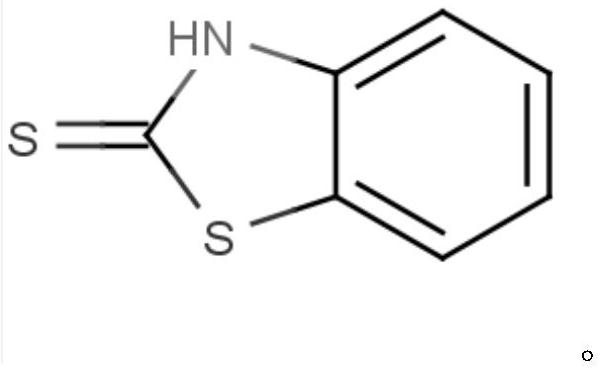

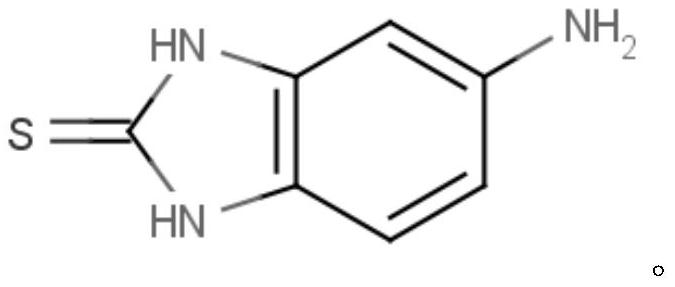

[0061] The raw materials used in Examples 1 to 5 are all the same except for the complexing agent, but the proportions are different. The imidazole heterocycles and derivatives thereof added in the water-based electroplating nickel sealing agent of Examples 1 to 5 are respectively Imidazole (Example 1), Methylimidazole (Example 2), Benzotriazole (Example 3), Tolylbenzotriazole (Example 4) and Methylimidazole (Example 5). There are certain differences between Embodiment 6 and Embodiment 7 and Embodiment 1 to Embodiment 5 in terms of raw materials.

[0062] The preparation process of the water-based electroplating nickel sealing agent of embodiment 1~embodiment 7 is as follows:

[0063] 1. Add alcohol solvent into the container, then add the fused heterocyclic compound containing mercapto (-SH), stir until completely dissolved, divide the water into two parts with similar volumes, add one part into the container and continue stirring until the solution is clear;

[0064] 2. Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com