Method for extracting oil from peony seeds or peony seed dregs

A peony seed meal and peony seed technology, which is applied in the production of edible oil/fat, fat oil/fat, and fat production, can solve the problems of high energy consumption, high cost, and solvent residue, and achieve low energy consumption and low equipment requirements , No solvent residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

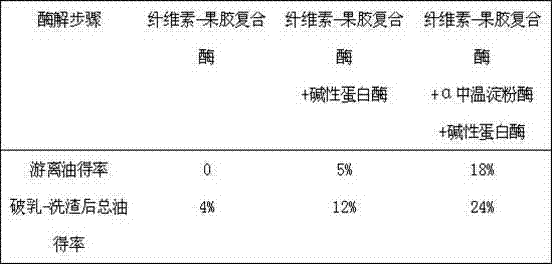

Embodiment 1

[0025] Crush the raw materials and pass through a 40-mesh sieve. Take 50g of seed powder, add 250ml of water, and mix to form a slurry for later use. Use 1mol / L hydrochloric acid to adjust the pH of the slurry to 4.5, add 15mL of cellulose-pectin complex enzyme (Danish Novozymes complex cellulase Celluclast 1.5L: polygalacturonase (pectinase) Pectinex Ultra SP-L Mixed at 2:1, enzyme activity 1.2*10 5 U / g), stirring and extracting at 50°C for 2 hours to obtain enzymolysis solution A, adjust the pH of enzymolysis solution A to 7 with 1mol / L sodium hydroxide, add 6mL α-medium temperature amylase (Danish Novozymes medium temperature amylase BAN 480, enzyme Live 4*10 4 U / g), stirring and extracting at 70°C for 0.5h to obtain enzymolysis solution B, adjust the pH of enzymolysis solution B to 8.5 with 1mol / L sodium hydroxide, add 1g alkaline protease (Novozyme Alcalase 2.4L, enzyme Live 2.5*10 5 U / g), stirring and extracting at 60°C for 2 hours to obtain the final enzymolysis s...

Embodiment 2

[0034] Crush the raw materials and pass through a 40-mesh sieve. Take 1000g of seed powder, add 4L of water, and mix to form a slurry for later use. Use 1mol / L hydrochloric acid to adjust the pH of the slurry to 4.5, add 30g of cellulose-pectin complex enzyme (commercially available domestic cellulase: pectinase in 1:1, enzyme activity 5*10 4 U / g), stirring and extracting at 50°C for 2.5h to obtain enzymolysis solution A, adjust the pH of enzymolysis solution A to 7 with 1mol / L sodium hydroxide, add 20g α-medium temperature amylase (commercially available domestic α-medium temperature amylase, enzyme Live 1*10 4 U / g), stirring and extracting at 70°C for 1 hour to obtain enzymolysis solution B, adjust the pH of enzymolysis solution B to 8.5 with 1mol / L sodium hydroxide, add 50g alkaline protease (commercially available domestic alkaline protease, enzyme activity 1 *10 5 U / g), stirring and extracting at 60°C for 2 hours to obtain the final enzymolysis solution. Centrifuge ...

Embodiment 3

[0039] Crush the raw materials and pass through a 40-mesh sieve. Take 500g of seed powder, add 2.5L of water, and mix to form a slurry for later use. Use 1mol / L hydrochloric acid to adjust the pH of the slurry to 4.5, add 45g of cellulose-pectin compound enzyme (commercially available domestic cellulase: pectinase is compounded at 1:1, and the enzyme activity is 2*10 4 U / g), stirring and extracting at 50°C for 2.5 hours to obtain enzymolysis solution A, adjust the pH of enzymolysis solution A to 7 with 1mol / L sodium hydroxide, add 8g of α-medium-temperature amylase (commercially available domestic α-medium-temperature amylase, enzyme Live 1*10 4 U / g), stirring and extracting at 70°C for 1 hour to obtain enzymolysis solution B, adjust the pH of enzymolysis solution B to 8.5 with 1mol / L sodium hydroxide, add 35g alkaline protease (commercially available domestic alkaline protease, enzyme activity 5 *10 4 U / g), stirring and extracting at 60°C for 2 hours to obtain the final ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com