Patents

Literature

214results about How to "The method is simple and efficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Data Integrity and Non-Repudiation

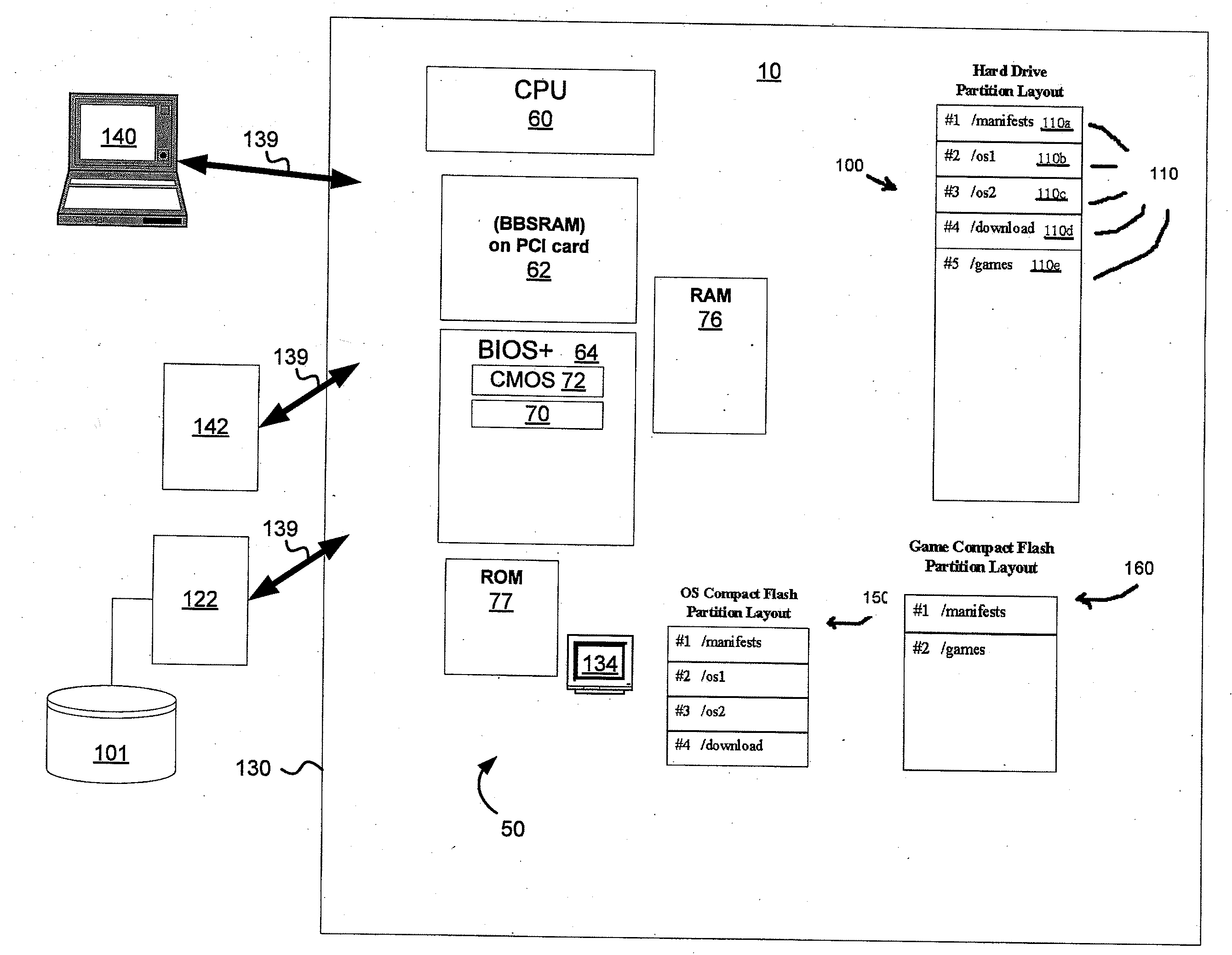

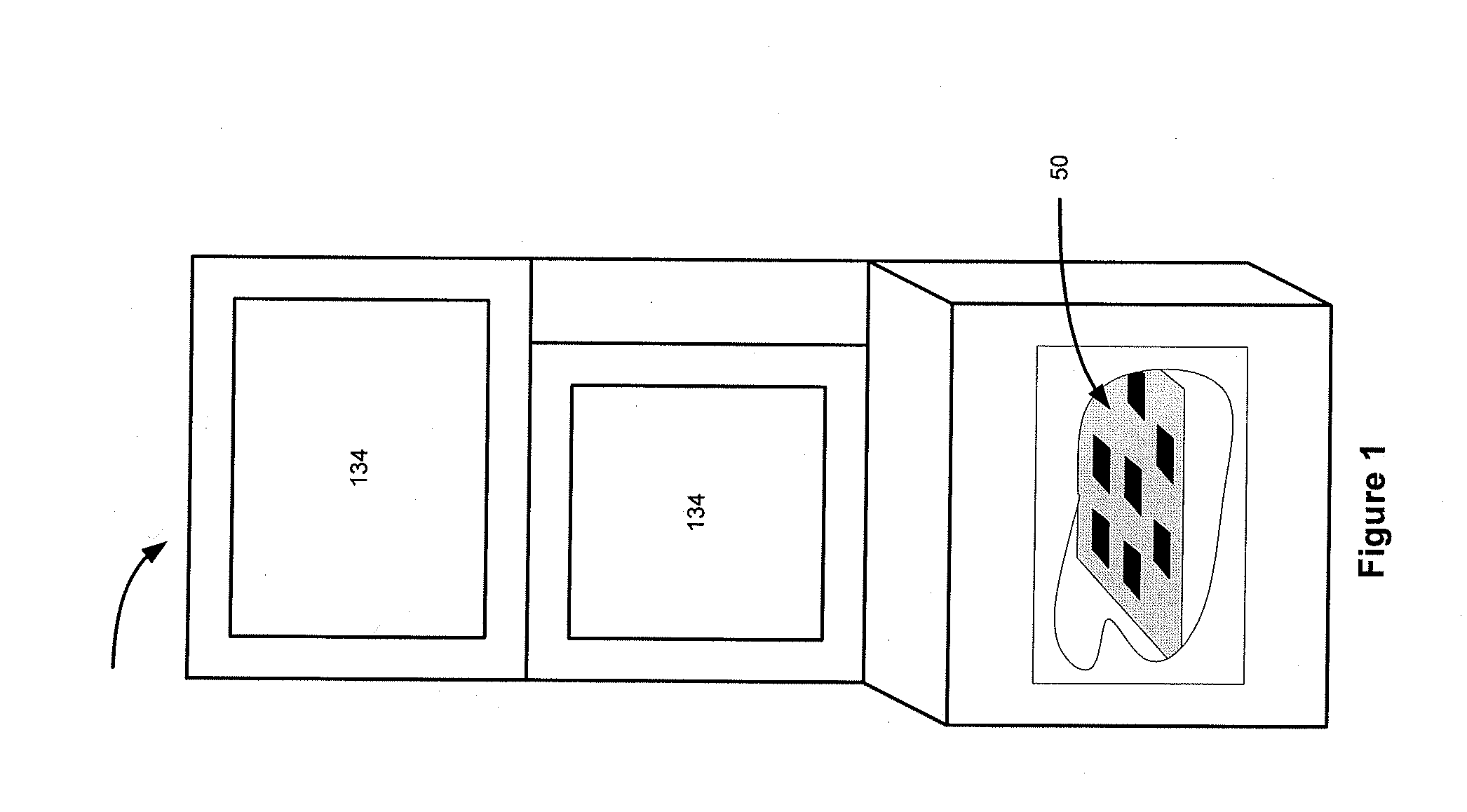

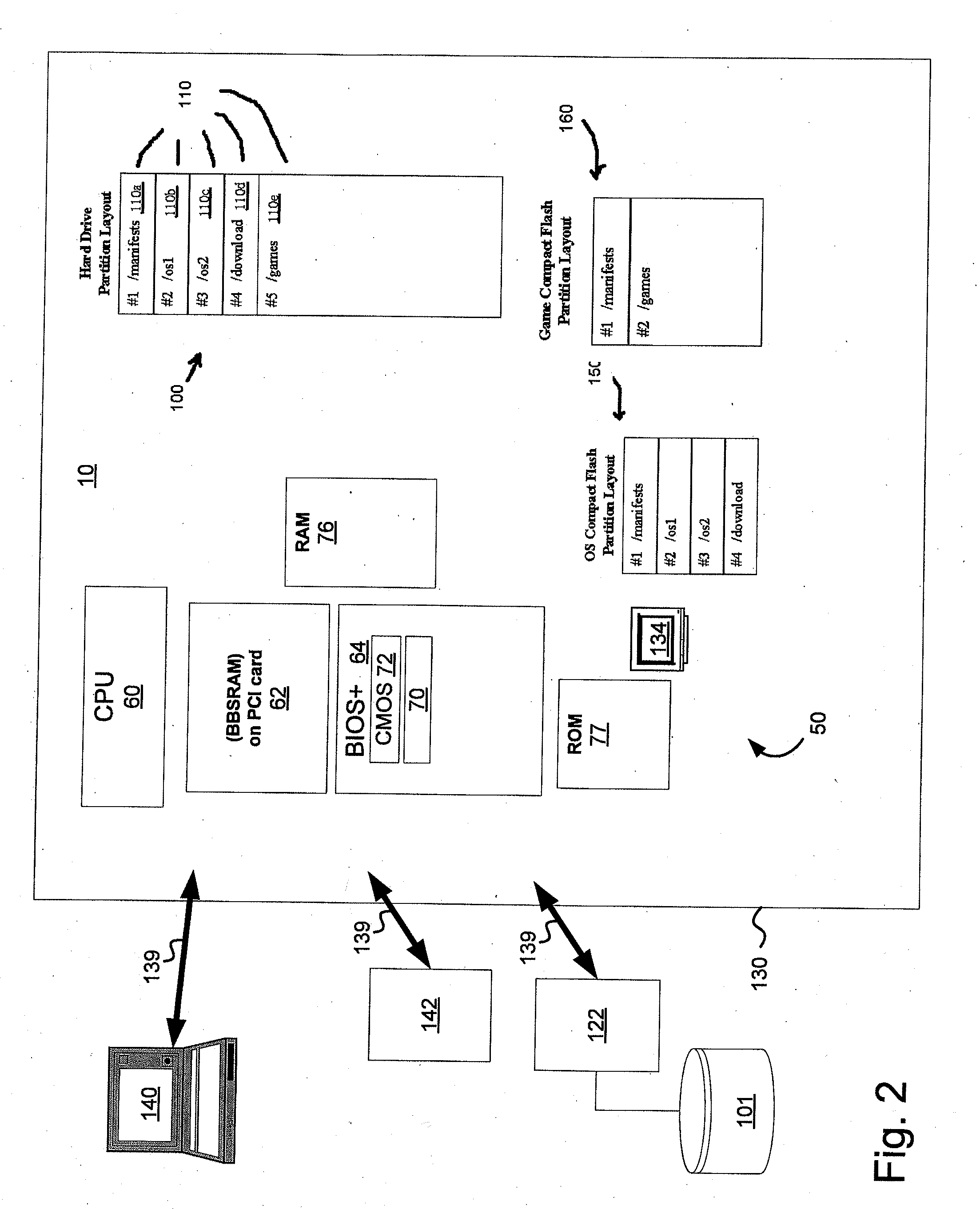

ActiveUS20080045342A1Reduce boot timeImprove loading timeUnauthorized memory use protectionHardware monitoringComputer hardwareData integrity

Disclosed is a system and method that uses digital signature technology to authenticate the contents of one or more manifests located on a storage device. Each manifest contains a list of file records, where each record contains the name of a file stored on the storage device, and a signature value derived from the contents of the file. At boot time, the gaming machine first authenticates the contents of the manifest and then authenticates the contents of the files using the signature value stored in the manifest. Files are verified using the signature, as they are needed, during the boot up of the operating system and throughout normal operation. This method reduces the boot time of the gaming machine and eliminates the need to check digital signatures for each individual file or over the entire contents of a non-secure media. Similarly, a method of adding authentication ability to legacy software components without necessarily altering the legacy software components is disclosed. Introduction of a stronger authentication algorithm, or when a private key has been compromised would normally require the software component to be re-built to support the new algorithm or private / public key pair; however, a method is disclosed where algorithms and key pairs may be changed and applied to legacy software without having to re-built, re-test, re-sign, or re-submit the component to regulatory agencies for approval. Also disclosed is a system and method of establishing a trusted environment containing a gaming operating system and associated authentication module, file system drivers, and / or network drivers that may be used to in the process of authenticating contents of one or more manifests located on a storage device.

Owner:LNW GAMING INC

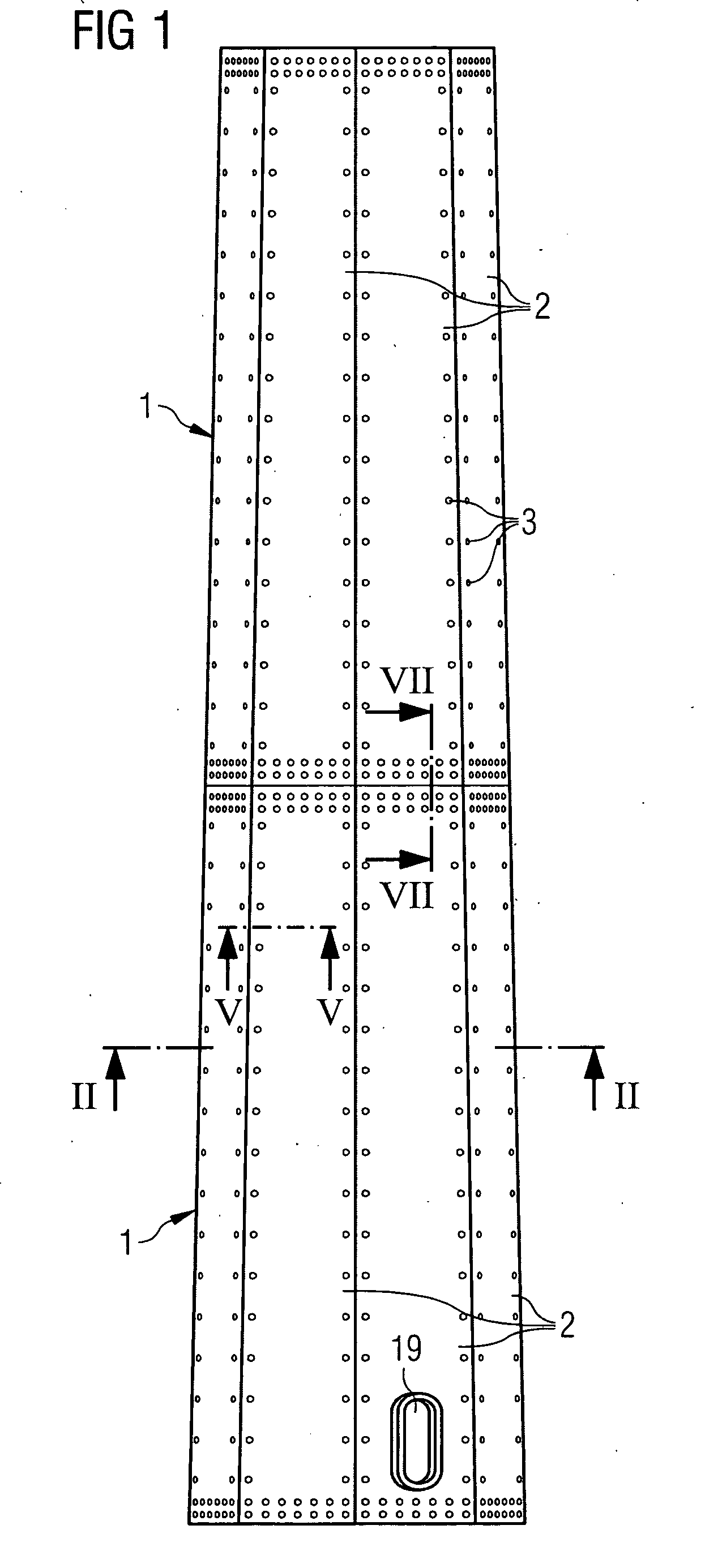

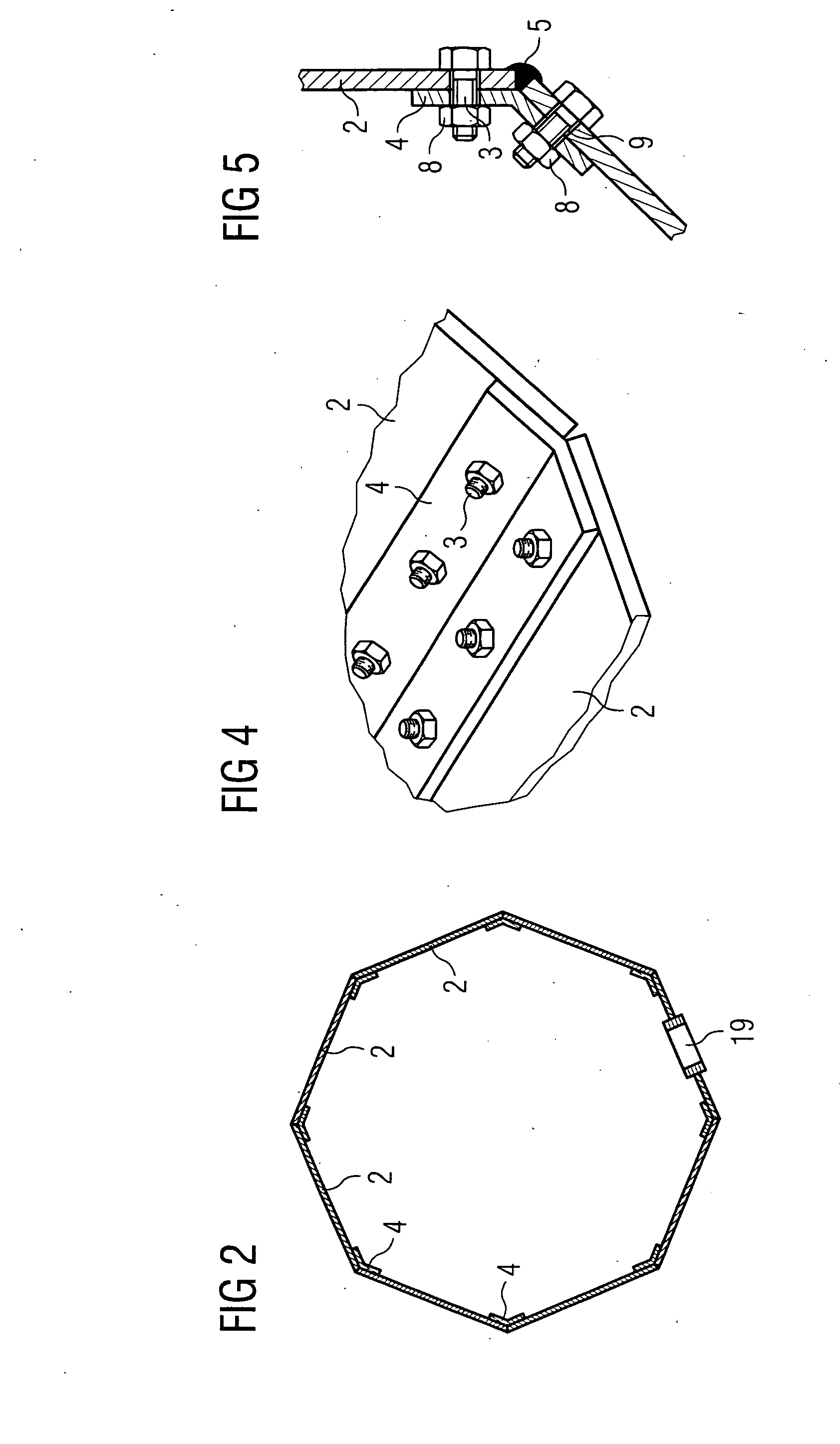

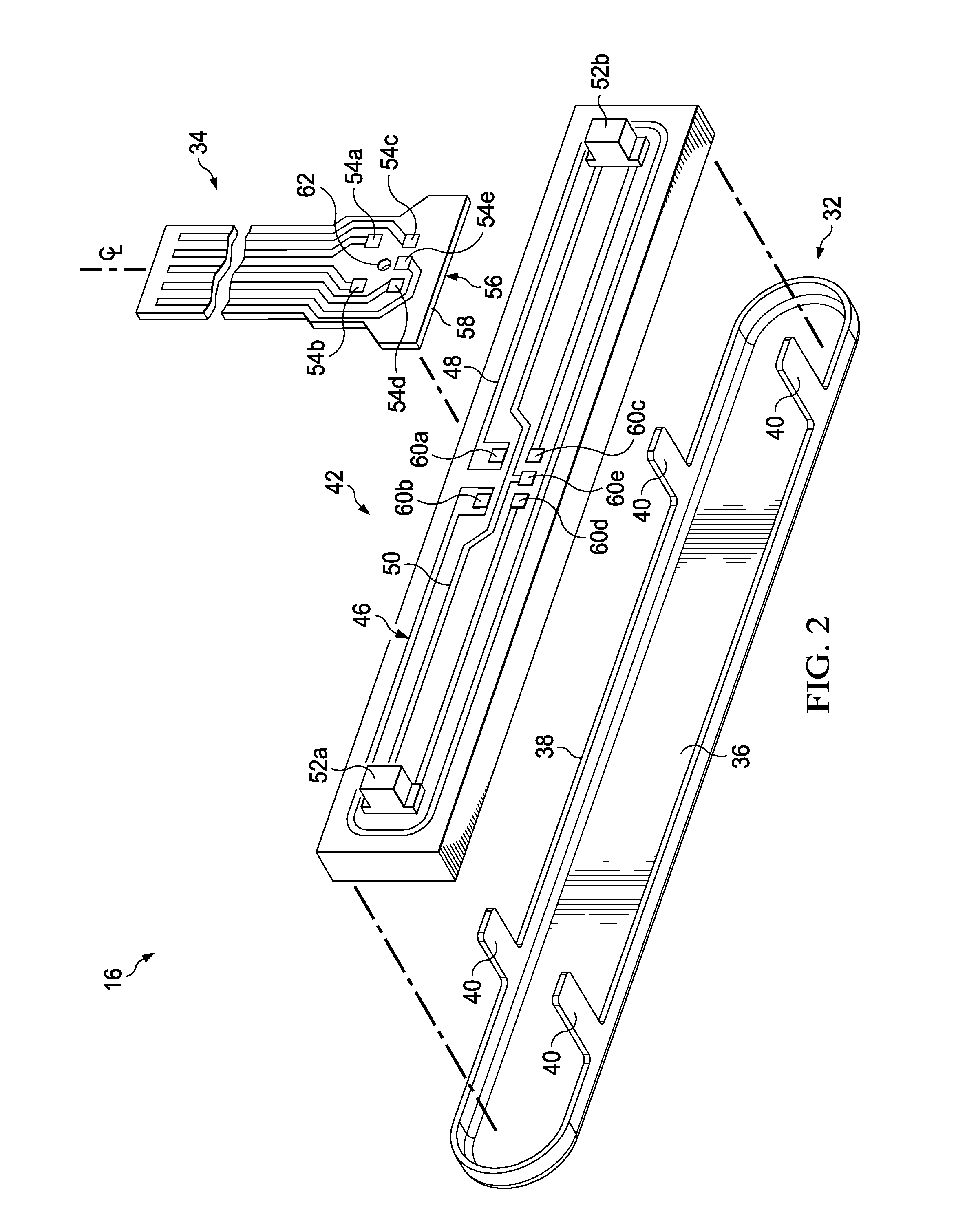

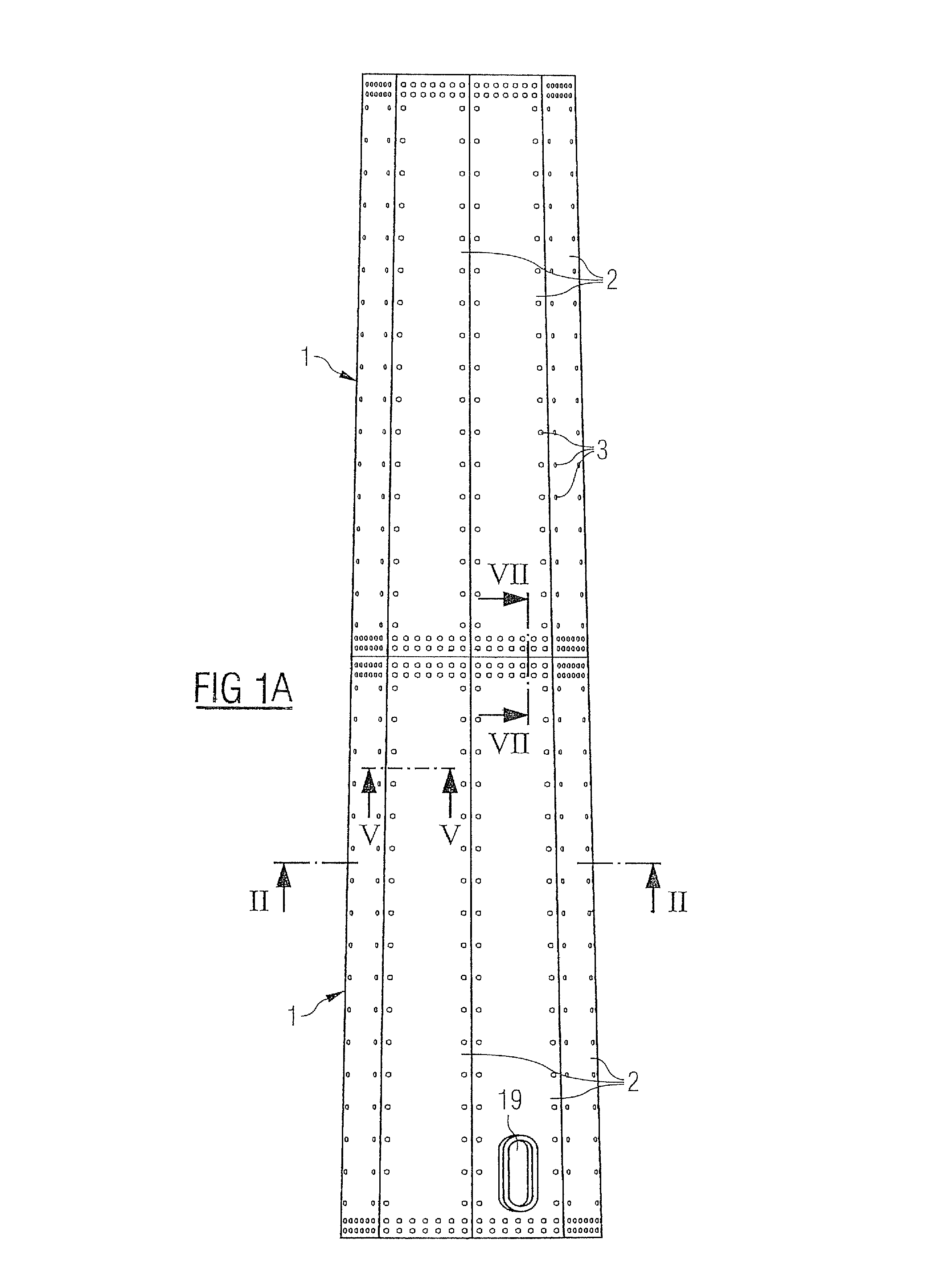

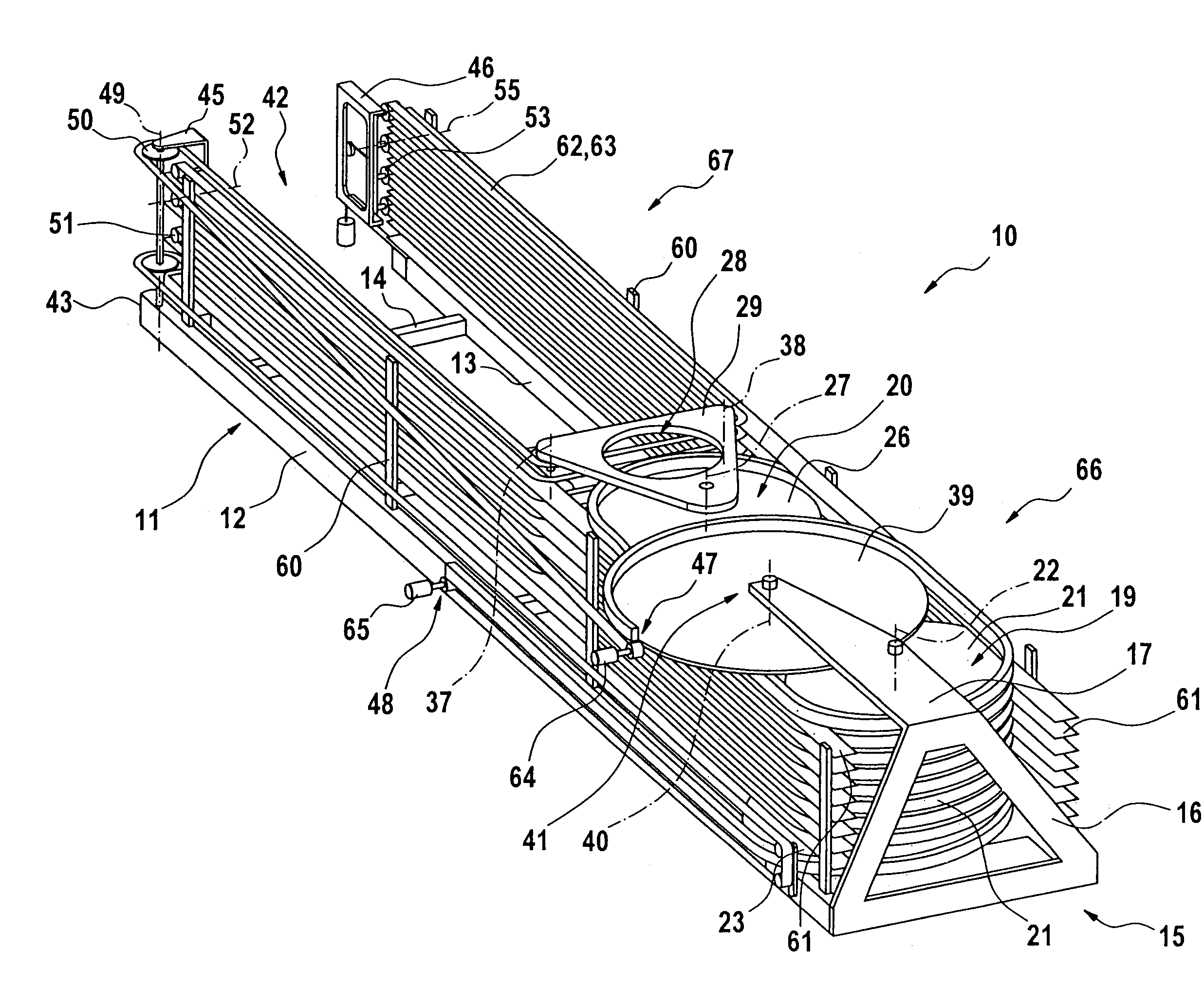

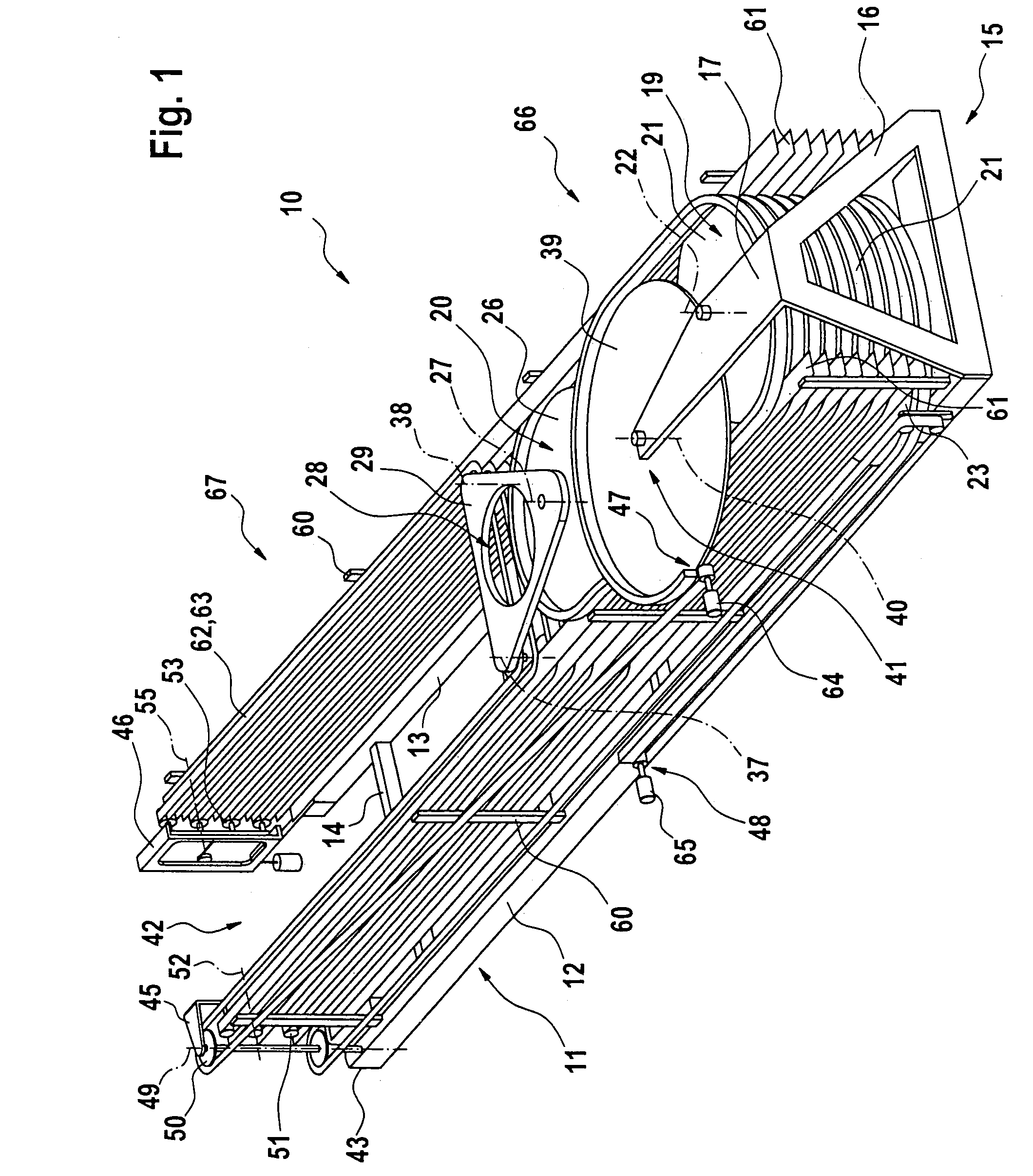

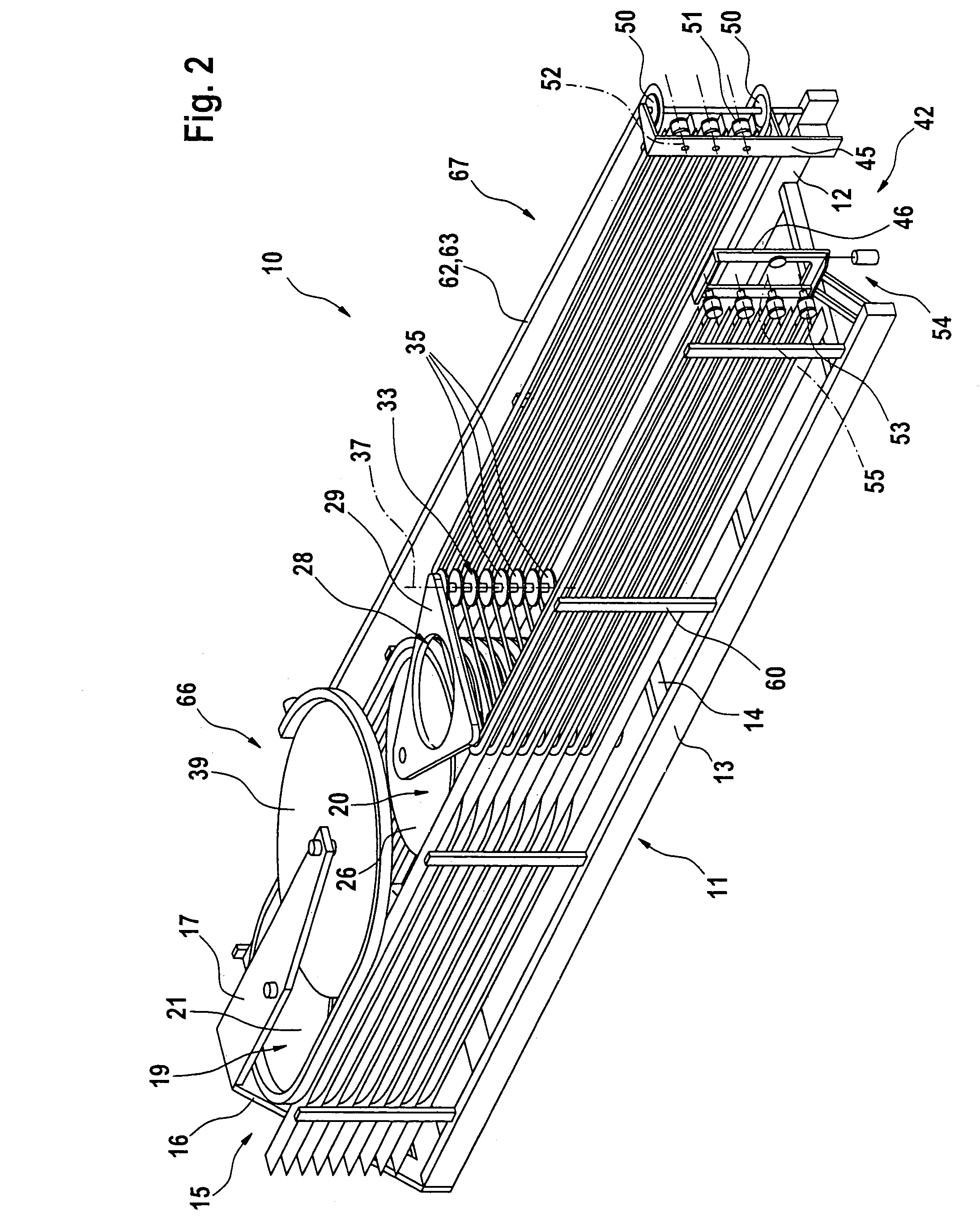

Wind turbine tower and method for constructing a wind turbine tower

ActiveUS20090021019A1Low costAvoids any rolling, bending and/or weldingEngine manufactureFinal product manufactureTowerTurbine

A wind turbine tower is provided, which comprises a number of segments with a polygonal cross section, each segment comprising a number of flat plates which are connected to each other so as to form the polygonal cross section. Further, a method for constructing a wind turbine tower which comprises segments assembled of flat plates is disclosed, wherein the flat plates are connected to each other so as to form segments with a polygonal cross section and the segments are connected to each other so as to form the tower.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

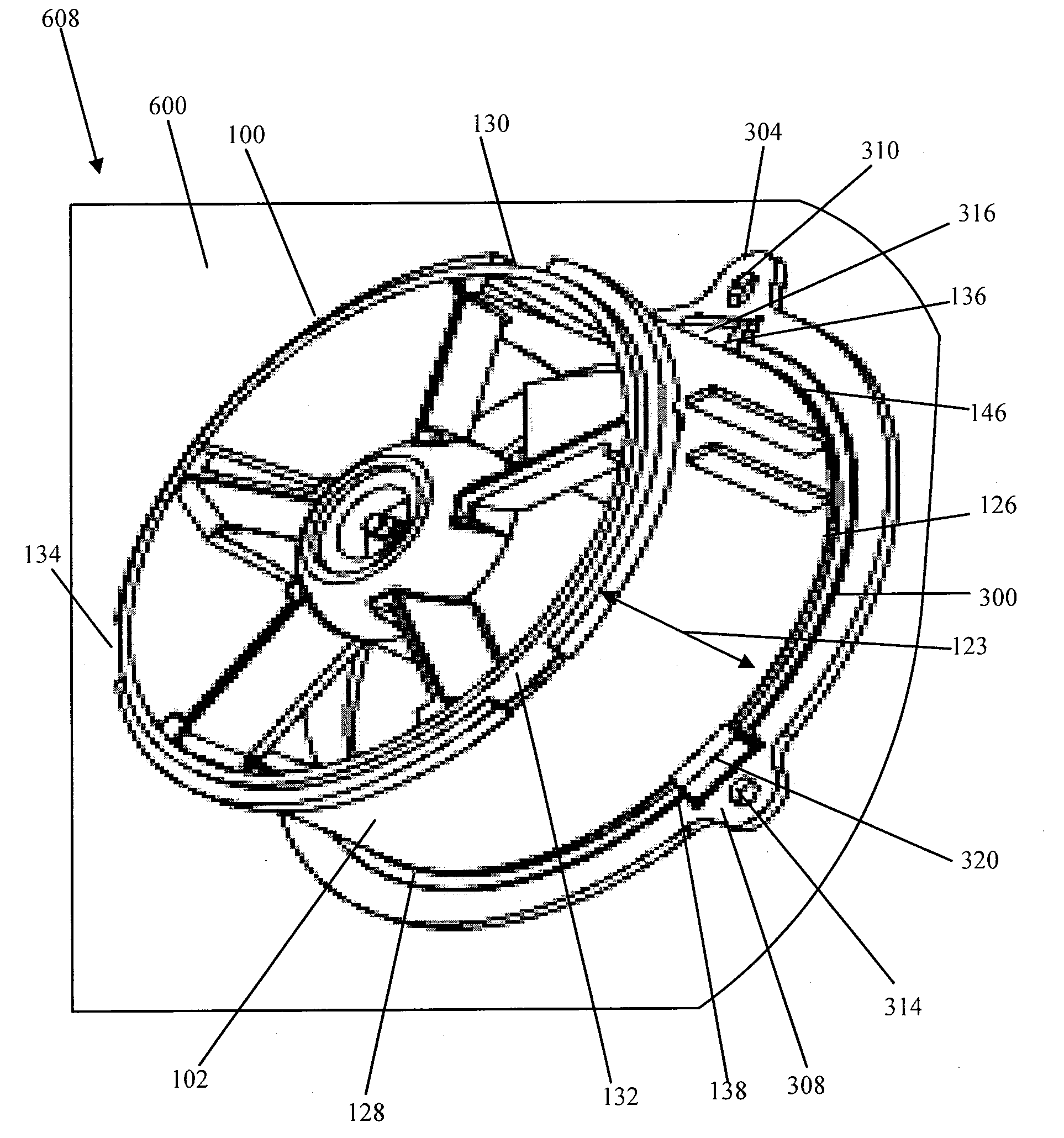

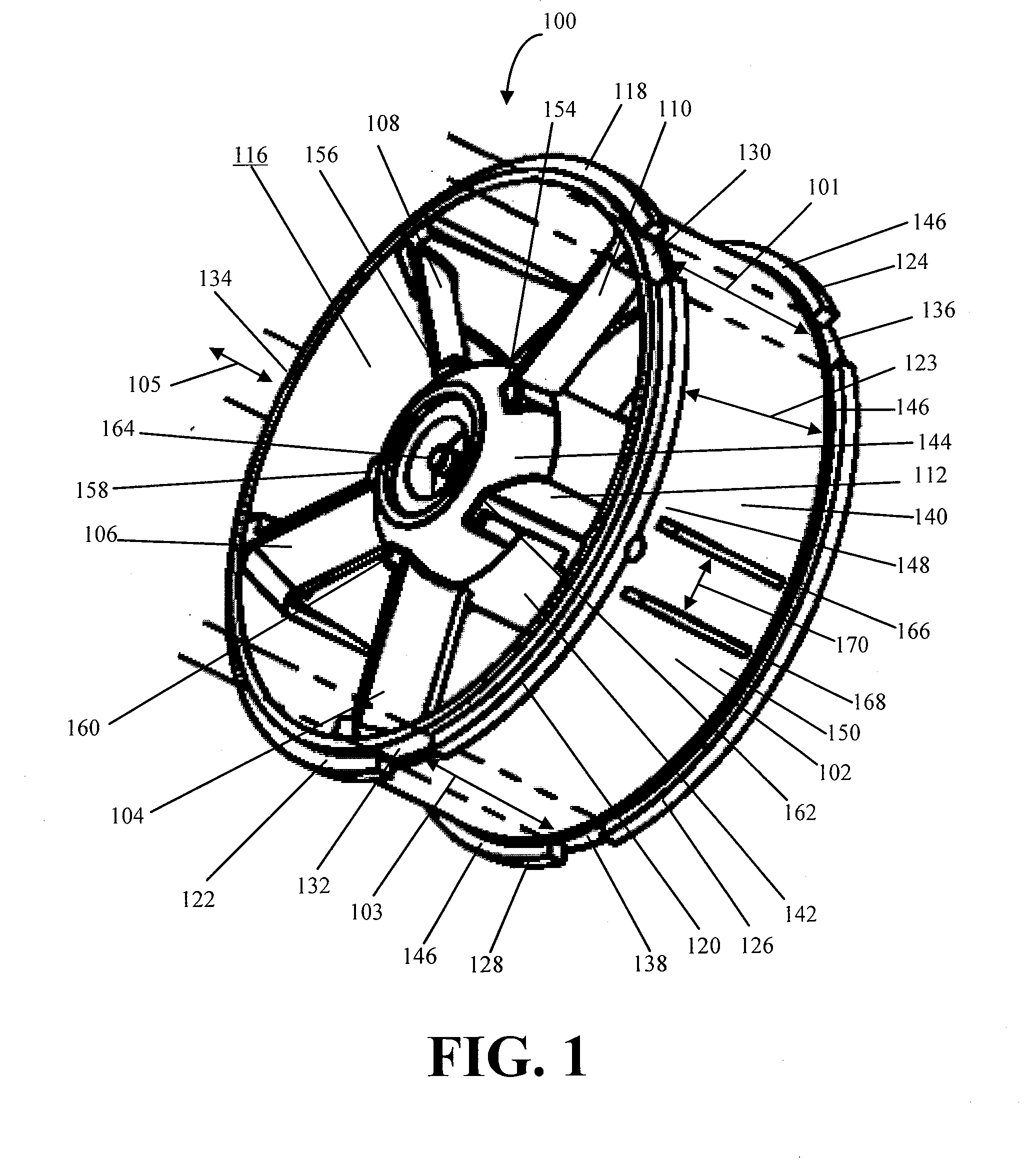

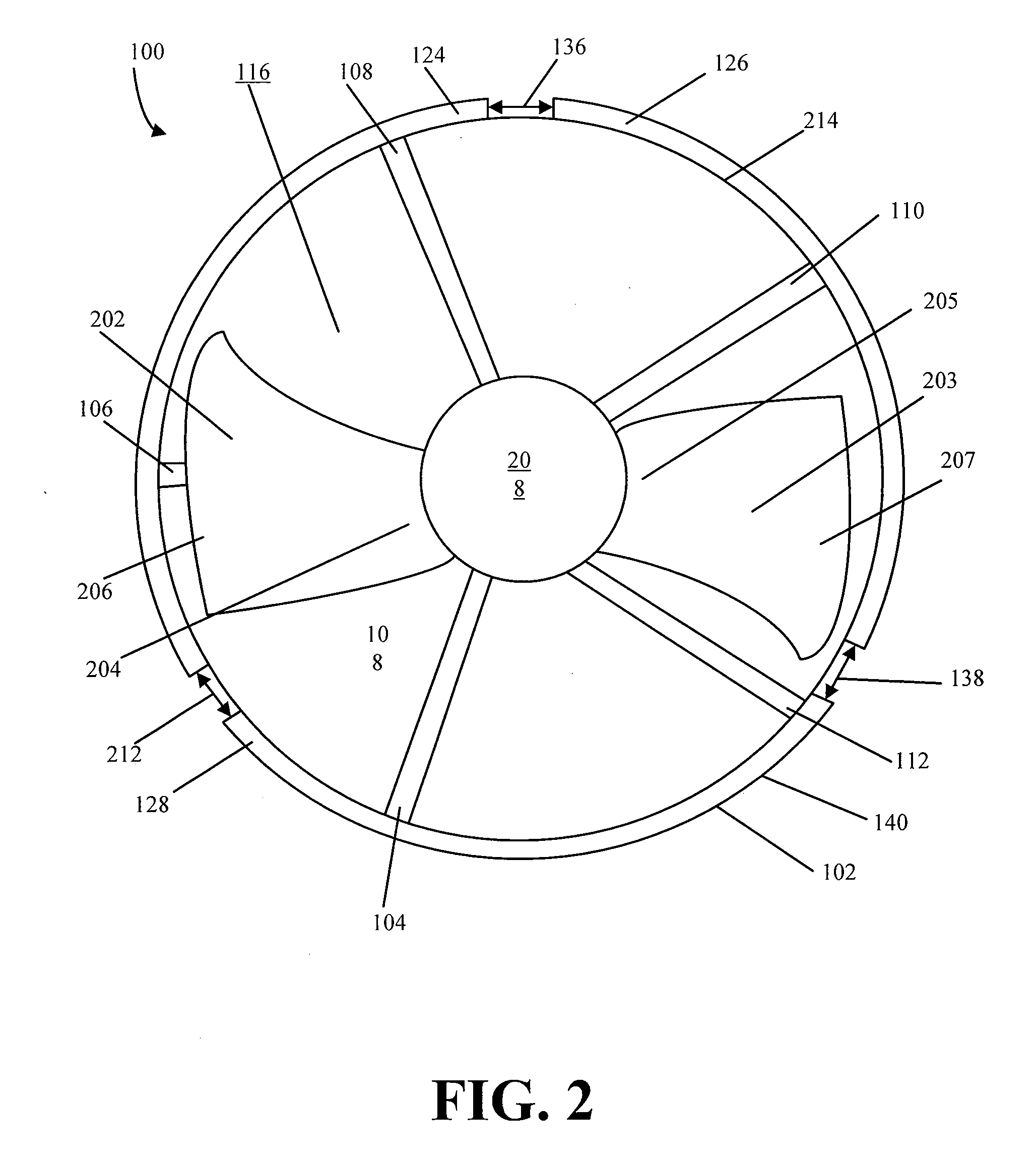

Fan with locking ring

InactiveUS20100111698A1Simple and efficient and reliable methodOvercome deficienciesPropellersRotary propellersEngineeringFan blade

An airflow apparatus comprising a stator section, at least one stator blade and a plurality of mounting flanges disposed on the stator section is provided. Additionally, the airflow apparatus includes at least one slot disposed between the plurality of mounting flanges, a rotor assembly coupled to the at least one stator blade, whereby the rotor assembly has a proximal end and a distal end. Furthermore, the airflow apparatus includes at least one fan blade coupled to the rotor assembly. The airflow apparatus also includes a locking apparatus, whereby the locking apparatus includes at least one mounting member and at least one coupling member, wherein the at least one slot is coupled to the at least one coupling member.

Owner:AVIONIC INSTR

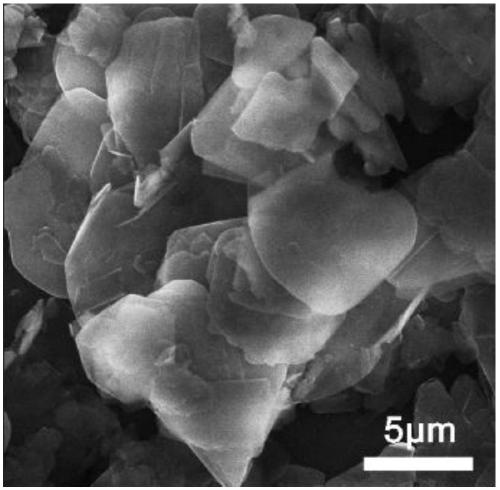

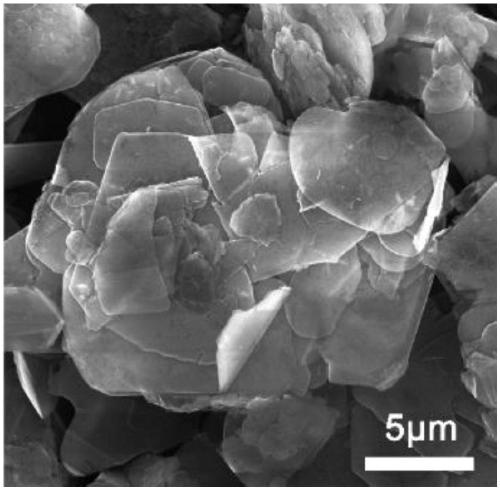

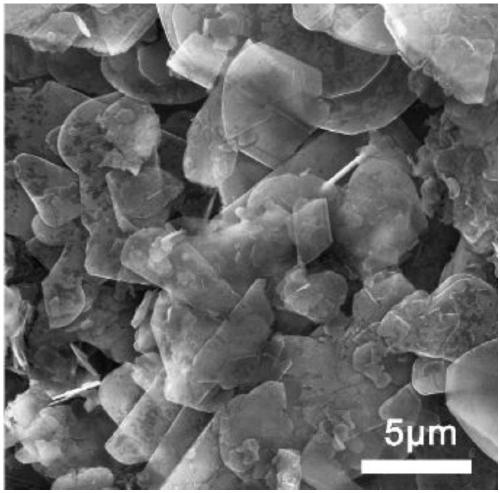

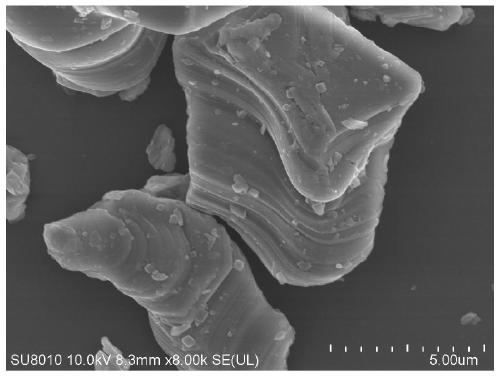

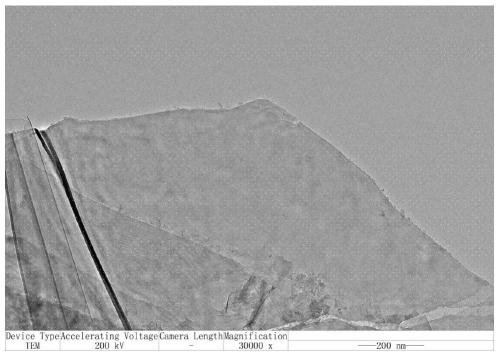

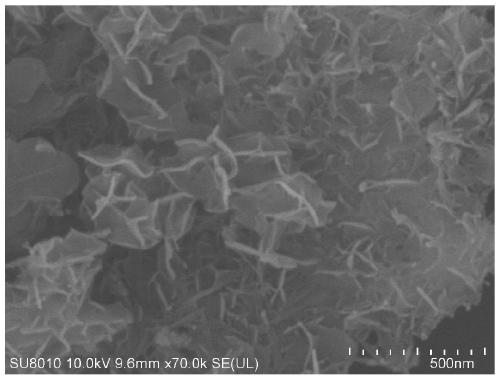

Preparation method of BN/epoxy resin heat conductive insulation composite material

The invention provides a preparation method of a BN / epoxy resin heat conductive insulation composite material and belongs to the field of preparation of heat conductive insulation composite materials.The method includes: firstly, performing annealing pretreatment to BN powder and then surface modification with a silane coupling agent; then according to certain ratio, filling an epoxy resin matrixwith the modified hexagonal BN micropowder and the modified cubic BN micropowder. The method is simple process, wherein by adding the BN in different appearances, dimensions and phase structures, effective heat conduction channels are formed to finally improve the heat conductivity of the epoxy resin. After modification, the interface combination between the HBN and the resin is strong, wherein the sheet-like HBN and bulk CBN are overlapped in the epoxy resin to form excellent heat conductive network, thus effectively reducing interfacial thermo-resistance. The composite material is beneficial to quick transmission of heat, improves heat conductivity of the epoxy resin, has excellent insulation performance, and is improved in mechanical property.

Owner:JILIN UNIV

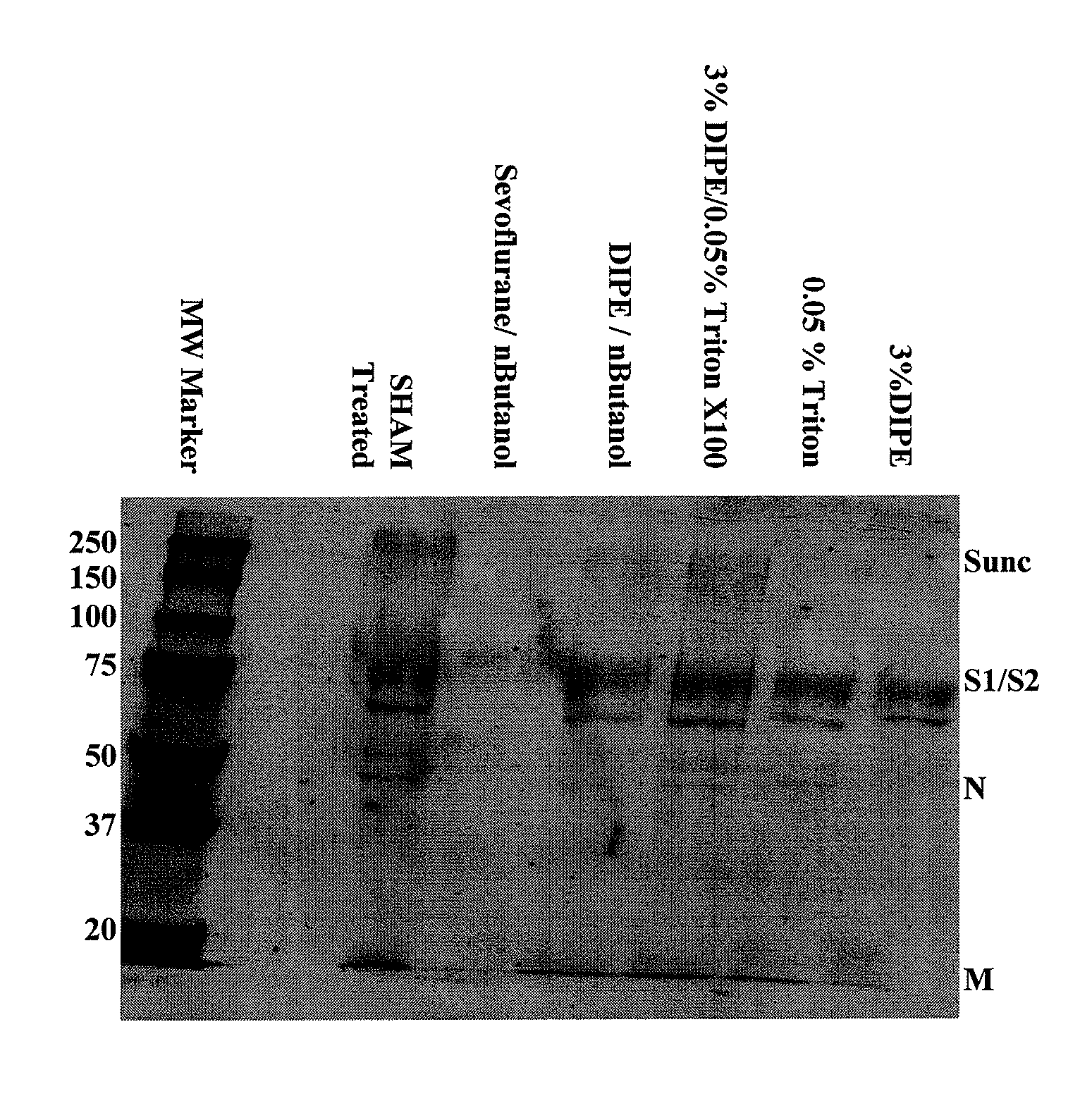

Method of treating cancer cells to create a modified cancer cell that provokes an immunogenic response

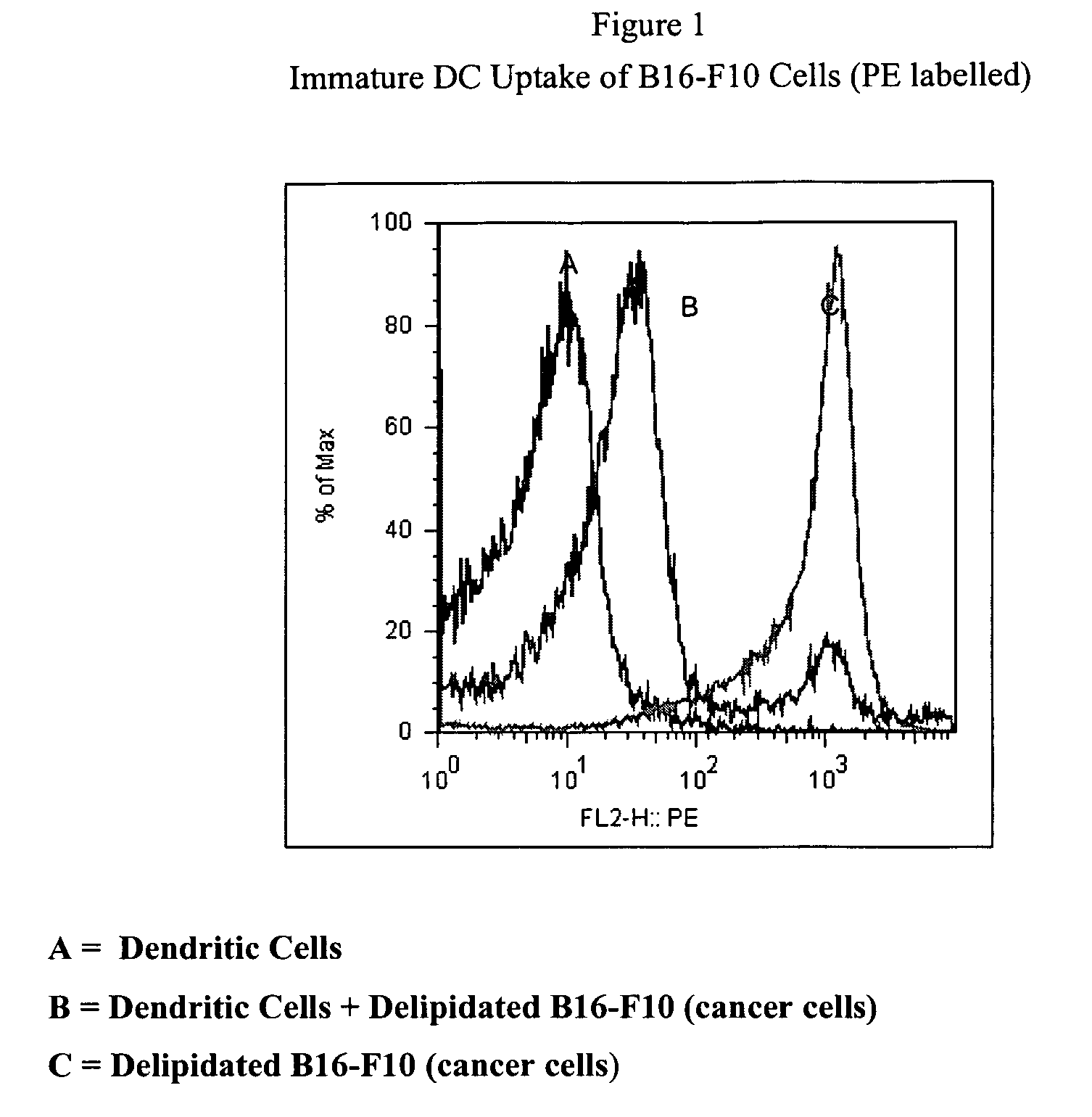

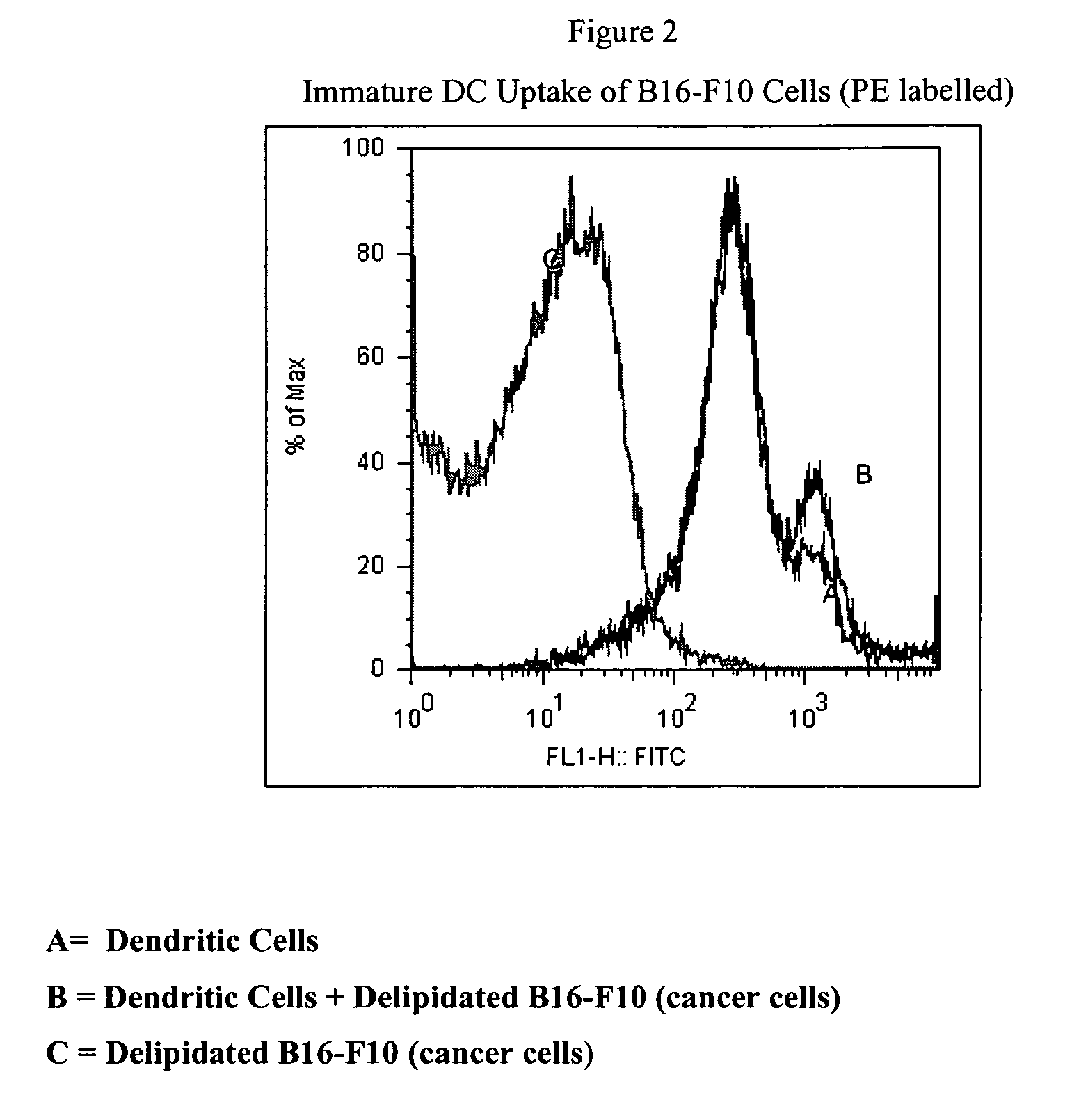

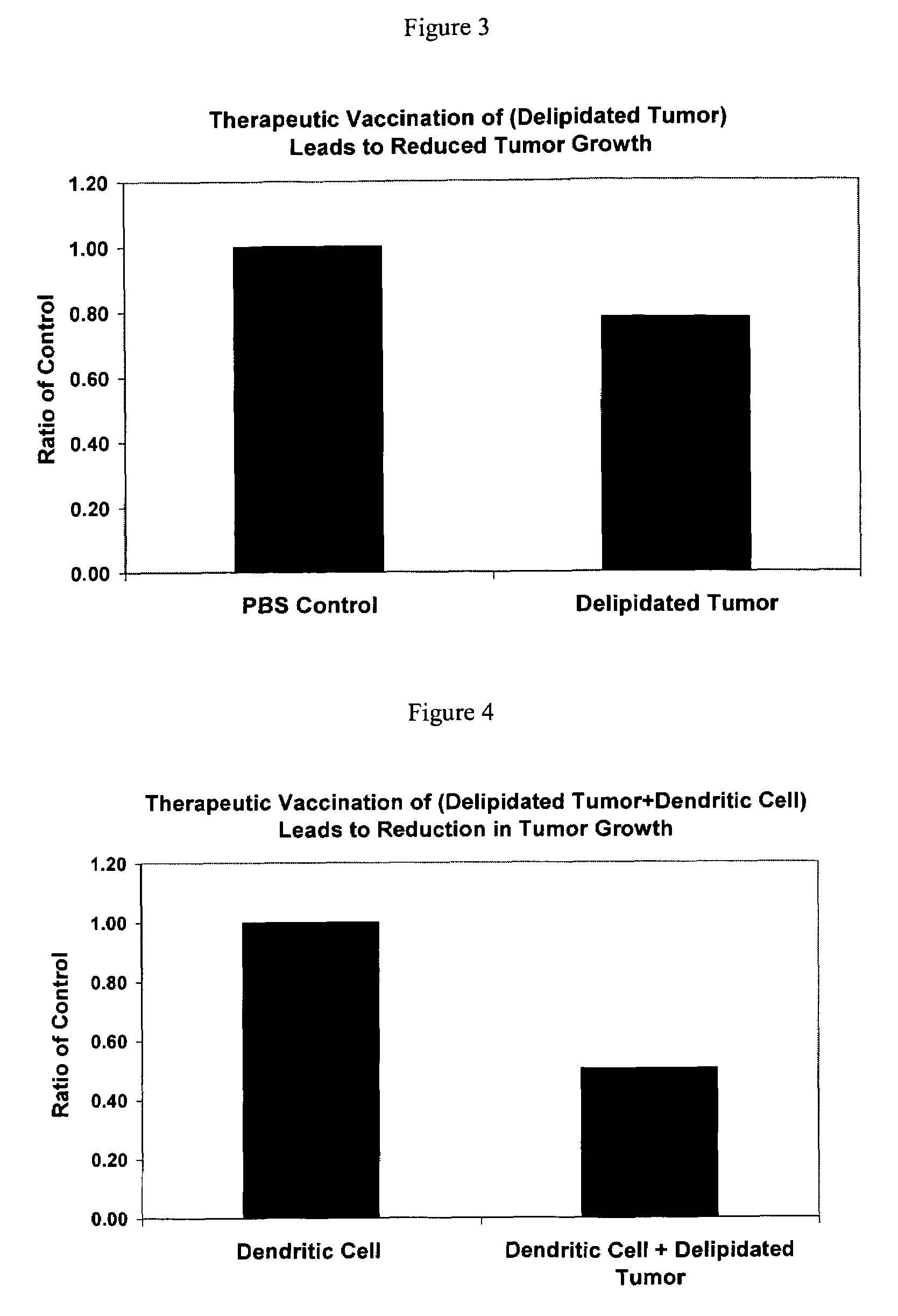

InactiveUS7361360B2Preventing occurrence and reoccurrenceSlow onsetSnake antigen ingredientsDead animal preservationLipid formationHeterologous vaccine

The present invention relates to a delipidation method employing a solvent system useful for extracting lipids from cancer cells, thereby creating a modified cancer cell particle. Upon delipidation of the cancer cells, a portion of the cancer cell antigens remain intact. These exposed antigens, or epitopes, foster and promote antibody production. The resulting modified cancer cell particle, or portions of the cancer cell, initiate a positive immunogenic response when administered to an animal or human and help to treat, prevent or delay the onset of cancer. The present invention provides autologous and heterologous vaccine compositions comprising the modified cancer cell with a pharmaceutically acceptable carrier. The present invention provides method of administering these vaccines to treat, prevent or delay the onset of cancer.

Owner:ELI LILLY & CO +1

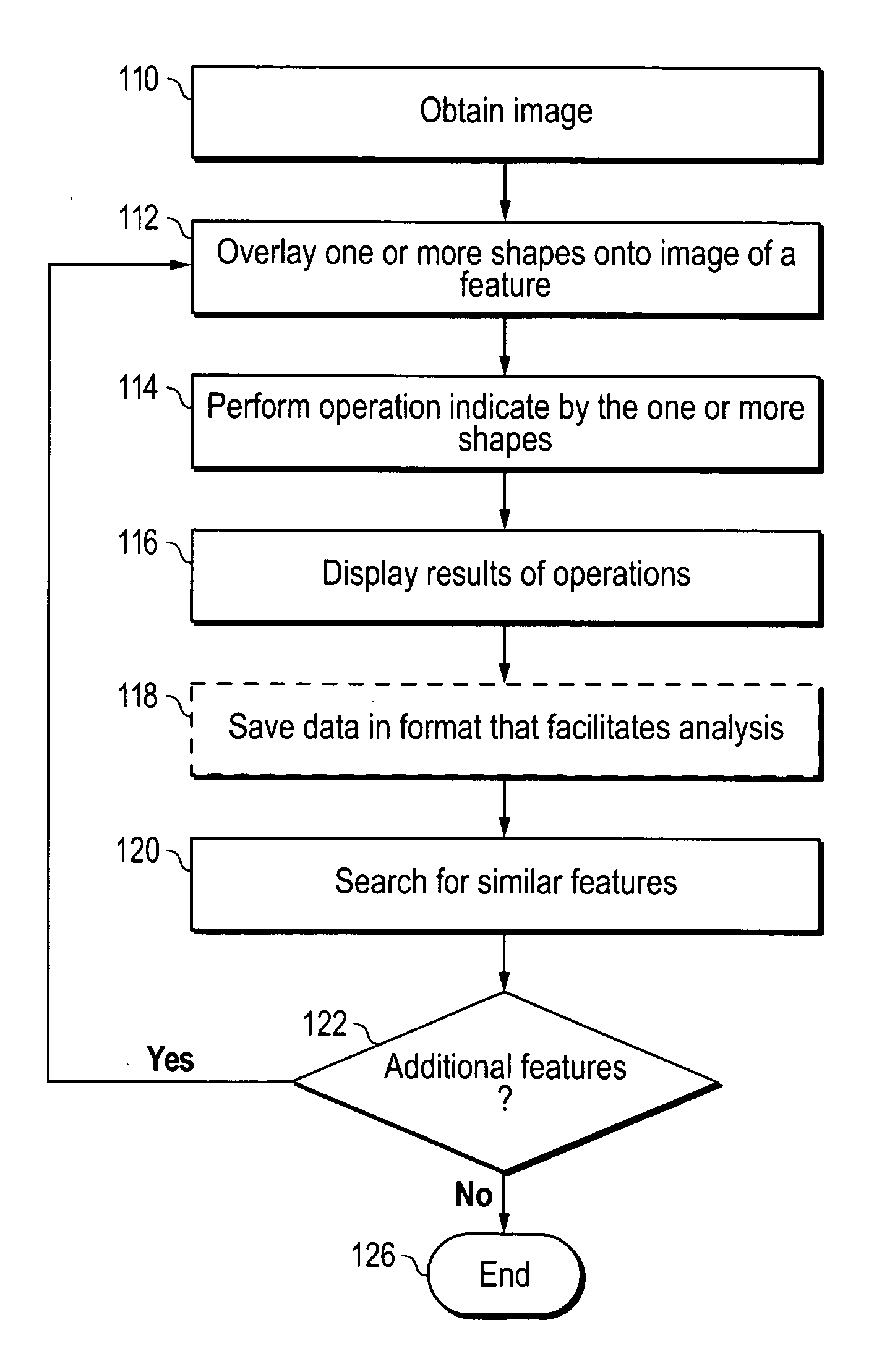

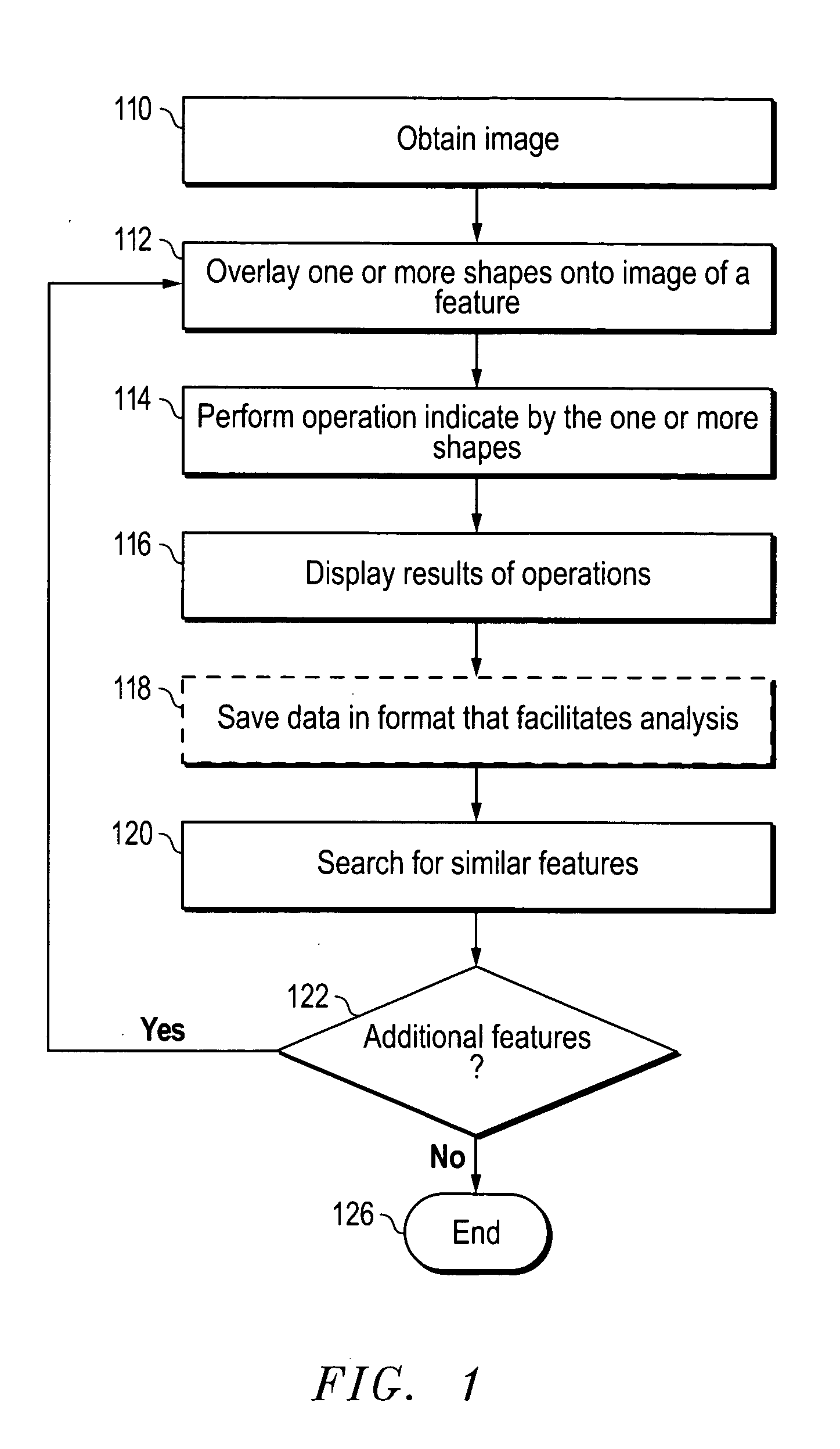

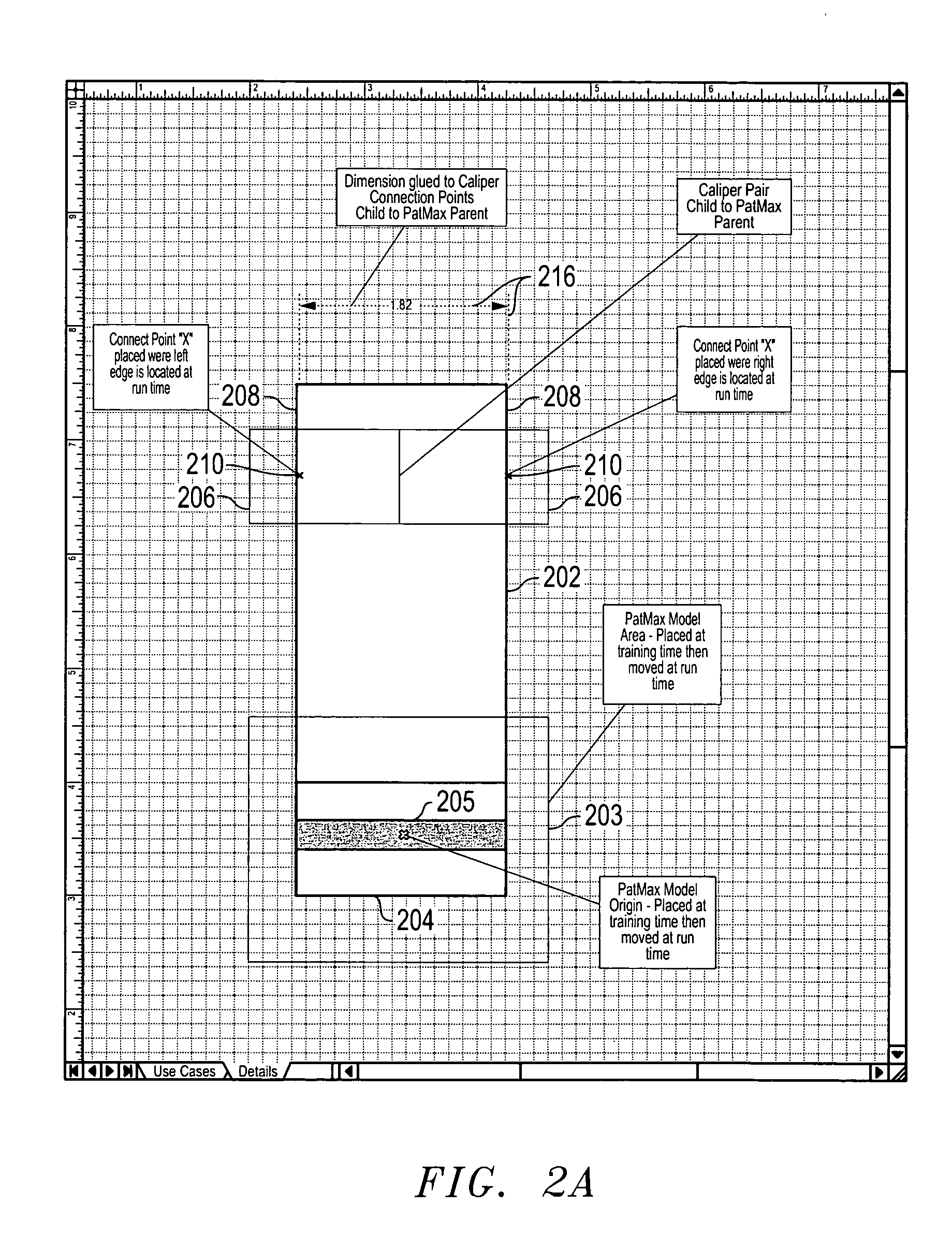

Graphical automated machine control and metrology

InactiveUS20050188309A1The method is simple and efficientSimple programmingProgramme controlSamplingGraphicsMetrology

A graphical programming system allows a user to place geometric shapes onto a scaled image, the shape having associated behavior that operates on the image or on the object of which the image is formed. In a preferred embodiment, the shapes are objects in the Visio program by Microsoft Corporation. The shapes are dragged from a stencil onto an image provided by ion beam or electron microscope image. The shape invokes software or hardware to locate and measure features on the image or to perform operations, such as ion beam milling, on the object that is imaged.

Owner:FEI CO

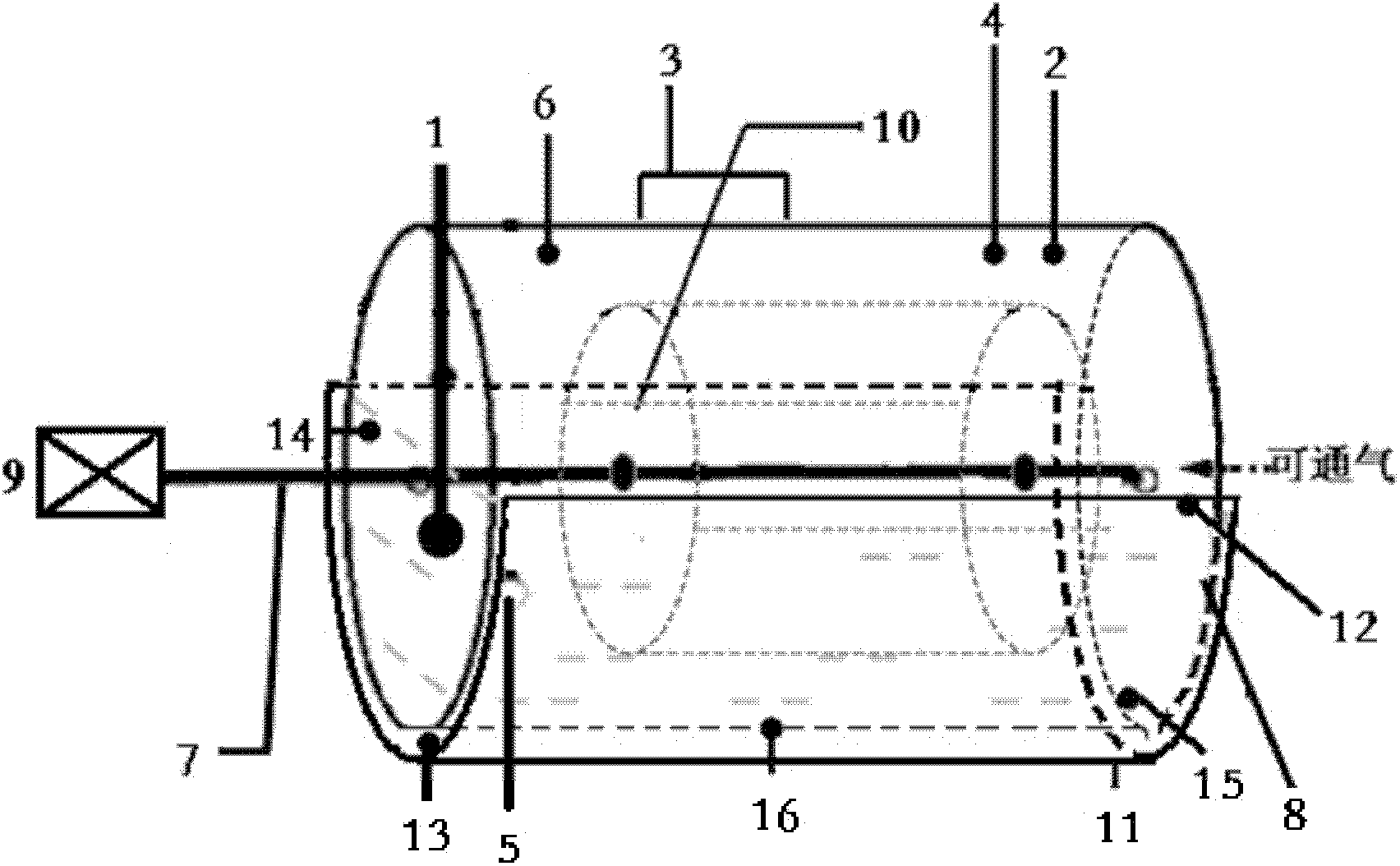

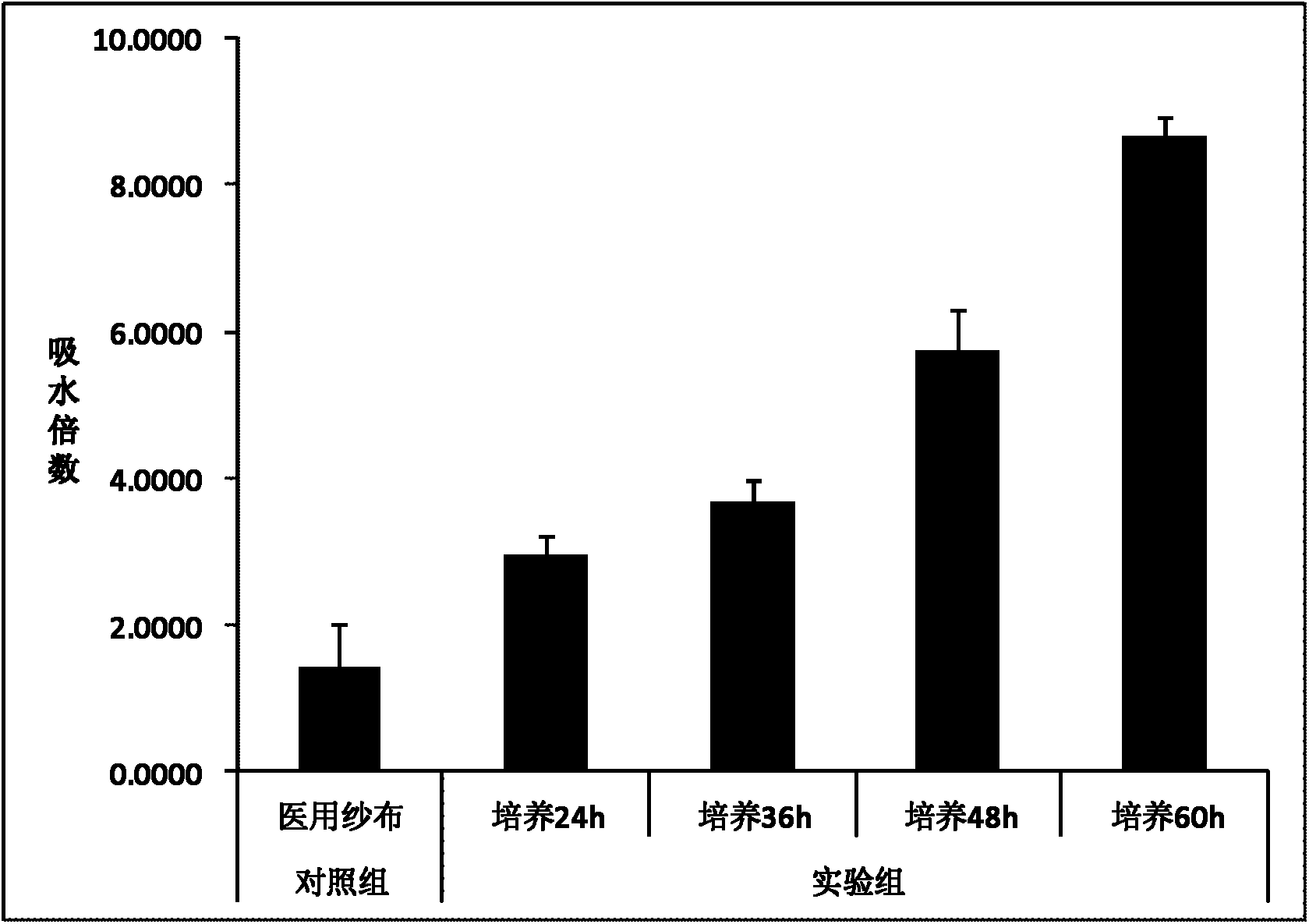

Method and device for preparing bacterial cellulose composite material quickly on large scale

ActiveCN102533904AReduce dosageGuaranteed StrengthBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumFermentation

The invention relates to a method and device for preparing bacterial cellulose composite materials quickly on a large scale. The method comprises the steps as follows: (1) a bacterial cellulose producing strain is inoculated in liquid medium for propagation and then transferred into a biological reactor containing framework material for perturbation cultivation, so that bacterial cellulose composite material can be obtained; and (2) bacterial cellulose of the bacterial cellulose composite material is peeled off from the framework material or the cellulose composite material is soaked in NaOH solution to be washed. The device comprises a thermometer opening, an acid liquor and alkali liquor feeding opening, a handle, an air vent, a pH meter opening, a nutrition feeding opening, a rotating shaft, a fermentation tank, a motor, a rotating drum, a fermentation tank jacket, a circulating water inlet, a circulating water outlet, a nutrient fluid inlet, a nutrient fluid outlet and a condensed water outlet. The rotating drum is fixed on the rotating shaft in the fermentation tank. The device provided by the invention has the advantages of simplicity, convenience, detachable die, low cost, high production efficiency and high degree of automation; and the obtained bacterial cellulose composite material can be widely applied.

Owner:DONGHUA UNIV

Synthesis method of 2, 5-disubstituted thiophene compound

ActiveCN102115468AWide variety of sourcesSimple and fast operationOrganic active ingredientsSaccharide with carbocyclic radicalsState of artReaction conditions

Owner:TOPHARMAN SHANDONG

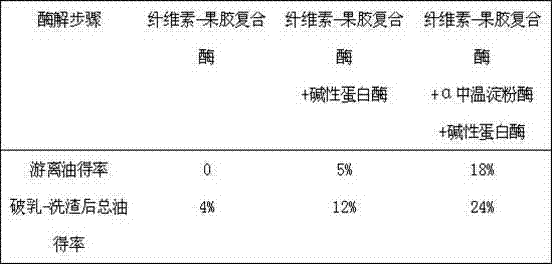

Method for extracting oil from peony seeds or peony seed dregs

ActiveCN103484235AReduce consumptionNo residueFatty-oils/fats productionEdible oils/fatsEmulsionProtein hydrolysates

The invention discloses a method for extracting oil from peony seeds or peony seed dregs. The method comprises the following steps: (1) pretreatment; (2) enzymolysis; (3) centrifuging; (4) demulsification; (5) dreg washing. Free oil, an emulsion layer, protein hydrolysate and dregs are obtained after enzymatic hydrolysate is centrifuged, wherein the free oil is peony seed oil, and a certain amount of oil can also be recovered after the emulsion layer and the dregs are subjected to demulsification and dreg washing respectively. According to the method, the peony seed oil can be extracted without drying raw materials, the operation is simple, the requirement for equipment is low, the oil yield is high, the oil quality is good, solvent residues and environmental pollution are avoided, and the obtained protein hydrolysate and dregs can also be further used comprehensively.

Owner:TONGLING RUIPU PEONY IND DEV +1

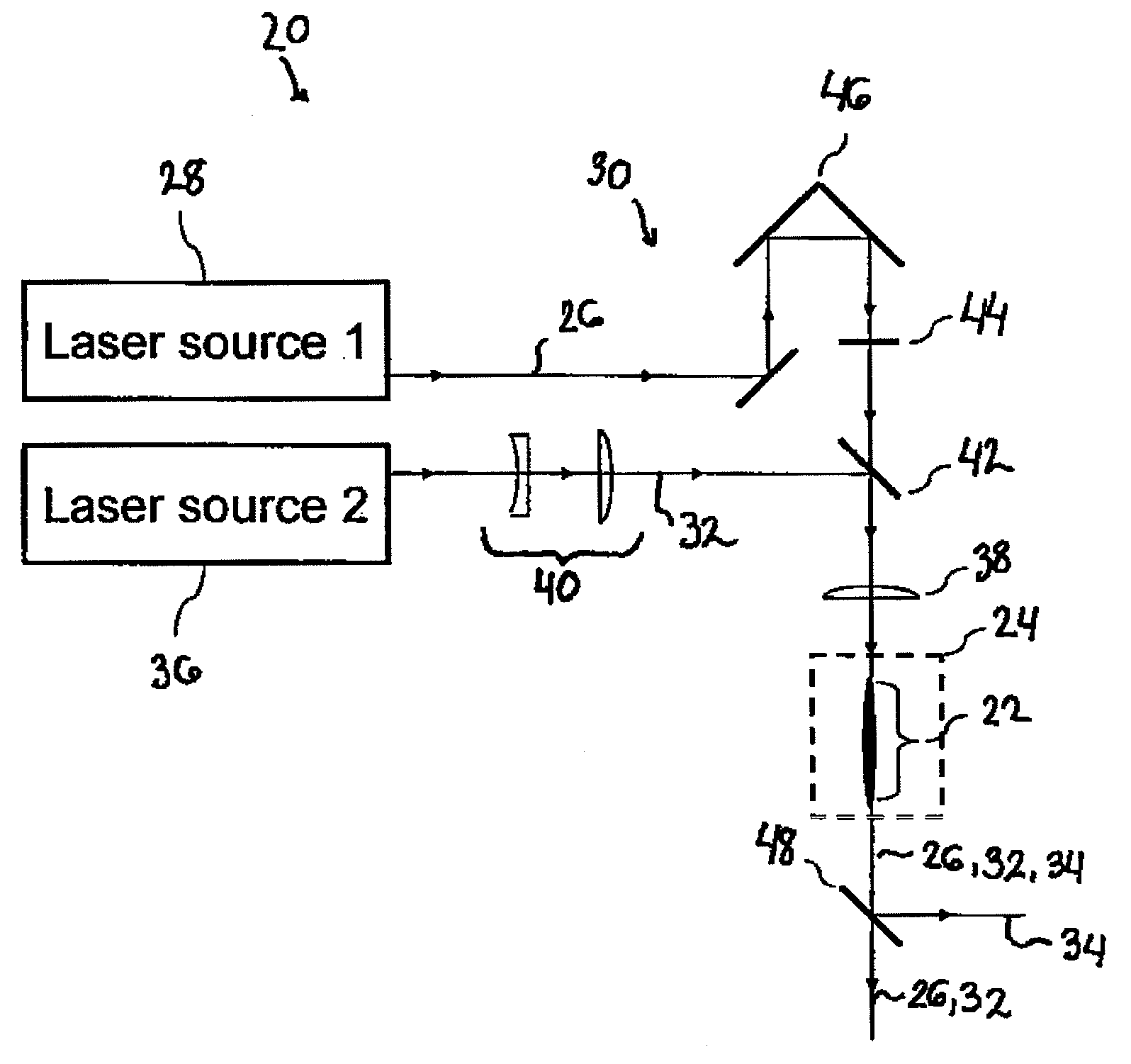

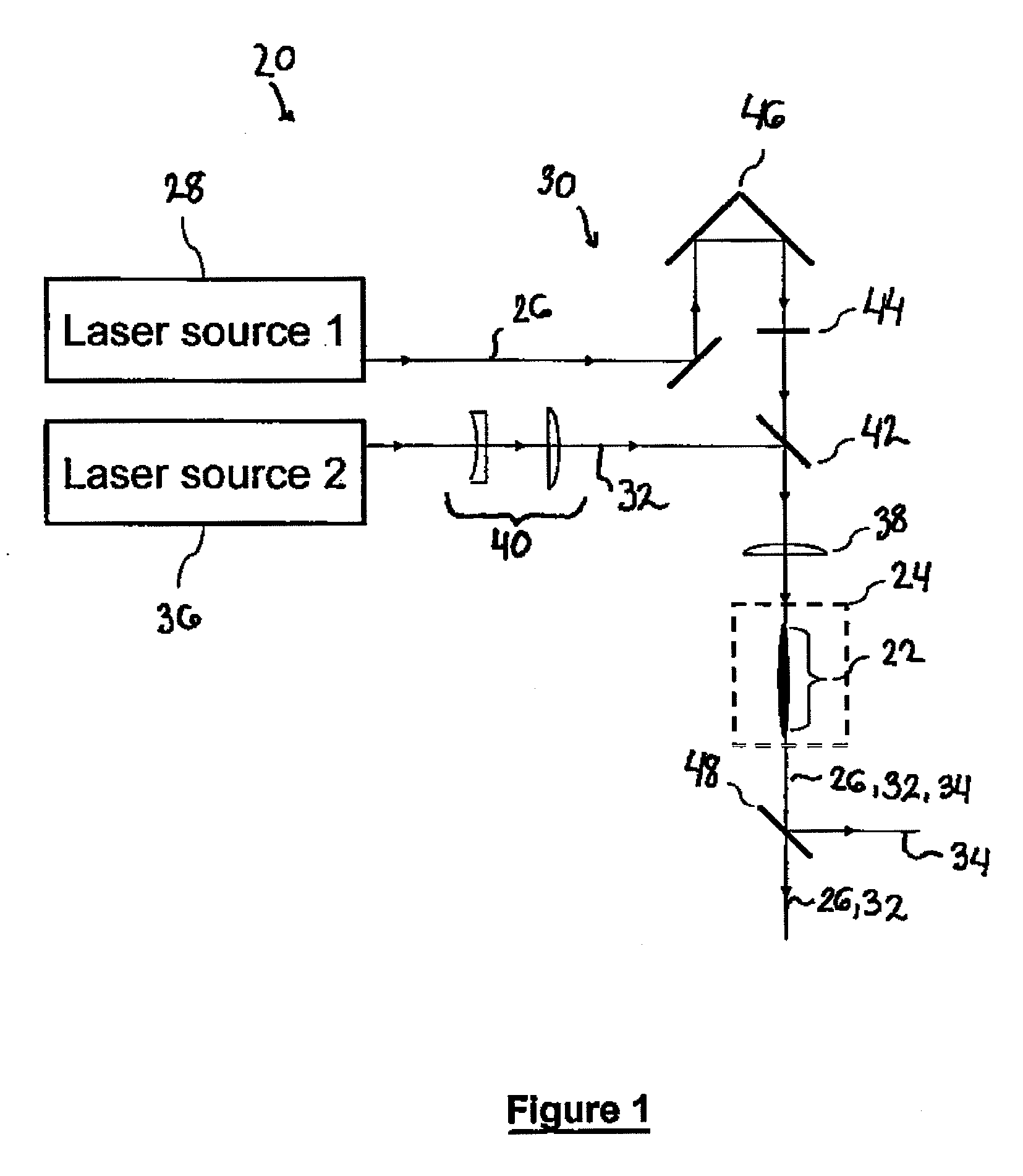

Method and Devices for Generating Stable and Tunable Light Pulses

InactiveUS20080225383A1The method is simple and efficientStable and powerful and tunableLaser detailsLight demodulationLight beamReady to use

Owner:UNIV LAVAL

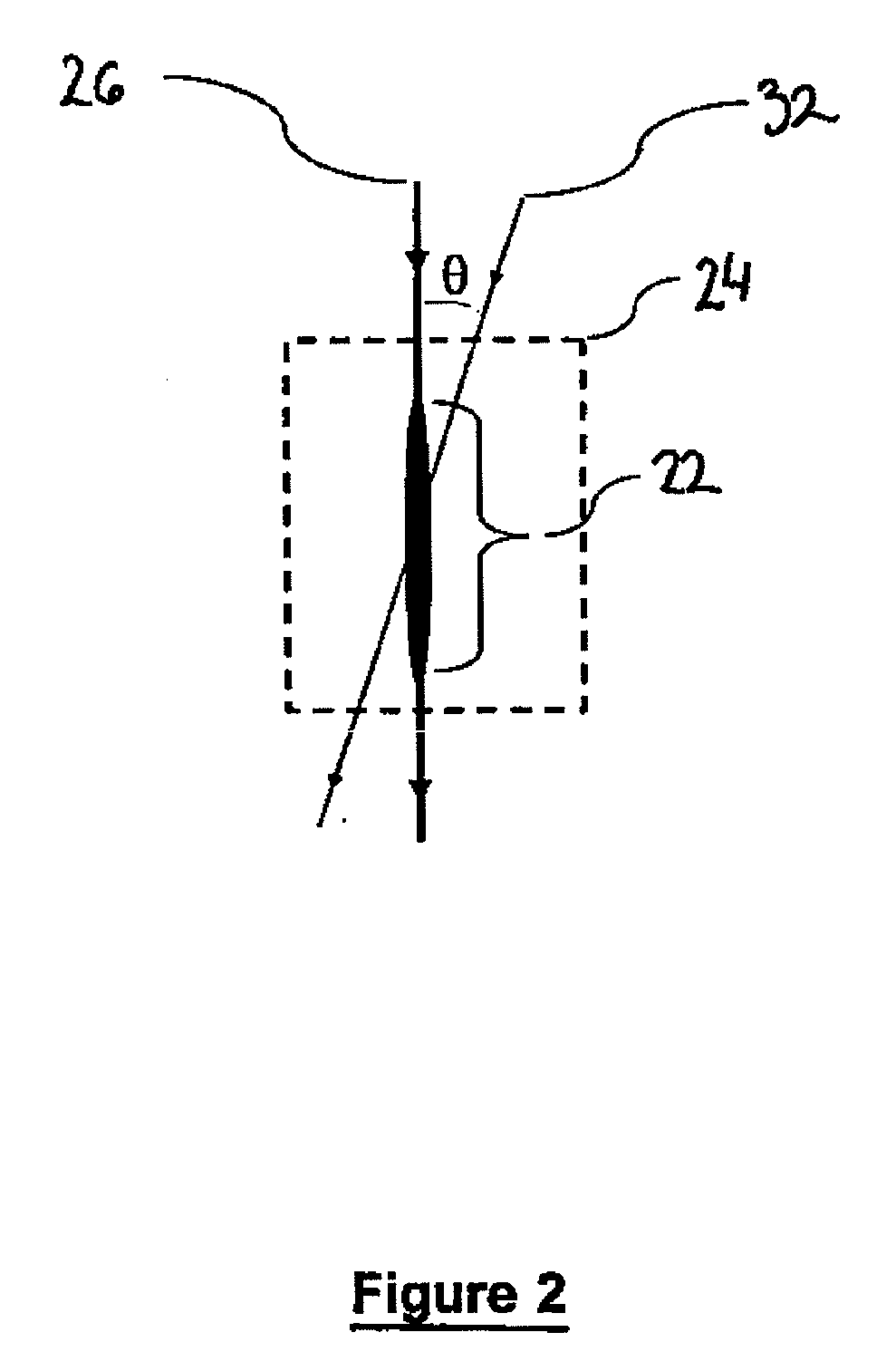

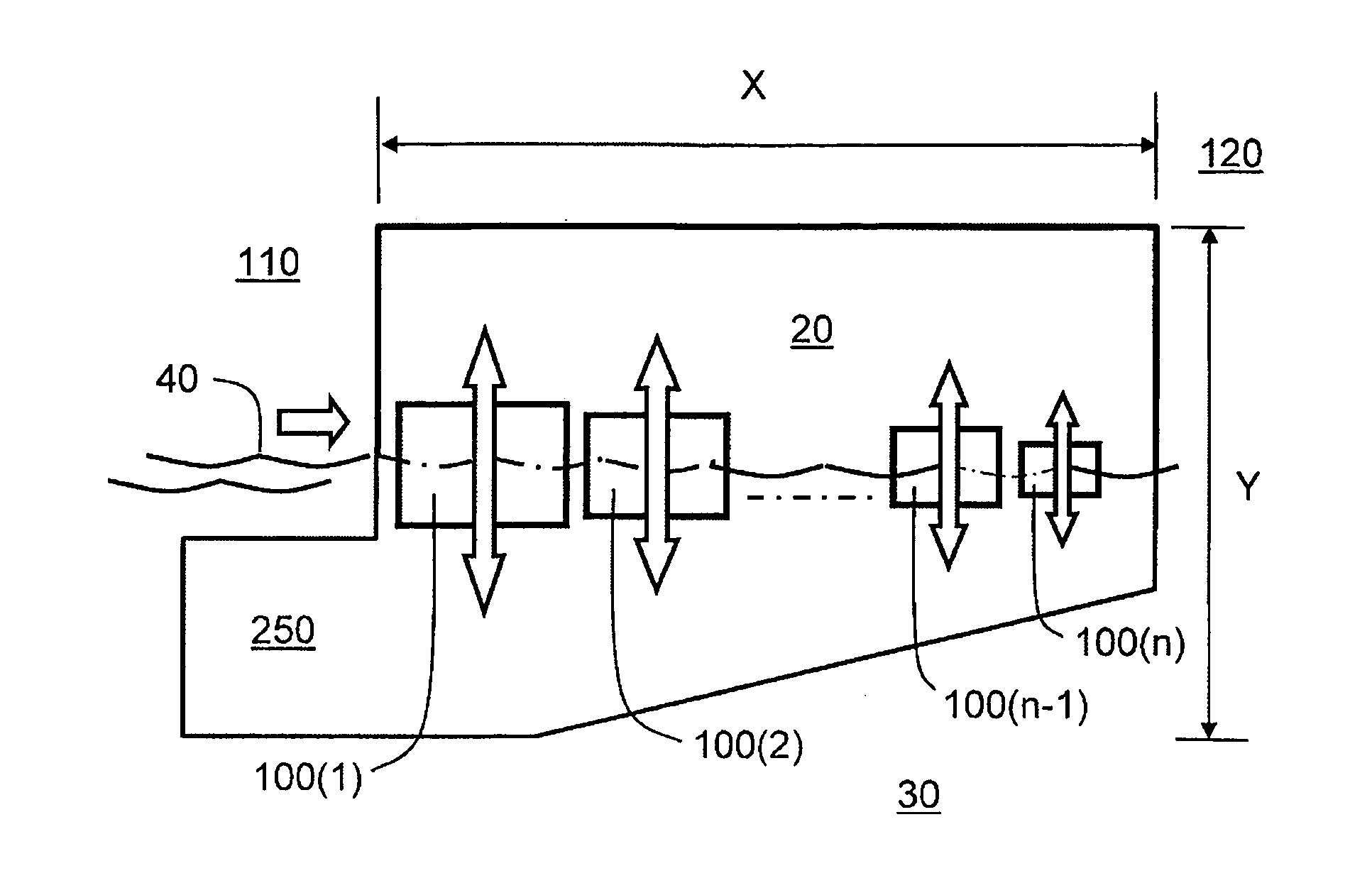

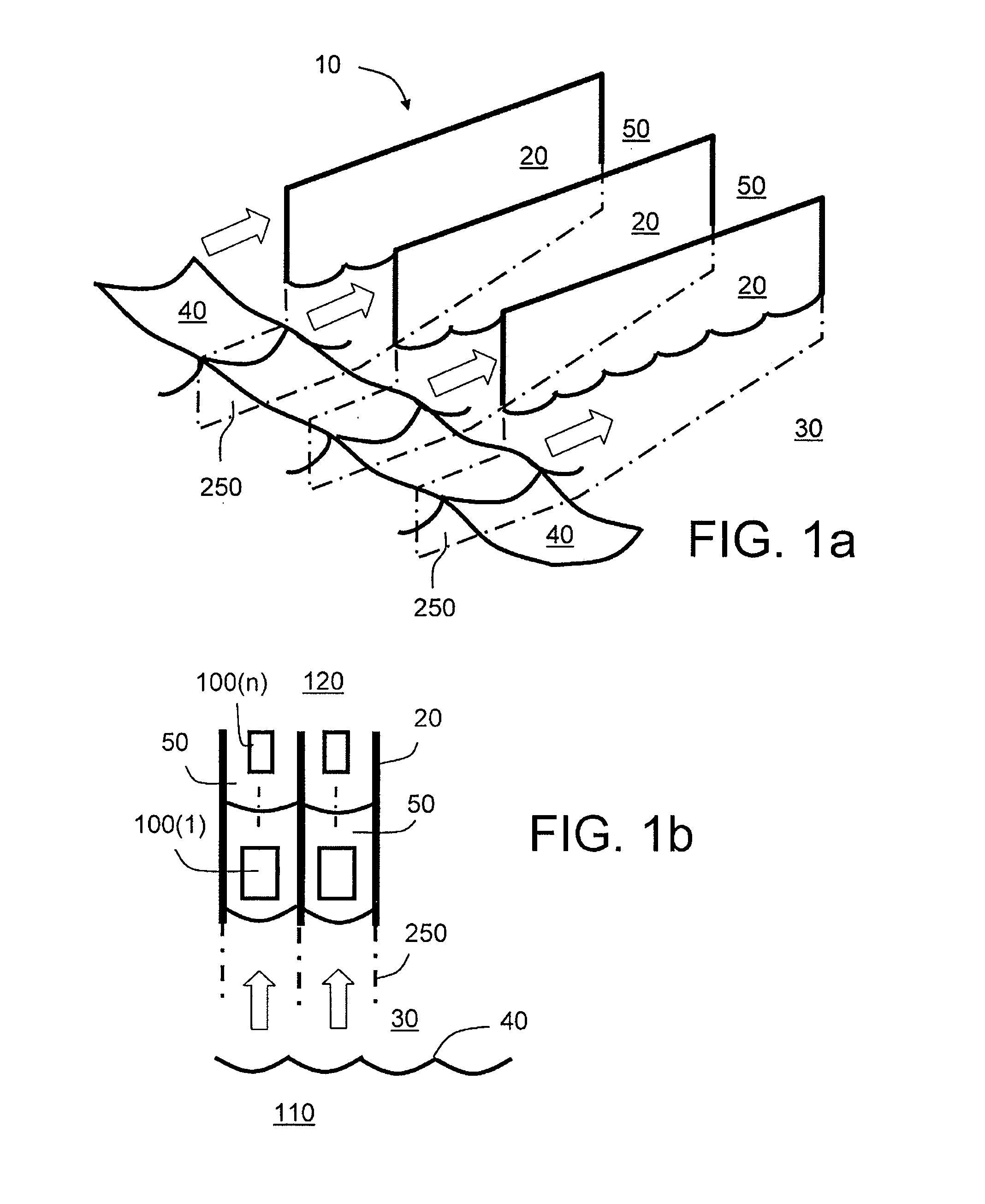

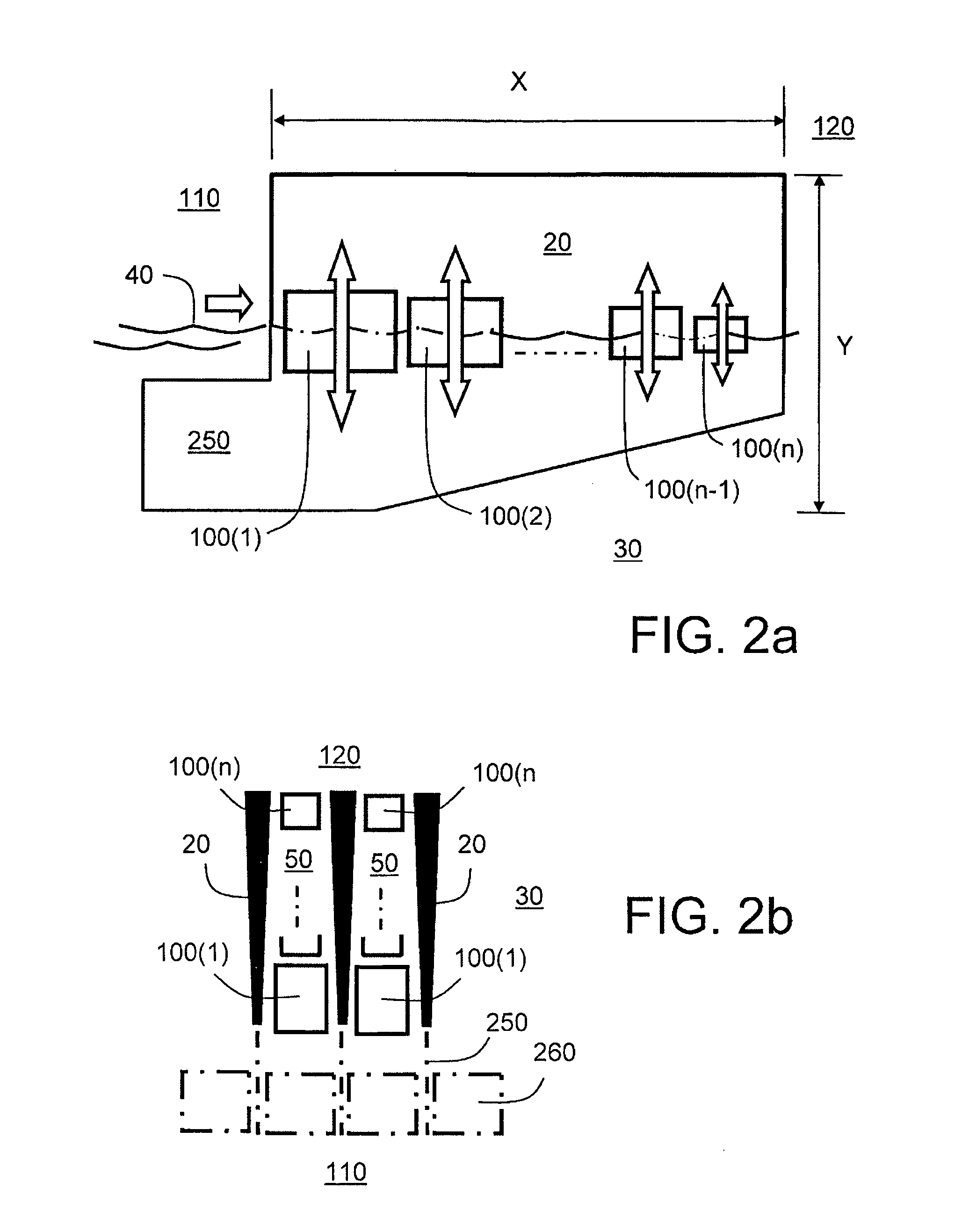

Energy System

InactiveUS20110187102A1Robust constructionThe method is simple and efficientWind motor with solar radiationWind energy with water energySea wavesAbsorbed energy

An ocean wave energy system is for generating power from ocean waves. The system comprises wall components defining one or more channels for guiding propagation of ocean waves therealong. Each channel has a first end for receiving the ocean waves and a second end remote from the first end. A float arrangement is disposed along each of the one or more channels between its first and second ends. Moreover, the float arrangement being arranged in size to progressively absorb energy from the ocean waves commencing with longest wavelength components in the waves and finishing with shortest wavelength components in the waves. The ocean wave energy system is capable of extracting energy efficiently and conveniently from ocean wave motion.

Owner:OCEAN WAVE ROCKER

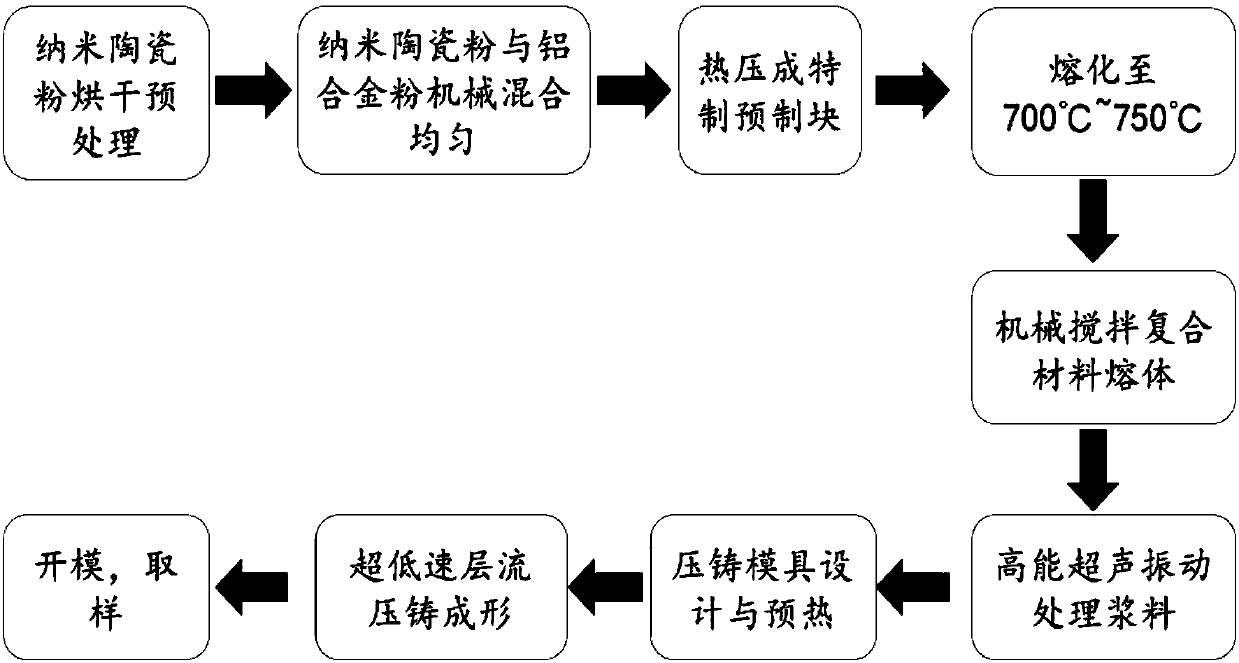

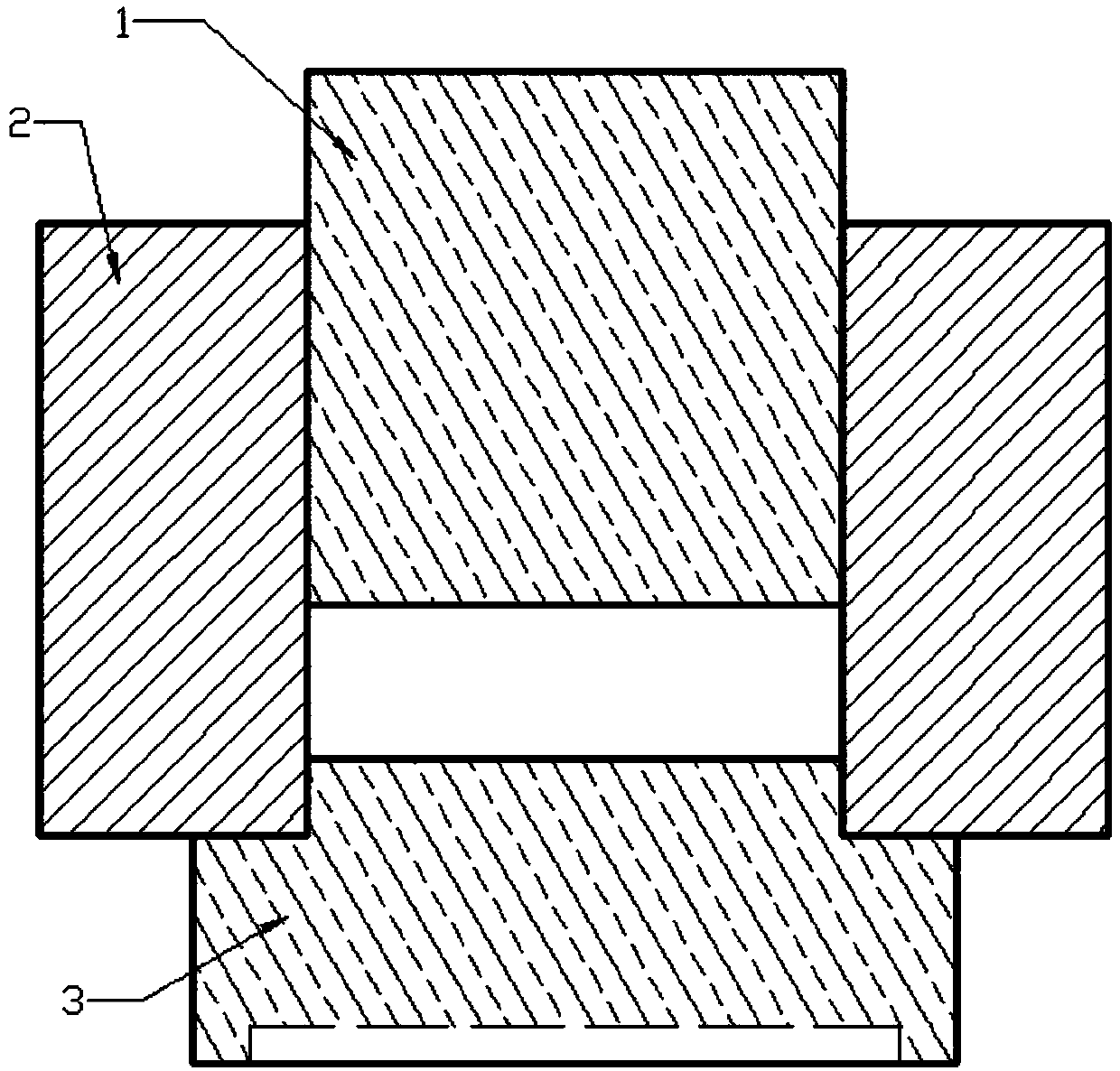

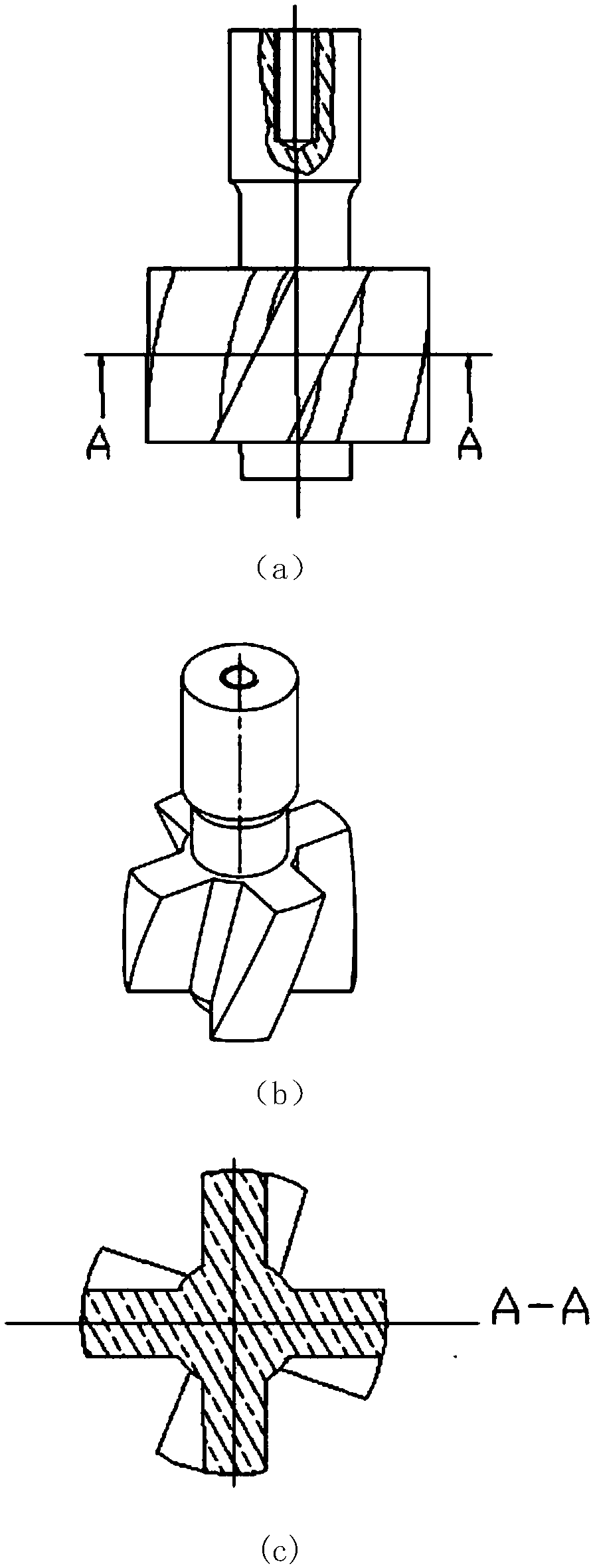

Forming method for nano particle reinforced aluminum-based composite material

The invention discloses a forming method for a nano particle reinforced aluminum-based composite material and belongs to the field of metal casting forming. Nano ceramic powder and micro size aluminumpowder or aluminum alloy powder are prepared into mixed powder with the nano ceramic particle content being 3-10%, the mixed powder is mechanically mixed into composite powder in a seal tank under argon protection, and the composite powder is hot-pressed into prefabricated blocks with the quality being about 150-200 g. The prefabricated blocks are melted after reaching about 750 DEG C, then mechanical stirring is conducted, and then high-energy supersonic vibration is conducted. Through ultra-low-speed laminar flow pressure casting, a composite material melt is pressed into a mold cavity of amold, mold opening is conducted for piece taking-out, and a nano ceramic particle reinforced aluminum-based composite material part with the mass fraction being 3-10% is obtained. According to the forming method for the nano particle reinforced aluminum-based composite material, the forming technique is simple and easy to achieve, the effect is good, and the problems that in casting, a ceramic particle reinforced aluminum-based composite material with the high mass fraction is large in viscosity and poor in liquidity, and ceramic particles are easy gathered are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

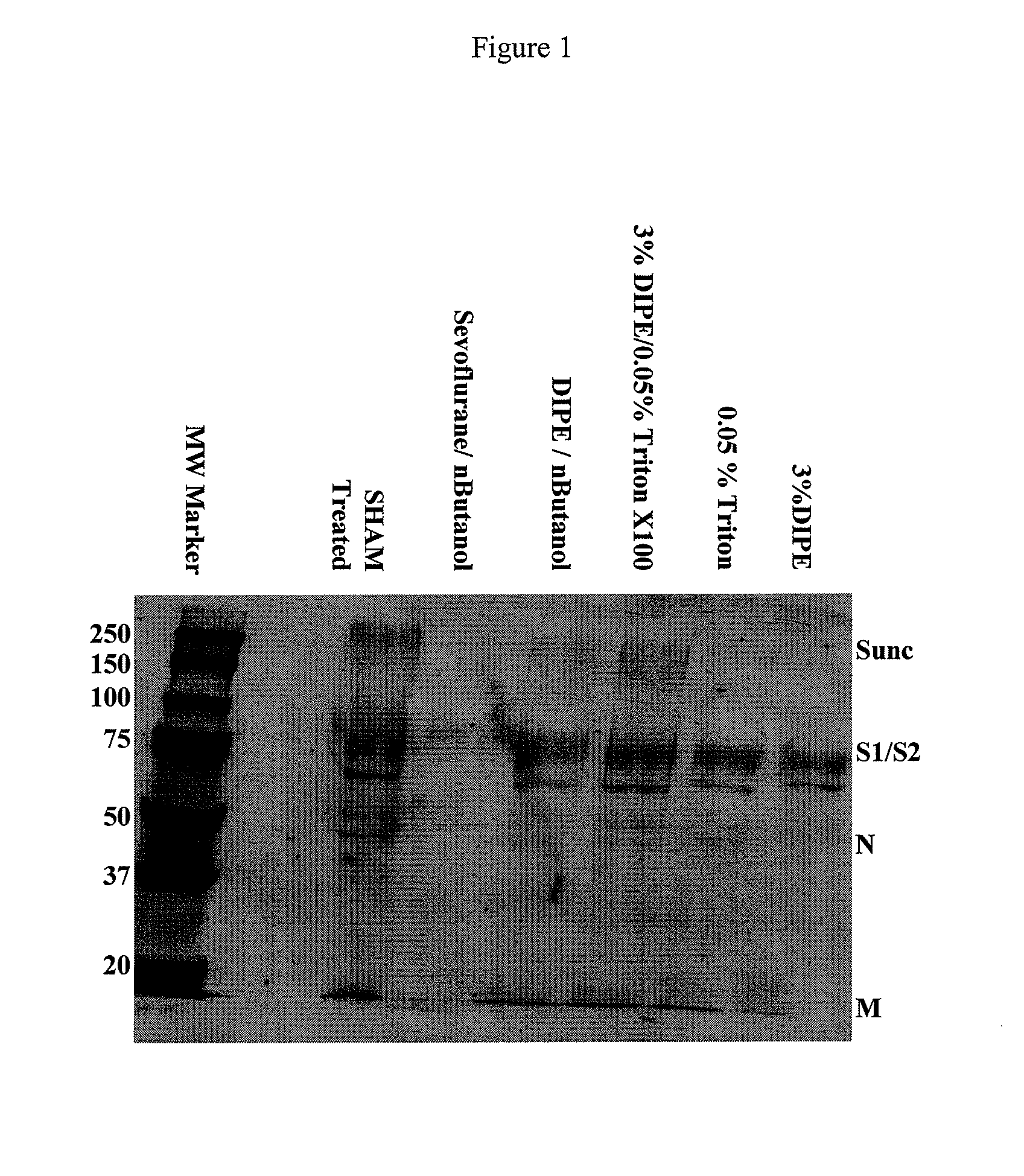

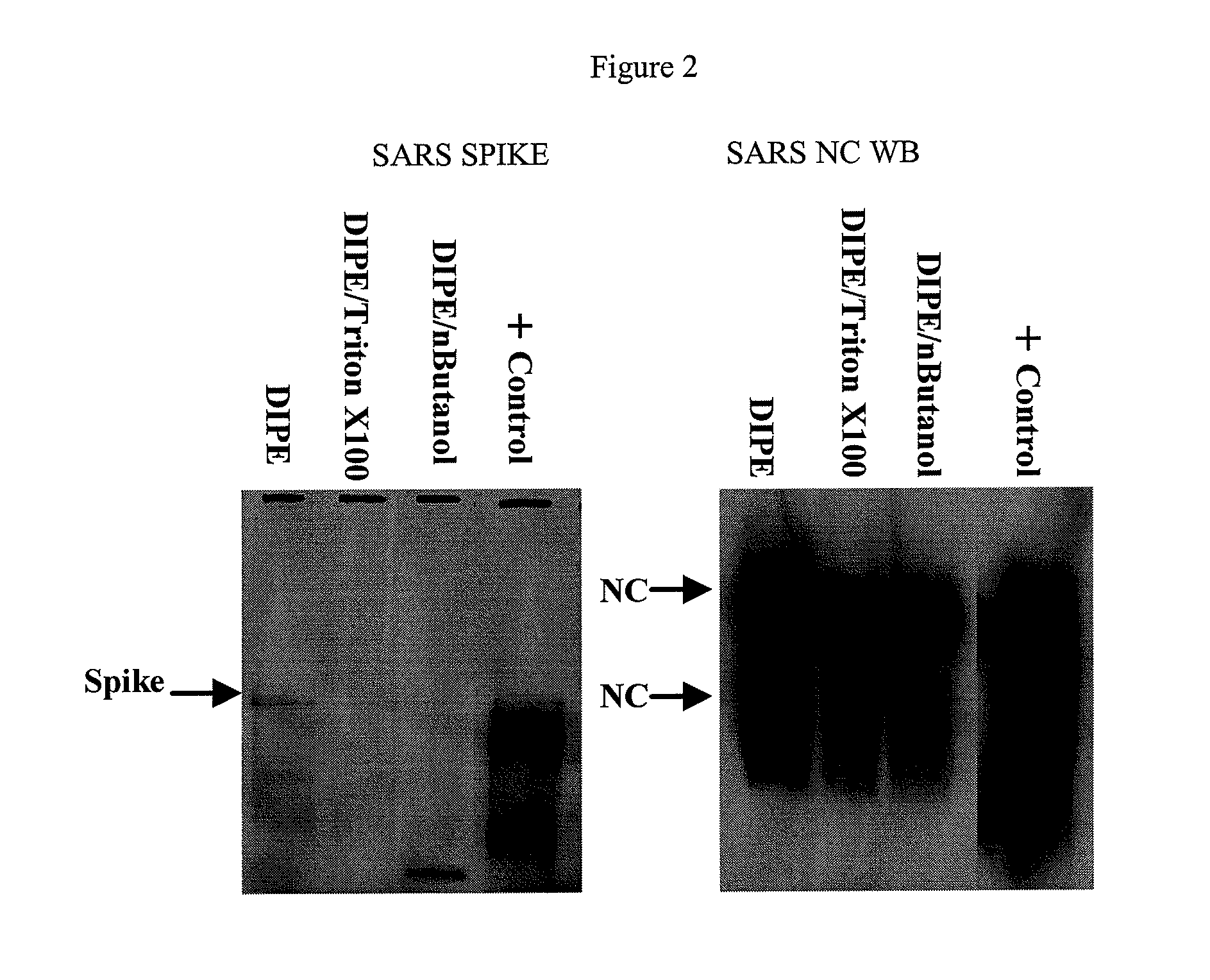

SARS Vaccine Compositions and Methods of Making and Using Them

InactiveUS20090017069A1The process is simple and effectiveThe method is simple and efficientSsRNA viruses positive-senseViral antigen ingredientsLipid formationViral Vaccine

Owner:ELI LILLY & CO +1

Bi-metal layered hydroxide chelated Ti3C2 compound as well as preparation method and application thereof

InactiveCN110075890ASimple and safe operationThe method is simple and efficientPhysical/chemical process catalystsElectrodesCobaltRaw material

The invention discloses a bi-metal layered hydroxide chelated Ti3C2-MXene catalyst as well as a preparation method and an application thereof, and relates to the technical field of electrochemistry. The preparation method of the bi-metal layered hydroxide chelated Ti3C2-MXene catalyst comprises following steps: Ti3AlC2-MAX is taken as a raw material, and Ti3C2-MXene is obtained with a LiF+HCl stripping method; hydroxide of Fe and Co is mixed with Ti3C2-MXene, the mixture is heated to 120 DEG C under protection of Ar gas and kept at the temperature for 3 h, and FeCo-LDH / Ti3C2-MXene is obtainedby centrifugation and 60-DEG C vacuum drying. The preparation of the bi-metal layered hydroxide compound is simple and safe to operate, a glassy carbon electrode supported with the FeCo-LDH / Ti3C2-MXene compound is taken as a working electrode, the electro-catalysis of hydrogen evolution process by cathodic water oxidation is studied, the initial potential is lower, and hydrogen output is larger.

Owner:LIAONING UNIVERSITY

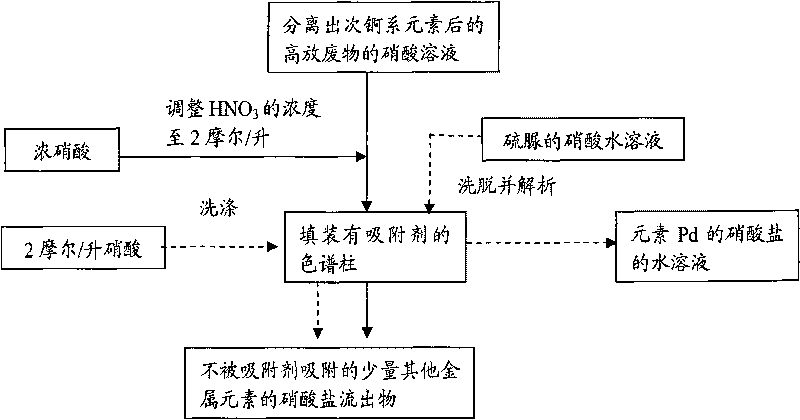

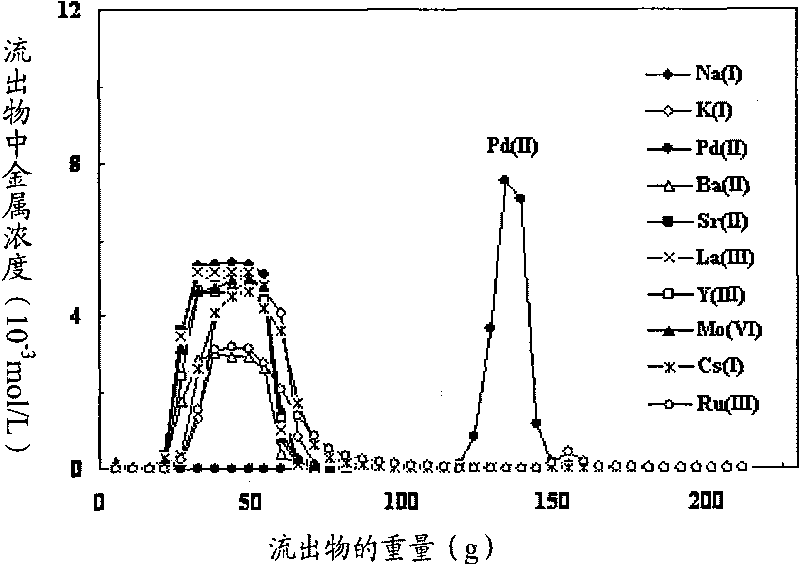

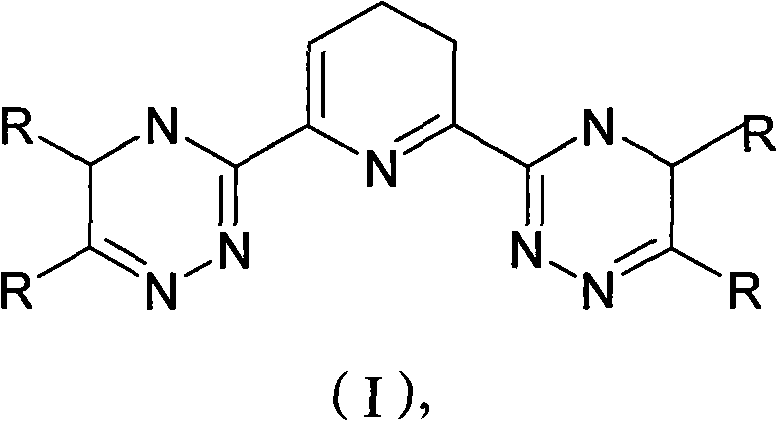

Method for separating element Pd from high-level radioactive waste

InactiveCN101690853AThe method is simple and efficientHigh selectivityOther chemical processesSolid sorbent liquid separationChromatography columnAqueous solution

The invention discloses a method for separating an element Pd from the high-level radioactive waste, which comprises the following steps: (1) adding concentrated nitric acid in nitrate solution of the high-level radioactive waste which separates minor actinides for adjusting the concentration of the nitric acid to 1.7-2.3 mol / L; (2) leading the nitrate solution of the high-level radioactive waste after the adjustment of the concentration of the nitric acid to pass through a column filled with an absorbent, and leading the element Pd to be absorbed by the column filled with the absorbent; and (3) using nitric acid water solution of thiourea to elute the column filled with the element Pd, and eluting out the element Pd in the form of nitrate, wherein the concentration of the thiourea in the nitric acid water solution of the thiourea is 0.1-0.3 mol / L, and the concentration of the nitric acid is 0.05-0.15 mol / L. The method is simple and high-efficient, the selectivity of the column is high, and the separation effect is good.

Owner:ZHEJIANG UNIV

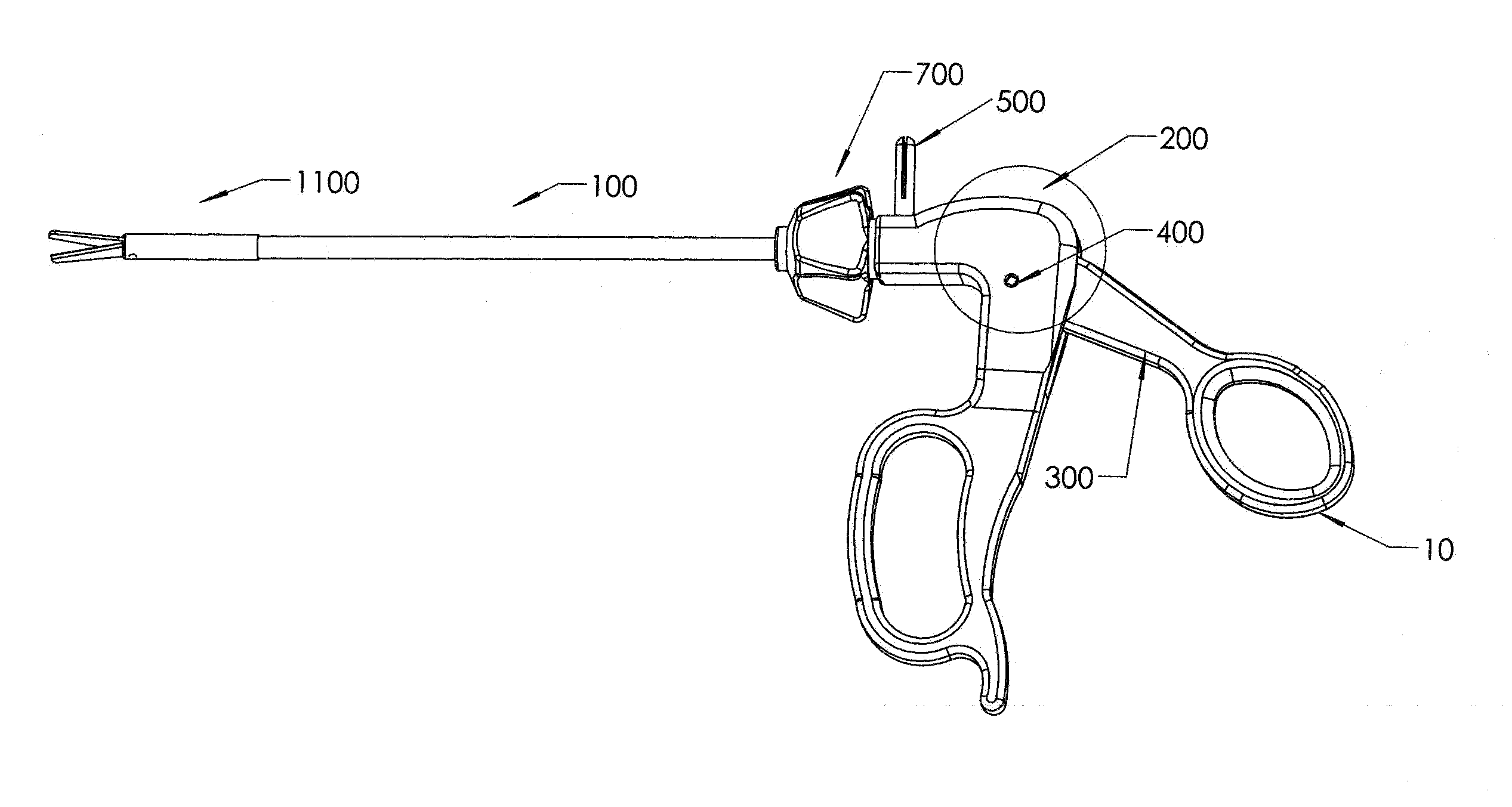

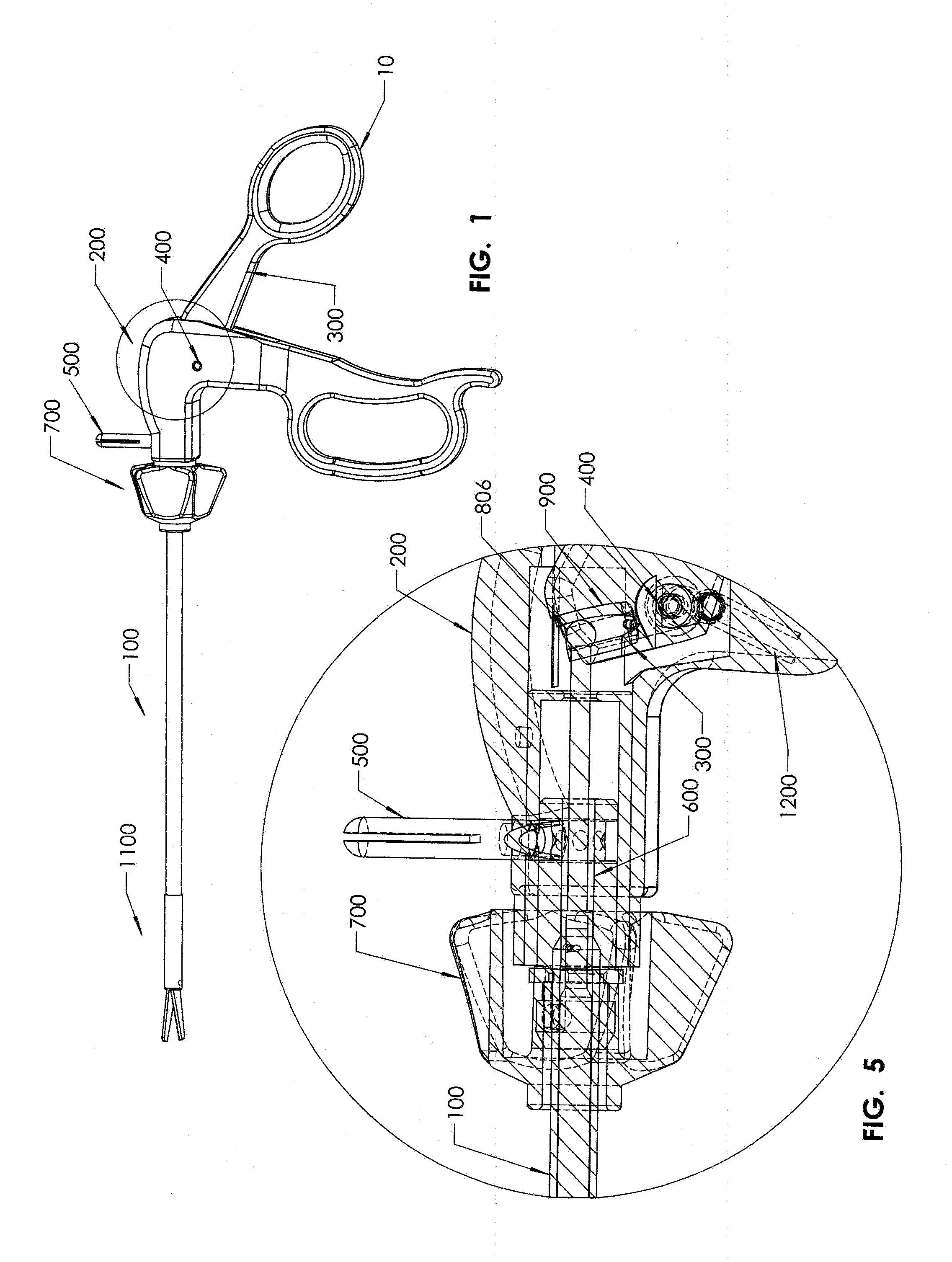

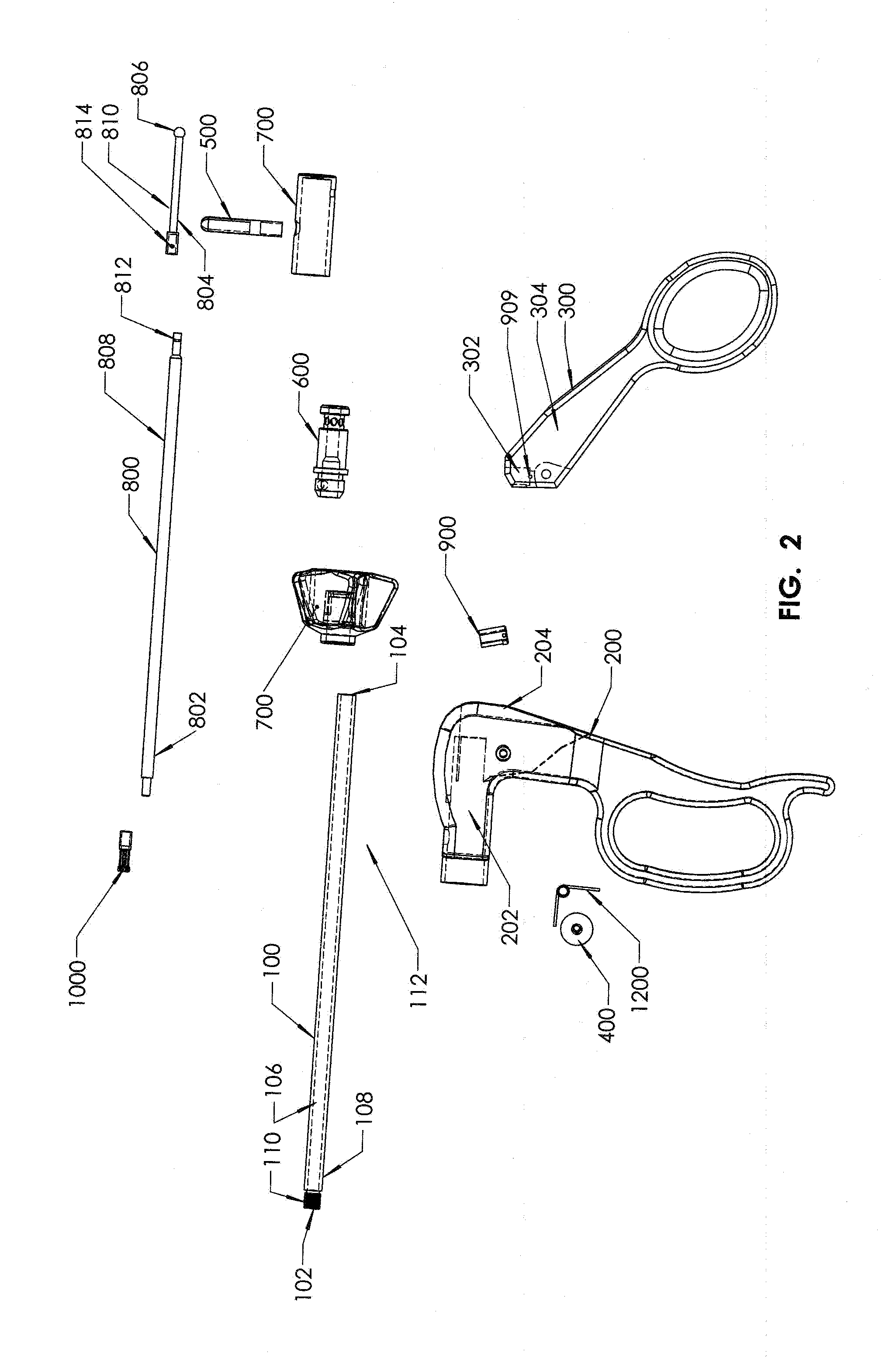

Surgical instrument with detachable tip

InactiveUS20120232338A1The method is simple and efficientPreserving reusableSuture equipmentsInternal osteosythesisEndoscopeSurgical device

An endoscopic hand instrument includes a tubular member having a throughbore extending between a first open end and a second open end, the throughbore including a first portion having a first inner diameter and a second portion having a second inner diameter, a collet member received within the throughbore, the collet member including at least two biasable arm members, the collet member being biased such that the two arm members extend radially outward into the first portion of the throughbore, the two arm members including an area defining an aperture, and a tip assembly having an engagement member, the engagement member being received between the two arm members and into the aperture, the tip assembly engaging the tubular member so as to force the two arm members into the second portion of the throughbore such that the two arm members are prevented from extending radially outward.

Owner:LIVNEH STEVE

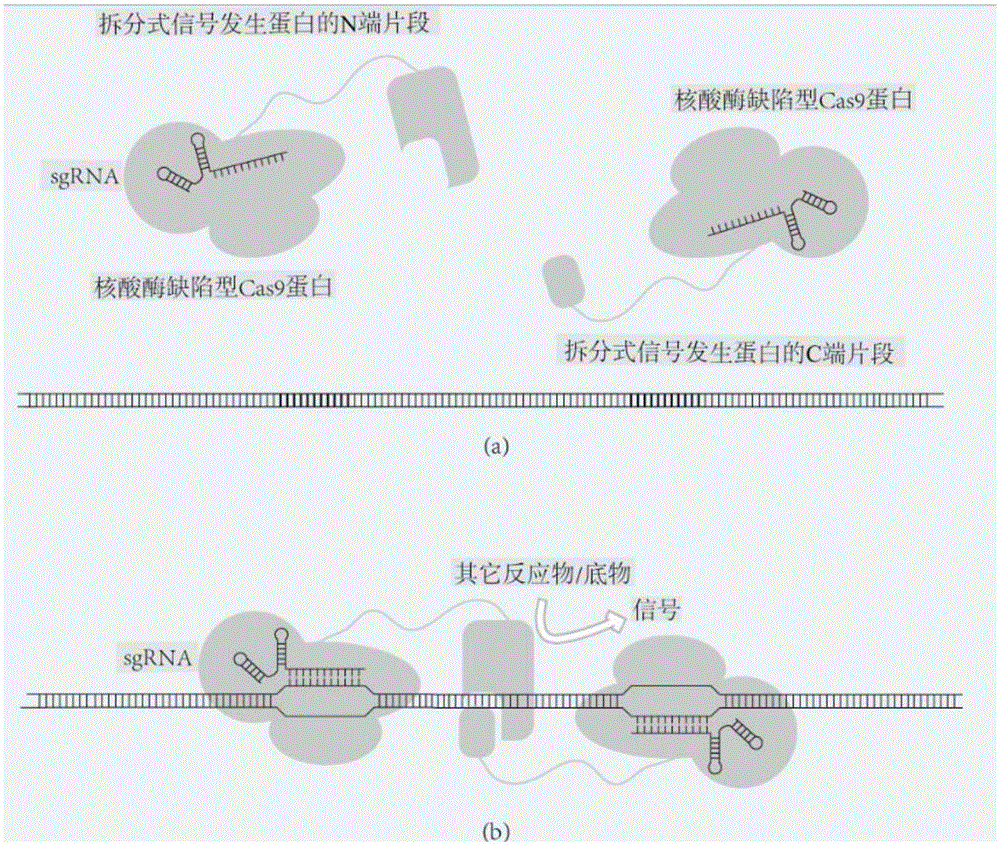

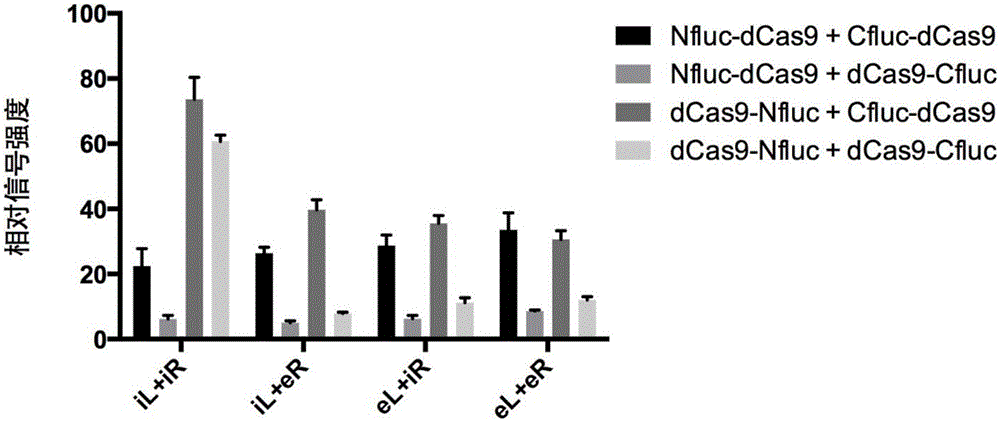

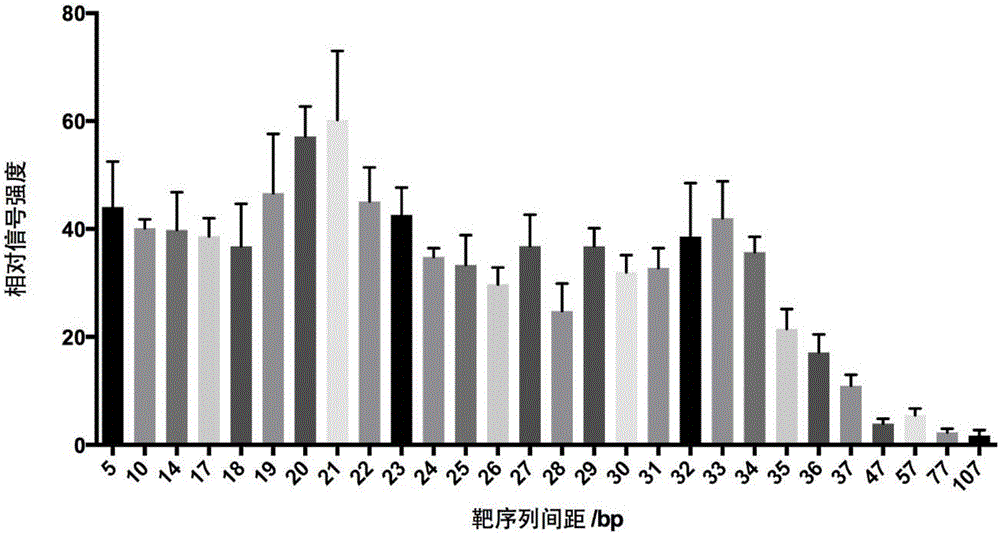

Detection method of nucleic acid

InactiveCN105177110AThe method is simple and efficientImprove portabilityMicrobiological testing/measurementFluorescence/phosphorescenceBone morphogenetic protein 6Nuclease

The present invention relates to an in vitro detection method that whether a sample contains target nucleic acid or not is detected by utilizing fusion protein of split-signaling morphogenetic protein and nucleic acid enzyme defect type Cas9 protein, a kit and a device.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI +1

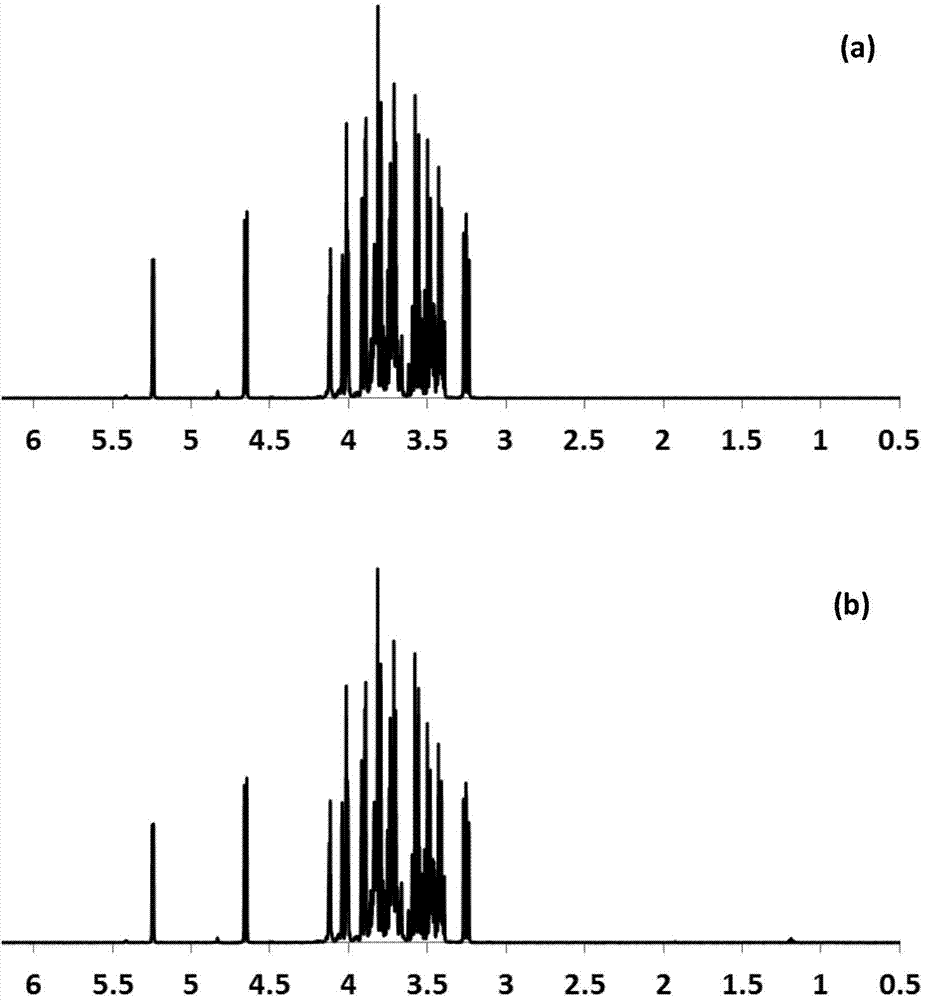

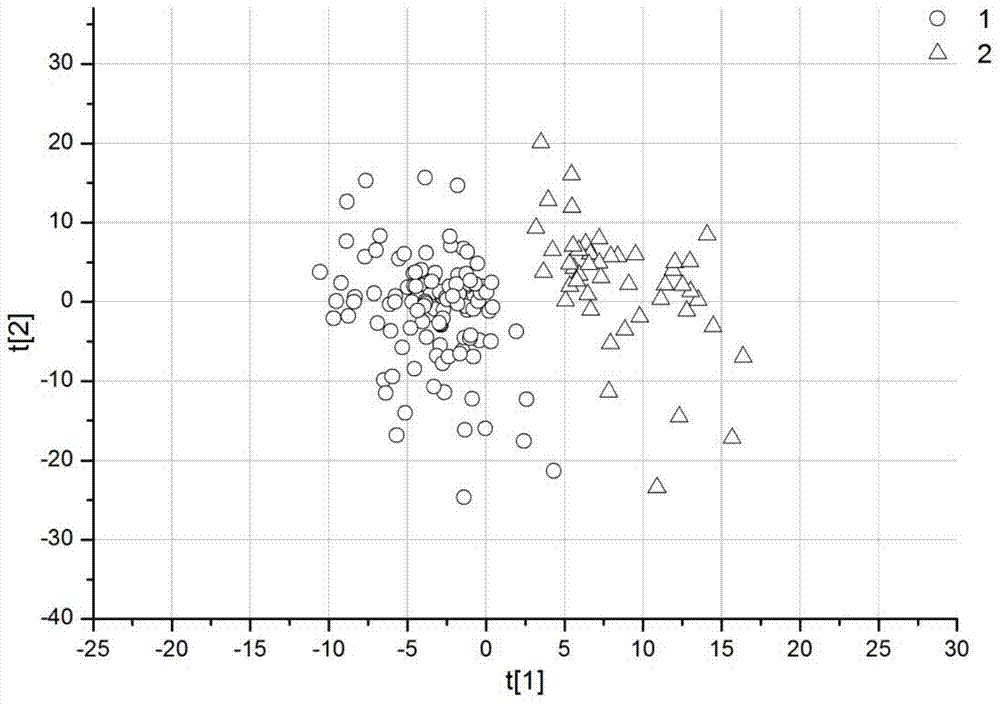

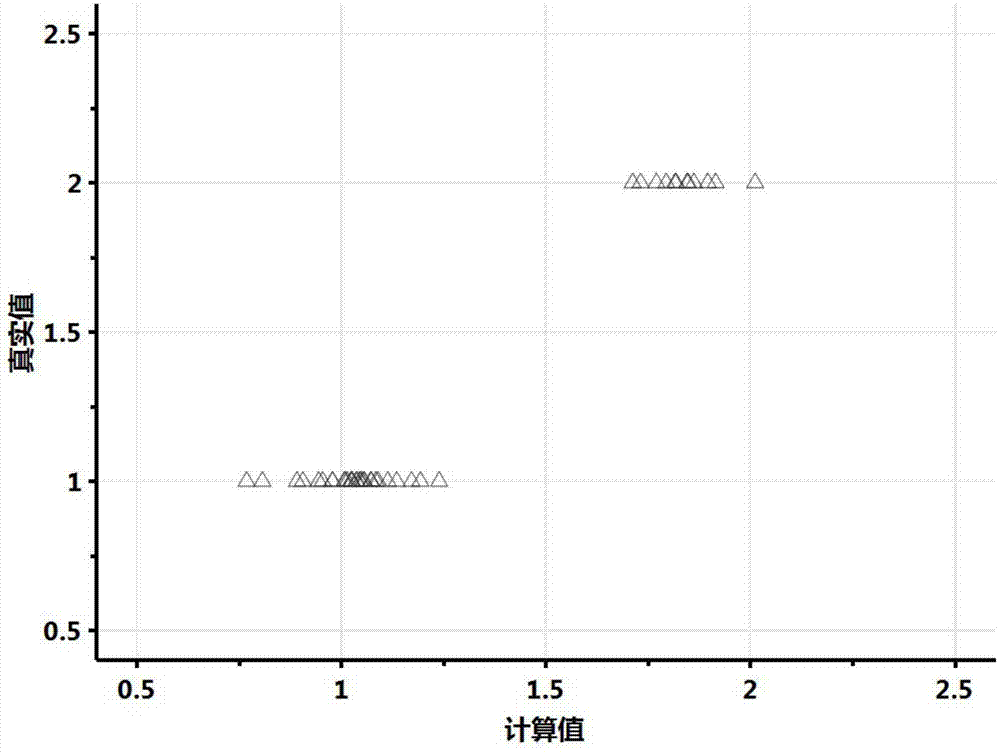

Method for distinguishing between pure and syrup-adulterated honey based on combination of hydrogen nuclear magnetic resonance and partial least square method

ActiveCN104713895ALow preprocessing requirementsMature and reliable technologyAnalysis using nuclear magnetic resonanceNMR - Nuclear magnetic resonanceHydrogen

The invention discloses a method for distinguishing between pure and adulterated honey based on combination of hydrogen nuclear magnetic resonance and a partial least square method. The method relates to food detection, and application of a hydrogen nuclear magnetic resonance fingerprint to food detection. The method comprises the following steps: firstly, building a pure honey database and a syrup-doped honey database respectively; secondly, building a distinguishing model, and carrying out a reliability test on the identification model; finally, distinguishing honey samples to be detected, and expanding the databases with the distinguishing results to improve the representativeness of the samples and the distinguishing capability. The method has the advantages that the technique is reliable, the operation is simple, a large quantity of samples can be treated in a short time, the dubious honey samples can be quickly screened out, the subjective factors and the personal errors can be avoided, and the conclusion can be scientific and reliable.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

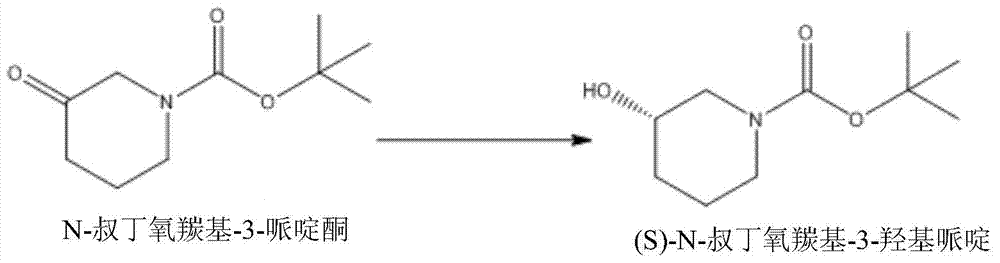

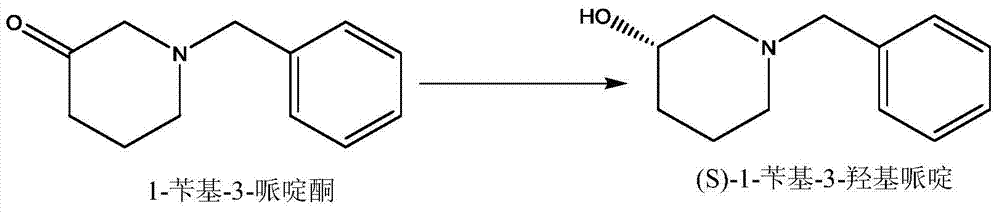

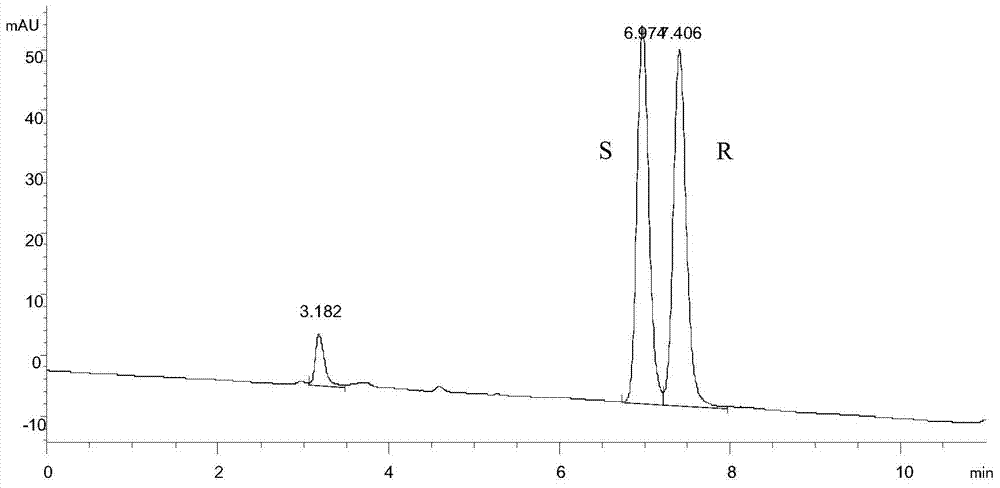

Production method of N-protection pipradrol

ActiveCN103789368AThe method is simple and efficientFermentationTert-Butyloxycarbonyl protecting groupIsopropyl alcohol

The invention discloses a production method of N-protection pipradrol. The structural formula of the N-protection pipradrol is shown in the specification, wherein R is tert-butyloxycarbonyl or benzyl. The production method is characterized in that the N-protection piperidone is taken as a substrate, and is obtained through a reaction in the presence of alcohol dehydrogenase, ADH-A, isopropyl alcohol and NAD<+1>; the alcohol dehydrogenase is cpsADH or cmADHmut. The method disclosed by the invention is efficient and simple and has relatively high value in industrial application.

Owner:SHANGHAI RES & DEV CENT OF INDAL BIOTECH +1

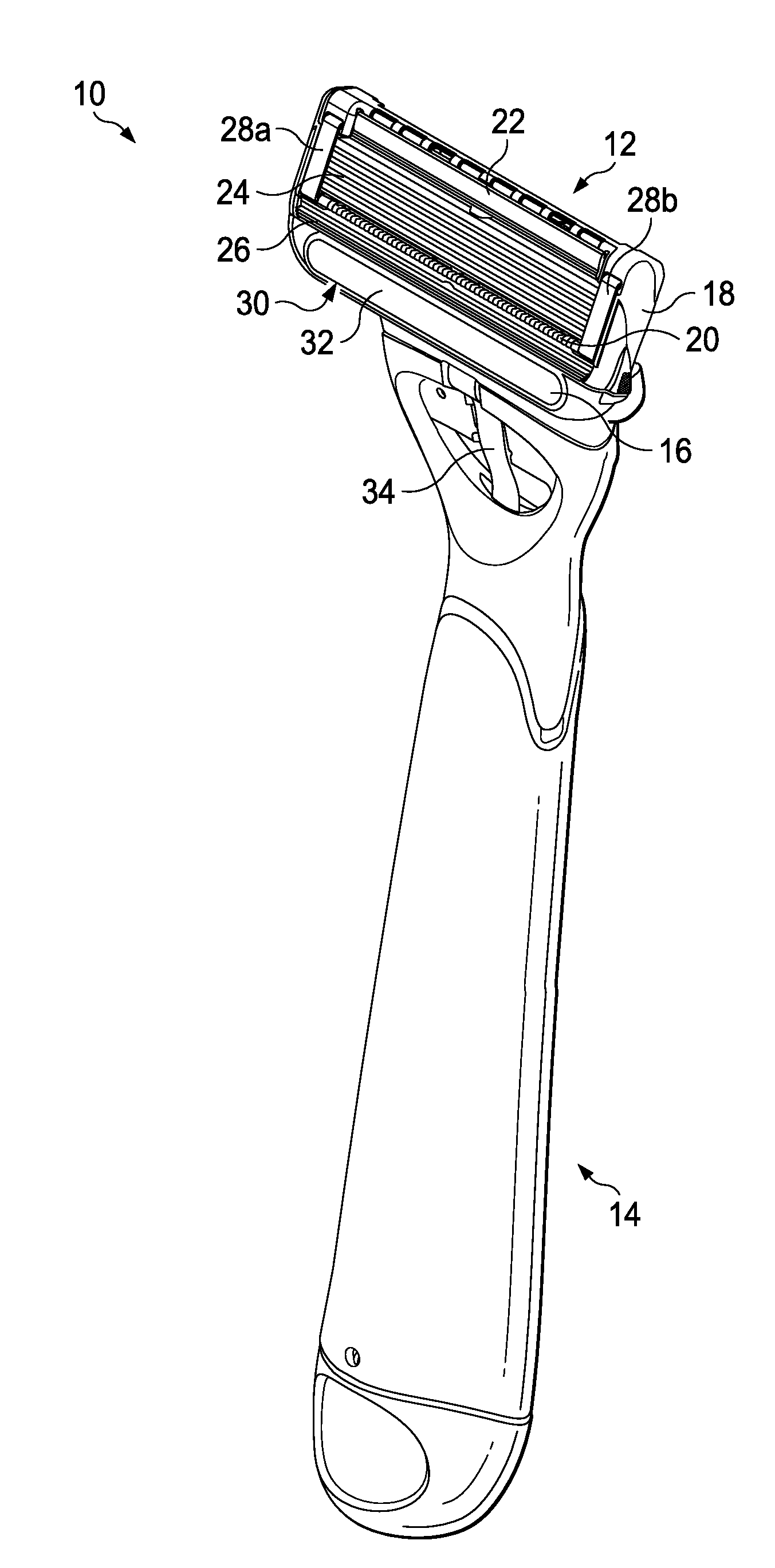

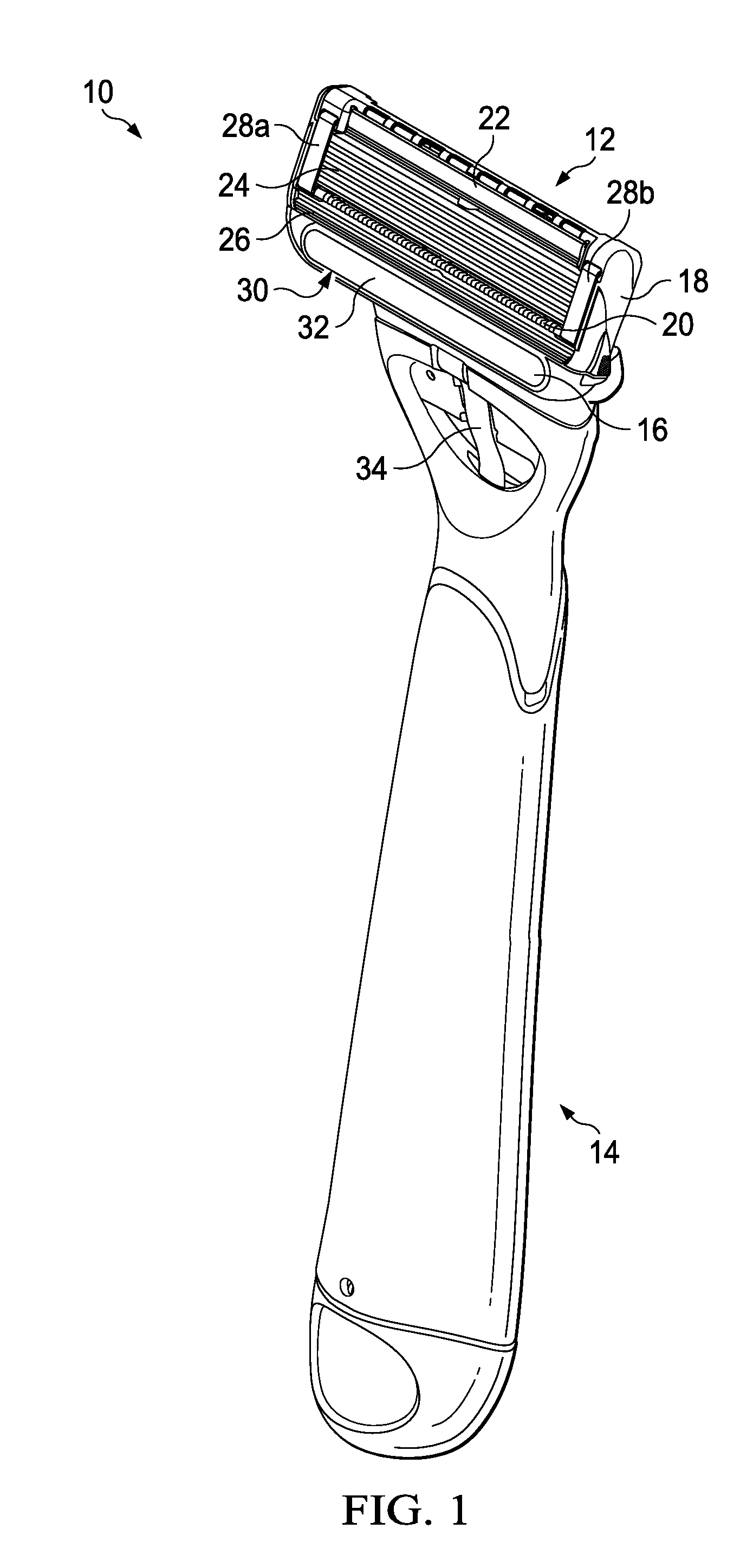

Method of assembling a personal care product

InactiveUS20160375596A1Simple methodSimple and efficientPrinted circuit assemblingElectrically conductive connectionsEngineeringFlexible electronics

A method of assembling a heating element for a shaving razor by providing an insulating member having a base with a plurality of spaced apart electrical terminals. A flexible printed circuit board having a plurality of spaced apart electrical terminals is provided. The electrical terminals of the insulating member are soldered to the corresponding electrical terminals of the flexible printed circuit board. A liquid non electrically conductive underfiller encapsulant is dispensed between the base of the insulating member of the base of the flexible printed circuit board forming a water tight seal between each of the spaced apart electrical terminals of the insulating member and between each of the electrical terminals of the flexible printed circuit board by curing the liquid non electrically conductive underfiller encapsulant.

Owner:THE GILLETTE CO

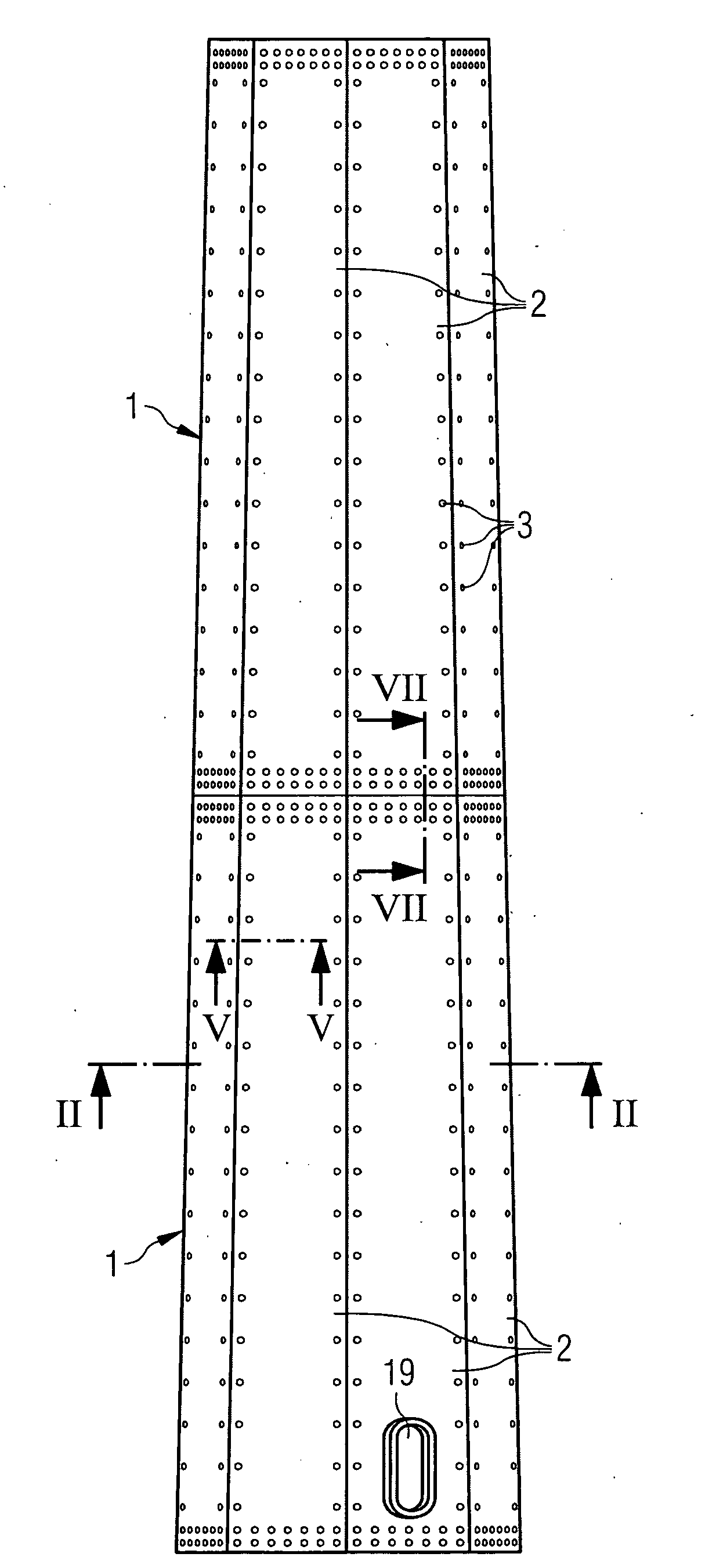

Wind turbine tower and method for constructing a wind turbine tower

ActiveUS8250833B2Low costAvoids any rolling, bending and/or weldingEngine manufactureFinal product manufactureTowerTurbine

A wind turbine tower is provided, which comprises a number of segments with a polygonal cross section, each segment comprising a number of flat plates which are connected to each other so as to form the polygonal cross section. Further, a method for constructing a wind turbine tower which comprises segments assembled of flat plates is disclosed, wherein the flat plates are connected to each other so as to form segments with a polygonal cross section and the segments are connected to each other so as to form the tower.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

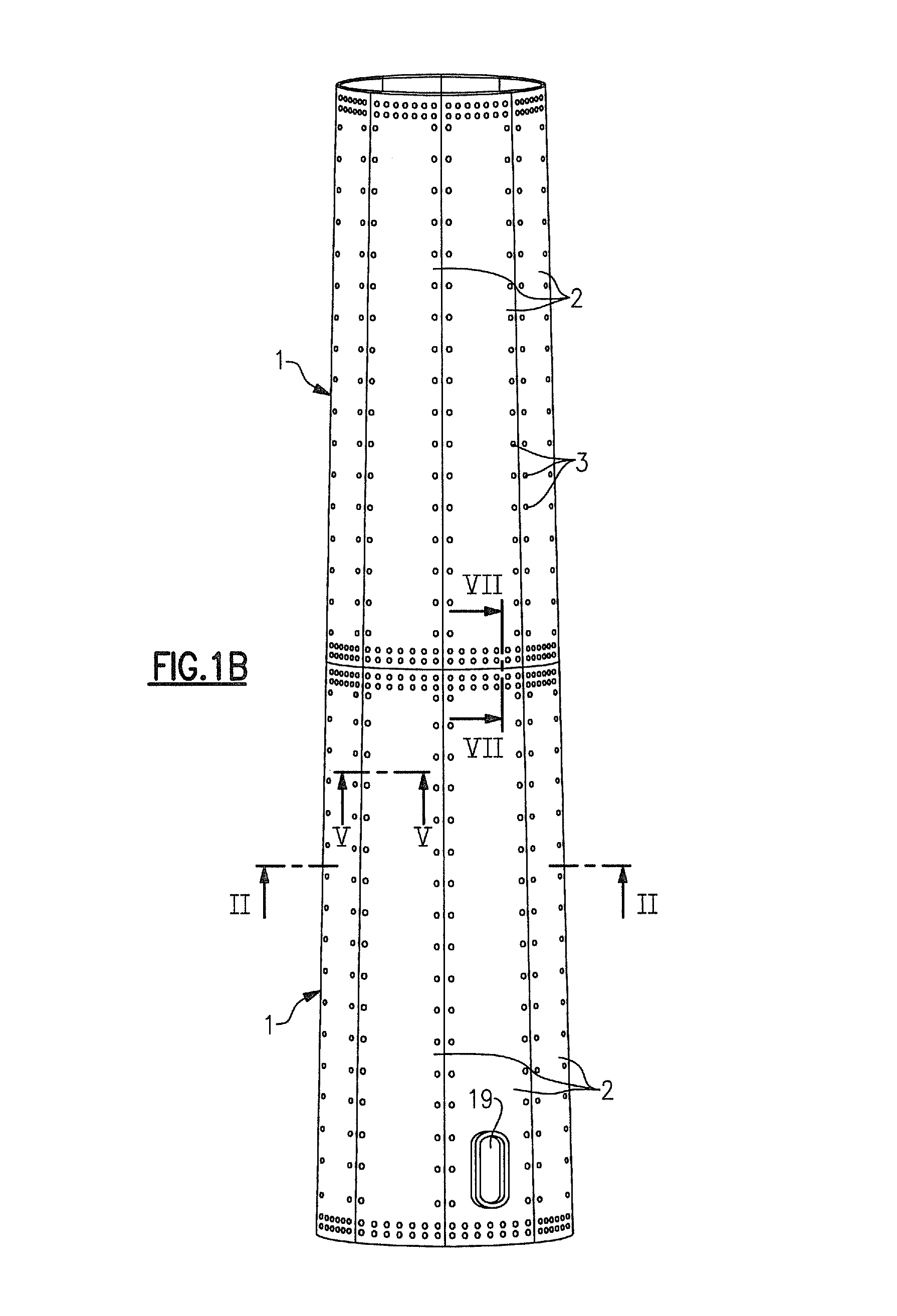

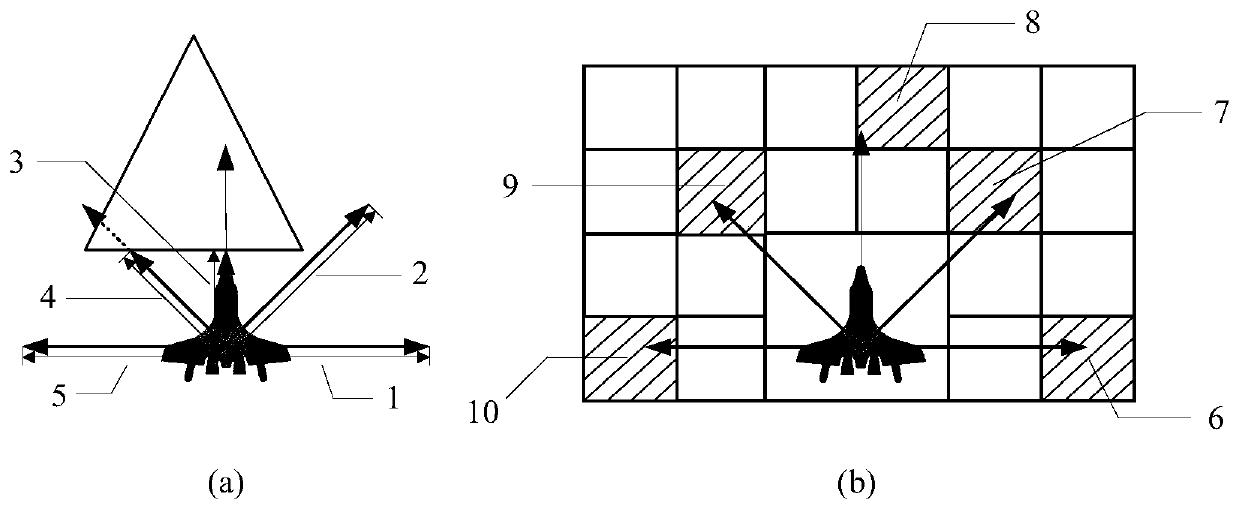

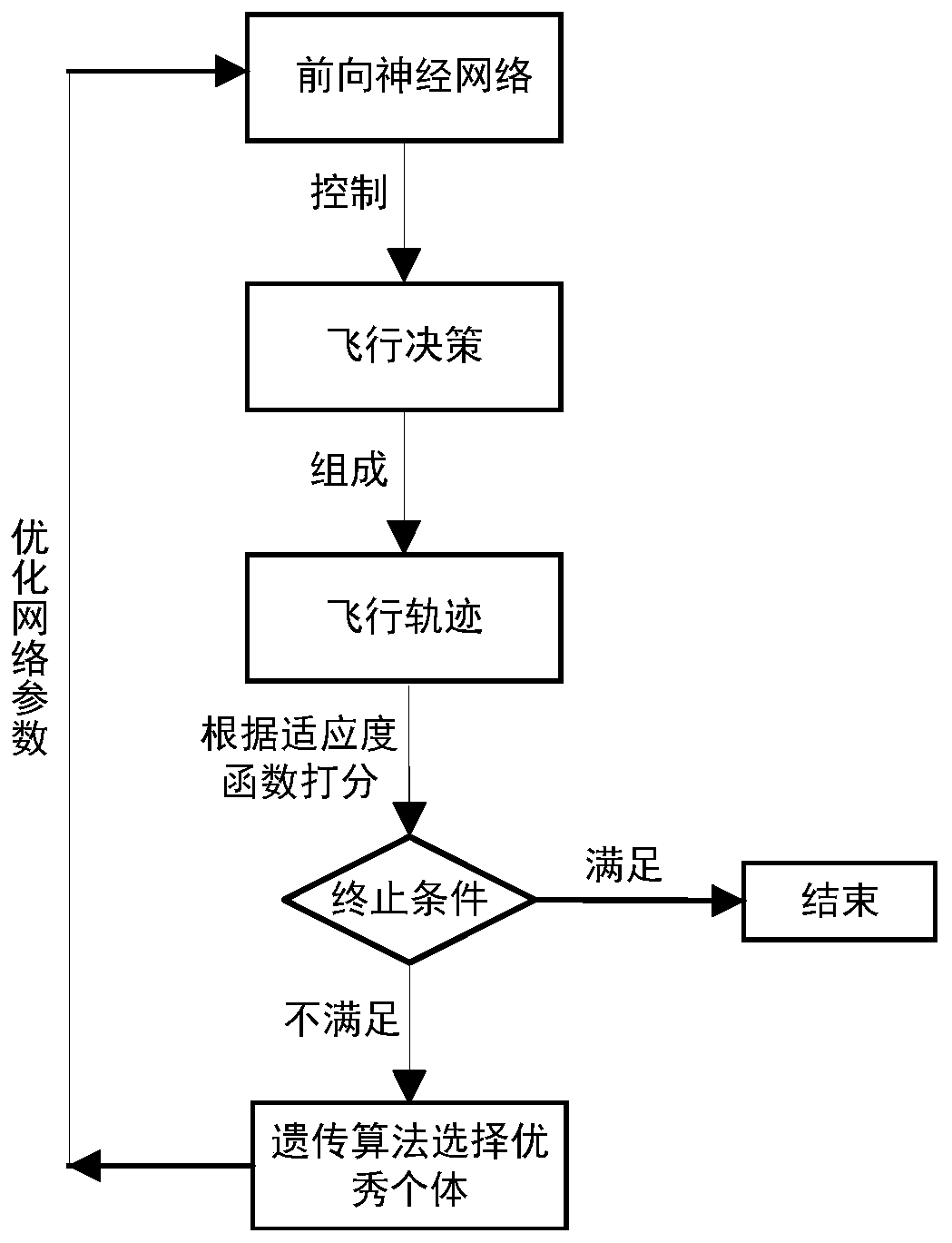

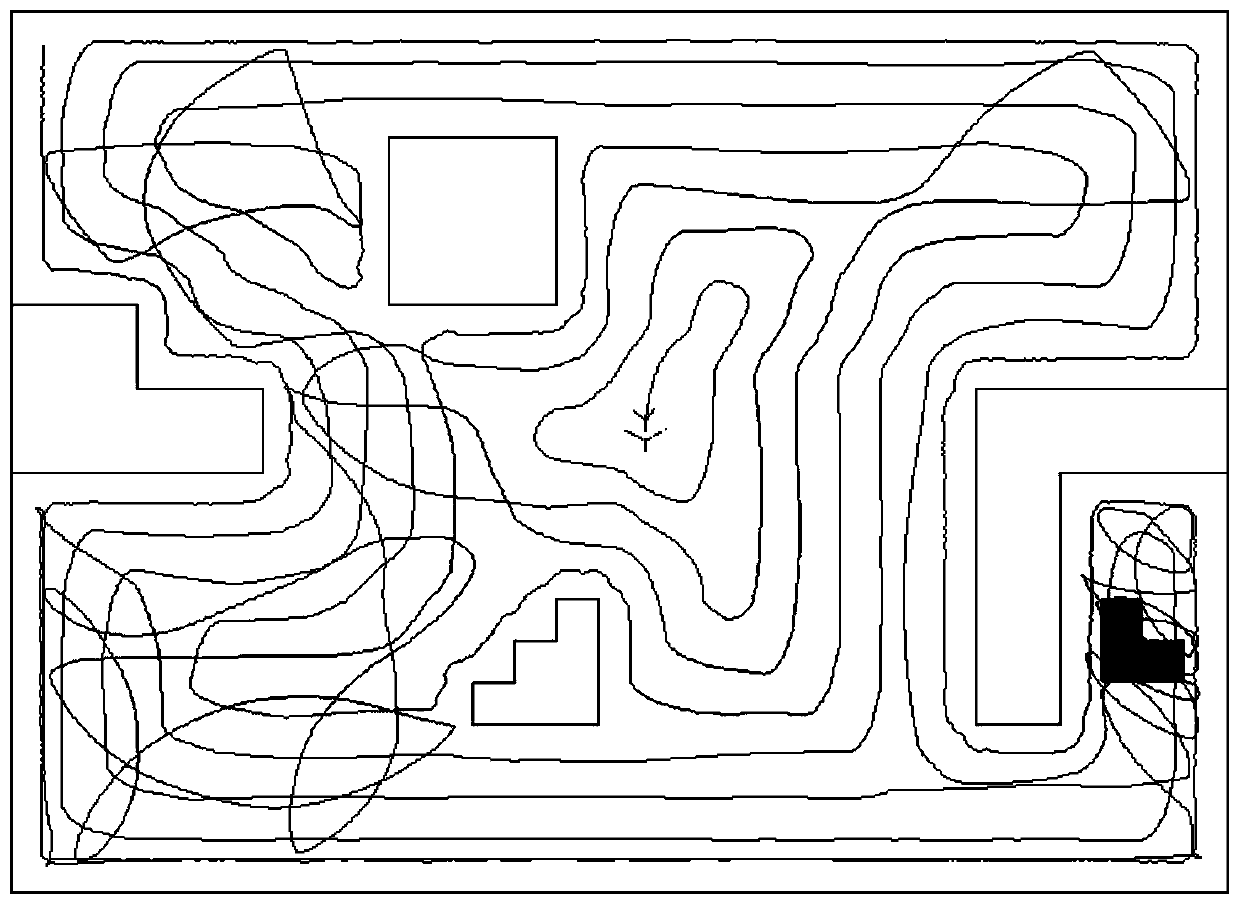

Unmanned aerial vehicle full-area reconnaissance path planning method of unsupervised learning type neural network

ActiveCN111399541AImprove mobilityImprove versatilityPosition/course control in three dimensionsOffline learningSimulation

The invention provides an unmanned aerial vehicle full-area reconnaissance path planning method of the unsupervised learning type neural network. Neural network parameters for controlling maneuveringof the unmanned aerial vehicle are obtained through iterative offline learning, so that the unmanned aerial vehicle can reconnaissance the whole area as quickly as possible on the premise of autonomously avoiding threats. Meanwhile, the maneuvering decision neural network obtained by the method has good mobility and universality in different terrains, and a new solution is provided for the unmanned aerial vehicle in intelligent path planning and autonomous maneuvering decision directions. The method is simple, convenient and efficient, the problem of re-planning or re-planning of the unmannedaerial vehicle due to environmental information change is effectively reduced, and the training time cost is effectively saved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Catalyst for reducing nitrogen oxides and method for producing the same

InactiveUS20120020875A1Long-lasting durabilityReduce capabilityMaterial nanotechnologyGas treatmentChemistryOxide

The object is to provide an exhaust gas reduction catalyst that exhibit high nitrogen oxide reduction performance, and to provide a simple and efficient method for producing the catalyst, in which the amount of the waste liquid is reduced, further, an object of the invention is to provide a zeolite-containing catalyst for reducing nitrogen oxides, which does not use an expensive noble metal or the like and which has high nitrogen oxide reduction performance. The present invention relates to a catalyst for reducing nitrogen oxides, which comprises: zeolite at least containing an aluminium atom and a phosphorus atom in the framework thereof; and a metal supported on the zeolite, wherein a coefficient of variation of intensity of the metal is at least 20%, when performing an elemental mapping of the metal in the catalyst with an electron probe microanalyzer, and, a catalyst for reducing nitrogen oxides, which comprises the zeolite containing at least a silicon atom, a phosphorus atom and an aluminium atom, and having an adsorption retention rate of at least 80% in a water vapor cyclic adsorption / desorption test at 90° C.

Owner:MITSUBISHI CHEM CORP

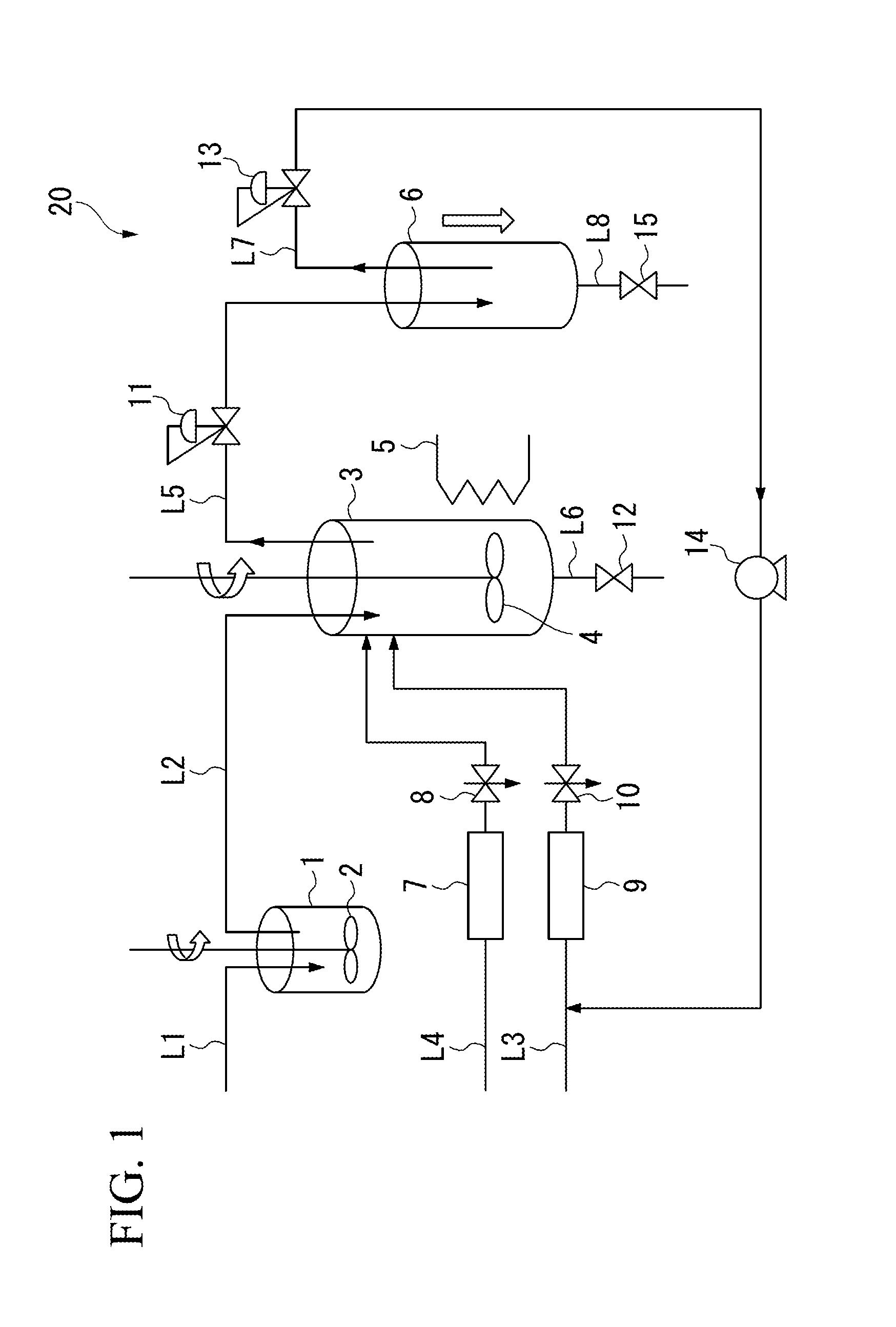

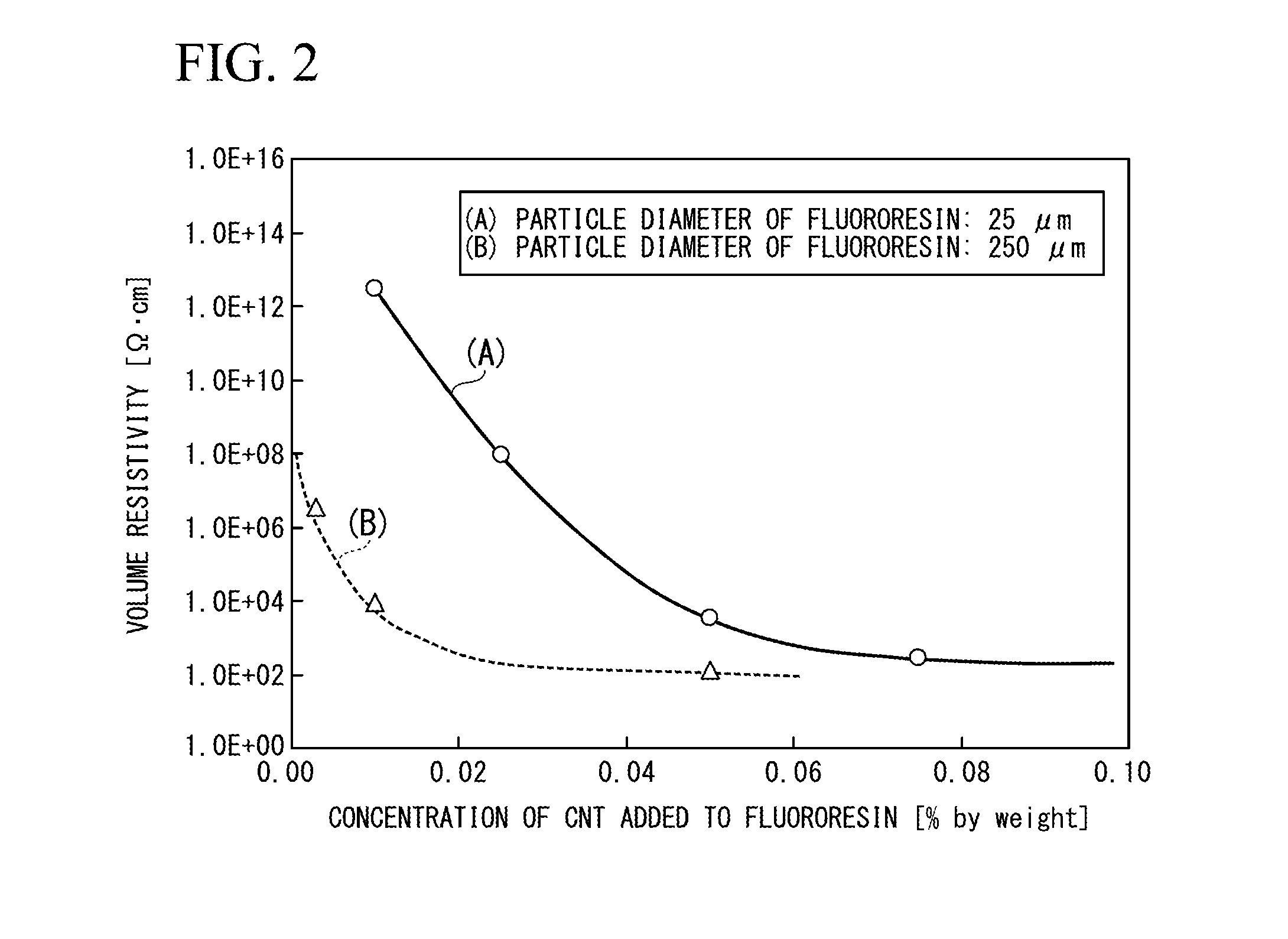

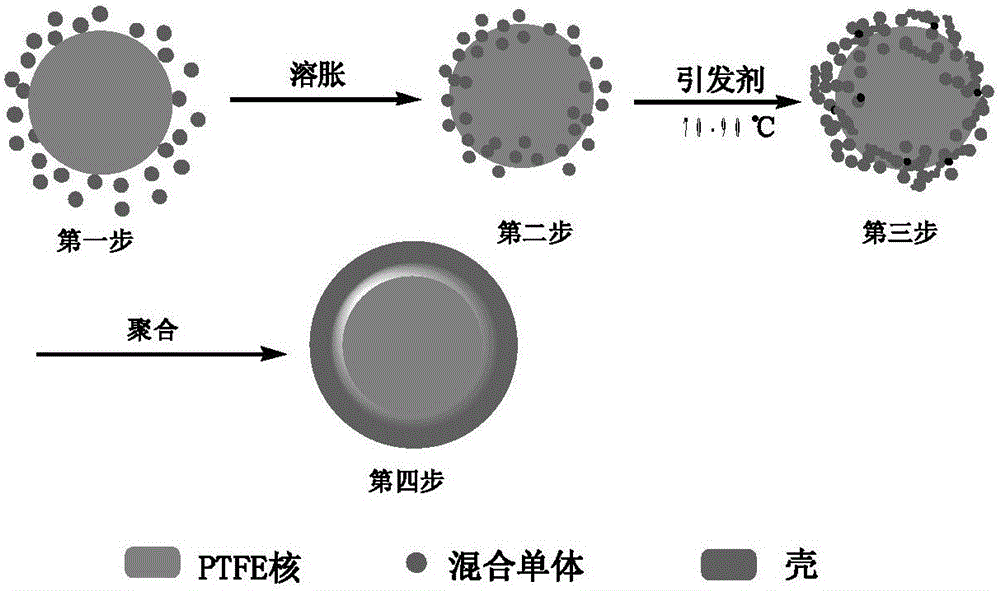

Composite resinous particles, method of producing composite resinous particles, composite resin molded body, and method of producing same

ActiveUS20130310522A1Improve productivitySimple methodOrganic conductorsBulk chemical productionCarbon nanotubeSlurry

A composite resin material particle is produced by a method including the steps of: forming a mixed slurry containing a resin material particle and carbon nanotubes; supplying the mixed slurry to a pressure vessel, followed by supplying carbon dioxide with stirring an inside of the pressure vessel; holding the inside of the pressure vessel at a temperature and at a pressure which allow the carbon dioxide to be maintained in a subcritical or supercritical state; and transferring the carbon dioxide to the outside of the pressure vessel.

Owner:NIPPON SANSO CORP

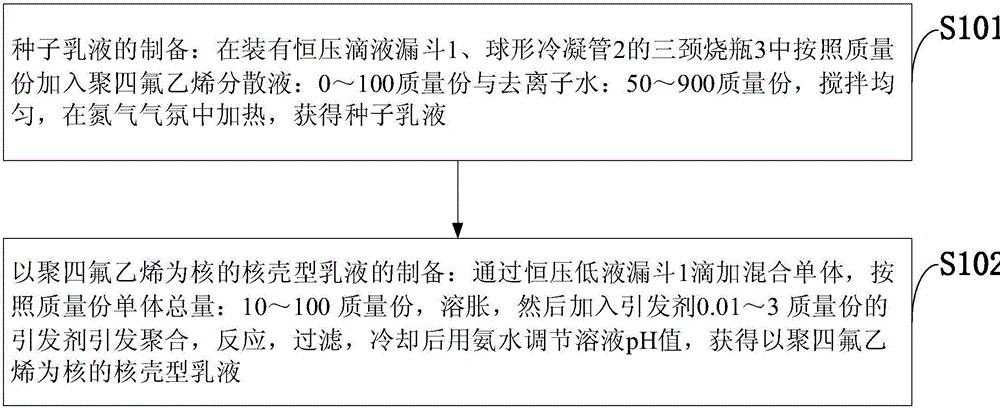

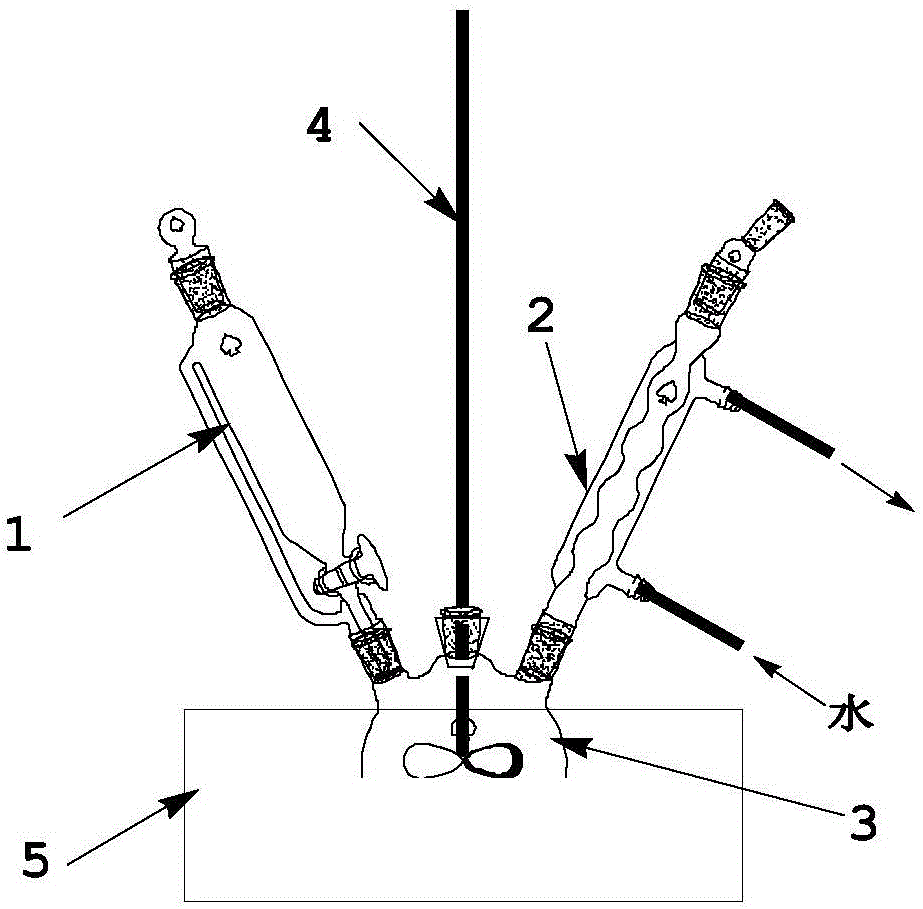

Core-shell type emulsion with PTFE as core and preparing method thereof

The invention discloses core-shell type emulsion with PTFE as a core and a preparing method thereof. PTFE dispersion liquid and deionized water are added into a three-necked flask with a constant-pressure dropping funnel and a spherical condenser pipe according to mass parts to be stirred evenly and heated in nitrogen so that seed emulsion can be obtained; mixed monomer is dropped through the constant-pressure dropping funnel, the total amount of monomer is 10-1,000 according to mass parts, swelling is conducted, then, initiator is added for initiating polymerization, reaction is conducted for 24 h, filtering is conducted, ammonium hydroxide is used for adjusting the pH value of the solution after cooling, and the core-shell type emulsion with PTFE as the core is obtained. The level of the adhesive force of an emulsion coating and a rubber surface can reach 4B, and the adhesive force is improved remarkably; contact angle and water absorption test results of emulsion rubber films show that the contact angle of the emulsion latex films can reach 117.94 degrees, the water absorption can be as low as 9.62wt%, and the hydrophobicity of the emulsion latex film is good through comprehensive analysis.

Owner:ANHUI UNIVERSITY

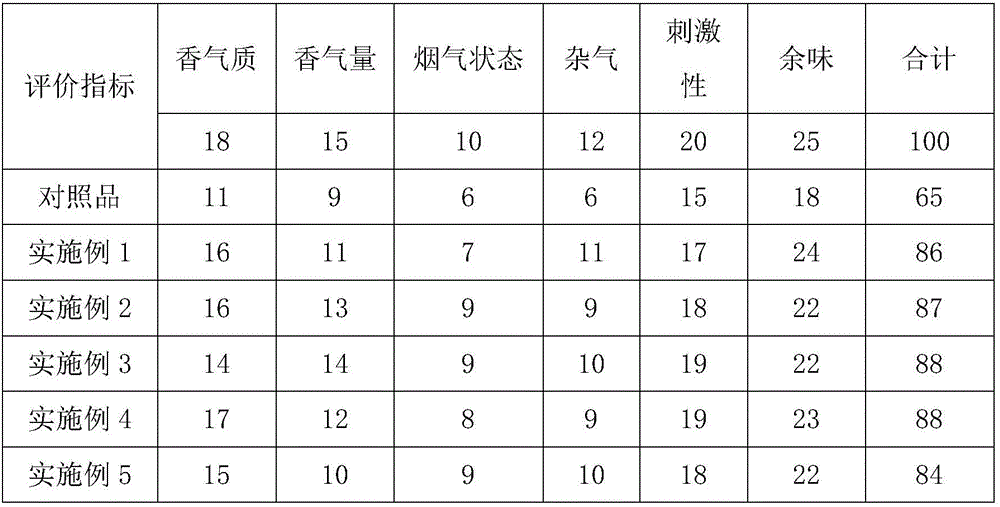

Preparation method of tea absolute oil for cigarettes

ActiveCN106753793AThe method is simple and efficientRich aromaTobacco preparationTobacco treatmentAcetic acidAlcohol

The invention provides a preparation method of tea absolute oil for cigarettes. The preparation method comprises the following steps: (1) tea leaves are smashed to be in the specification of 10-20 meshes; (2) an ethanol solution is added, and dynamic countercurrent extraction is performed; (3) an extracting solution is subjected to reduced pressure concentration, and a concentrated tea solution is obtained; (4) the concentrated tea solution is extracted multiple times with ethyl acetate, ethyl acetate phases are collected and subjected to reduced pressure concentration, and a tea extract is obtained; (5) ethanol is added to the tea extract, ethanol precipitation is performed, and an ethanol precipitation liquid is obtained; (6) the ethanol precipitation liquid is filtered through a ceramic membrane and subjected to reduced pressure concentration, and the tea absolute oil is obtained. The provided method is simple, efficient, energy-saving and environment-friendly; the prepared tea absolute oil has almost real and strong fragrance and can enrich the aroma of cigarettes, improve the fragrance quality and aftertaste in an oral cavity and endow the cigarettes with peculiar style characteristics after being added to the cigarettes.

Owner:HUBEI CHINA TOBACCO IND

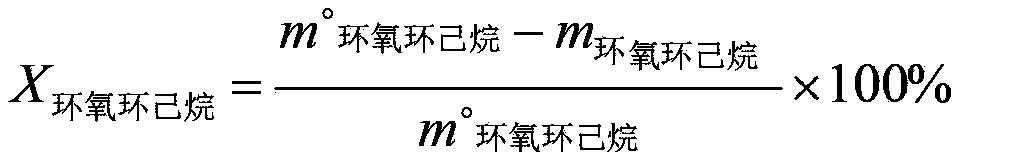

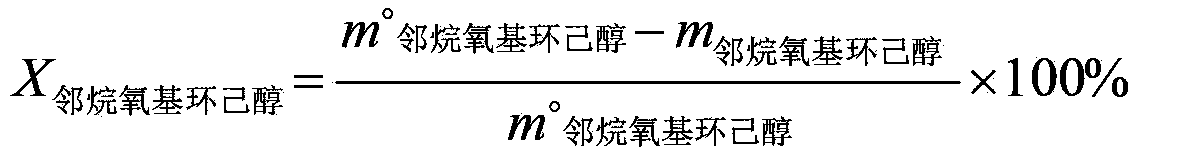

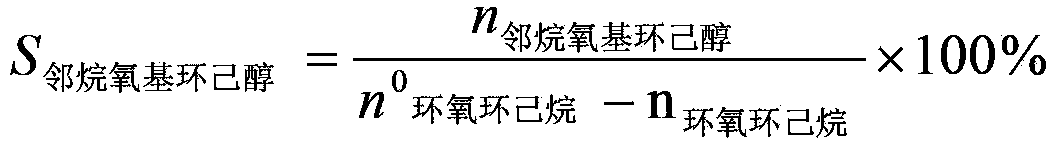

Method for preparing o-alkoxyphenol from epoxy cyclohexane

InactiveCN104072343AThe method is simple and efficientOrganic compound preparationEther preparation from oxiranesEpoxyAlcohol

The invention provides a method for preparing o-alkoxyphenol from epoxy cyclohexane. The method comprises the following steps: (1) under an alcoholysis condition, contacting epoxy cyclohexane and alcohol with a catalyst, and separating so as to obtain o-alkoxyphenol; (2) under a catalytic dehydrogenation condition, contacting the o-alkoxyphenol with a dehydrogenation catalyst, whose active component comprises the VIII group metal elements. The method can synthesize o-alkoxyphenol directly from epoxy cyclohexane, and furthermore has the advantages of simple process and high efficiency.

Owner:YUEYANG CHANGDE CHEM IND

Storage device with variable storage capacity

InactiveUS7163099B2Reliable transportationEconomical and simpleCigarette manufacturePackagingEngineeringStorage area

Storage device with variable storage capacity. The storage device includes an input area, an output area, a continuous conveying element connecting the input area to the output area. The continuous conveying element is guided by guide elements in a looping manner from the input area to the output area, whereby the continuous conveying element defines a multi-layered storage area adapted to store products and a multi-layered return area adapted to be free of products. The multi-layered storage and return areas are arranged side by side and change in length depending on a state of fullness of the storage device while an overall length of the continuous conveying element remains generally constant. At least one storage layer of the multi-layered storage area and at least one storage layer of the multi-layered return area is arranged on a common horizontal plane. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:HAUNI MASCHINENBAU AG

Method for low-temperature copperizing of surface of titanium or titanium alloy

ActiveCN111733417AHigh mechanical strengthEfficient removalPharmaceutical delivery mechanismSolid state diffusion coatingBiocompatibilityTitanium alloy

The invention relates to a method for low-temperature copperizing of the surface of titanium or a titanium alloy. The method comprises the steps that surface ultrasonic rolling treatment is conductedon a titanium or titanium alloy workpiece under the condition of ultralow temperature to enable the surface of the titanium or titanium alloy workpiece to plastically deform and sequentially form a gradient nano-structure layer including equiaxial nano-crystals, lamellar nano-crystals and macro-crystals from the most superficial layer to a core part; the workpiece subjected to ultrasonic rolling treatment is subjected to degreasing, oil removal and acid cleaning activation treatment; then the workpiece is plated with copper, cleaned and blow-dried; and finally the treated workpiece is placed into a vacuum annealing furnace to be subjected to copperizing treatment and then taken out for air cooling, a copper-plated layer is stripped, and cleaning and blow drying are carried out. According to the method, the copperizing temperature of the surface of the titanium or titanium alloy can be greatly decreased, the copperizing time is shortened, the copperizing thickness is increased, qualitycontrollability of an obtained copperized layer is strong, the copperized layer is uniform, flat and good in finish degree and has the good antibacterial property and biocompatibility, and the methodcan meet the clinical demand for human body hard tissue implants.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Method for continuously extracting flaxseed gum and secoisolariciresinol diglucoside from flaxseed meal

InactiveCN108409813AReduce manufacturing costReduce energy consumptionSugar derivativesSugar derivatives preparationChemistryBy-product

The invention relates to a method for continuously extracting flaxseed gum and secoisolariciresinol diglucoside from flaxseed meal. The method comprises the following steps: 1) separation of shells and cores of flaxseeds: pulverizing and sieving flaxseed meal, and separately collecting upper-layer flaxseed shells and lower-layer flaxseed cores which are sieved; 2) extraction of flaxseed gum: taking the flaxseed shells as raw materials, and extracting the flaxseed gum with hot water in a microwave assisted manner; 3) extraction of secoisolariciresinol diglucoside: mixing and extracting the degummed flaxseed shells and an ethanol-sodium hydroxide solution to obtain coarse secoisolariciresinol diglucoside; and 4) purification of the secoisolariciresinol diglucoside: purifying the secoisolariciresinol diglucoside coarse product by using macroporous resin to obtain high-purity secoisolariciresinol diglucoside. The flaxseed gum and the secoisolariciresinol diglucoside are continuously extracted from the flaxseed meal, a new way for fully utilizing the flaxseed meal is provided, meanwhile, a convenient and speedy method for preparing various effective constituents of the flaxseeds is provided, flaxseed oil making by-products are utilized effectively, and the production cost of target products is reduced. The method has the advantages of low energy consumption, high product extractingrate, high economic benefit, low environment pollution and the like, and is suitable for large-scale production.

Owner:广州利众生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com