Core-shell type emulsion with PTFE as core and preparing method thereof

A core-shell emulsion technology, applied in the field of core-shell emulsion and its preparation, to achieve the effects of good hydrophobicity, outstanding comprehensive performance, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

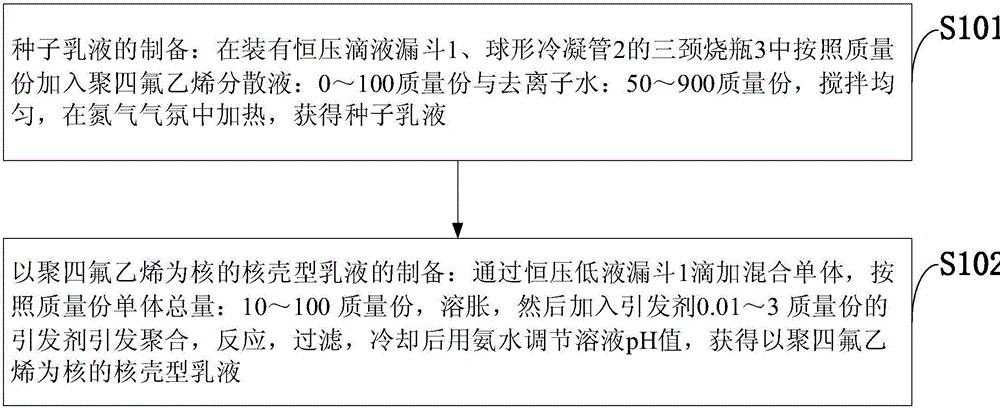

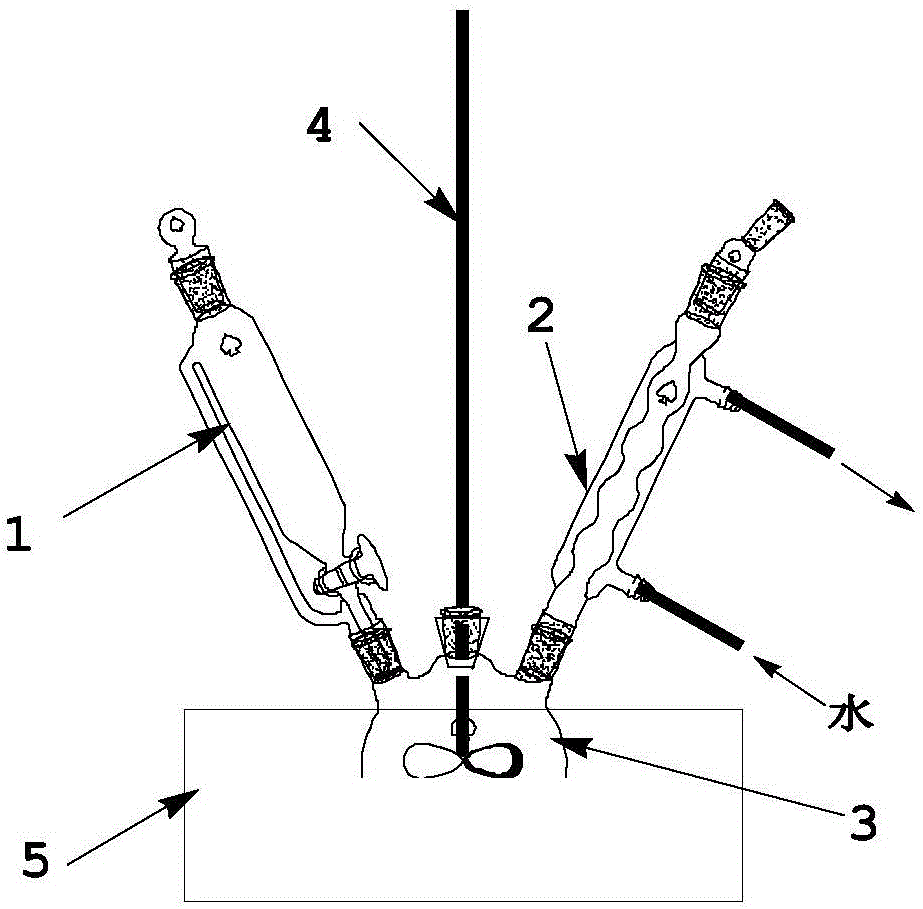

[0031] Such as figure 1 As shown, the preparation method of the core-shell emulsion with PTFE as the core of the embodiment of the present invention comprises the following steps:

[0032] S101: Preparation of seed emulsion: In the three-necked flask 3 equipped with a constant pressure dropping funnel 1 and a spherical condenser 2, add polytetrafluoroethylene dispersion in parts by mass: 0-100 parts by mass and deionized water: 50- 900 parts by mass, stirred evenly, with a rotation speed of 250-400 rpm, and heated to a reaction temperature of 70-90°C in a nitrogen atmosphere to obtain a seed emulsion;

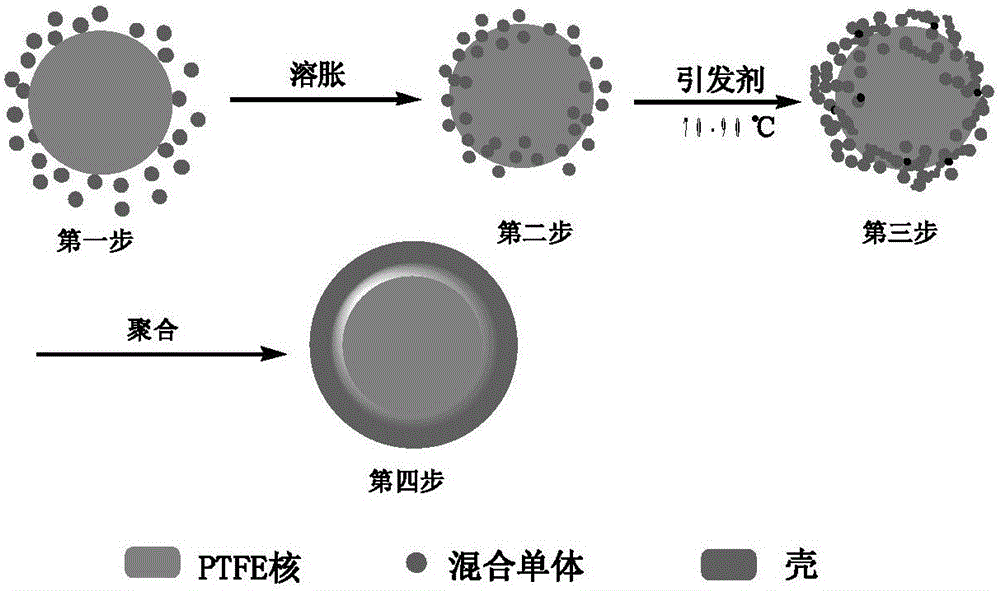

[0033] S102: Preparation of core-shell emulsion with polytetrafluoroethylene as the core: add the mixed monomer dropwise through a constant pressure low liquid funnel, according to the total amount of monomers in parts by mass: 10 to 100 parts by mass, swell for 5 to 20 minutes, and then Add 0.01-3 parts by mass of initiator to initiate polymerization, react for 24 hours, filt...

Embodiment 1

[0039]Get 12g polytetrafluoroethylene dispersion (240nm in particle size, 57wt% solid content) and 120g deionized water and mix uniformly in 250ml three-necked flask 3, stirring speed is 300rpm, feed nitrogen simultaneously, be heated to reaction temperature 75 ℃, Obtain seed emulsion; Get each 8g of MMA and BA, constitute mixed monomer, drop in the three-necked flask 3 by constant pressure dropping funnel 1, drip in 30min, swelling 15min, add potassium persulfate solution (0.12gKPS is dissolved in 10 g deionized water) to initiate polymerization, react for 24 hours, filter with 100 mesh nylon mesh after the reaction is completed, adjust the pH value of the solution to 7-8 with ammonia water after cooling, and prepare the core-shell type PTFE-P (MMA-BA) emulsion.

[0040] Figure 5 It is the TEM picture of the emulsion particles of Example 1 after being dyed with phosphotungstic acid. It can be clearly seen that the emulsion particles have a core-shell structure, wherein the b...

Embodiment 2

[0042] Get 12g polytetrafluoroethylene dispersion (240nm in particle size, 57wt% solid content) and 120g deionized water and mix uniformly in 250ml three-necked flask 3, stirring speed is 300rpm, feed nitrogen simultaneously, be heated to reaction temperature 75 ℃, Obtain seed emulsion; Get 8.7gMMA and 7.3gBA to form mixed monomer, add dropwise in the three-necked flask 3 by constant pressure dropping funnel 1, drip in 30min, swelling 15min, add potassium persulfate solution (0.12gKPS is dissolved in 10g deionized water) to initiate polymerization, react for 24 hours, filter with 100-mesh nylon mesh after the reaction is completed, adjust the pH value of the solution to 7-8 with ammonia water after cooling, and prepare the core-shell type PTFE-P (MMA-BA) emulsion.

[0043] Figure 6 It is the TEM picture of the emulsion particles of Example 2 after being dyed with phosphotungstic acid. It can be clearly seen that the emulsion particles have a core-shell structure, wherein the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com