Preparation method of tea absolute oil for cigarettes

A technology for tea and tobacco, which is applied in the field of preparation of tea absolute for tobacco, which can solve the problems of large amount of organic solvents, damage and pollution of heat-sensitive aroma components of tea, achieve vivid and rich aroma, improve oral aftertaste, and enhance aroma quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

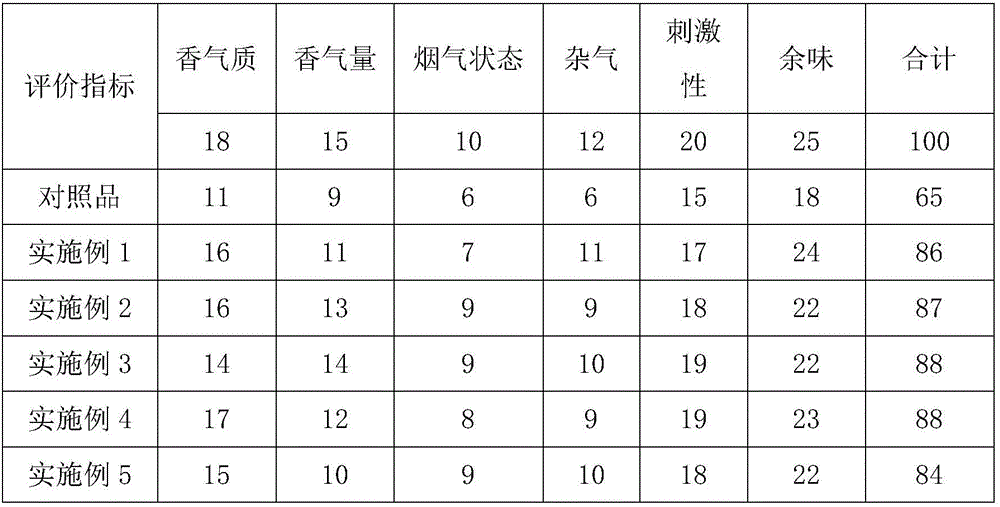

Examples

Embodiment 1

[0020] A preparation method of tea absolute for tobacco, the specific steps are as follows:

[0021] (1) Pulverize tea leaves to 10 meshes, prepare tea raw materials, and set aside.

[0022] (2) Add 6 times the amount of 20% ethanol aqueous solution to the tea raw material treated in step (1), and extract dynamically countercurrently twice at 60° C. for 1 hour each time. After the extraction is completed, combine the two extracts.

[0023] (3) The combined extracts were concentrated under reduced pressure to a relative density of 1.0580 under the conditions of -0.093 MPa and 50° C. to obtain a tea concentrate.

[0024] (4) Add 0.8 times the weight of ethyl acetate solution to the tea concentrate, mix well to carry out the first liquid-liquid extraction, leave to stand and separate to obtain the ethyl acetate phase.

[0025] (5) Repeat the extraction 3 times into the water phase treated in step (4), add 0.4 times the weight of ethyl acetate solution each time, and collect the ...

Embodiment 2

[0030] A preparation method of tea absolute for tobacco, the specific steps are as follows:

[0031] (1) Pulverize tea leaves to 20 meshes, prepare tea raw materials, and set aside.

[0032] (2) Add 5 times the amount of 30% ethanol aqueous solution to the tea raw material treated in step (1), and conduct dynamic countercurrent extraction at 55° C. for 2 times, each time for 1.5 hours. After the extraction, combine the two extracts .

[0033] (3) Concentrate the combined extracts under reduced pressure to a relative density of 1.060 under the conditions of -0.095 MPa and 55° C. to obtain a tea concentrate.

[0034] (4) Add 1.2 times the weight of ethyl acetate solution to the tea concentrate, mix well to carry out the first liquid-liquid extraction, leave to stand and separate to obtain the ethyl acetate phase.

[0035] (5) Repeat the extraction 4 times into the water phase treated in step (4), add 0.3 times the weight of ethyl acetate solution each time, and collect the eth...

Embodiment 3

[0040] A preparation method of tea absolute for tobacco, the specific steps are as follows:

[0041] (1) Pulverize tea leaves to 20 meshes, prepare tea raw materials, and set aside.

[0042] (2) Add 2.5 times the amount of 15% ethanol aqueous solution to the tea raw material treated in step (1), and conduct dynamic countercurrent extraction at 60° C. for 2 times, each time for 1.5 h. After the extraction, combine the two extracts .

[0043] (3) The combined extracts were concentrated under reduced pressure to a relative density of 1.0424 under the conditions of -0.090 MPa and 52° C. to obtain a tea concentrate.

[0044] (4) Add 1.0 times the weight of ethyl acetate solution to the tea concentrate, mix well to carry out the first liquid-liquid extraction, leave to stand and separate to obtain the ethyl acetate phase.

[0045] (5) Repeat the extraction 6 times into the water phase treated in step (4), add 0.2 times the weight of ethyl acetate solution each time, and collect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com