Method for low-temperature copperizing of surface of titanium or titanium alloy

A titanium alloy and copper infiltration technology, which is applied in the fields of medical formula, superimposed layer plating, metal material coating process, etc., can solve the problem that titanium or titanium alloy implants are easy to cause bacterial infection, high temperature of copper infiltration, and long time consumption To achieve good antibacterial performance and biocompatibility, reduce the temperature of copper infiltration, and increase the thickness of copper infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] For the low-temperature copper infiltration treatment on the surface of TA2 titanium rod, the steps are as follows:

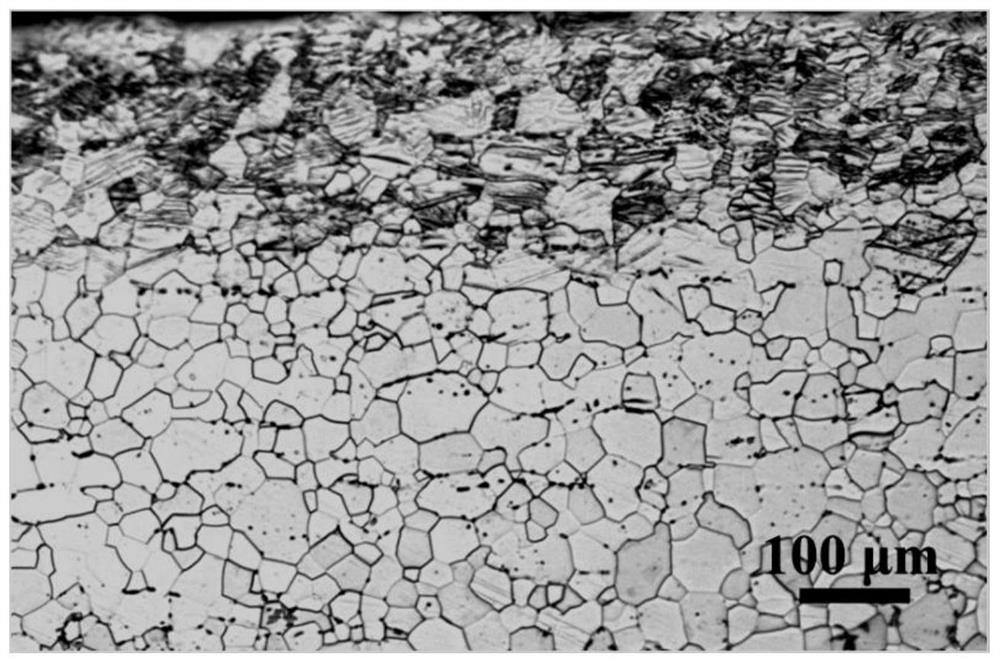

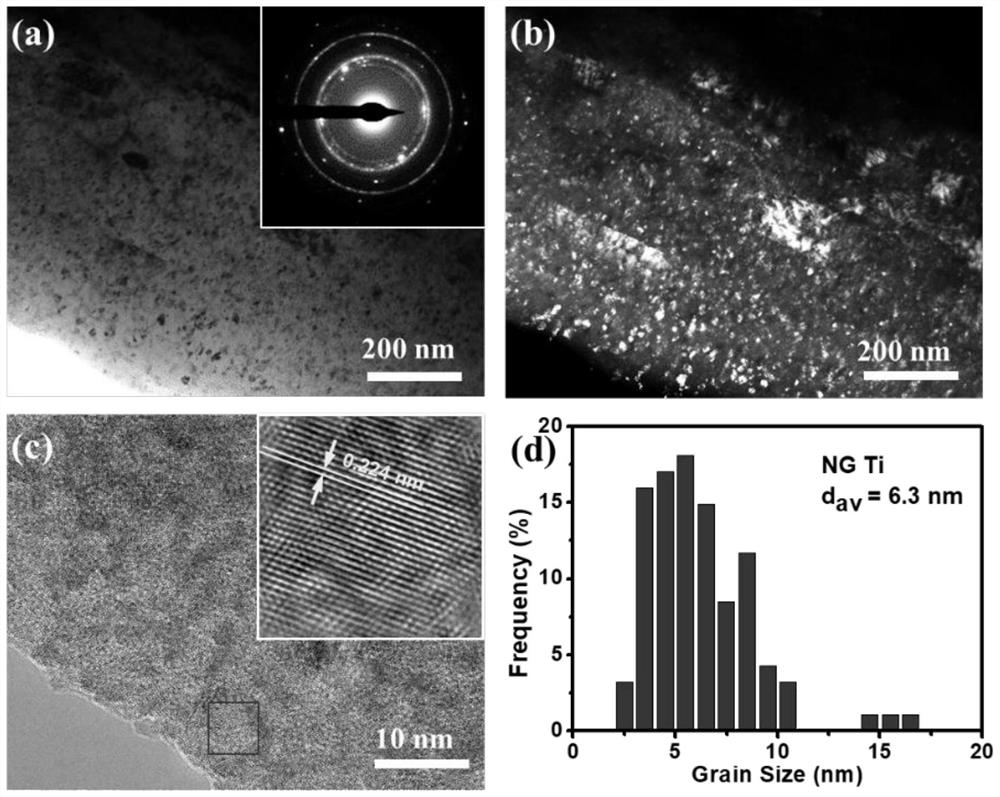

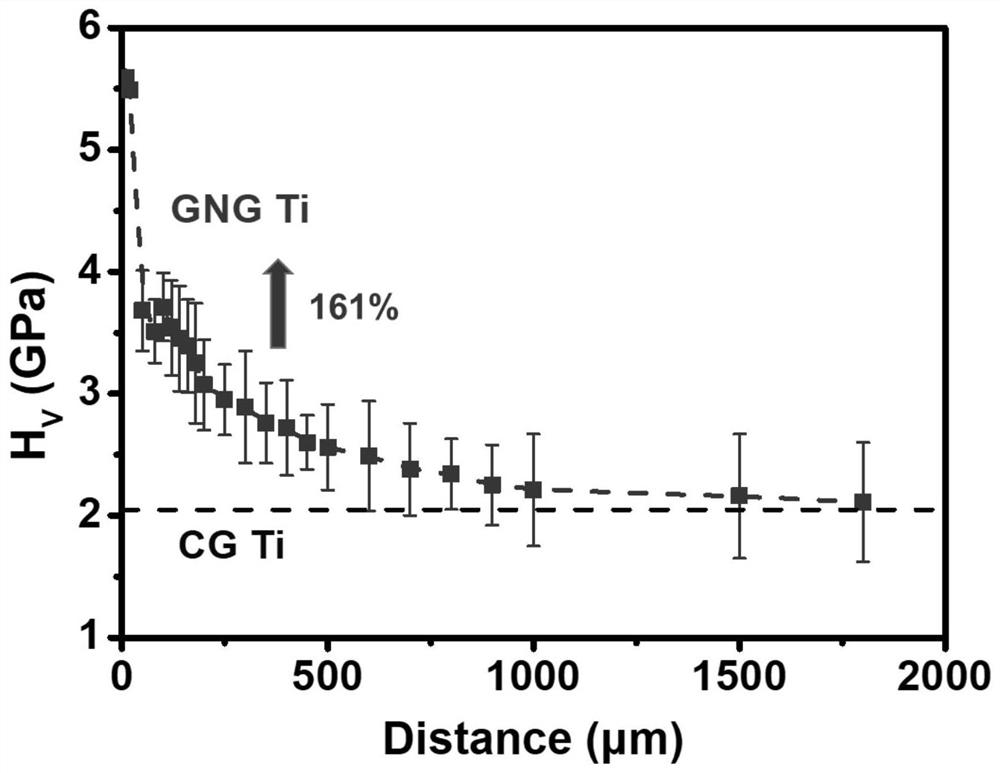

[0031] Step 1) will The TA2 titanium rod is fixed on the lathe, and the WC-Co cemented carbide ball (generally 6-12mm in diameter) of the ultrasonic rolling tool is in contact with the surface of the TA2 titanium rod workpiece and pressed into a certain depth. The depth is 20μm, the processing pass is 10, the amplitude of ultrasonic rolling processing is 10μm, and the output frequency is 30kHz. During the ultrasonic rolling process, liquid nitrogen is used for cooling to realize surface ultrasonic rolling under ultra-low temperature conditions. Ultra-low temperature surface ultrasonic After the rolling treatment, the surface of the TA2 titanium rod workpiece is plastically deformed, thereby forming a gradient nanostructure layer, and its cross-section is as follows: figure 1 As shown, the gradient nanostructure layer is composed of equiaxed nanocrystal...

Embodiment 2

[0037] For the low-temperature copper infiltration treatment on the surface of TC4 titanium alloy plate, the steps are as follows:

[0038] Step 1) Fix the TC4 titanium alloy plate of 100×100×5mm on the milling machine, the WC-Co cemented carbide ball of the ultrasonic rolling processing tool is pressed into the depth of 40 μm per pass, and the processing pass is 10. The processing amplitude is 10 μm, the output frequency is 30 kHz, and liquid nitrogen is used for cooling during the ultrasonic rolling process.

[0039] Step 2) Use organic solvent acetone to carry out ultrasonic cleaning and degreasing treatment to the parts obtained in step 1); then soak in 40% HNO 3 and 3% HF solution for 2s, washed with water and dried;

[0040] Step 3) Carry out copper plating to the TC4 titanium alloy processed through step 2), adopt CuSO 4 90g / L, pH=1 electrolyte, current density 30mA / cm 2 , the bath temperature is 30°C, and the electroplating time is 5 hours.

[0041] Step 4) Carry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com