Method and device for preparing bacterial cellulose composite material quickly on large scale

A technology of bacterial cellulose and composite materials, applied in biochemical equipment and methods, methods based on microorganisms, biochemical cleaning devices, etc., can solve the problems of not covering most of the gaps, long cultivation period, uneven distribution, etc., and achieve The effect of shortening the production cycle, long cycle, and cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Bacteria culture

[0053] Insert Acetobacter xylinum into 300mL liquid medium (per 1L of water, 20g of mannitol, 3g of peptone, 5g of yeast extract, pH 3.0, sterilized at 121°C for 20min; or 200g of glucose, 5g of yeast extract, Tryptone 5g, citric acid 115g, Na 2 HPO 4 2.7g, 1L of water, pH 7.5, sterilized at 121°C for 20min) for expansion, cultured on a shaking table at 20°C, 100r / min or standing for 12h before use;

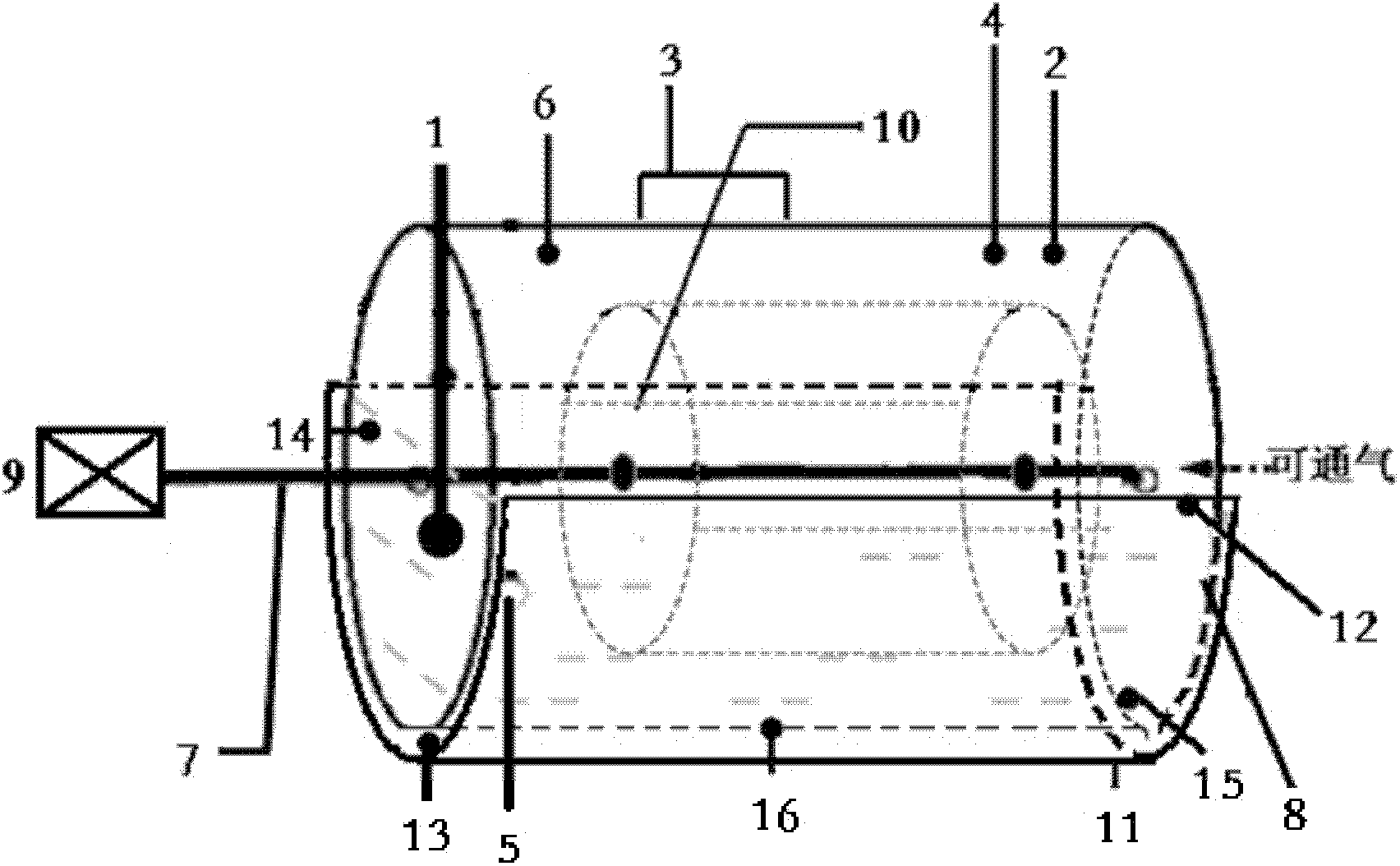

[0054] (2) Fermentation preparation of bacterial cellulose composite membrane

[0055] The liquid culture medium containing the production strain prepared in step (1) is transferred to a bioreactor equipped with a fixed gauze or silk skeleton material drum, and then the drum rotates at a speed of 7, 15, 30 and 60rpm for disturbance cultivation , after dynamic culture at 30°C for 1 day, the bacterial cellulose / gauze or bacterial cellulose / silk composite film can be obtained, and the film formation conditions are shown in Table 1; On the skeleton m...

Embodiment 2

[0066] (1) Bacteria culture

[0067] Put kombucha (kombucha) into 300mL liquid seed culture medium according to the inoculation amount of 1-10 discs with a diameter of 0.5cm containing bacteria BC membrane (per 1L of water, green tea 5g, glucose 10, peptone 3g, yeast extract 5g , pH3.0, pasteurized for 30min; per 1L of water, 100g of glucose, 3g of peptone, 5g of yeast extract, pH7.5, sterilized at 121°C for 20min) to expand the culture, shake the table at 25°C and 150r / min Cultivate or statically cultivate for 24 hours before use;

[0068] (2) Fermentation preparation of bacterial cellulose composite membrane

[0069] The liquid medium containing the production strain prepared in step (1) is transferred to a bioreactor equipped with a drum of polyester, nylon or polypropylene fiber skeleton material, and then the rotating drum is disturbed and cultivated at a speed of 15 or 25rpm. After 10 days of dynamic culture at 30°C, the film-forming product can be harvested;

[0070]...

Embodiment 3

[0076] (1) Bacteria culture

[0077] Insert Gluconacetobacter xylinus into 300mL liquid medium (per 1L of water, maltose 100g, peptone 3g, yeast extract 5g, pH 4.5, sterilized at 121°C for 20min; or fructose 160g, yeast extract 5g, tryptone 5g, citric acid 1.15g, Na 2 HPO 4 2.7g, 1L of water, pH 6.0, sterilized at 121°C for 20min) for expansion, cultured on a shaking table at 30°C, 250r / min or standing for 48h before use;

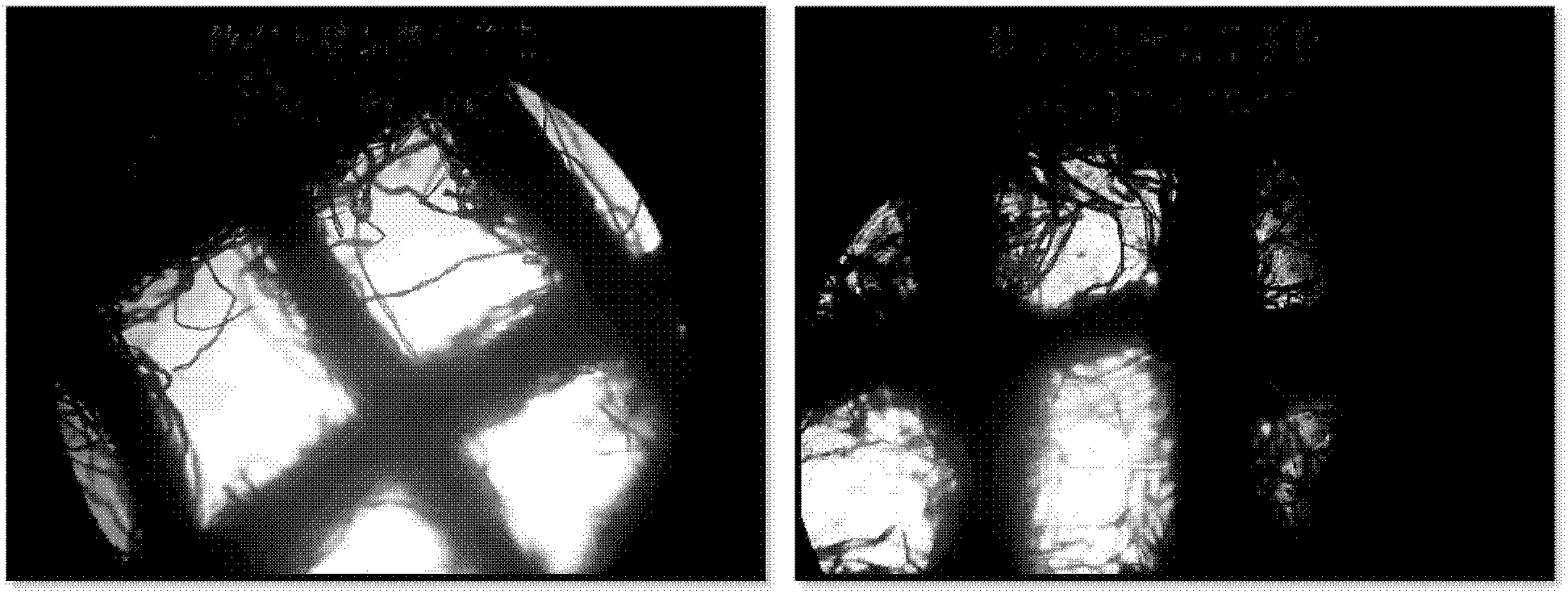

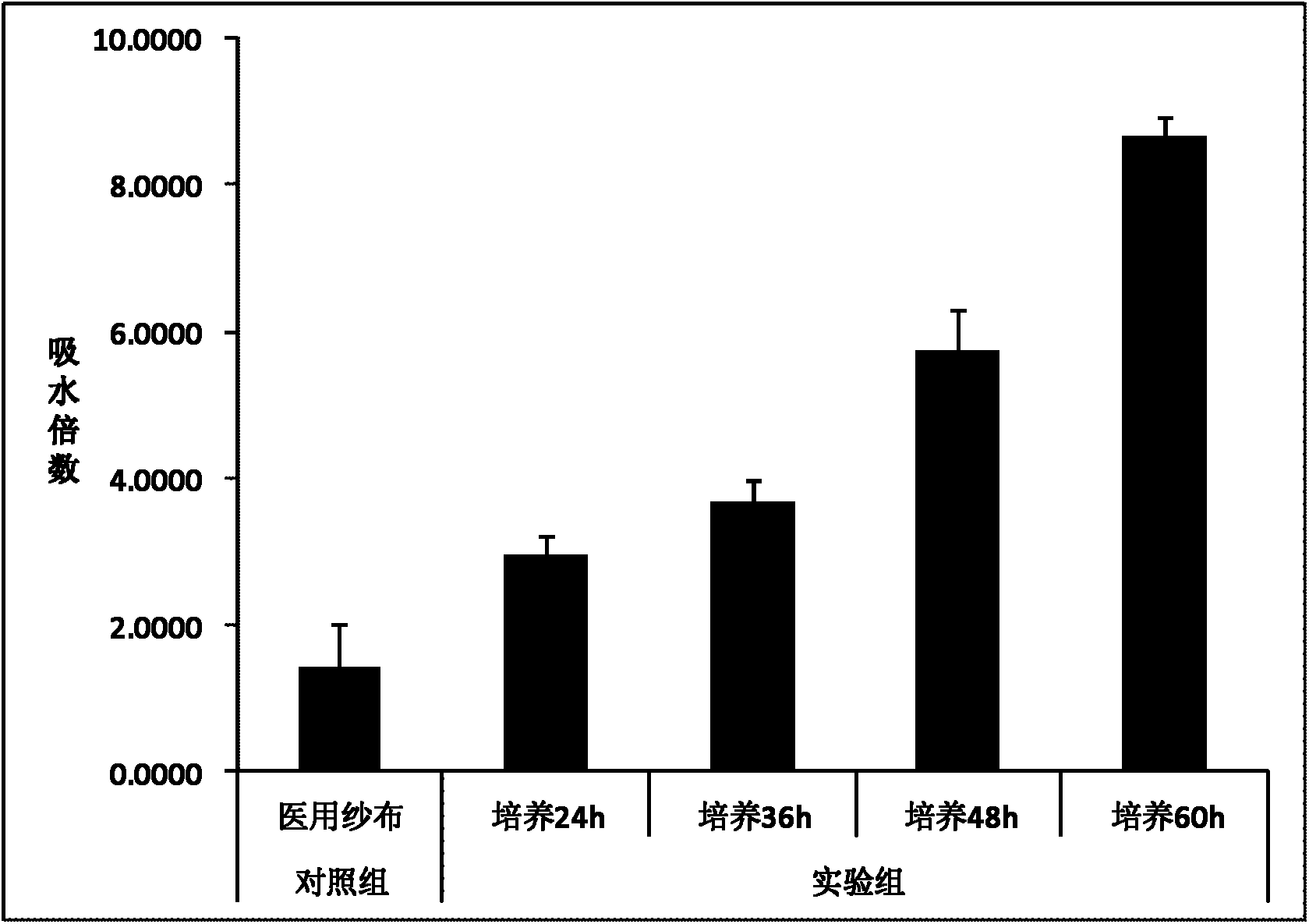

[0078] (2) Fermentation preparation of bacterial cellulose composite membrane

[0079] Transfer the liquid culture medium containing the production strain prepared in step (1) to a bioreactor equipped with a titanium dioxide metal mesh drum, then rotate the drum at a speed of 15 rpm for disturbed culture, and culture at 30°C for 24h and 36h respectively After 48h and 60h, the bacterial cellulose / titanium dioxide composite membrane can be obtained;

[0080] Or get the activated bacterial classification of step (1) to insert in the 300mL liquid fermentati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com