Patents

Literature

149results about How to "Robust construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

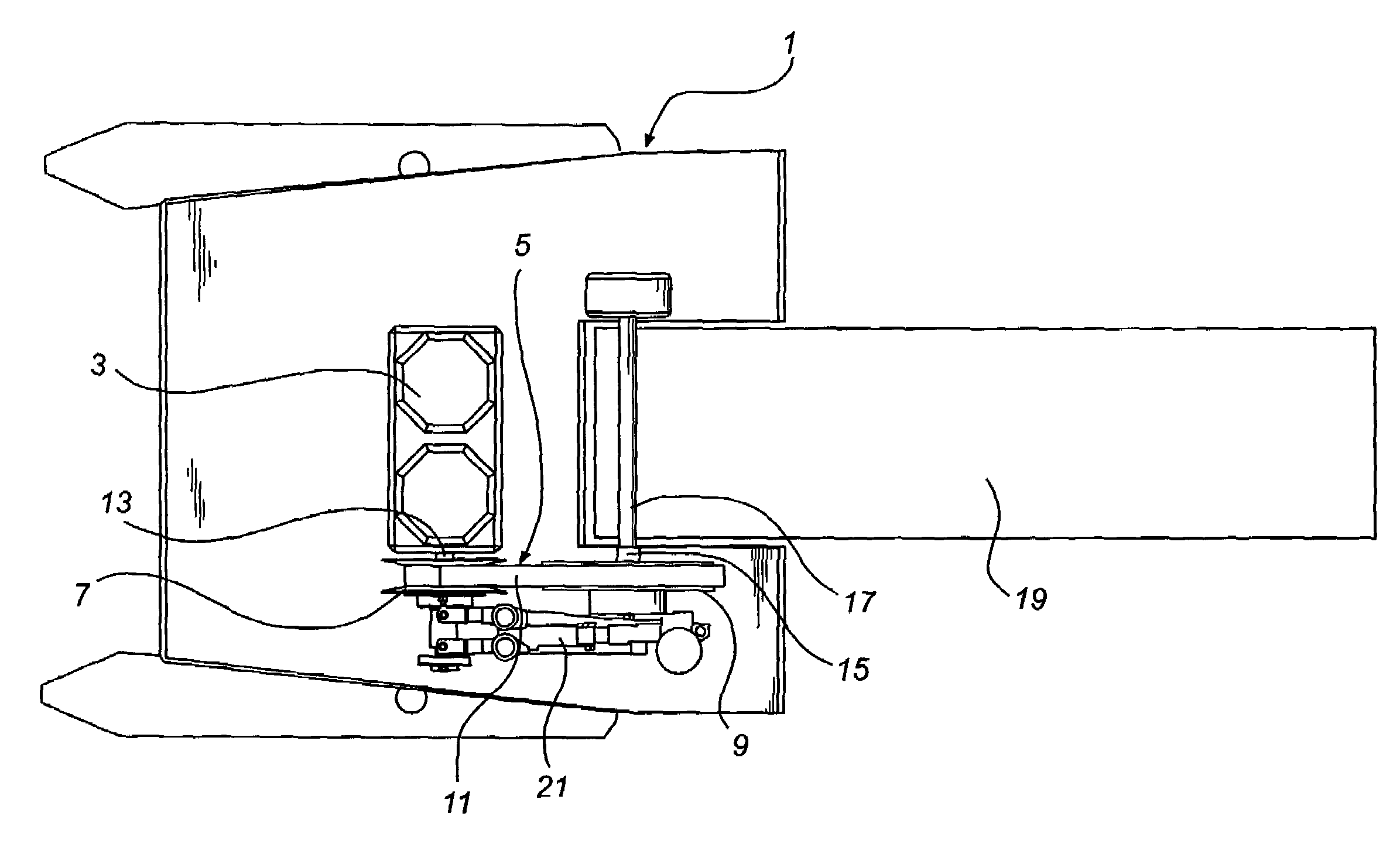

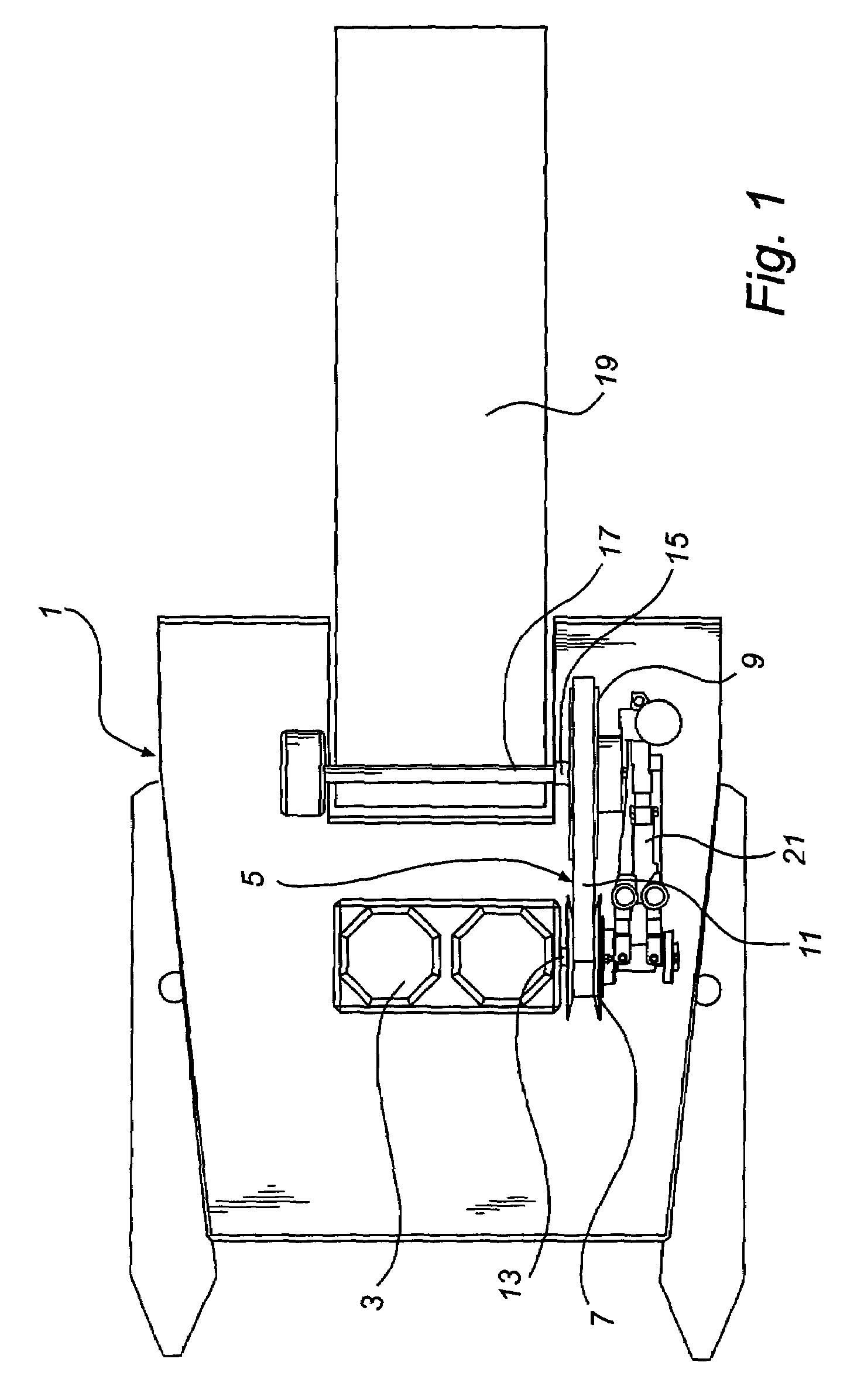

Land vehicle braking system

InactiveUS20090265069A1Robust constructionInexpensive to manufactureAnalogue computers for trafficAutomatic initiationsAutomotive engineeringVideo camera

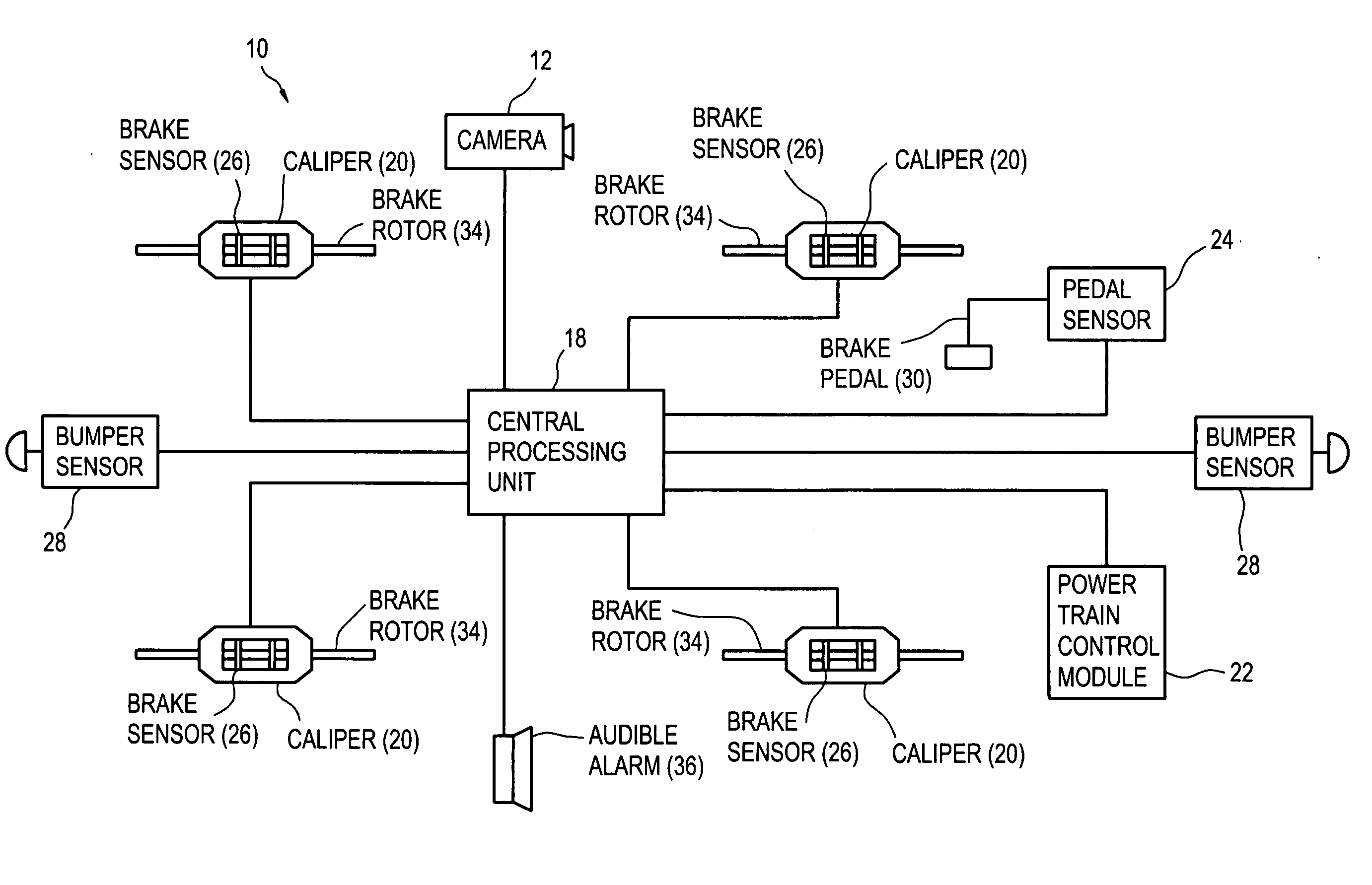

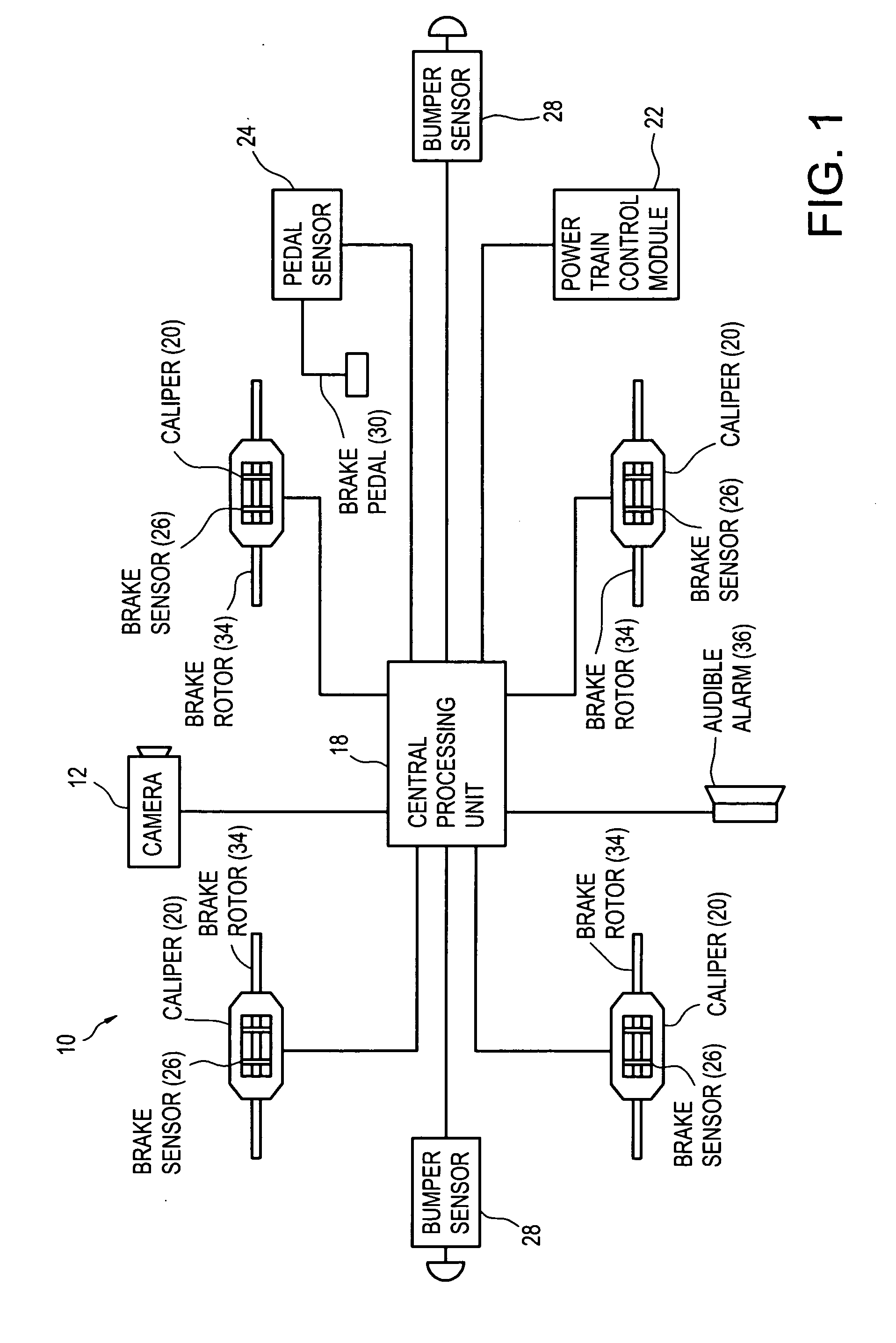

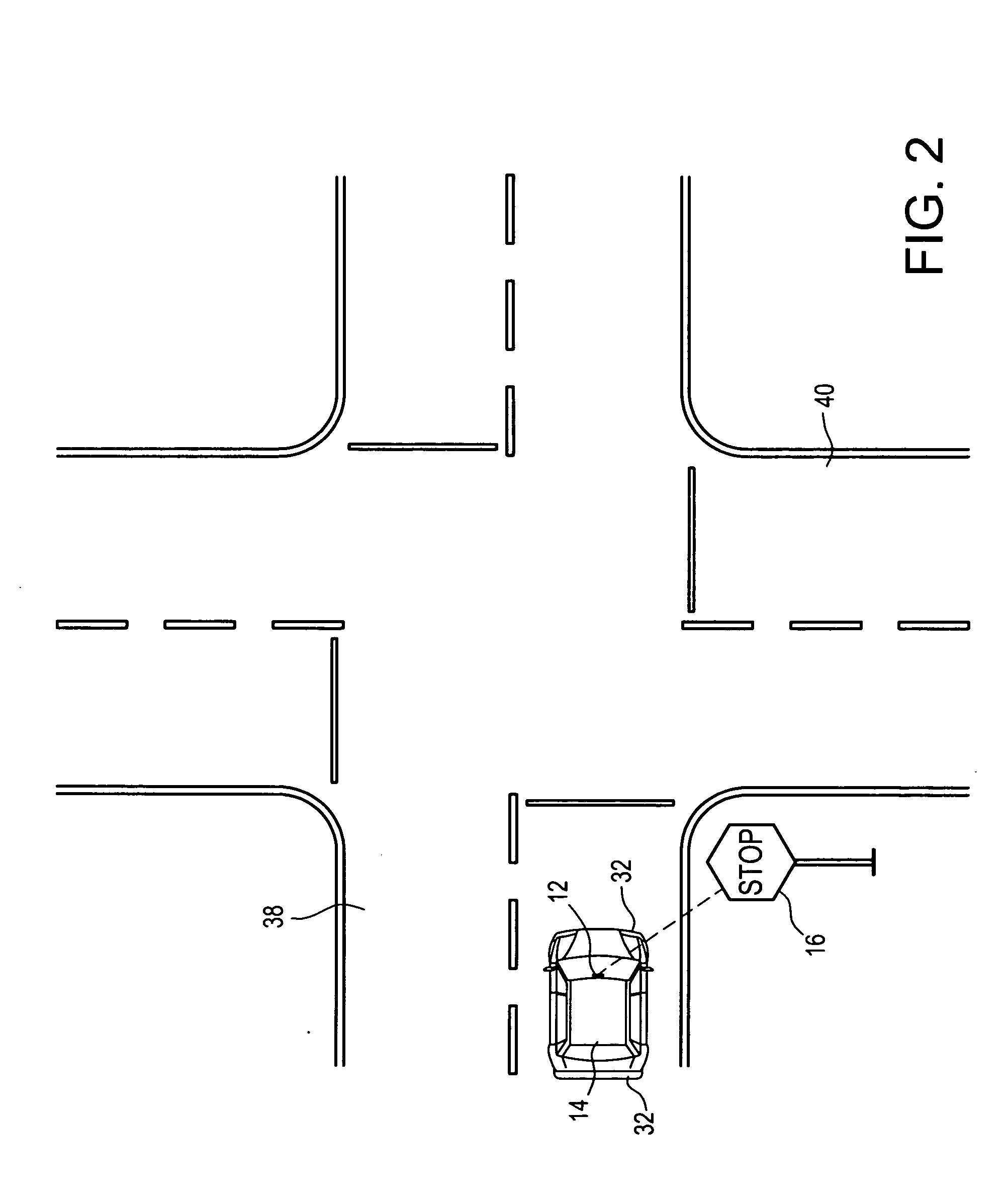

A braking system in a land vehicle having wheels for movement and a motor rotating the wheels. The braking system includes a brake rotor that is secured to one of the wheels. A brake caliper is secured to the vehicle for grasping the rotor in response to a caliper actuation signal. A brake pedal is secured to the land vehicle for movement by the vehicle driver. A pedal sensor is connected to the pedal for sensing the movement thereof and generating a braking signal in response to the movement of the pedal. A power train control module is secured to the vehicle for controlling the speed at which the motor rotates the wheels in response to a deactivation signal. A camera is mounting on the vehicle for generating a video signal representative of the incident light entering the camera. A central processing unit (CPU) is connected to the pedal sensor, the brake caliper and the camera. The CPU is adapted to receive the braking signal from the pedal sensor and, in response thereto, transmit a caliper actuation signal to the brake caliper. The CPU is also adapted to receive the video signal from the camera and process the video signal to determine whether the incident light entering camera includes light of a red color. In response to detecting light of a red color, CPU transmits a caliper actuation signal to the brake caliper and a deactivation signal to the power train control module.

Owner:DESBRUNES HERMAN

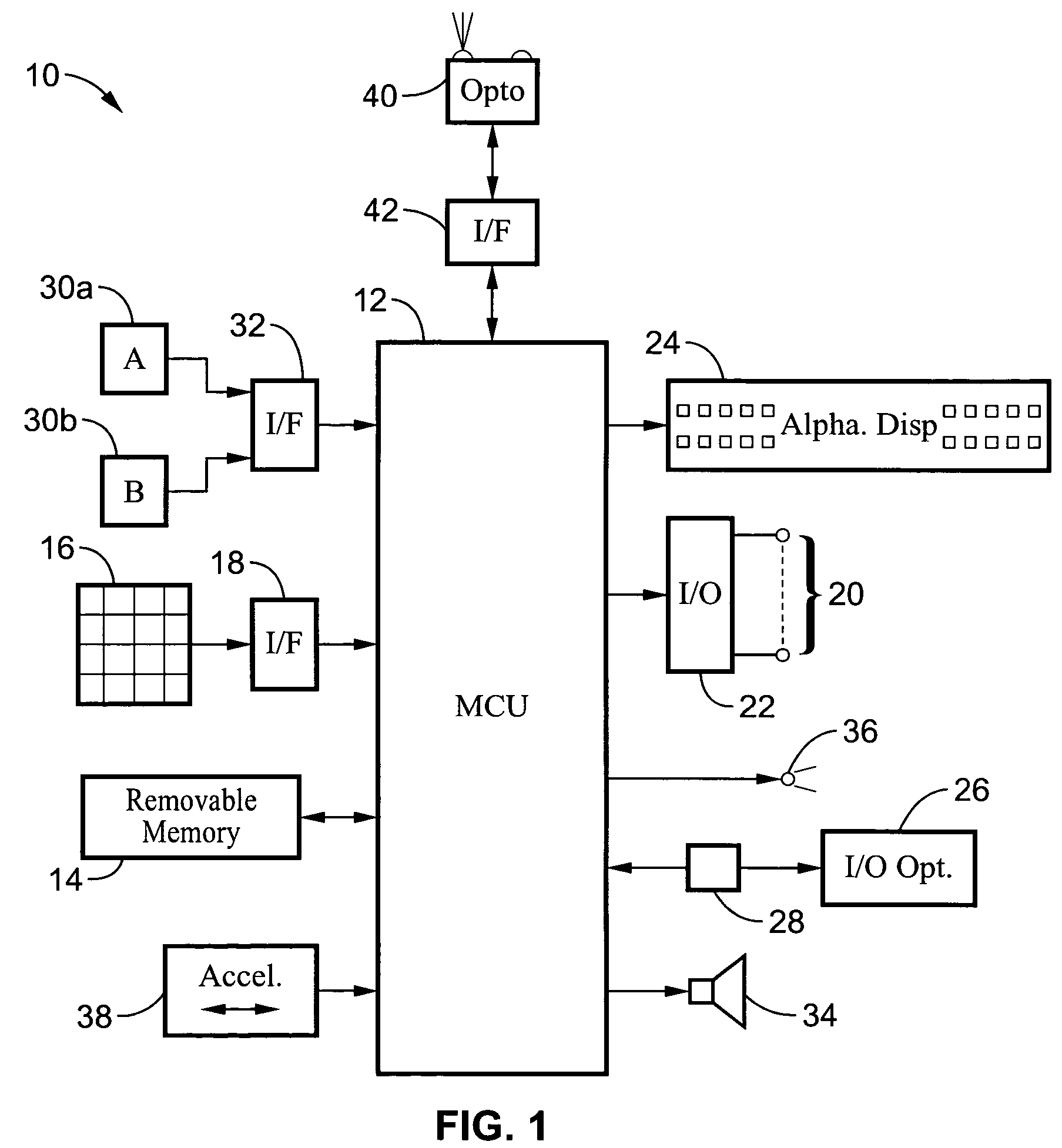

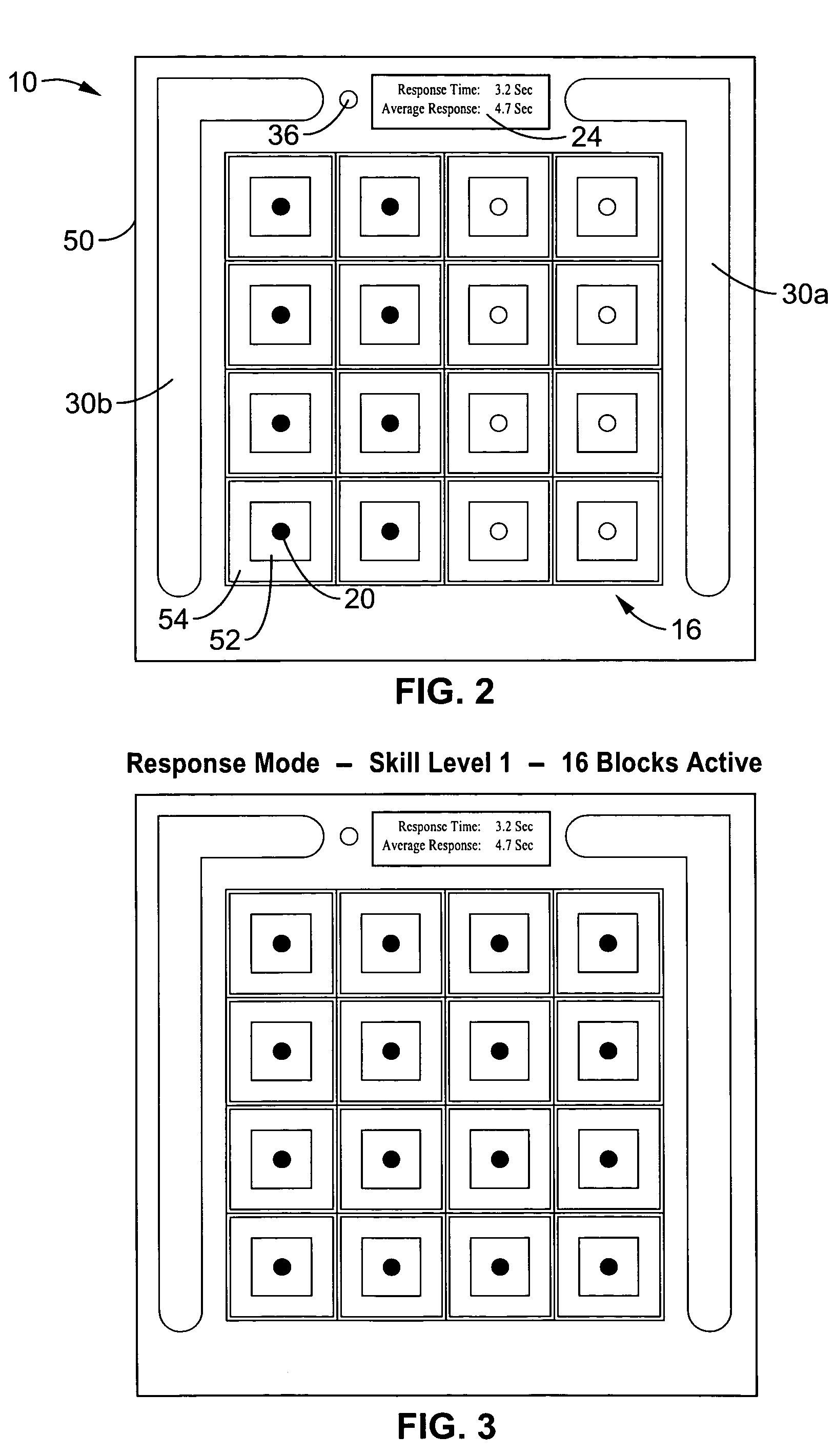

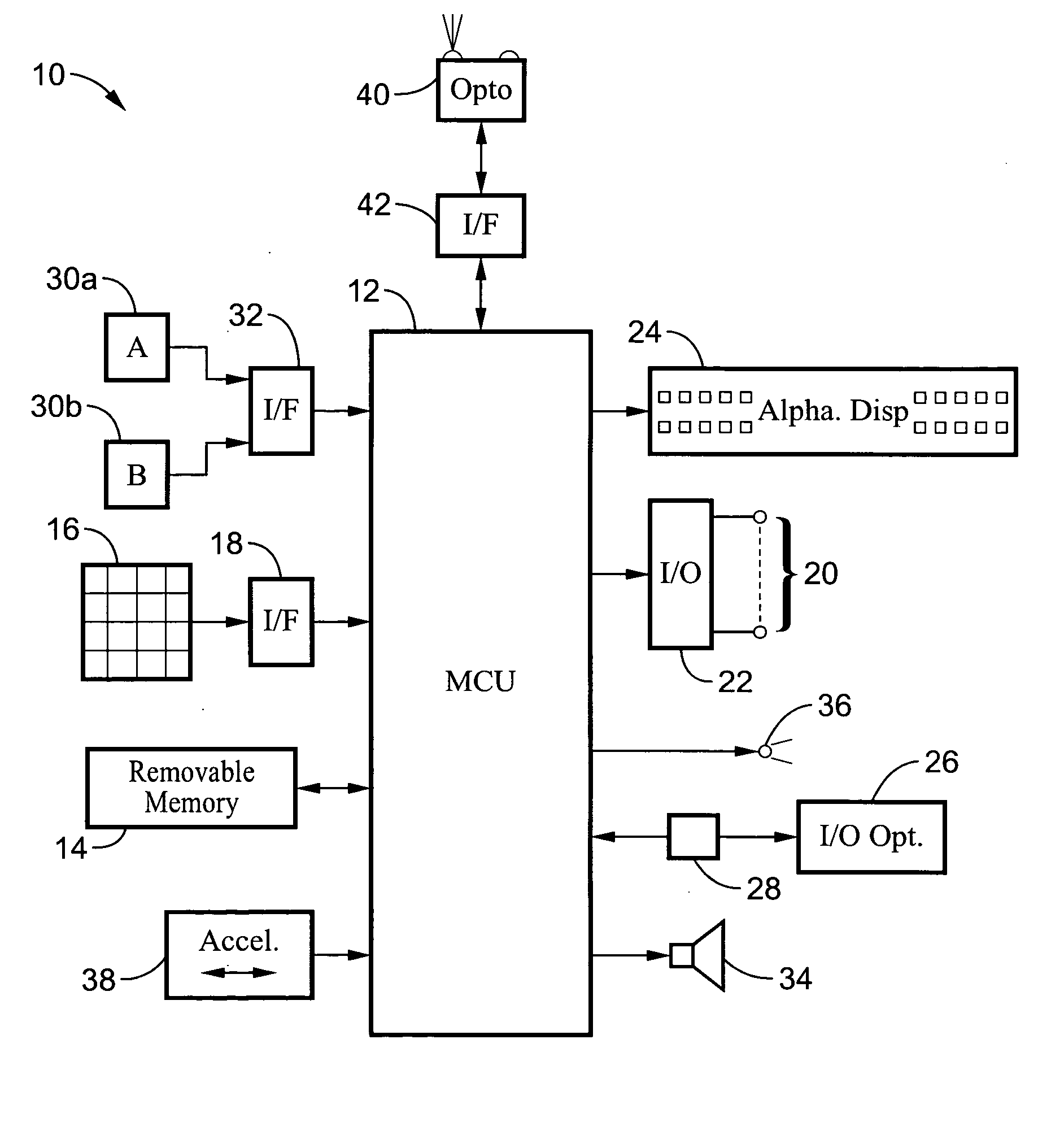

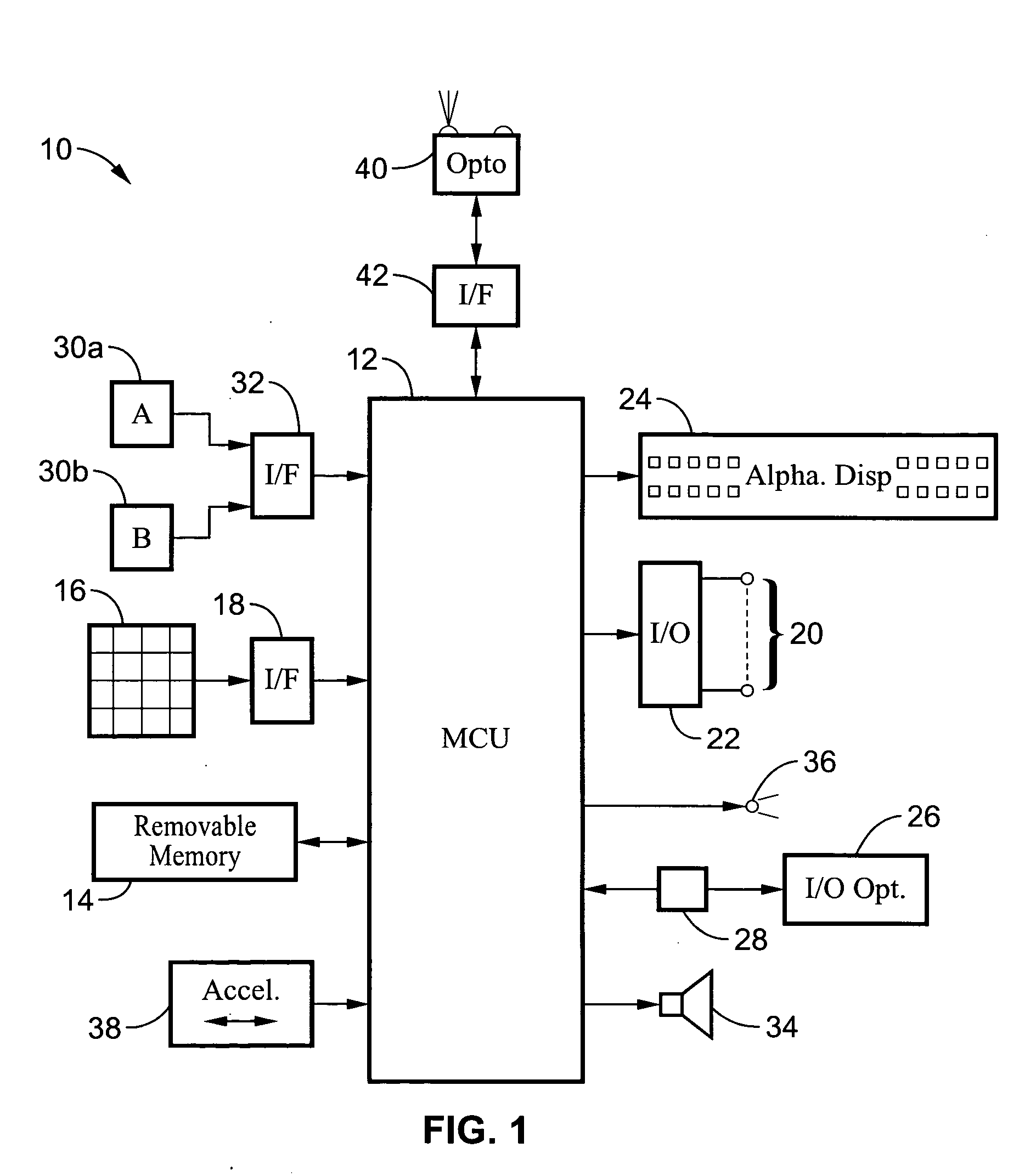

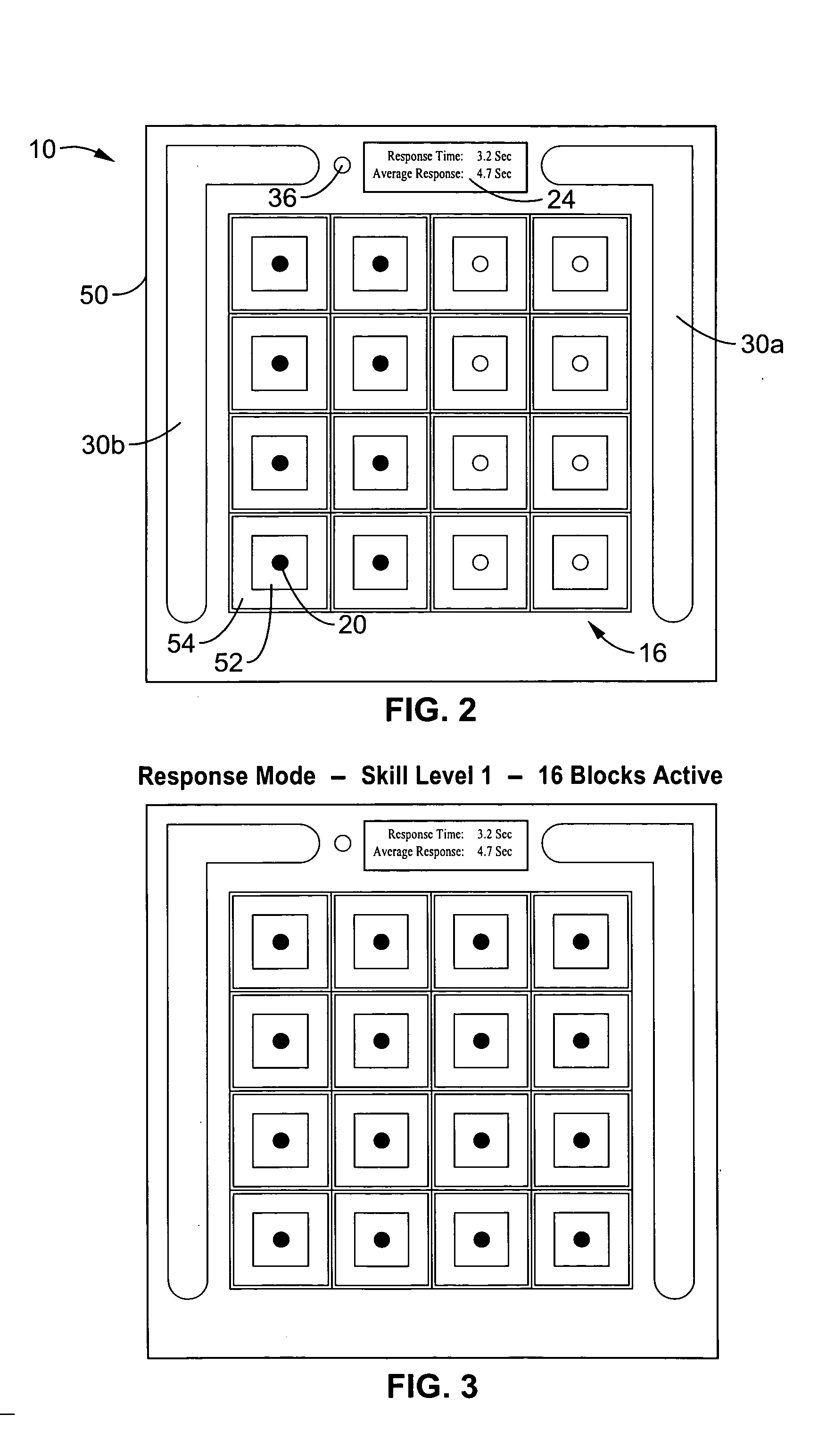

Interactive neural training device

InactiveUS7452336B2Easy to useNot easy to damageElectrotherapyPerson identificationTouch PerceptionHand movements

Owner:INTERACTIVE NEURO TECH

Interactive neural training device

InactiveUS20050065452A1Easy to useNot easy to damageElectrotherapyPerson identificationTouch PerceptionHand movements

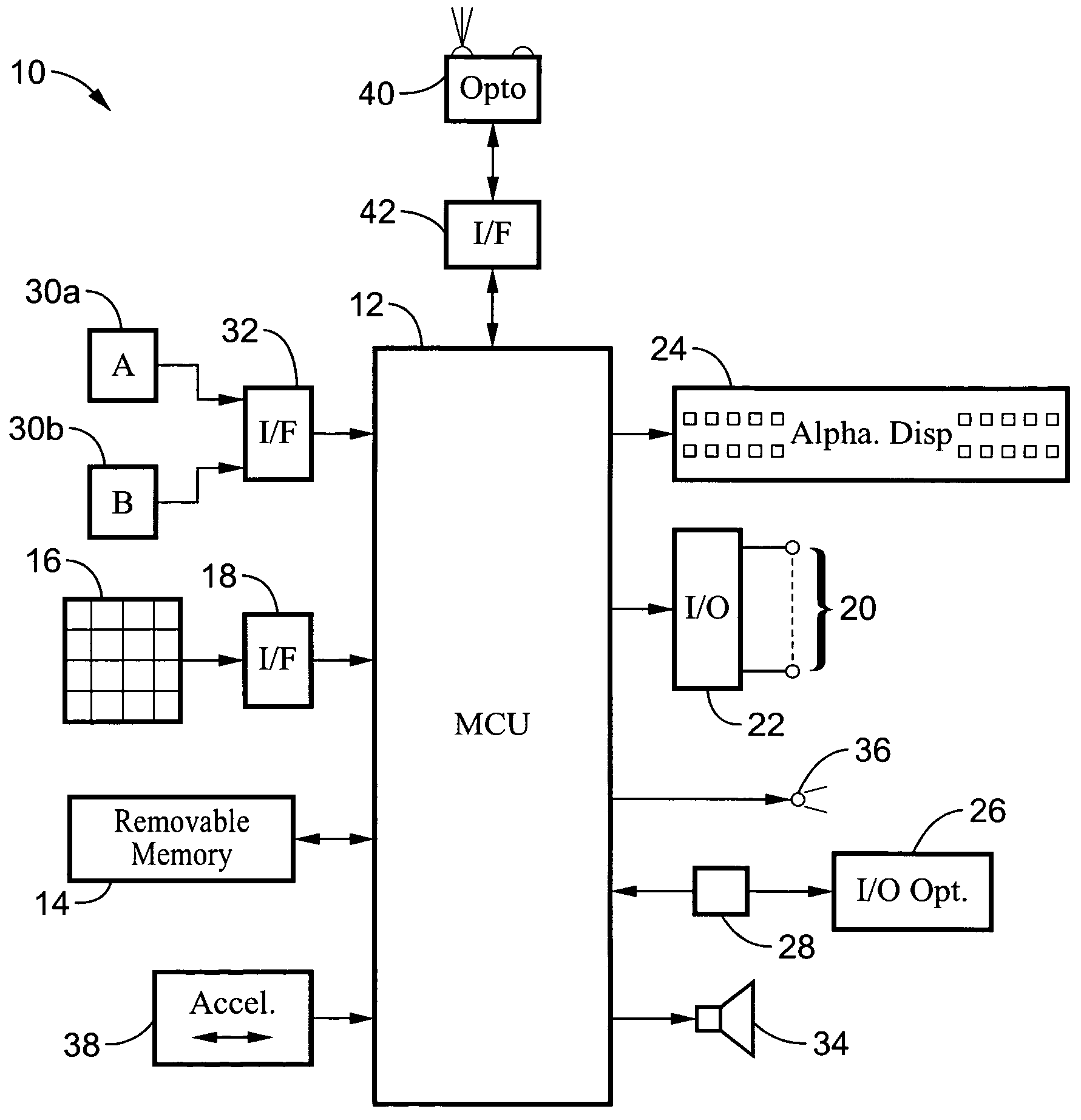

An apparatus and method for rehabilitating patients and assessing tactile skills in response to visual stimuli generated from a portable neural training device. The device generates a visual output to elicit tactile response (hand movement) from the patient. The device preferably automatically adjusts the difficulty of a session in response to demonstrated patient skill level (i.e. combination of correct responses, speed, and accuracy of responses). The invention evaluates and challenges the patient to control tactile response, overcome visual perception difficulties, or practice simple multi-tasking or reasoning skills. The invention also provides information which is valuable to those administering the rehabilitation program or assessing patient skill and / or progress. By way of example the neural training device is described with an embodiment having discrete fixed keys and an embodiment utilizing a touch sensitive display screen.

Owner:INTERACTIVE NEURO TECH

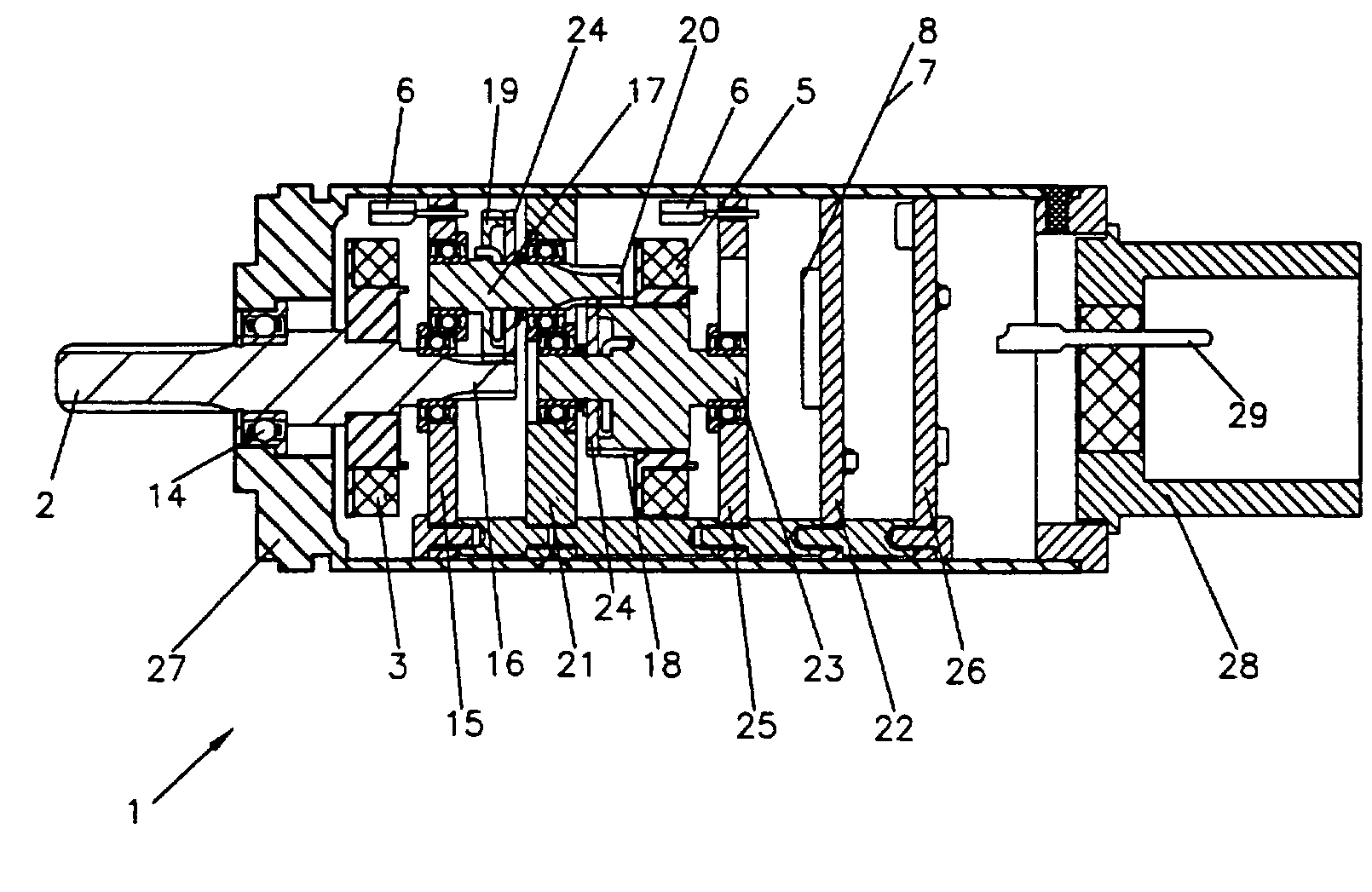

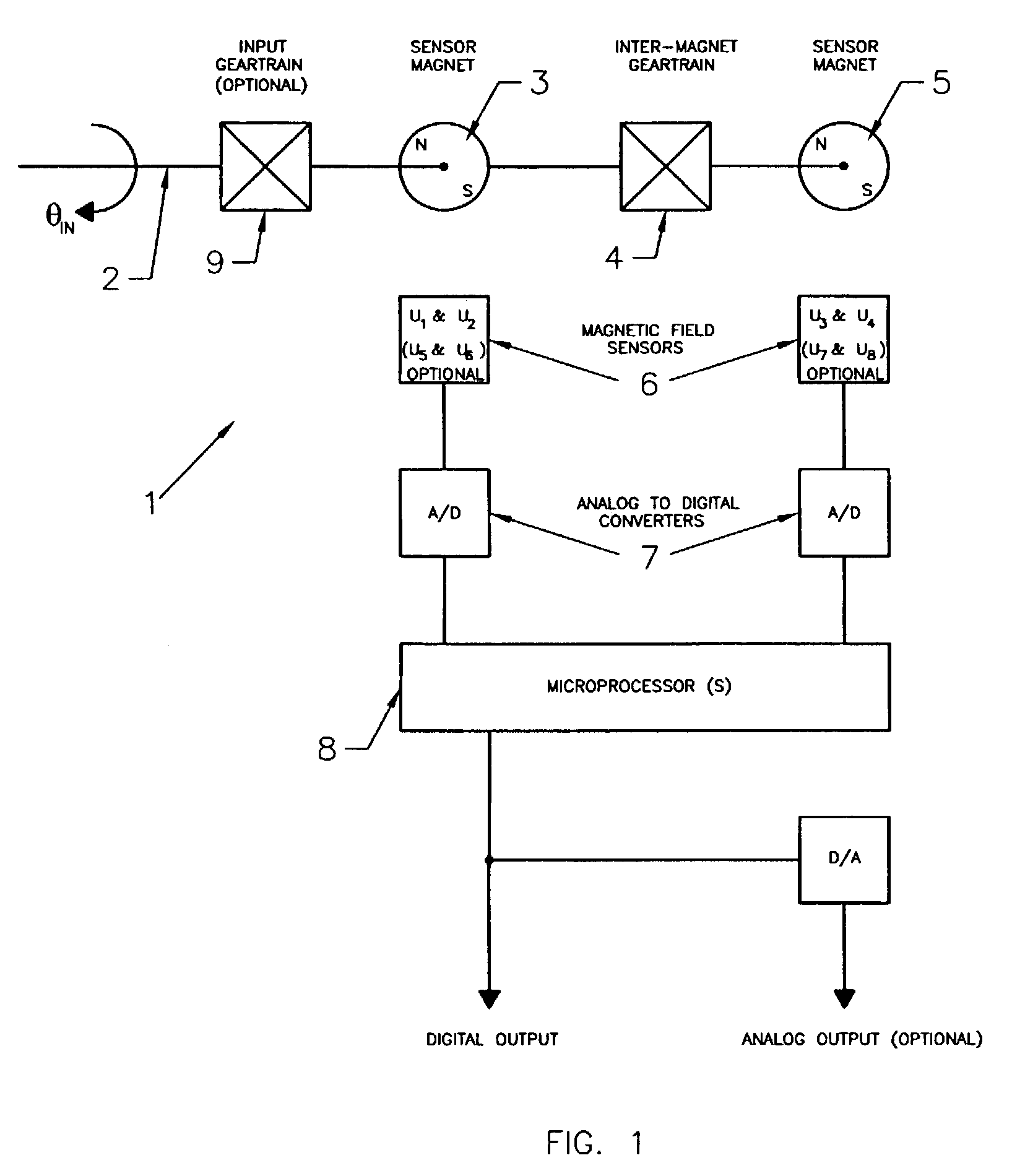

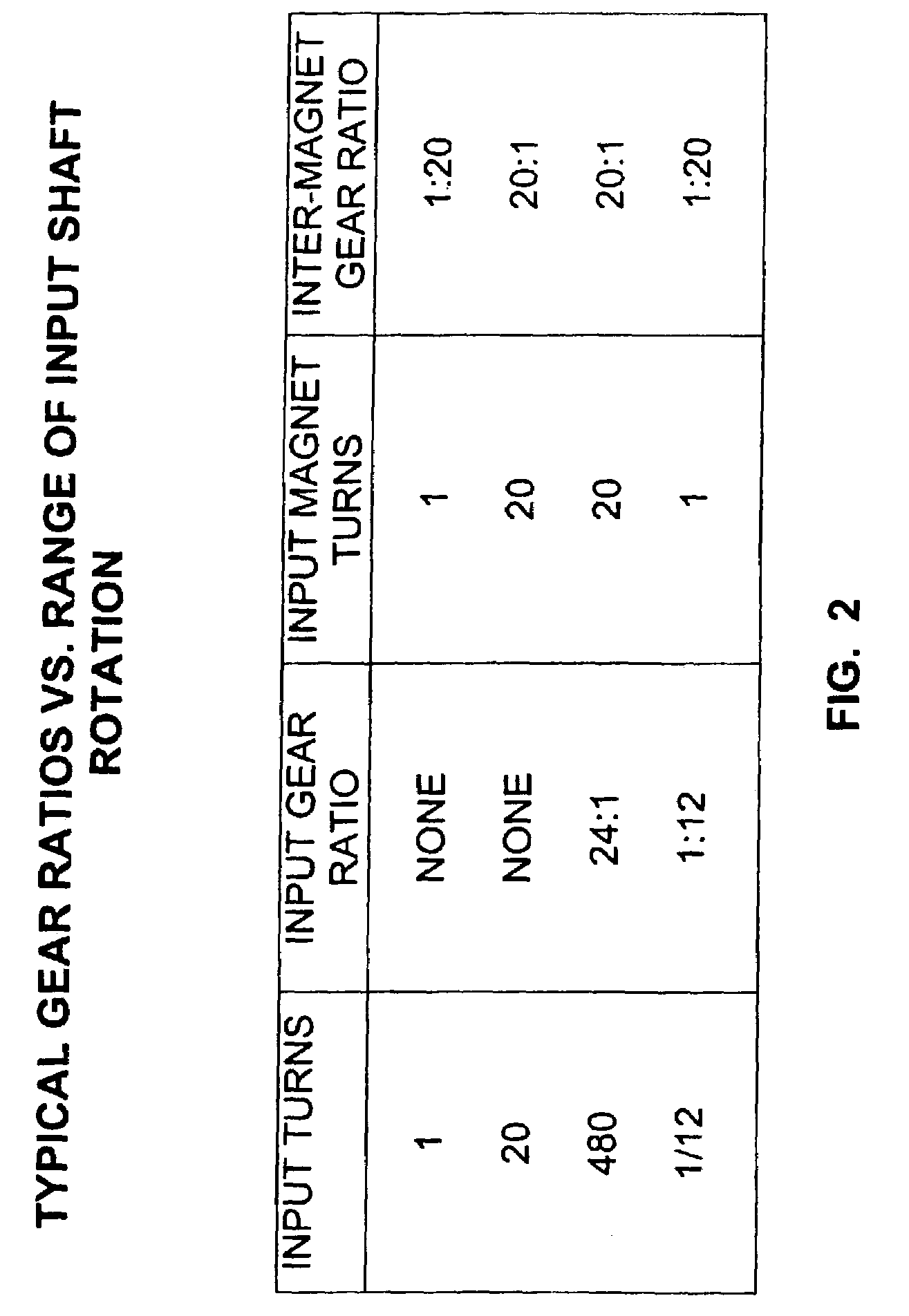

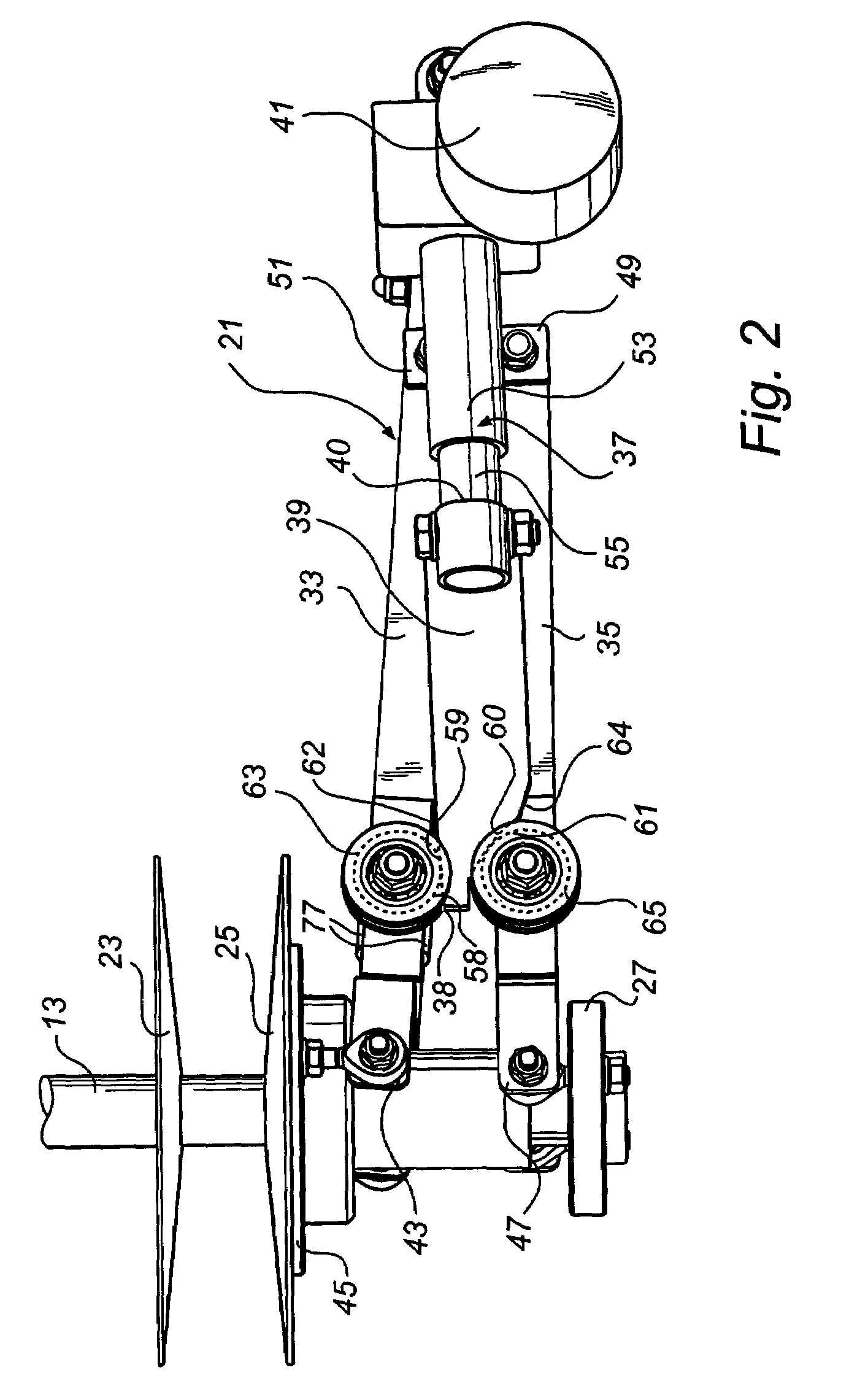

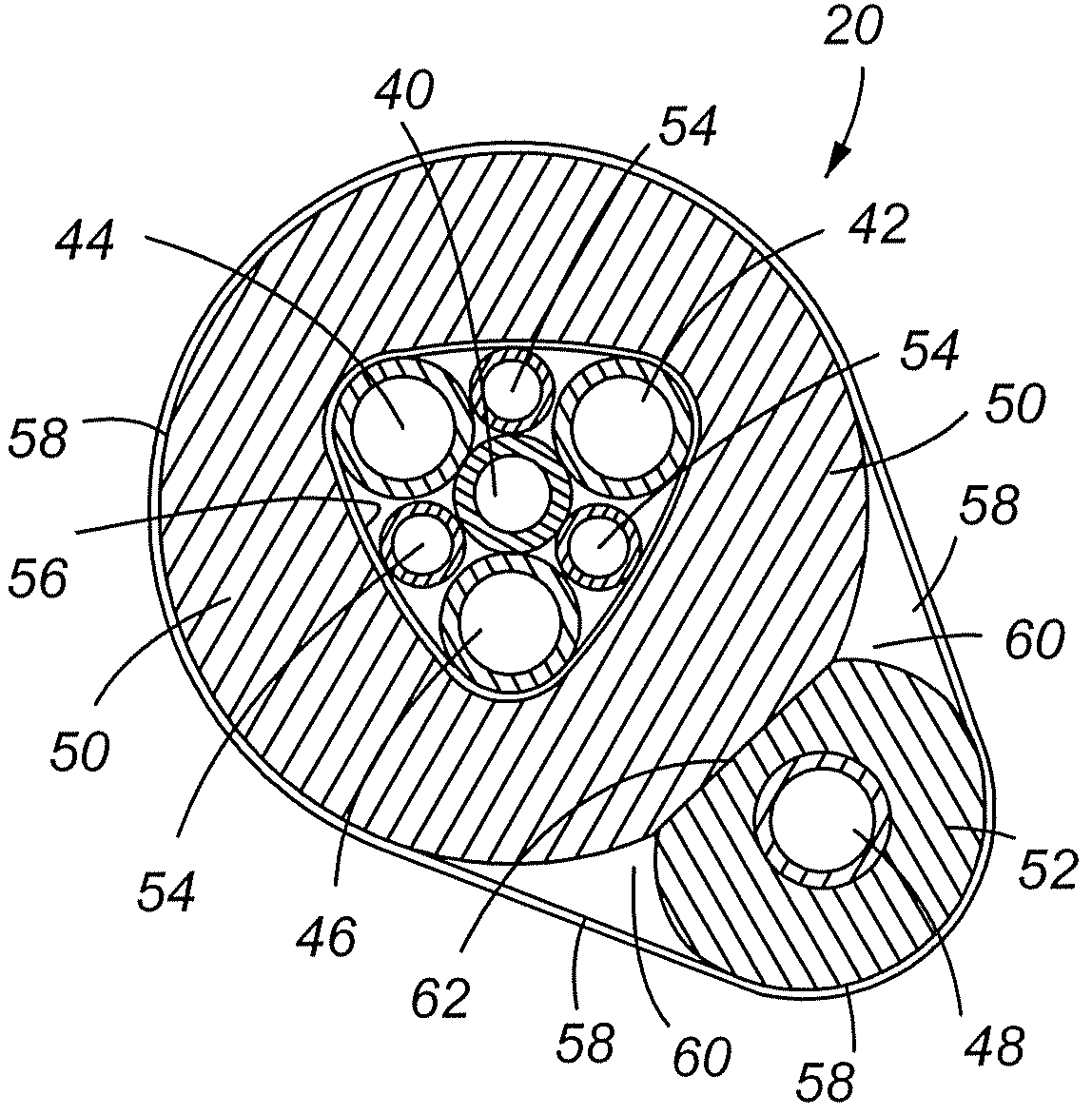

Contactless angular position sensor and method for sensing angular position of a rotatable shaft

InactiveUS7307415B2Improve accuracyRobust constructionSolid-state devicesMagnetic field measurement using galvano-magnetic devicesSignal conditioning circuitsAngular rotation

A contactless rotary shaft position sensor provides for precision computation of shaft angle for a wide range of input shaft rotational angles. The sensor includes two annular two-pole magnets which are connected by a precision, motion-transmitting gear train. An optional second gear train between one of the magnets and the input shaft can provide additional angular rotation scaling to accurately measure either fractional or a large number of multiple turns of the input shaft. The gear ratios are selected such that one of the magnets does not rotate more than one revolution. Pairs of ratiometric Hall-effect or magnetoresistive sensors provide differential voltage signals which are used for sensing angular position of each magnet over a full 360 degrees of rotation. The single-turn magnet provides an absolute, coarse indication of input shaft rotation with a typical accuracy of 2%. The gear ratio between the magnets produces several turns of the second magnet for each turn of the single-turn magnet. Since the gear ratio between the magnets is fixed, the angle sensed for the multi-turn magnet can be predicted from the position of the single-turn magnet. This is compared to the multi-turn magnet's actual sensed rotation. The result is an improvement in accuracy directly proportional to the gear ratio between the magnets. Computation of the individual magnet rotation angles and the input shaft angle is performed using a microprocessor and appropriate signal conditioning circuits. Utilizing two magnets, input shaft rotation can be accurately measured to within 0.1% of maximum range.

Owner:BVR TECH

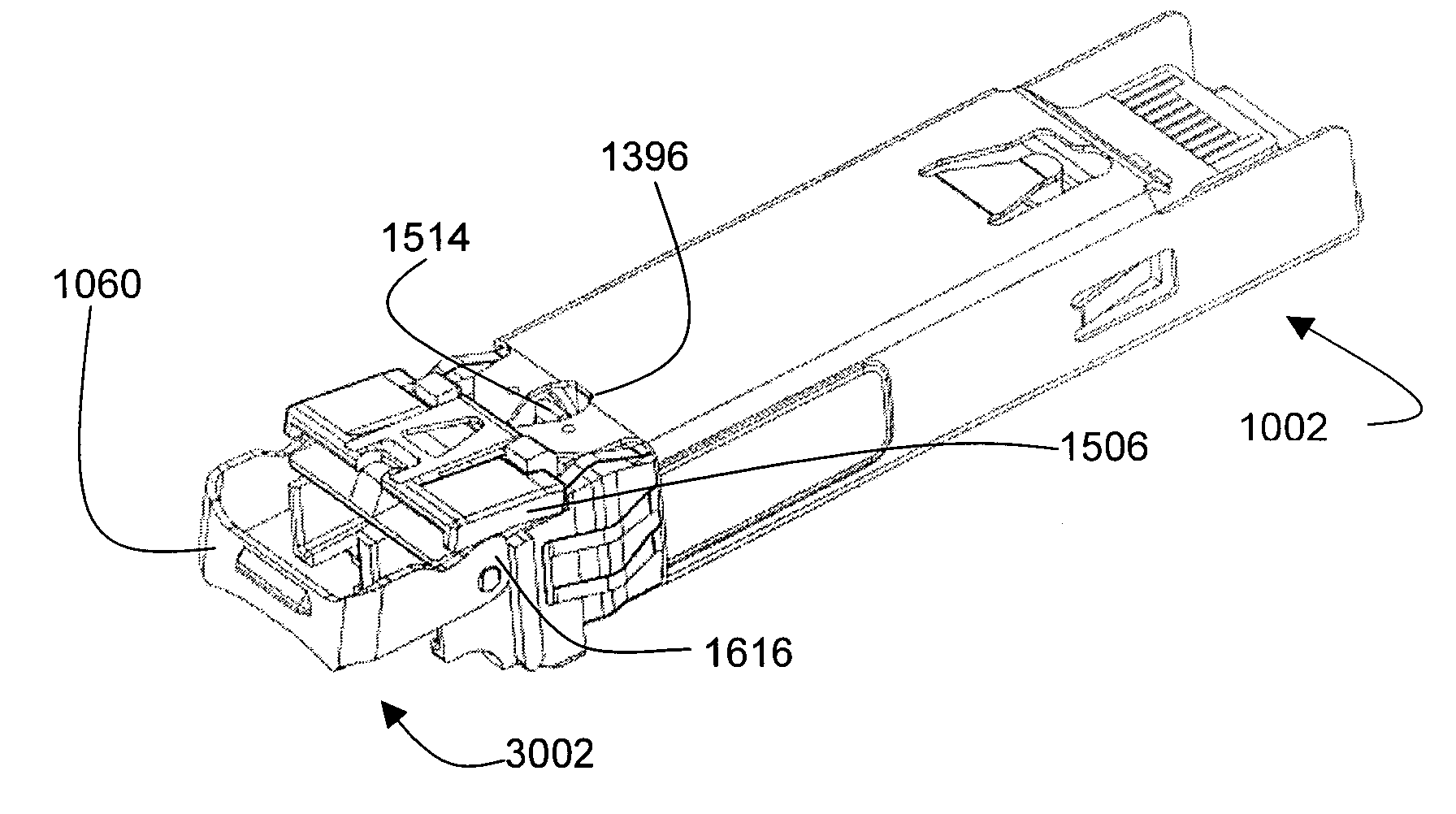

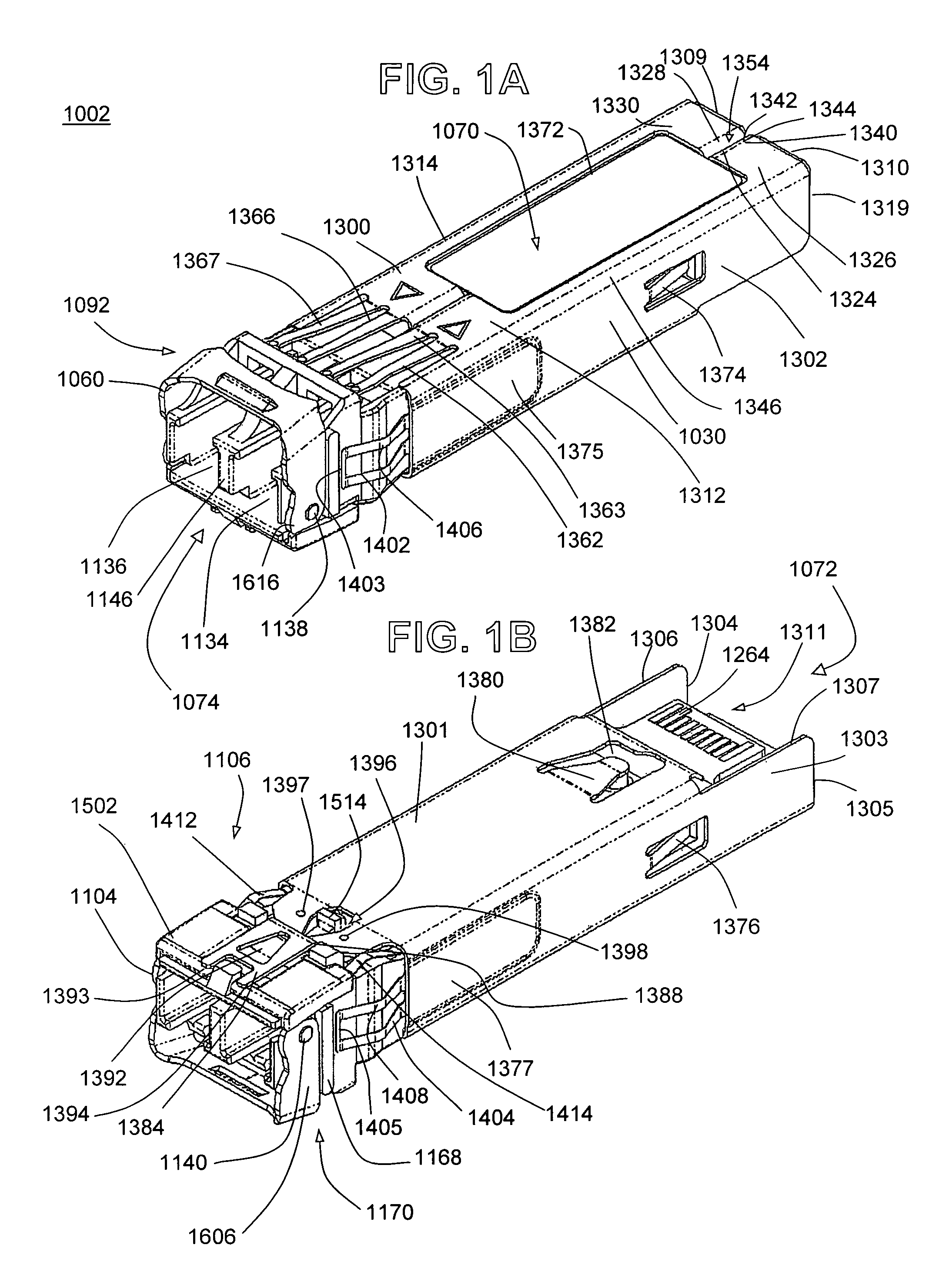

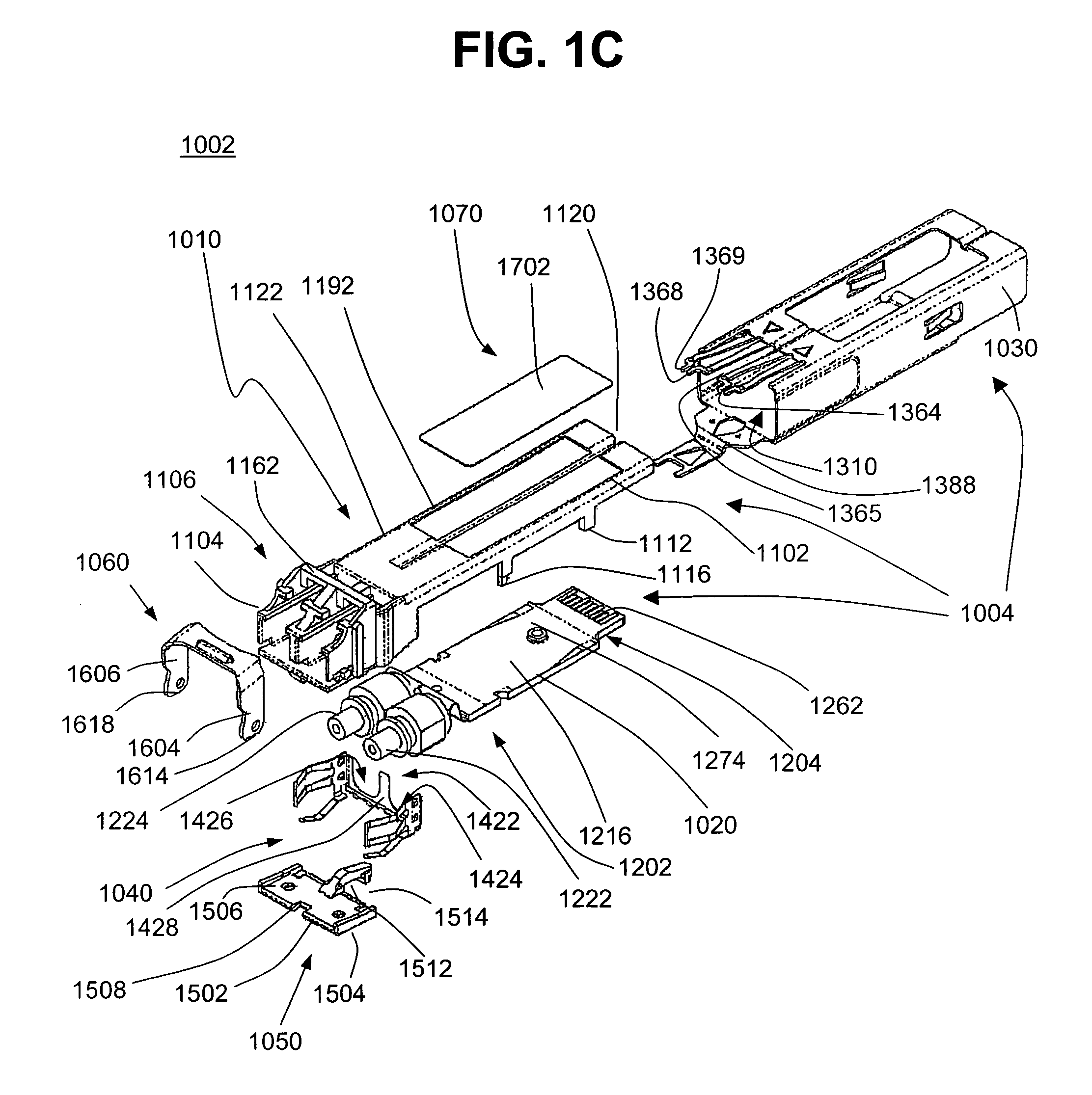

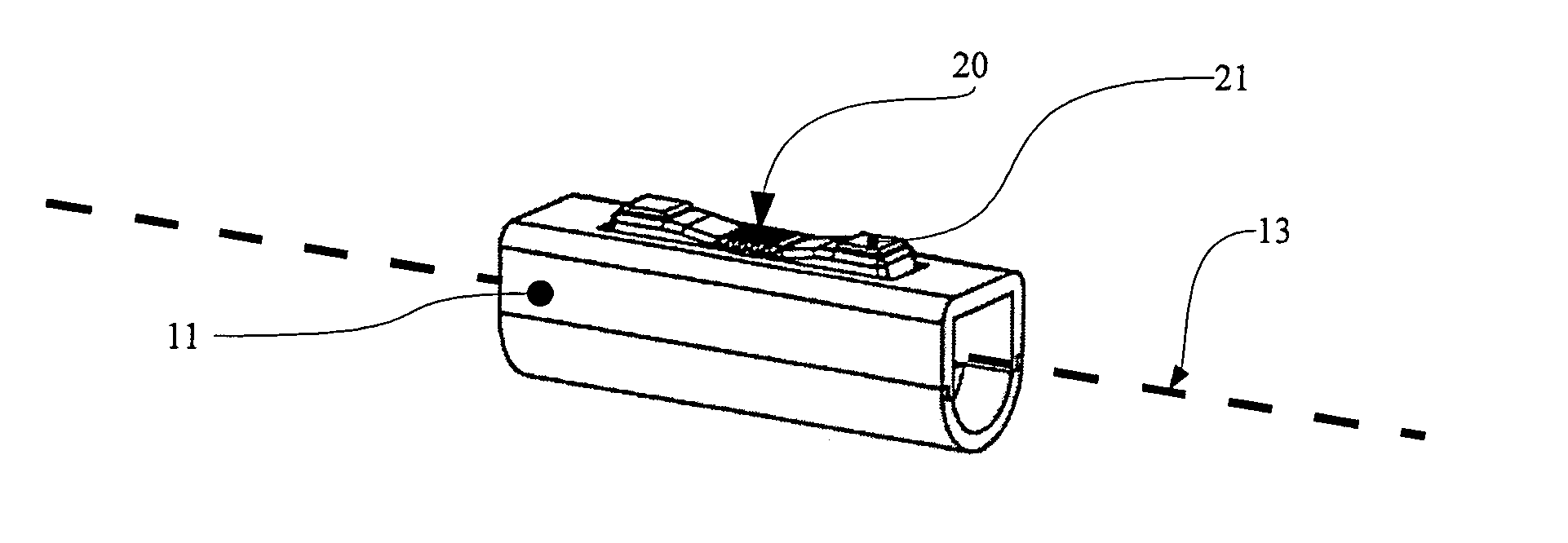

Transceiver module

ActiveUS7114857B1Easy to operateMinimal costCoupling device detailsCoupling light guidesTransceiverEngineering

The present invention provides transceiver modules in which a transceiver may be ejected from a cage into which the transceiver is inserted by pivoting a handle mounted on the transceiver.

Owner:LUMENTUM OPERATIONS LLC

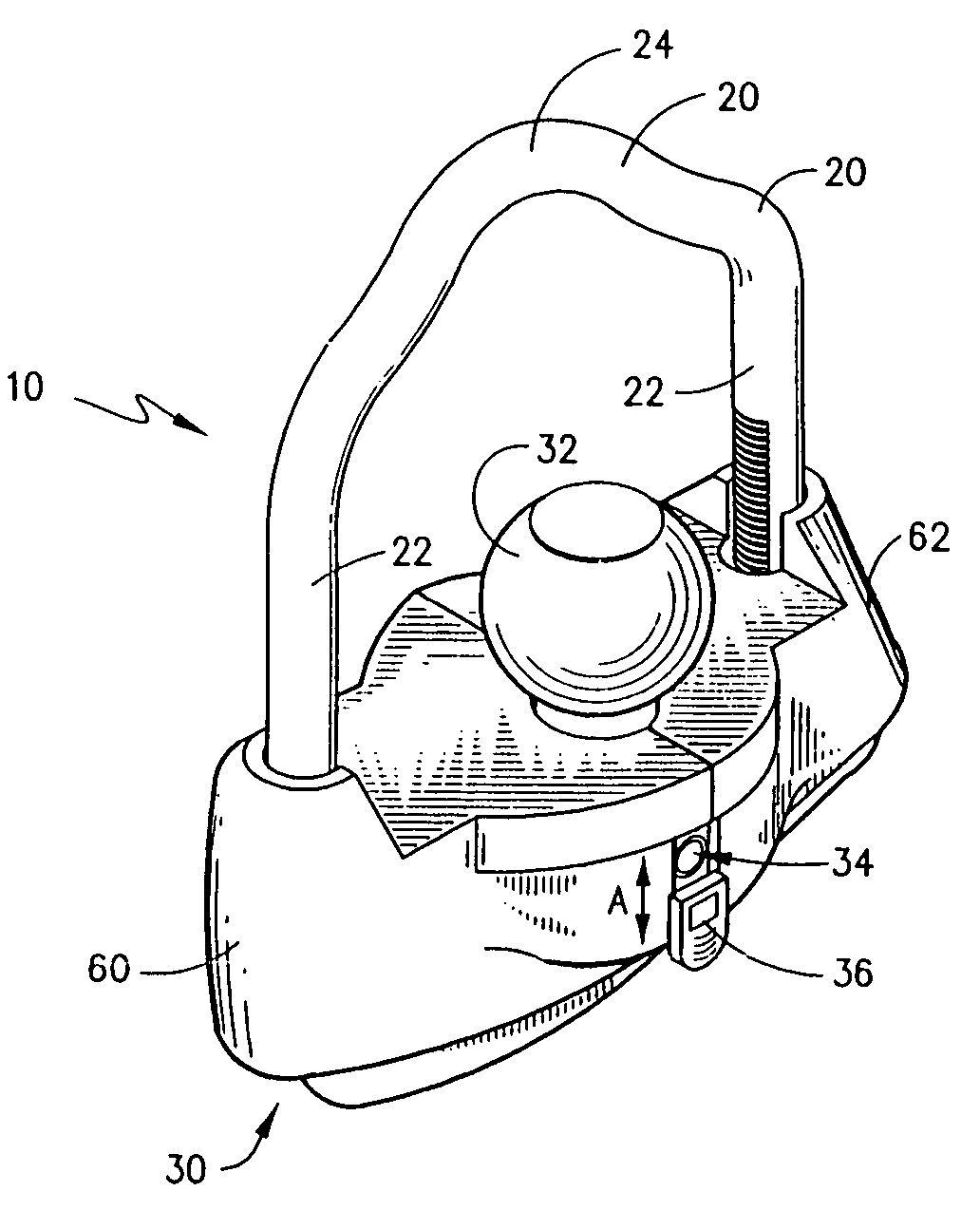

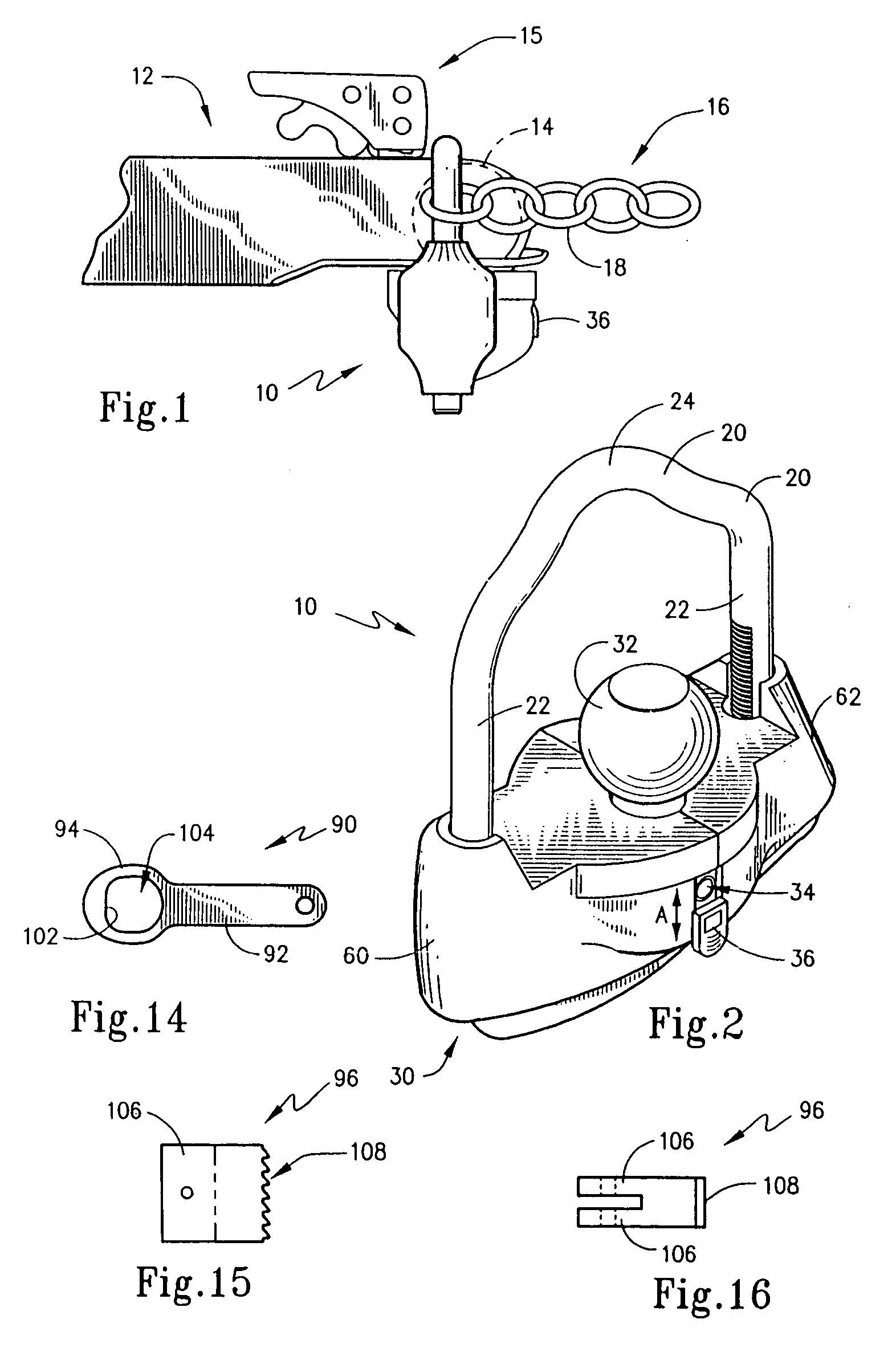

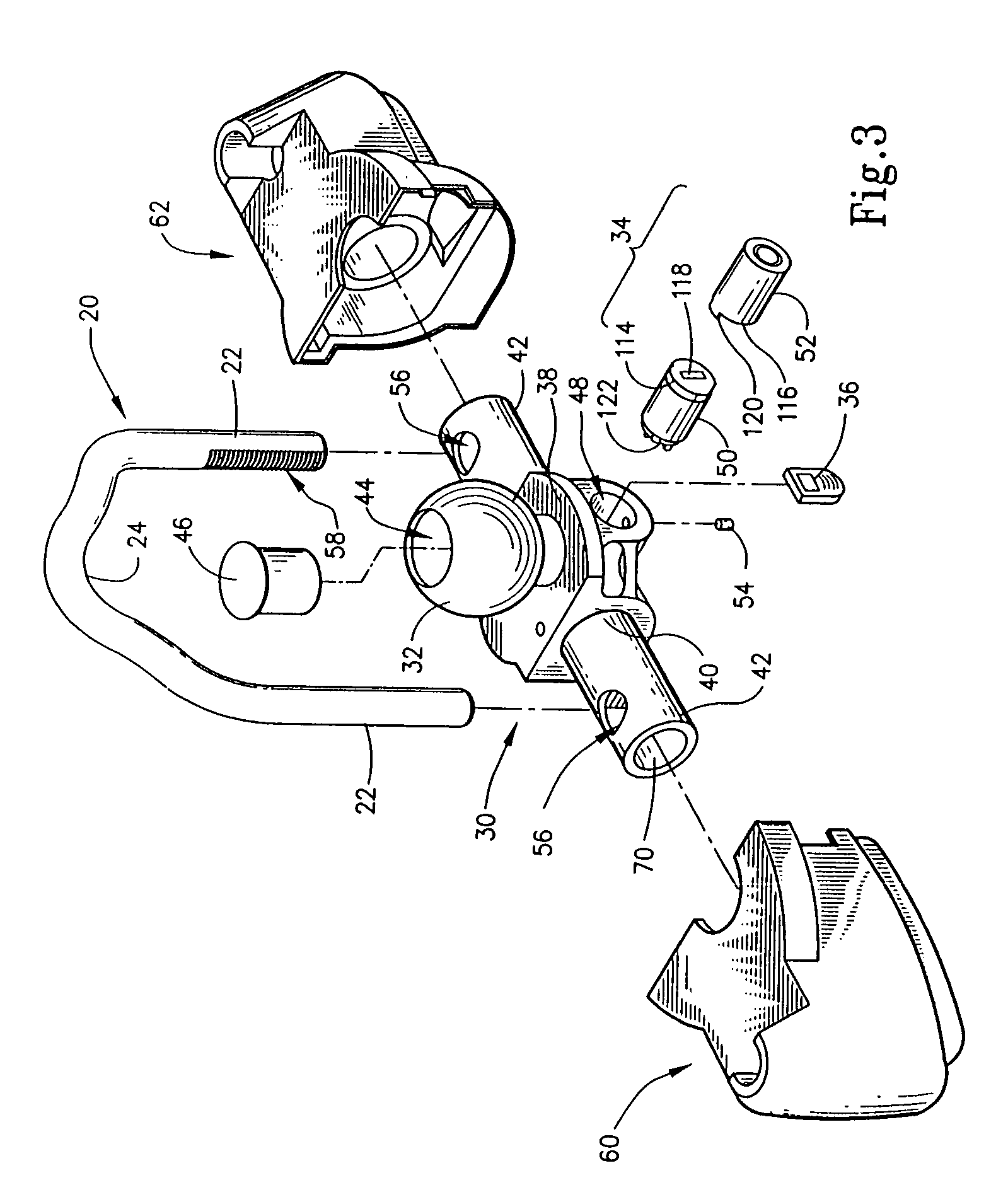

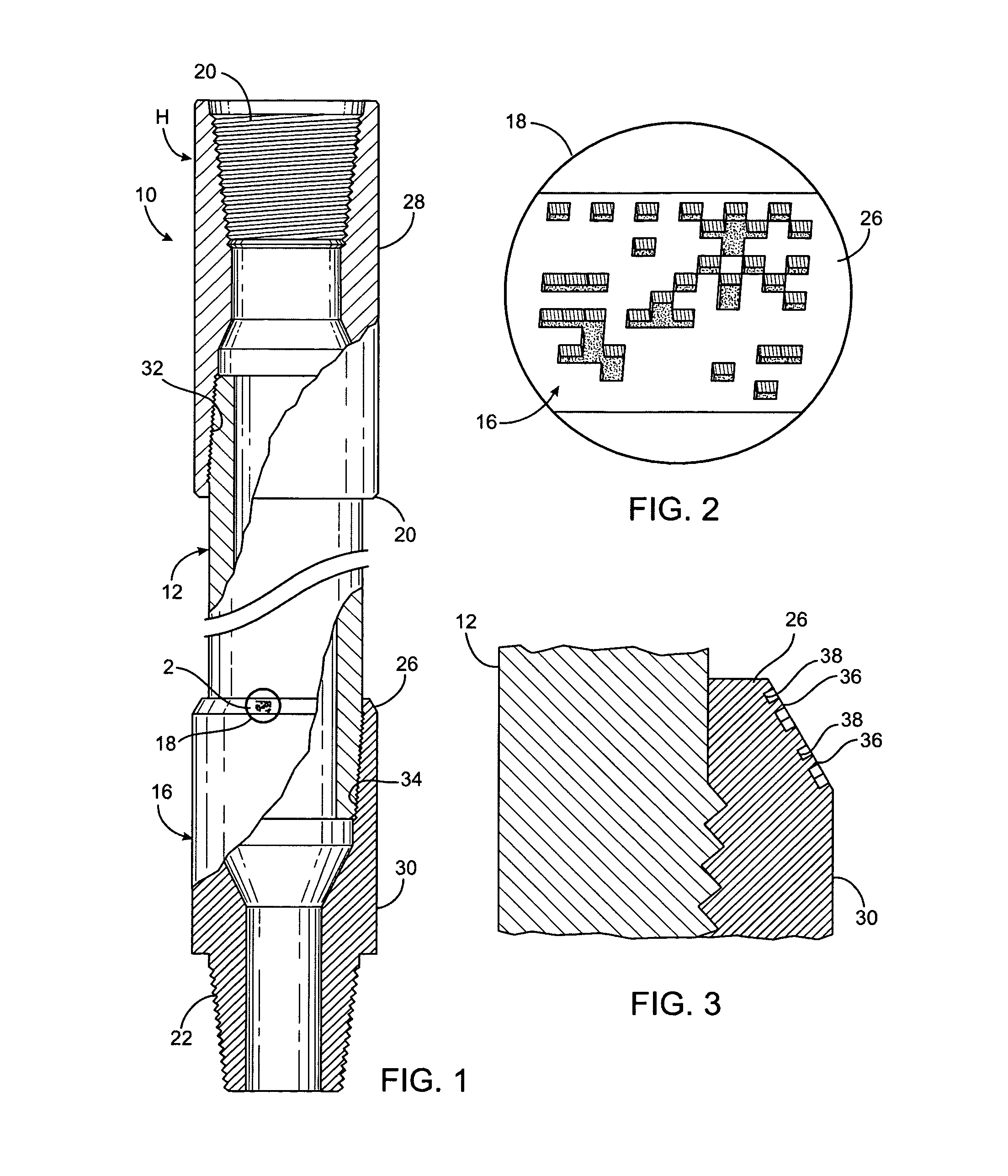

Locking device for trailer hitches and method therefor

InactiveUS7121121B2Robust constructionTelevision system detailsBicycle locksLocking mechanismEngineering

A method and apparatus to secure the coupler section of a trailer provides a locking device that includes a lock housing having a hitch ball element to engage the recess in the coupler, a shackle member lockable to the housing and having a bridge section that spans the hitch ball element, and a latch assembly to latch and unlatch the shackle member. The shackle member is shown to be U-shaped with legs that extend through and secure to the lock housing. The latch assembly provides a ratchet-type engagement to allow adjustable locking. A rotatable lock mechanism drives a cam based latch mechanism between a latch state and an unlatch state.

Owner:WYERS PHILIP W

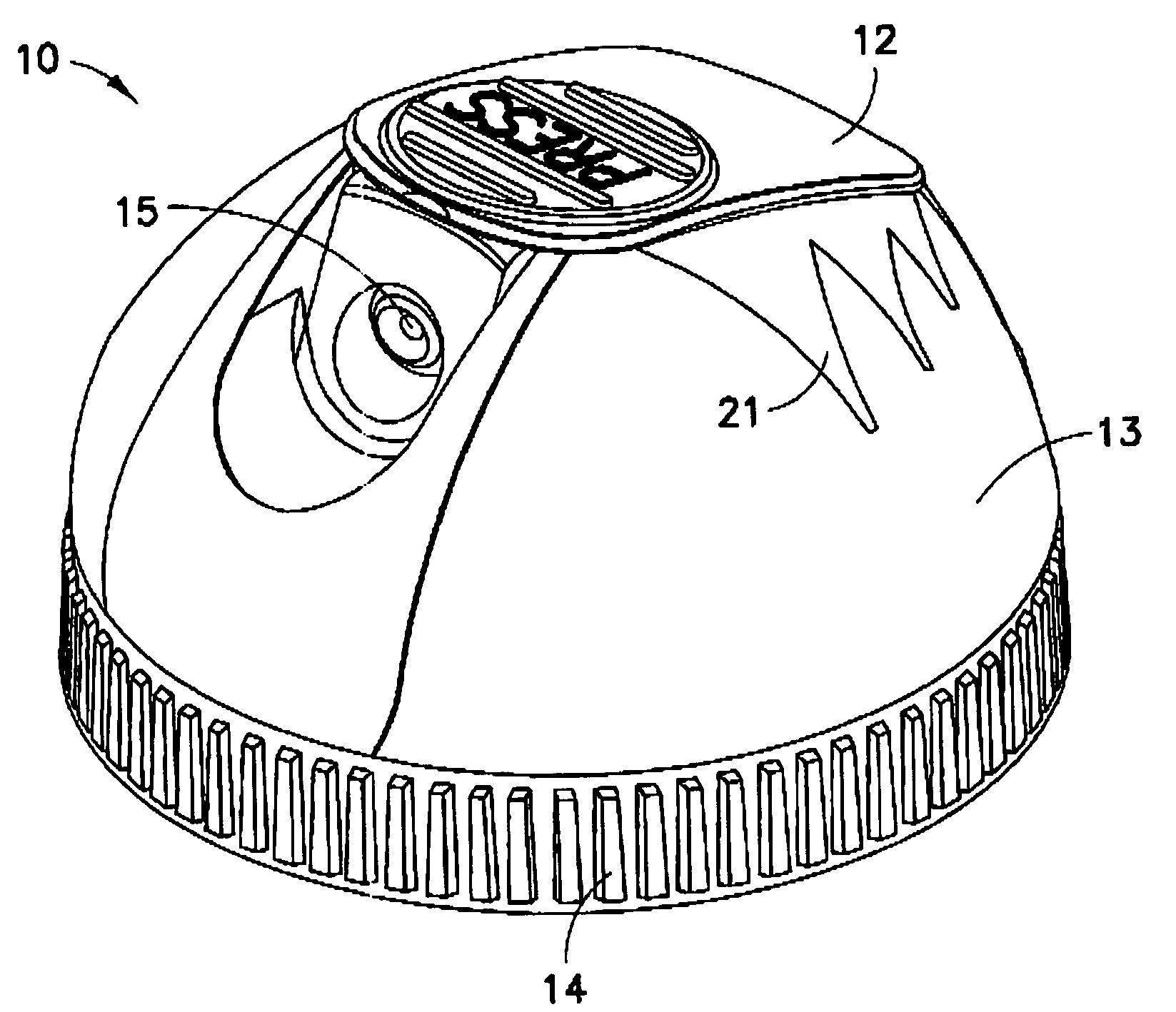

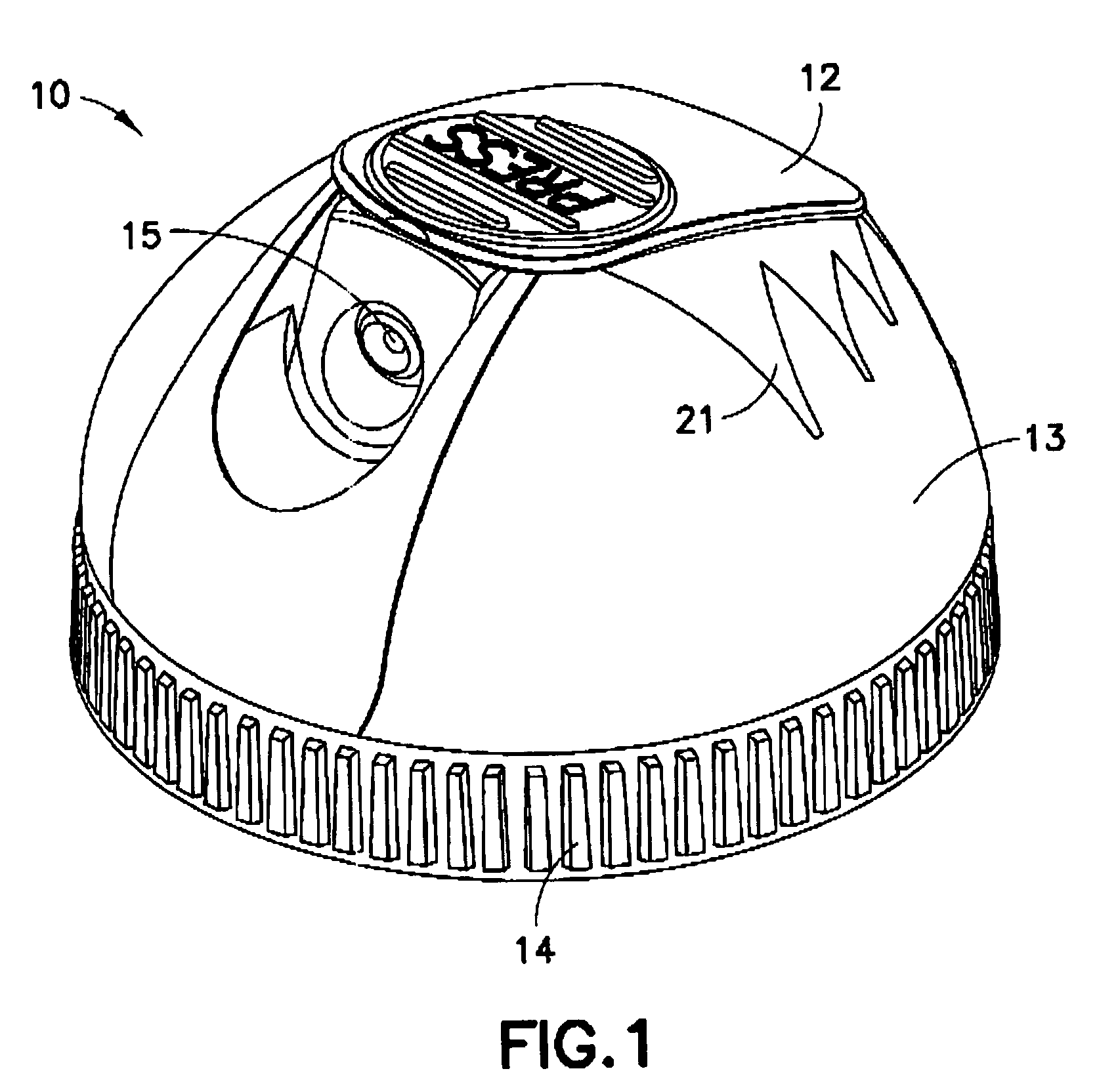

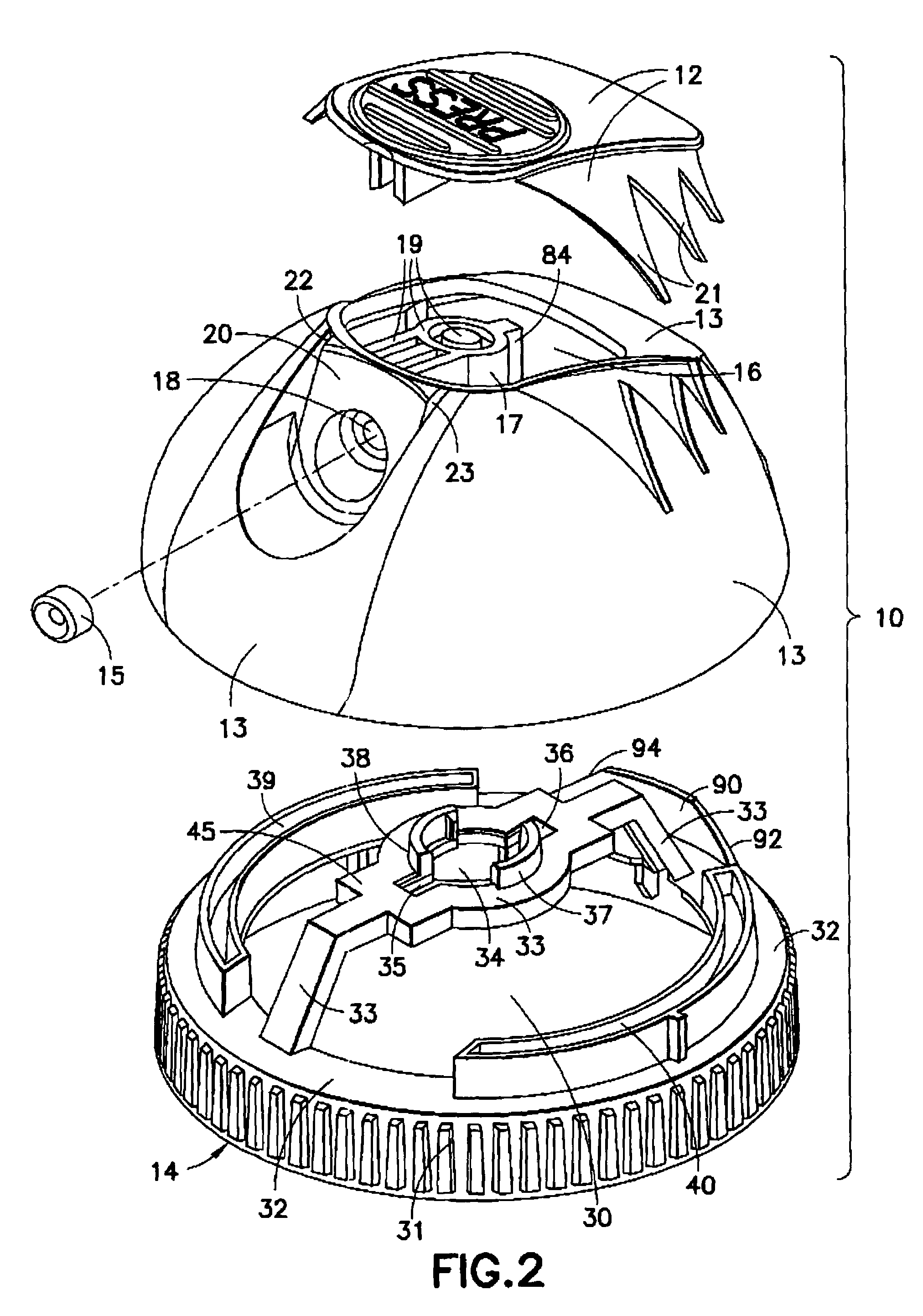

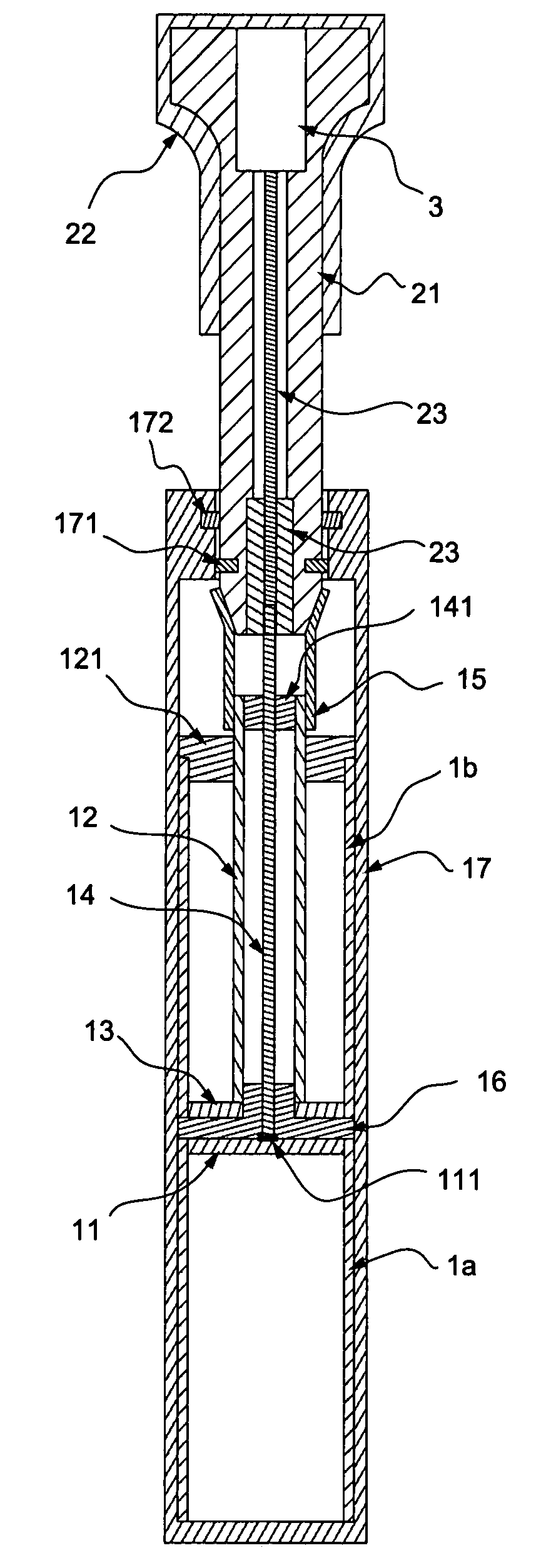

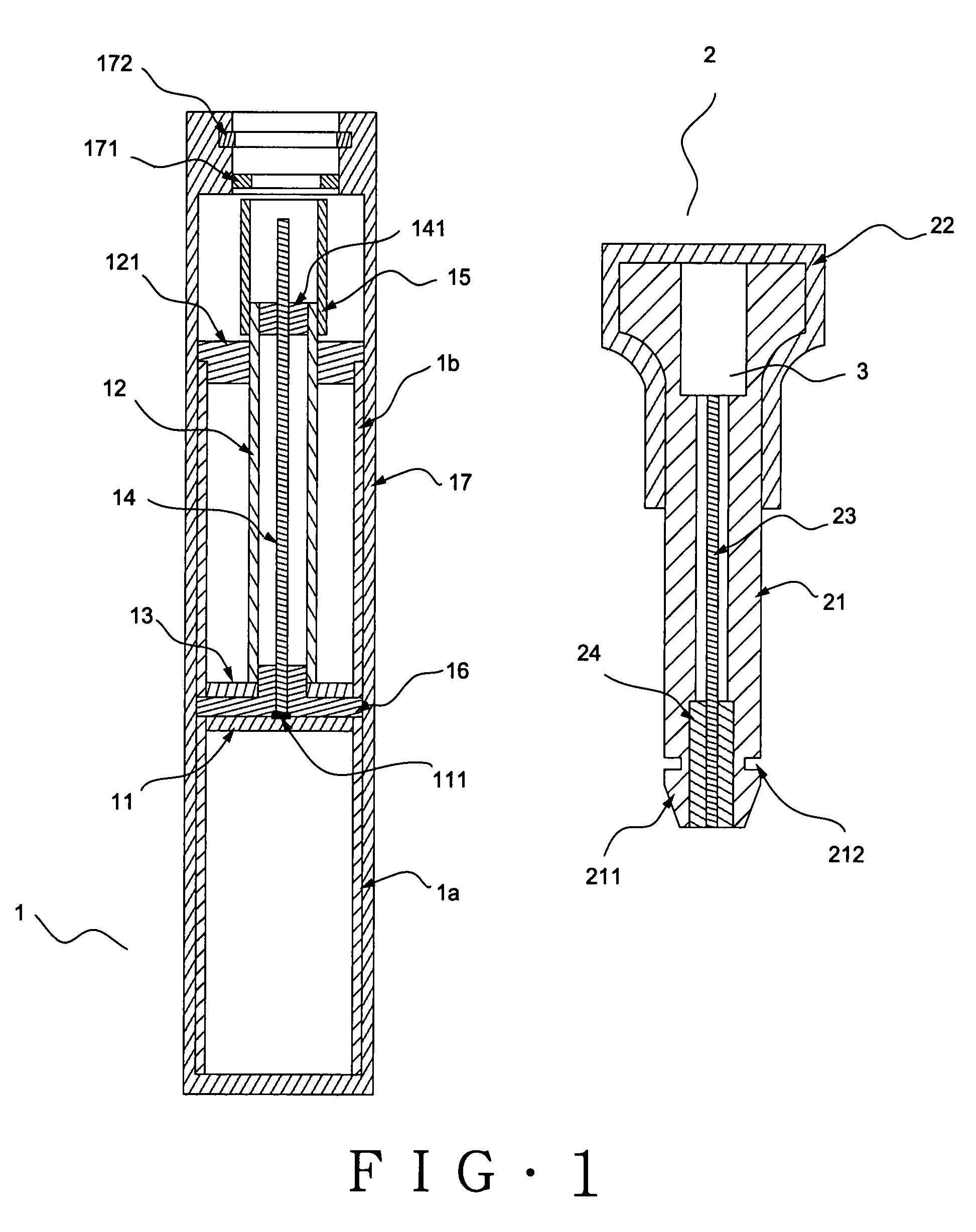

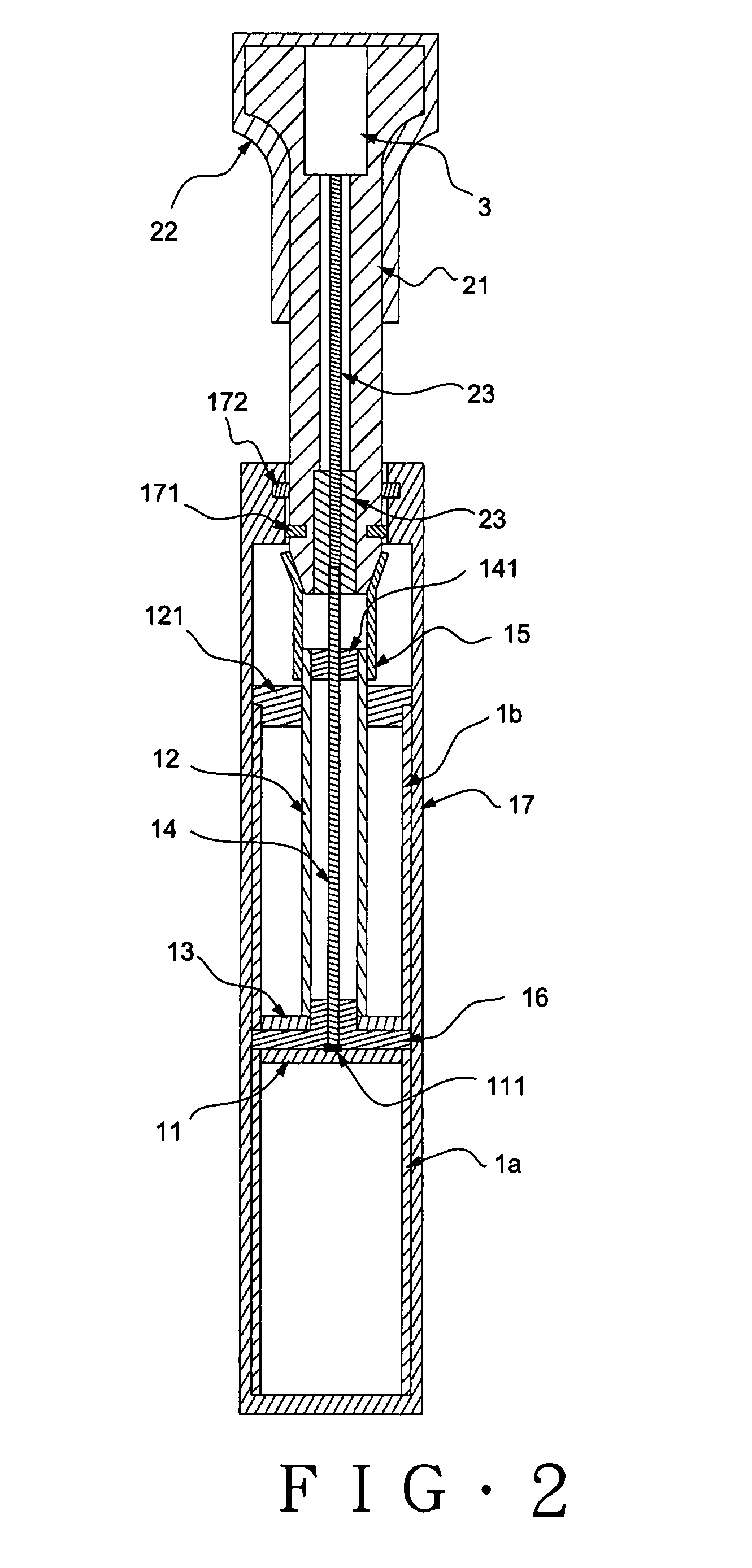

Locking aerosol dispenser

ActiveUS7530476B2Robust constructionEasy to assembleDecorative coversClosure decorative/protective coversEngineeringMechanical engineering

A locking aerosol dispenser with a dome, a top thermoplastic elastomeric button member molded over a dome opening, and a base lock member. The rotatable base lock rotates from locked to unlocked position with respect to the essentially non-rotatable dome. A product channel member in the dome is held by the elastomeric button, and not otherwise attached to the dome. The base lock has an upstanding bridge with unlocking slots within which extend fingers on the product channel member when the dispenser is unlocked and actuated. The base lock is not attached to the aerosol valve mounting cup. The dome is attached to the base lock member and the aerosol valve mounting cup, the dome capturing the base lock member between the dome and aerosol container.

Owner:PRECISION VALVE CORP

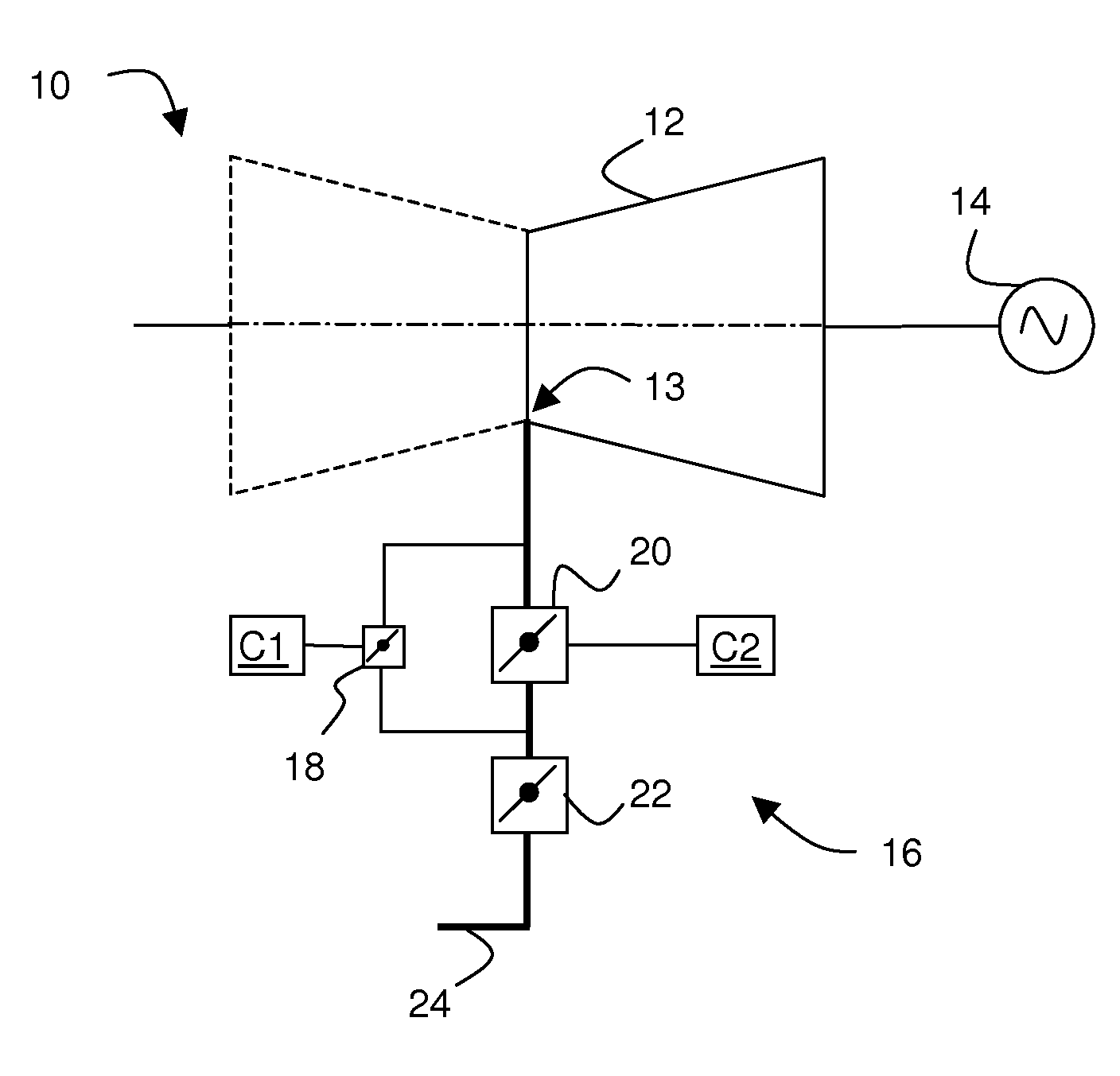

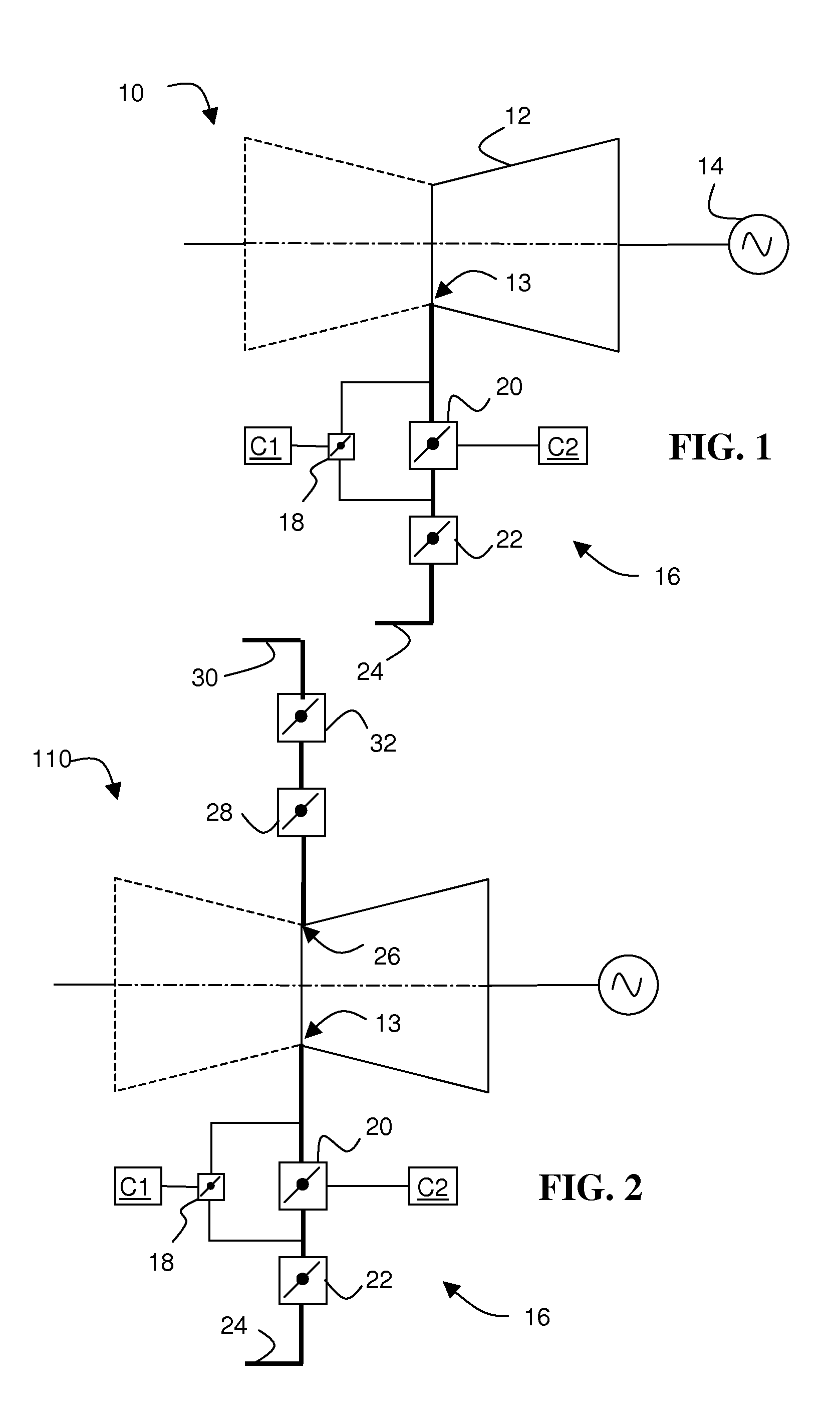

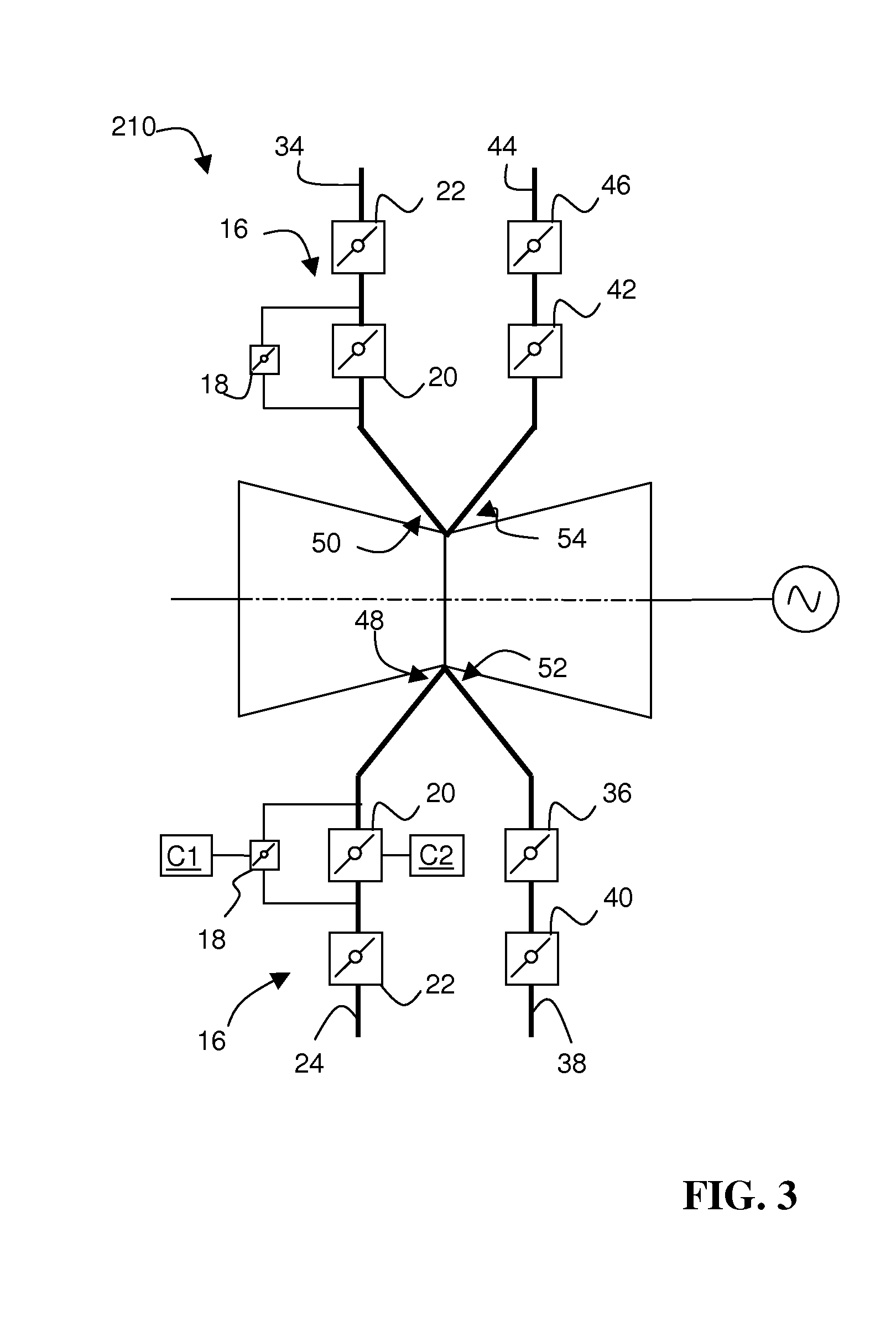

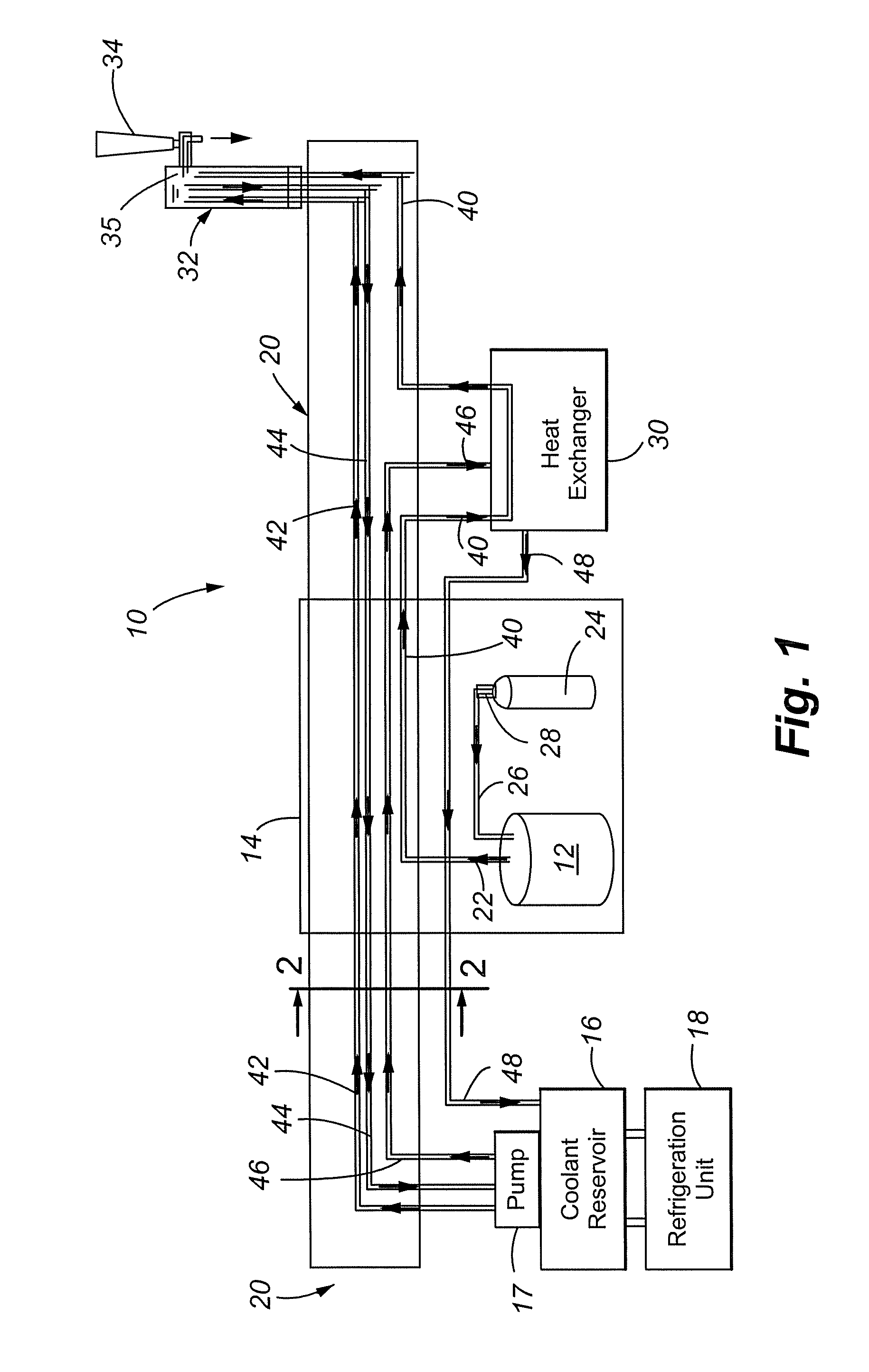

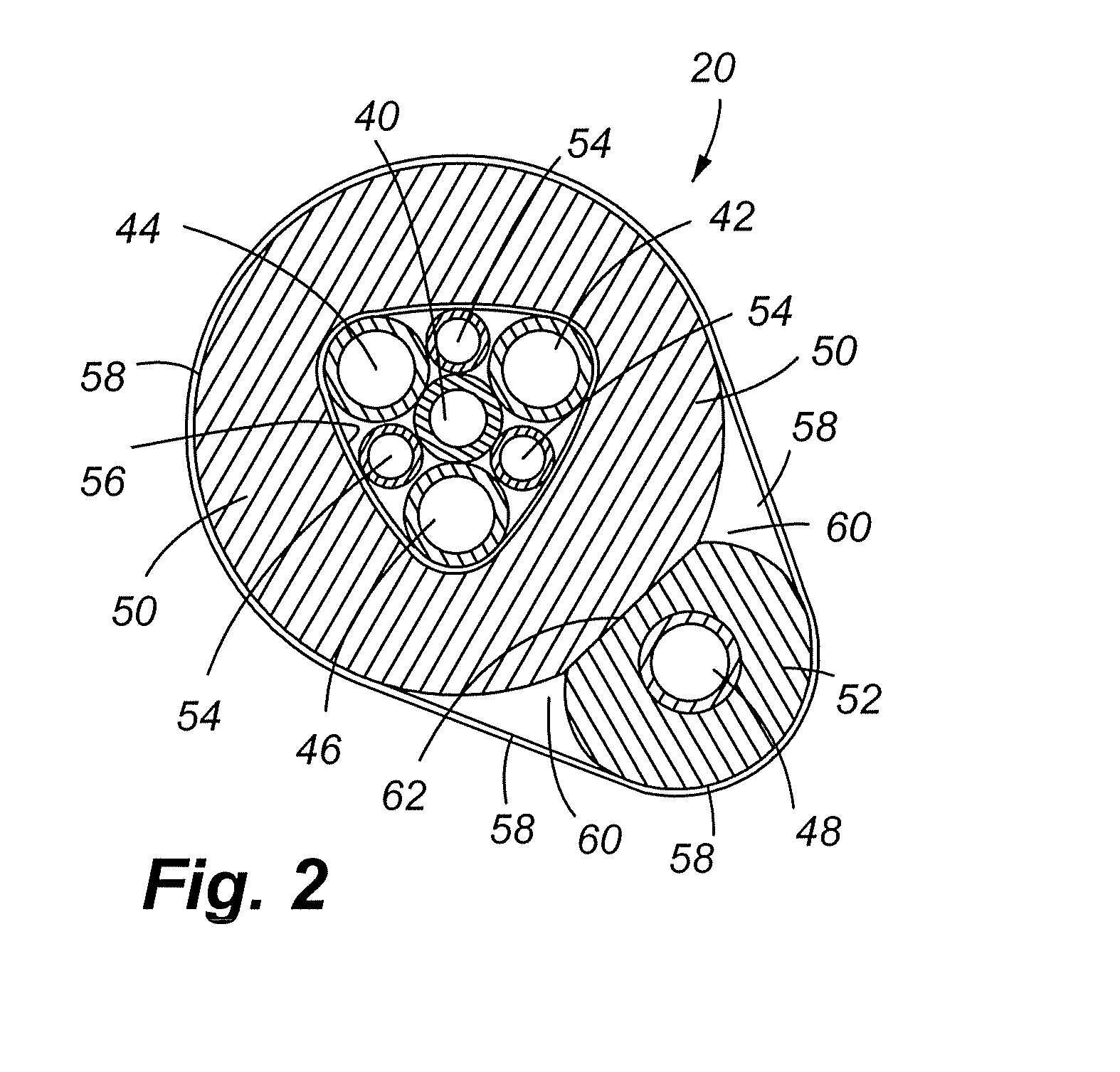

Geothermal power generation

InactiveUS20130247569A1Small volume flowSmall diameterEngine componentsSteam engine plantsEngineeringControl valves

A valve arrangement (16) for a geothermal steam turbine generator (10) comprises first and second steam control valves (18, 20) for regulating the supply of steam to the steam turbine generator (10). The first and second steam control valves are arranged in parallel in a steam supply line (24) and the first steam control valve (18) has a smaller fully-open diameter than the second steam control valve (20). The first steam control valve (18) is arranged to regulate the volume flow rate of steam supplied to the steam turbine generator (10) during a speed-control phase, until the steam turbine generator (10) attains a predetermined rotational speed at which it can be connected to an ac electrical system. The second steam control valve (20) is arranged to regulate the volume flow rate of steam supplied to the steam turbine generator (10) during a load-control phase, after the end of the speed-control phase, once the steam turbine generator (10) has attained the predetermined rotational speed and is connected to the ac electrical system.

Owner:ALSTOM TECH LTD

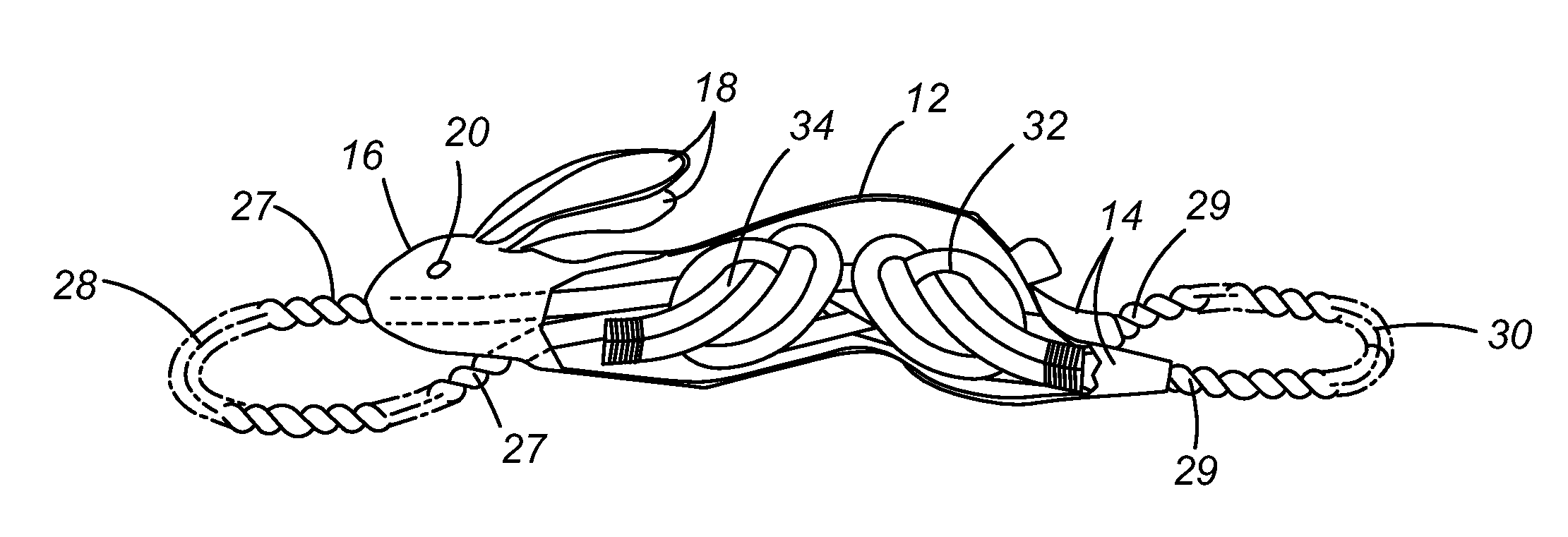

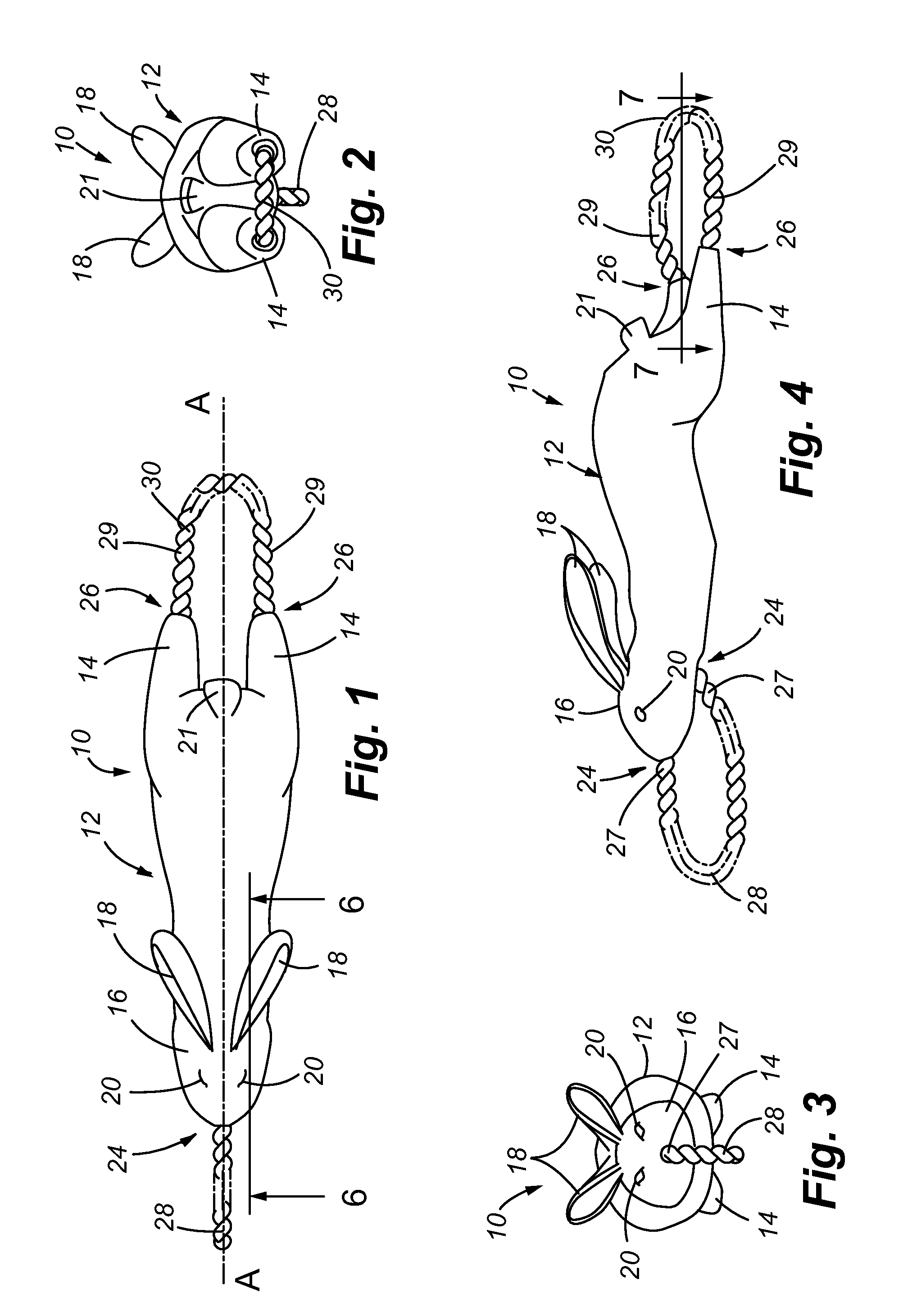

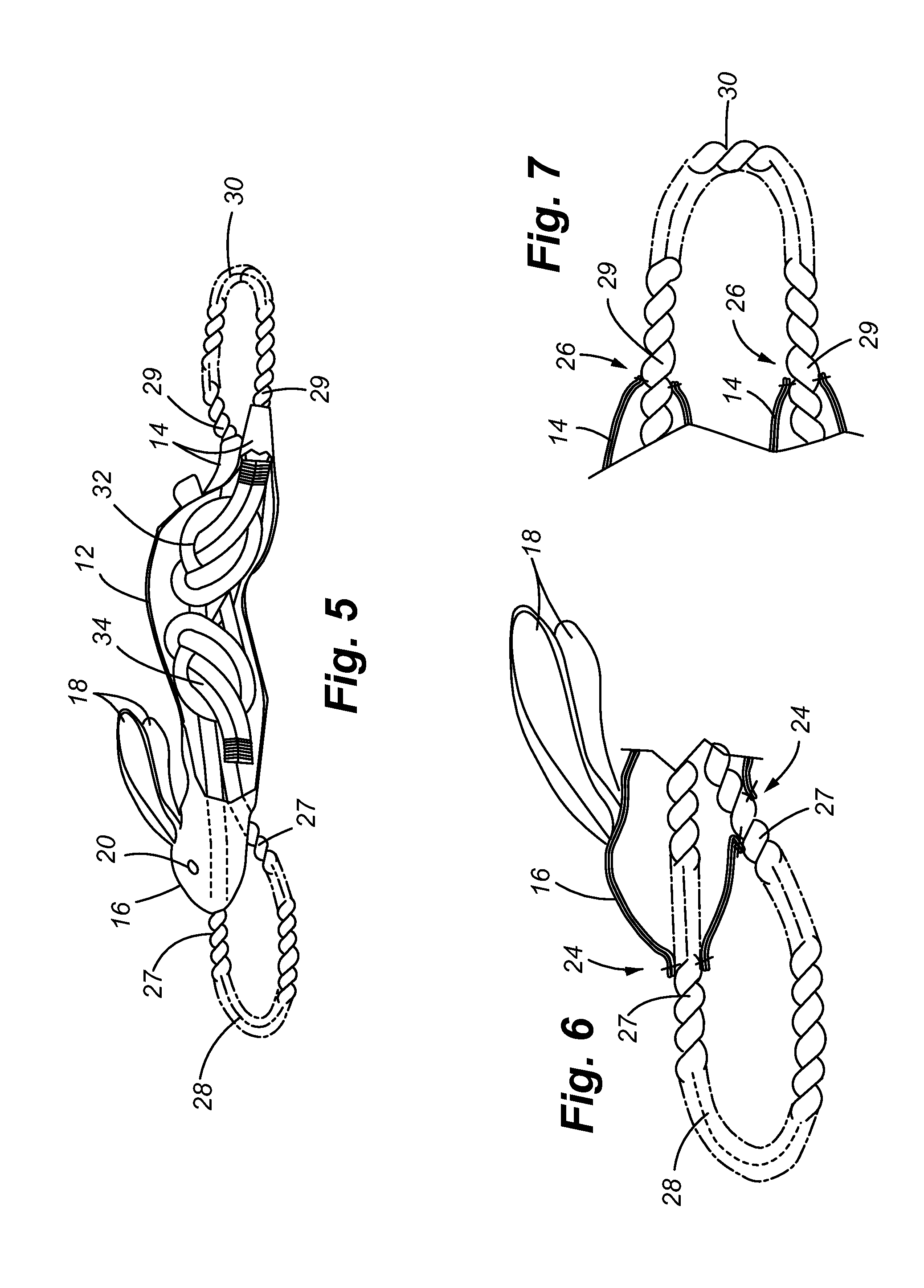

Pet toy with flexible body and rope support configurations

ActiveUS8393300B2Less stressRobust constructionFilament handlingOther apparatusEngineeringCompanion animal

Owner:THE KONG

Four-position rocker switch for electrosurgical handpiece

ActiveUS20090076504A1Easy to operateQuality improvementSurgical instrument detailsElectric switchesEngineeringRocker arm

A surgical apparatus includes an actuation unit disposed on a handle and a control unit providing at least three modes for controlling the electrical instrument. The actuation unit contains a switching rocker with an operating element, which is rotatable about a rocker axis that can be shifted perpendicular to the surface of the handle, so that starting from an initial position a first or second function position can be reached by forwards or backwards rotation about the rocker axis, and a third function position can be reached by pressing the operating element inward, two sensors being disposed on the operating element, one on the left and the other on the right side of the rocker axis, in such a way that by means of the sensors the function position selected by means of the switching rocker can be determined by the control unit.

Owner:ERBE ELEKTROMEDIZIN GMBH

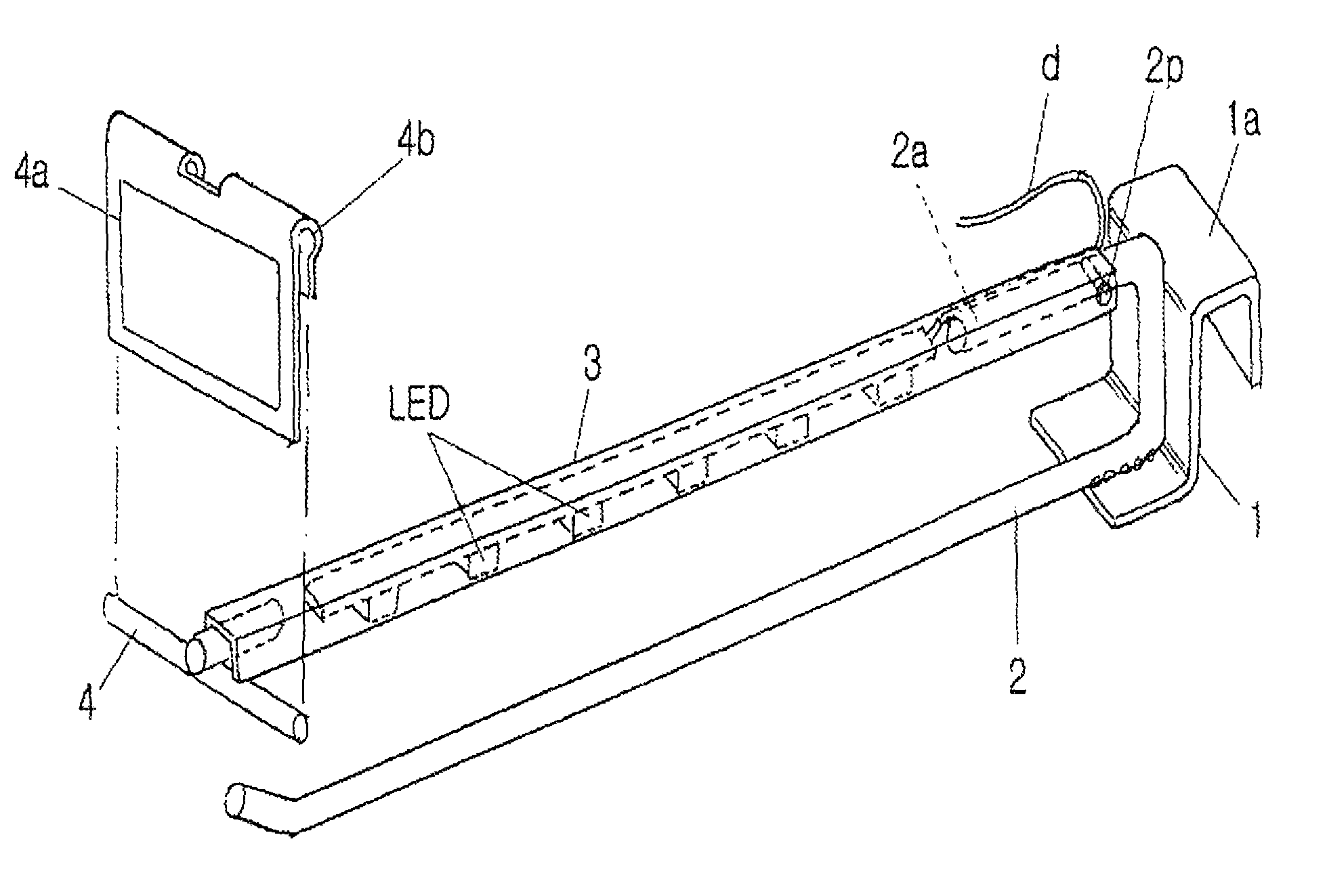

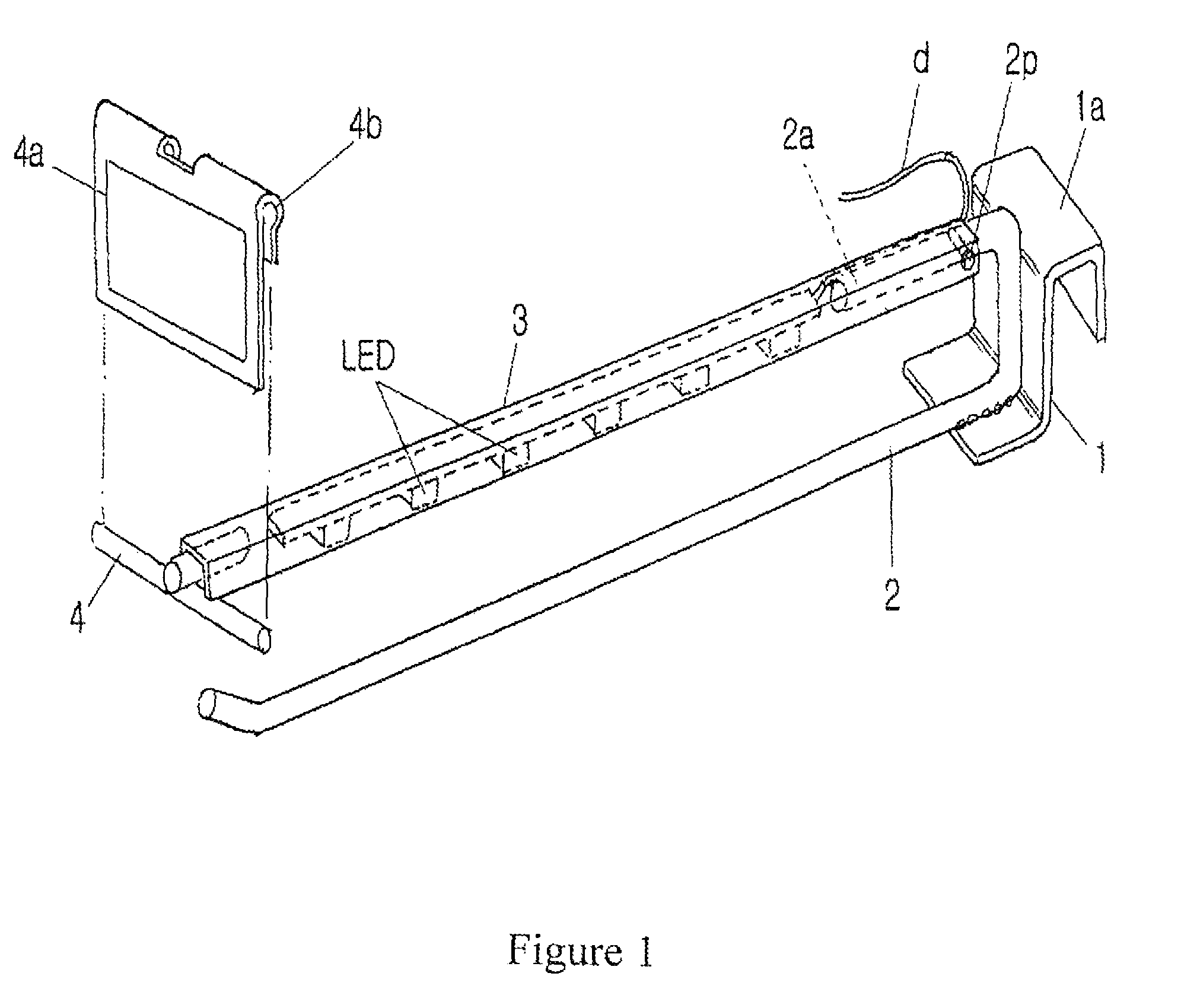

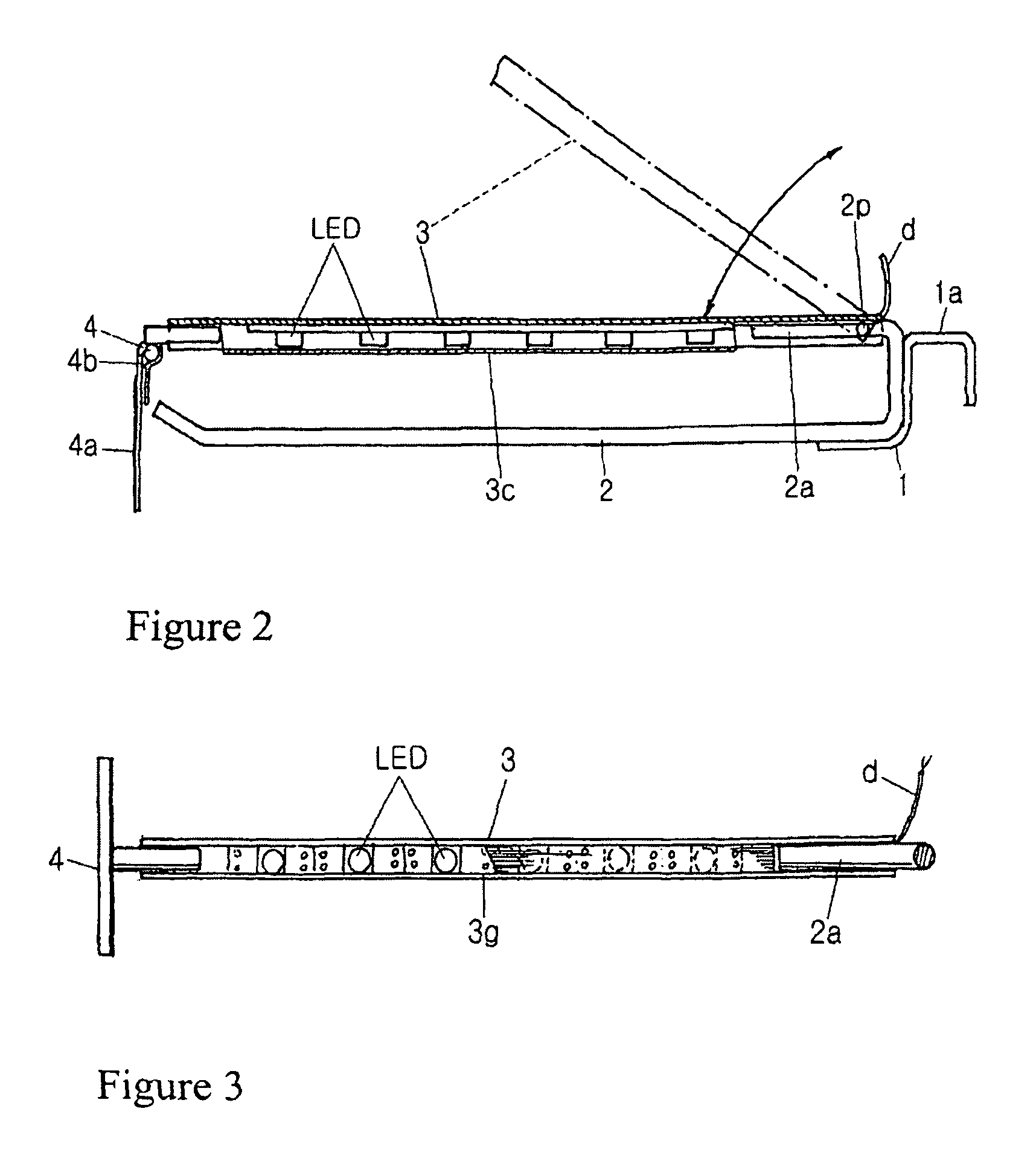

Hanger with a display light bar

Owner:OH SE KI

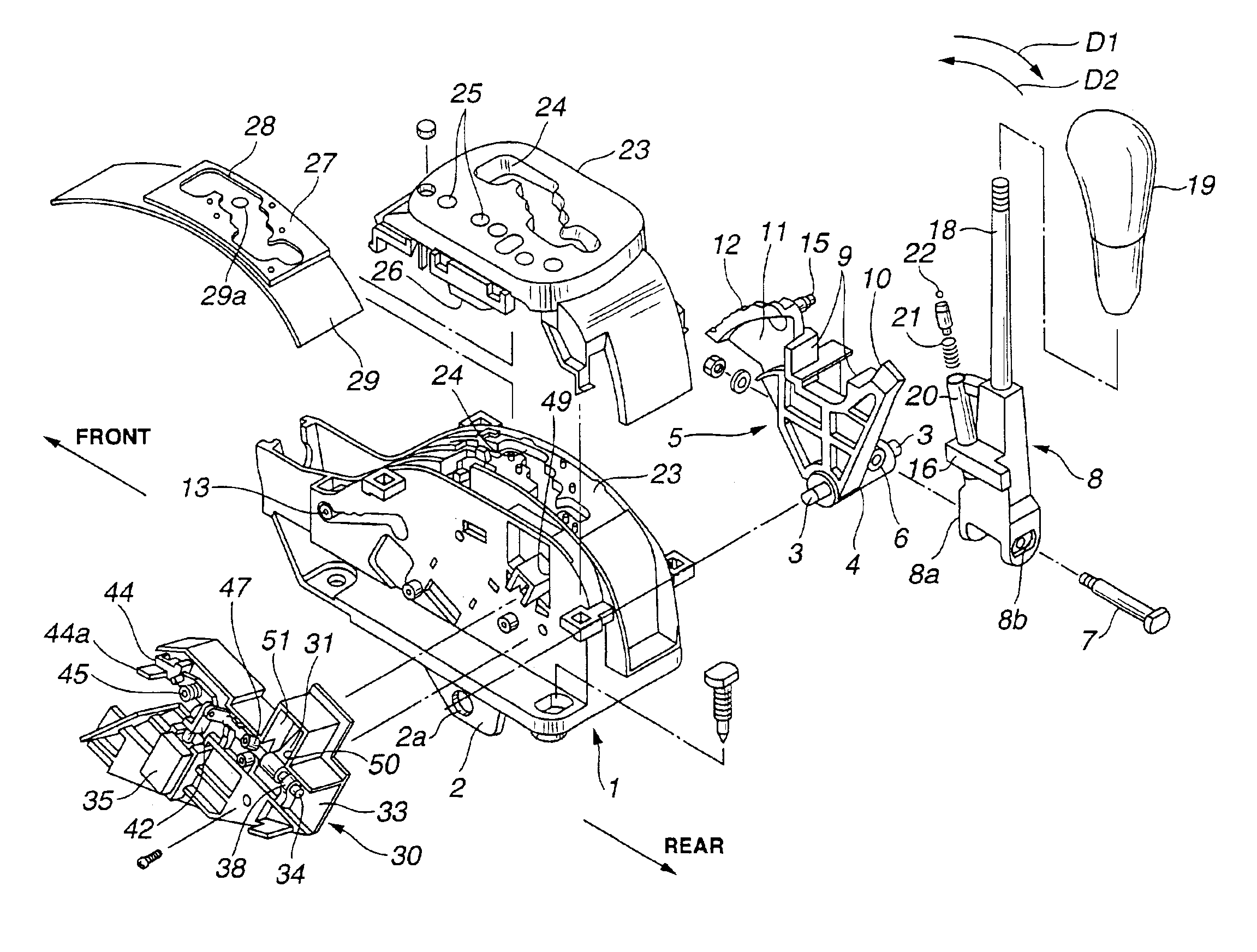

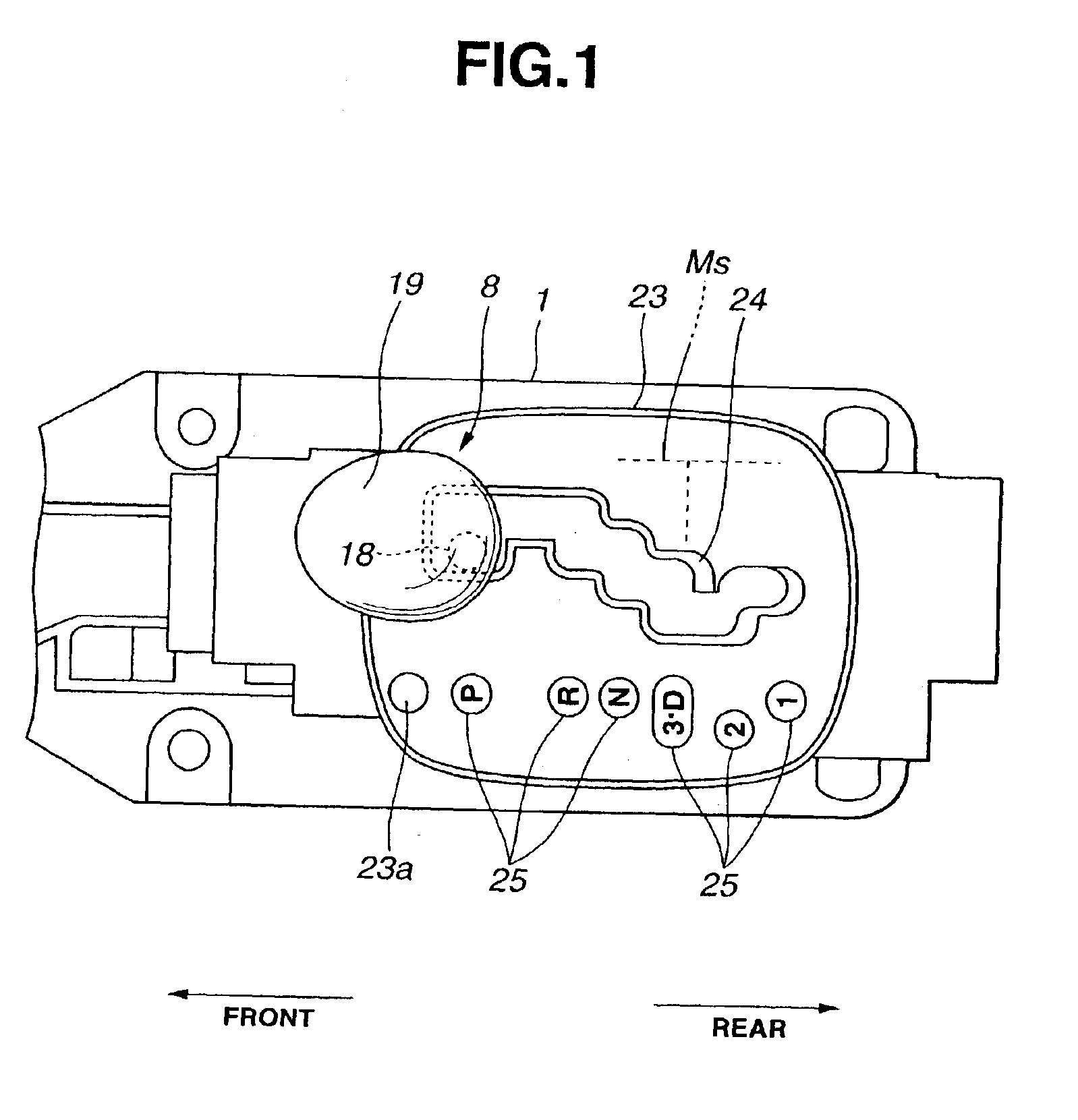

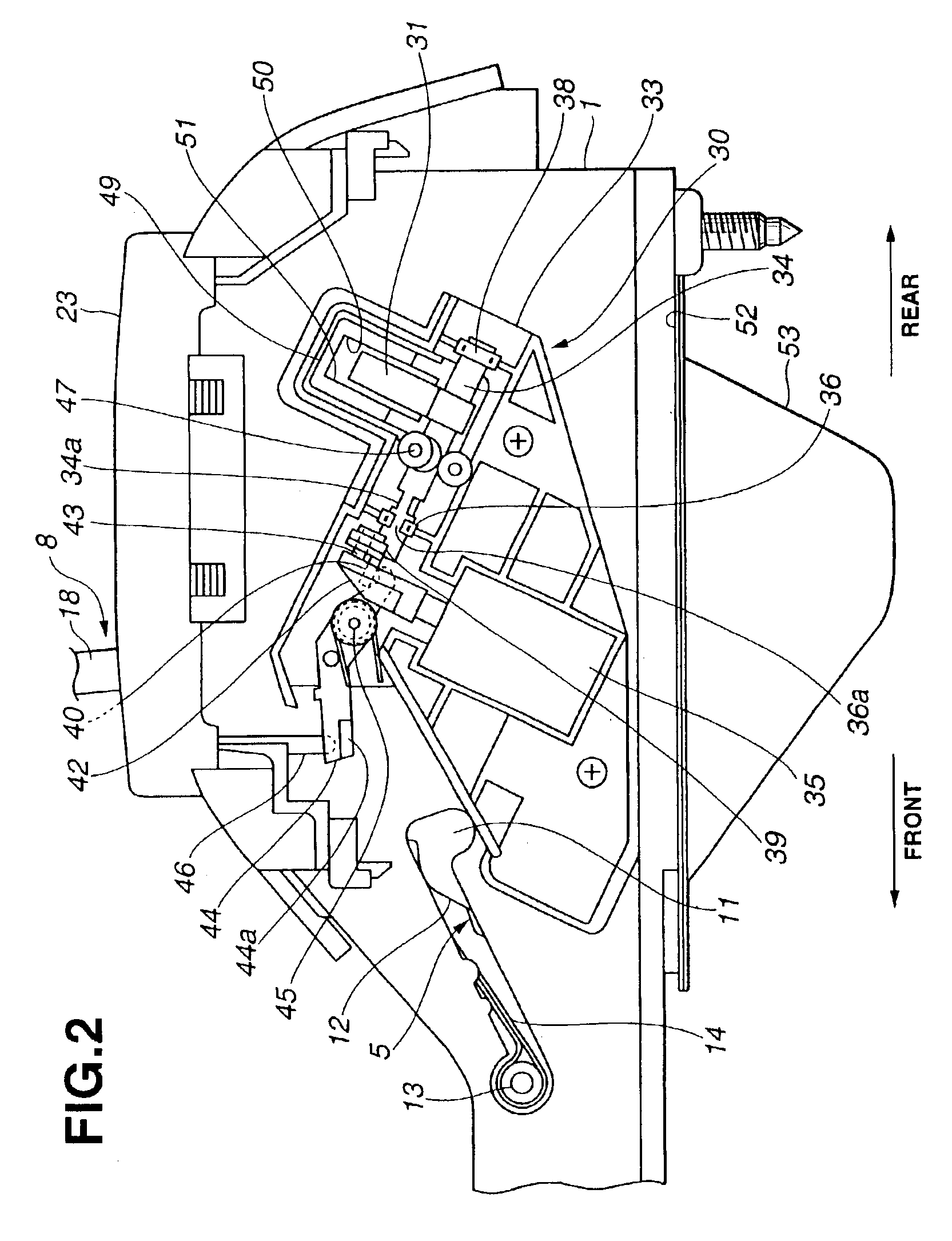

Shift lever device

InactiveUS6865967B2Robust constructionManual control with multiple controlled membersGearing controlEngineeringElectrical and Electronics engineering

Owner:FUJI KIKO CO LTD

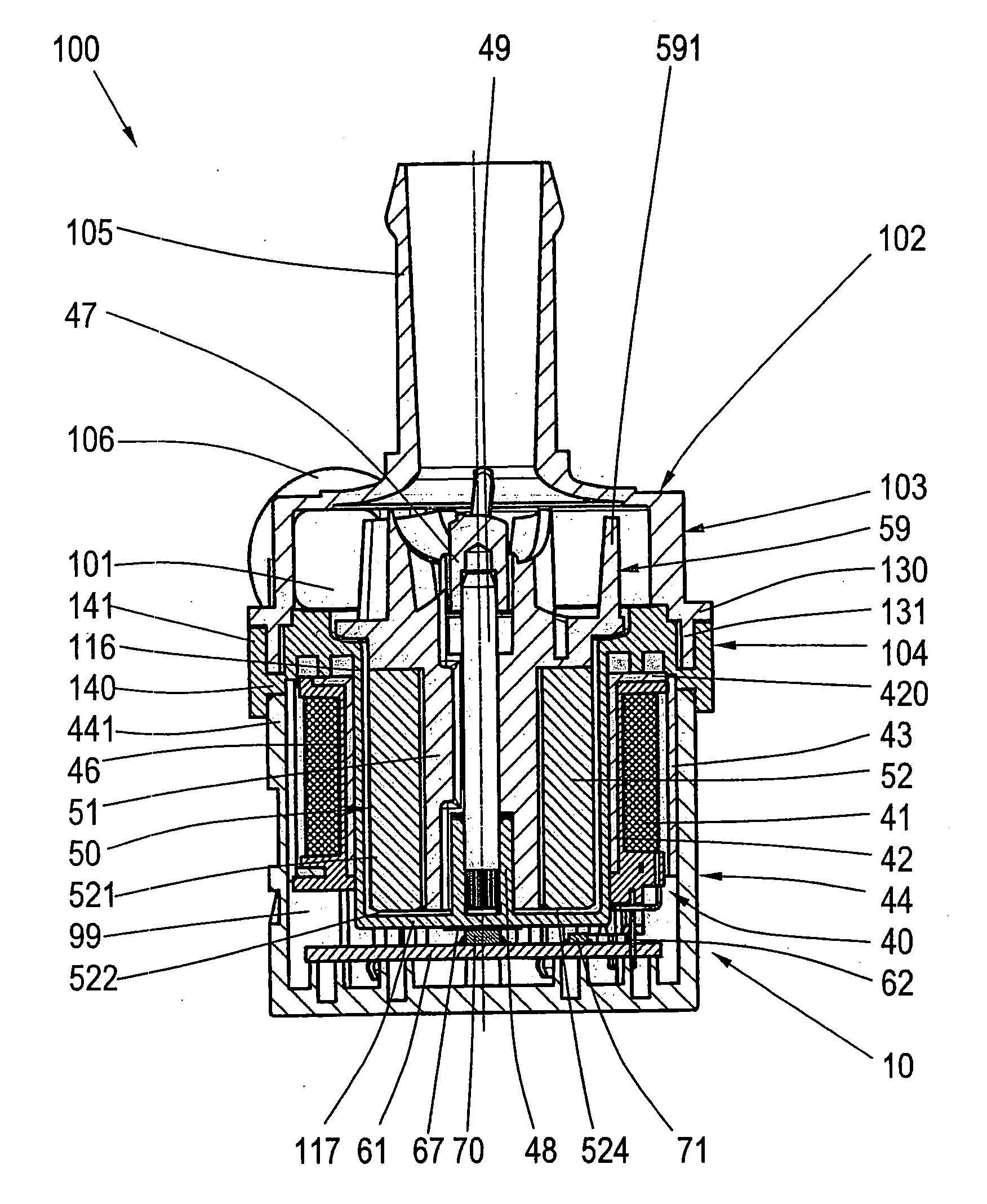

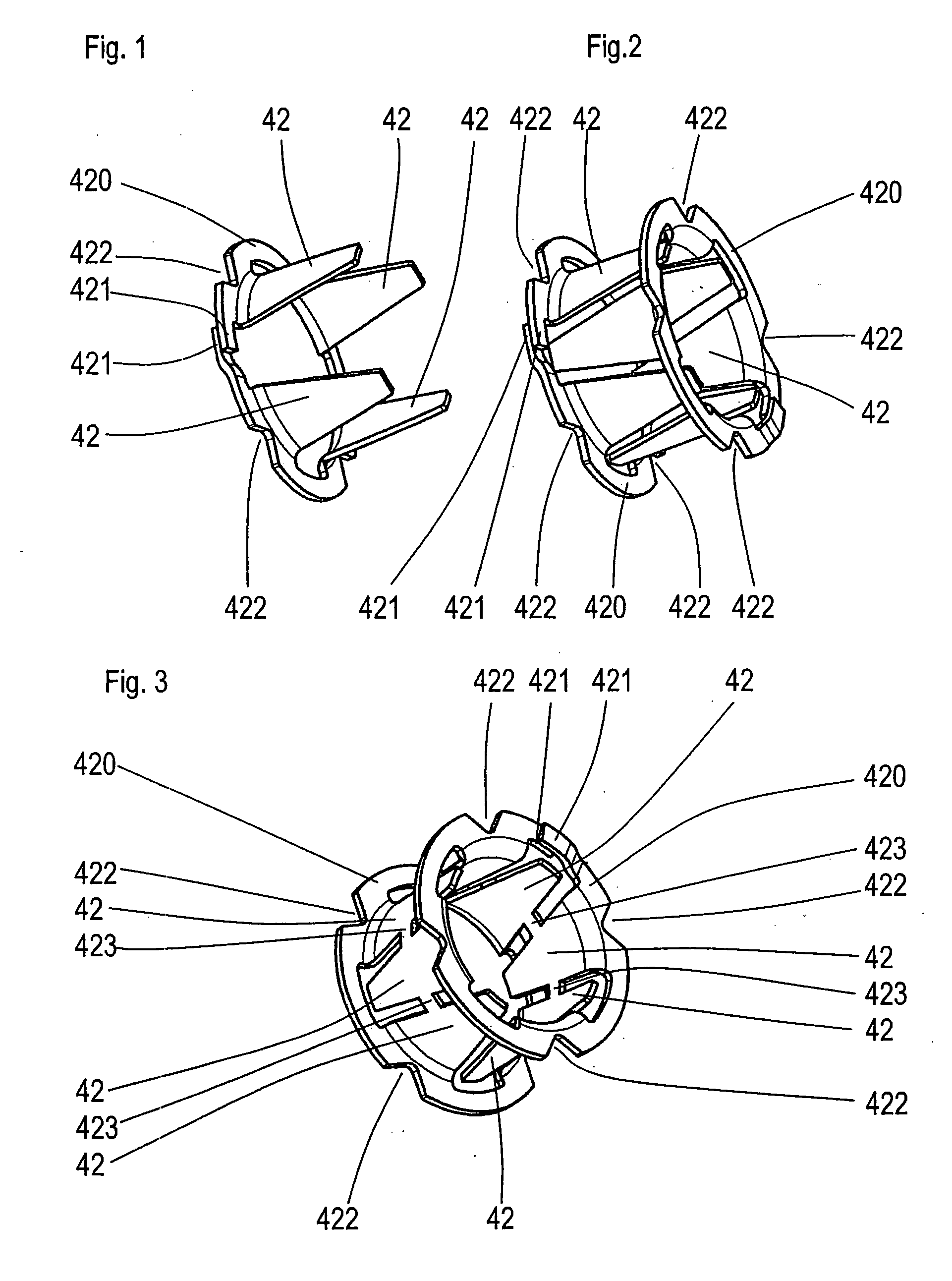

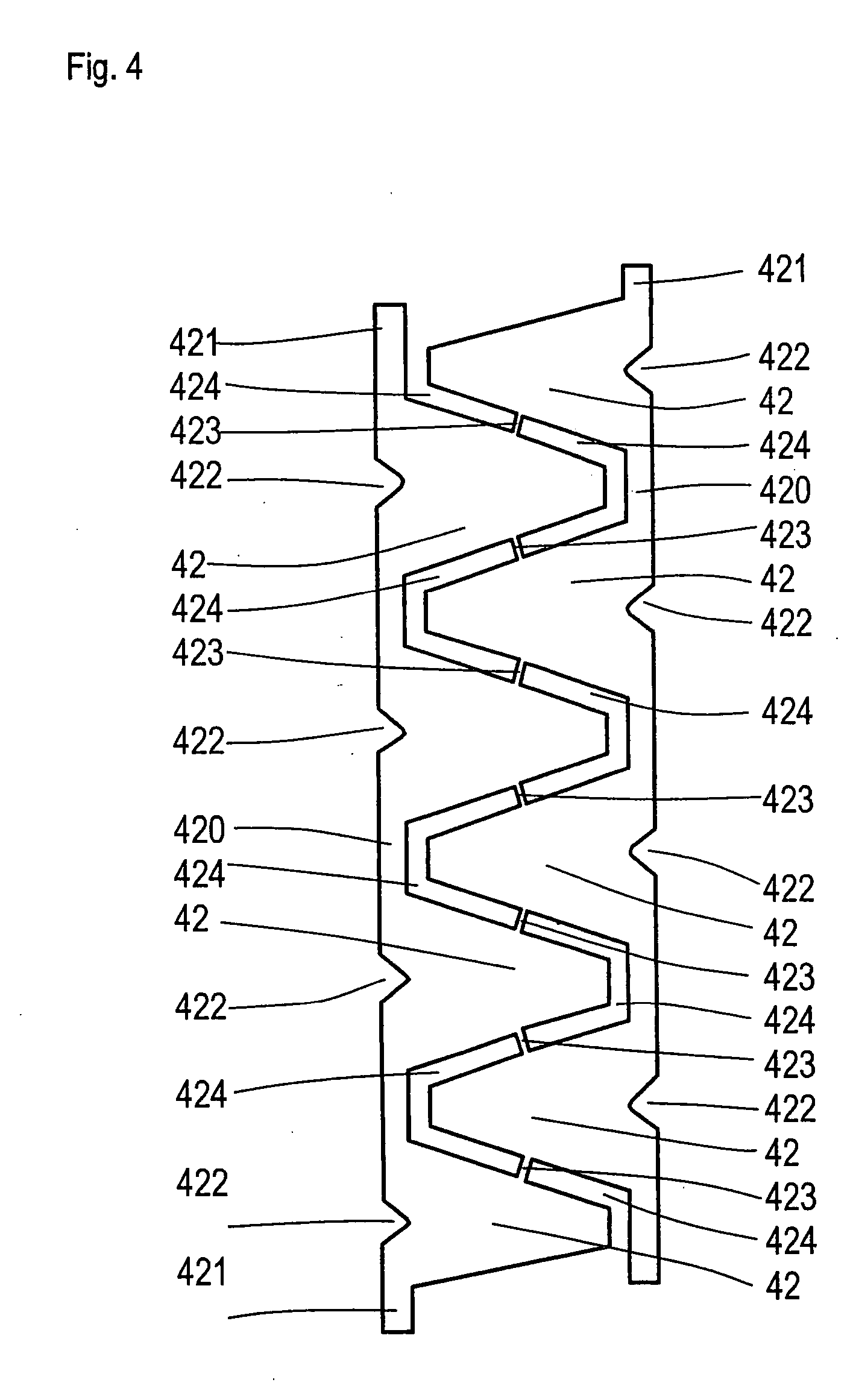

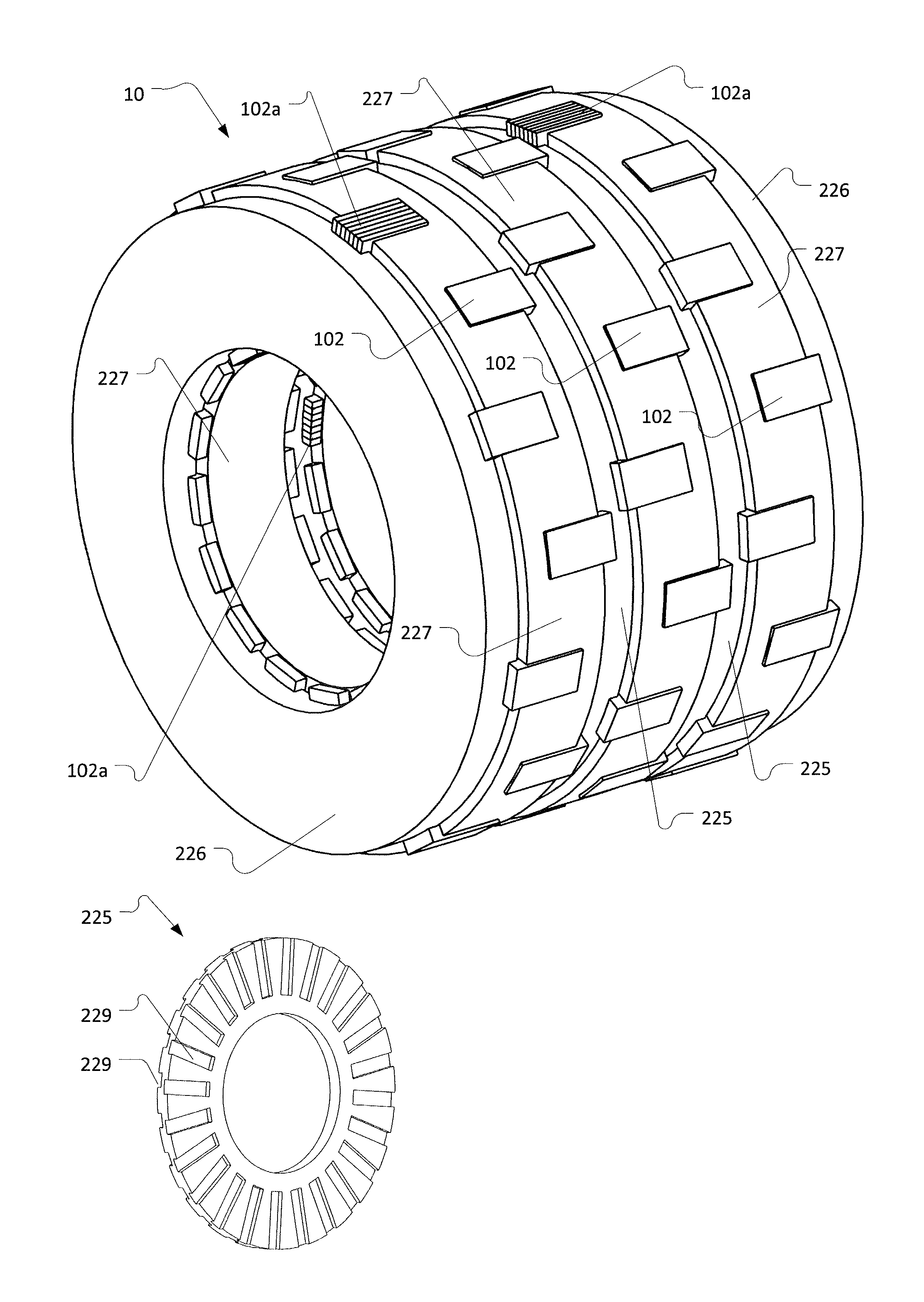

Electric motor

InactiveUS20070286753A1Easy to assembleRobust structureWindings insulation materialMagnetic circuit stationary partsPermanent magnet rotorConductor Coil

The invention relates to an electric motor comprising a permanent magnet rotor, which is supported rotationally about a central axis, a wound stator having a cylinder ring-shaped stator winding, claw poles, which are disposed perpendicularly to ring disc-shaped stator plates and around the central axis, and a cylinder jacket-shaped yoke ring, the length of the claw poles in the axially parallel direction being clearly greater than half the inner diameter of the stator. It is the object of the invention to provide an electric motor, in which the stator is composed of the least number of components, requires simple assembly and has a robust structure and optimum efficiency, thereby enabling greater design flexibility, usability of installation space and thus an economic construction. This objective is solved according to the invention in that the magnetically conductive part of the stator comprises a cylinder jacket-shaped yoke ring and two ring disc-shaped stator plates, the stator plates are each designed as a single piece with a plurality of claw poles and the ring disc-shaped stator plates comprise ends, which are connected to one another.

Owner:BUHLER MOTOR GMBH

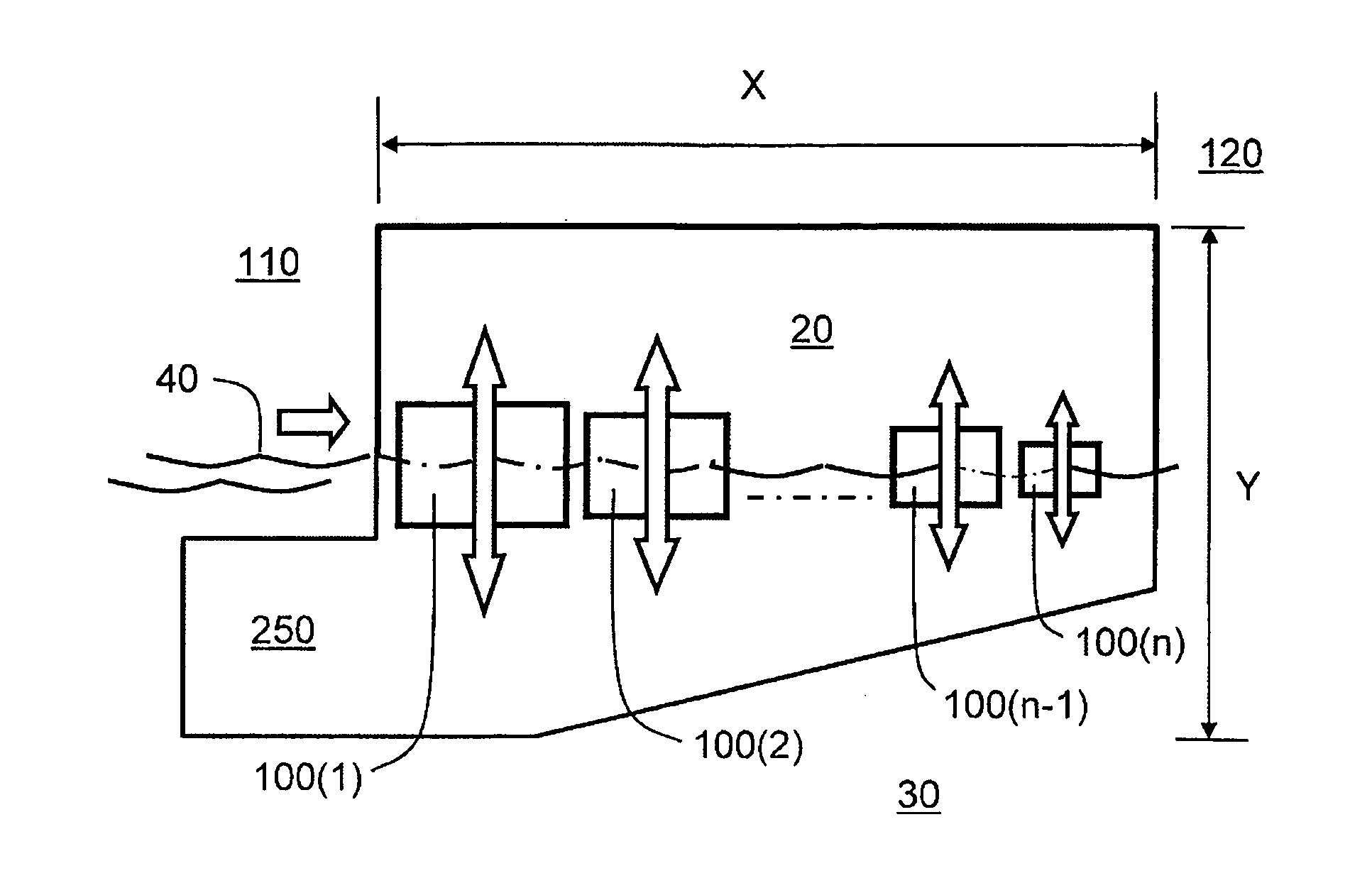

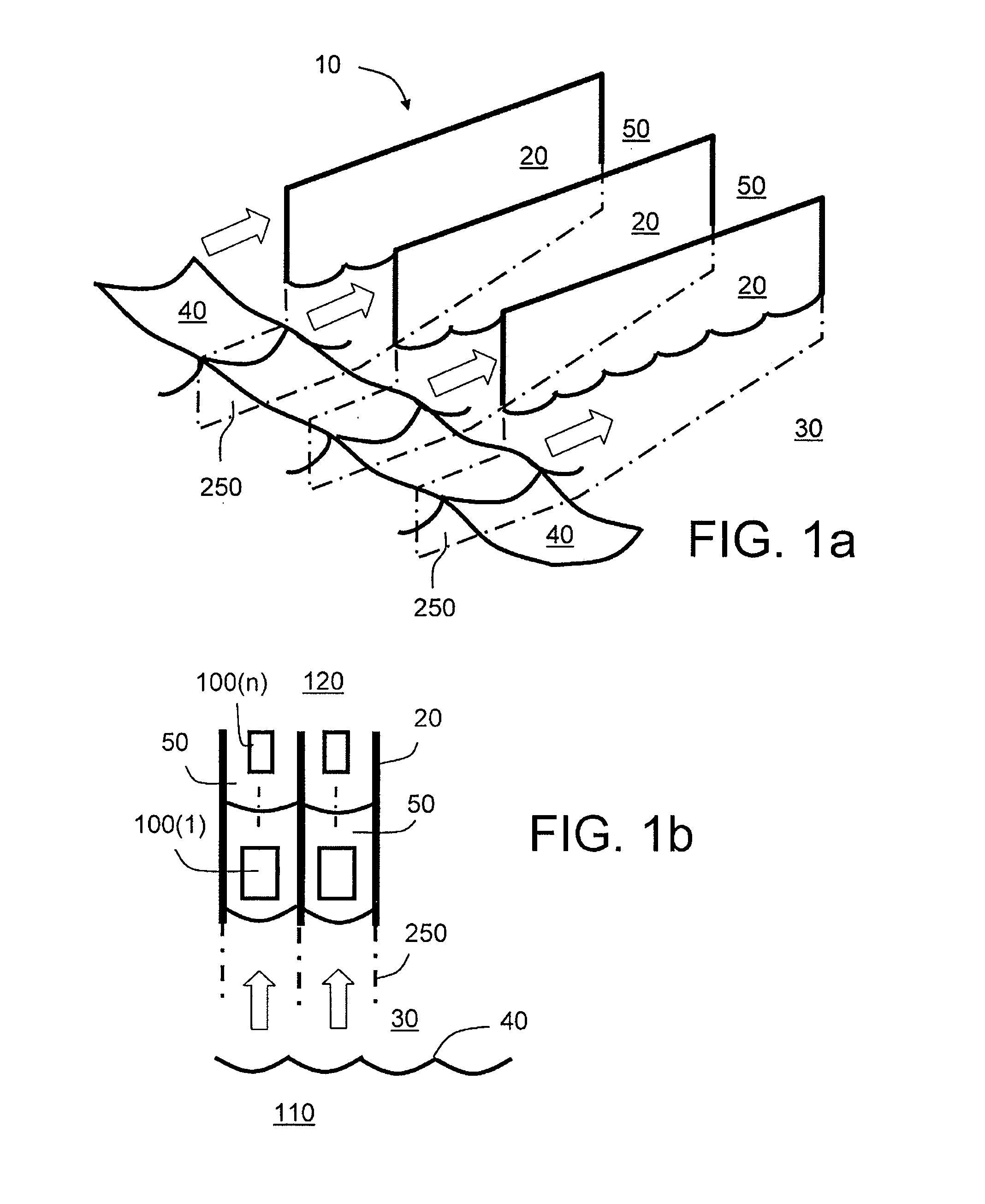

Energy System

InactiveUS20110187102A1Robust constructionThe method is simple and efficientWind motor with solar radiationWind energy with water energySea wavesAbsorbed energy

An ocean wave energy system is for generating power from ocean waves. The system comprises wall components defining one or more channels for guiding propagation of ocean waves therealong. Each channel has a first end for receiving the ocean waves and a second end remote from the first end. A float arrangement is disposed along each of the one or more channels between its first and second ends. Moreover, the float arrangement being arranged in size to progressively absorb energy from the ocean waves commencing with longest wavelength components in the waves and finishing with shortest wavelength components in the waves. The ocean wave energy system is capable of extracting energy efficiently and conveniently from ocean wave motion.

Owner:OCEAN WAVE ROCKER

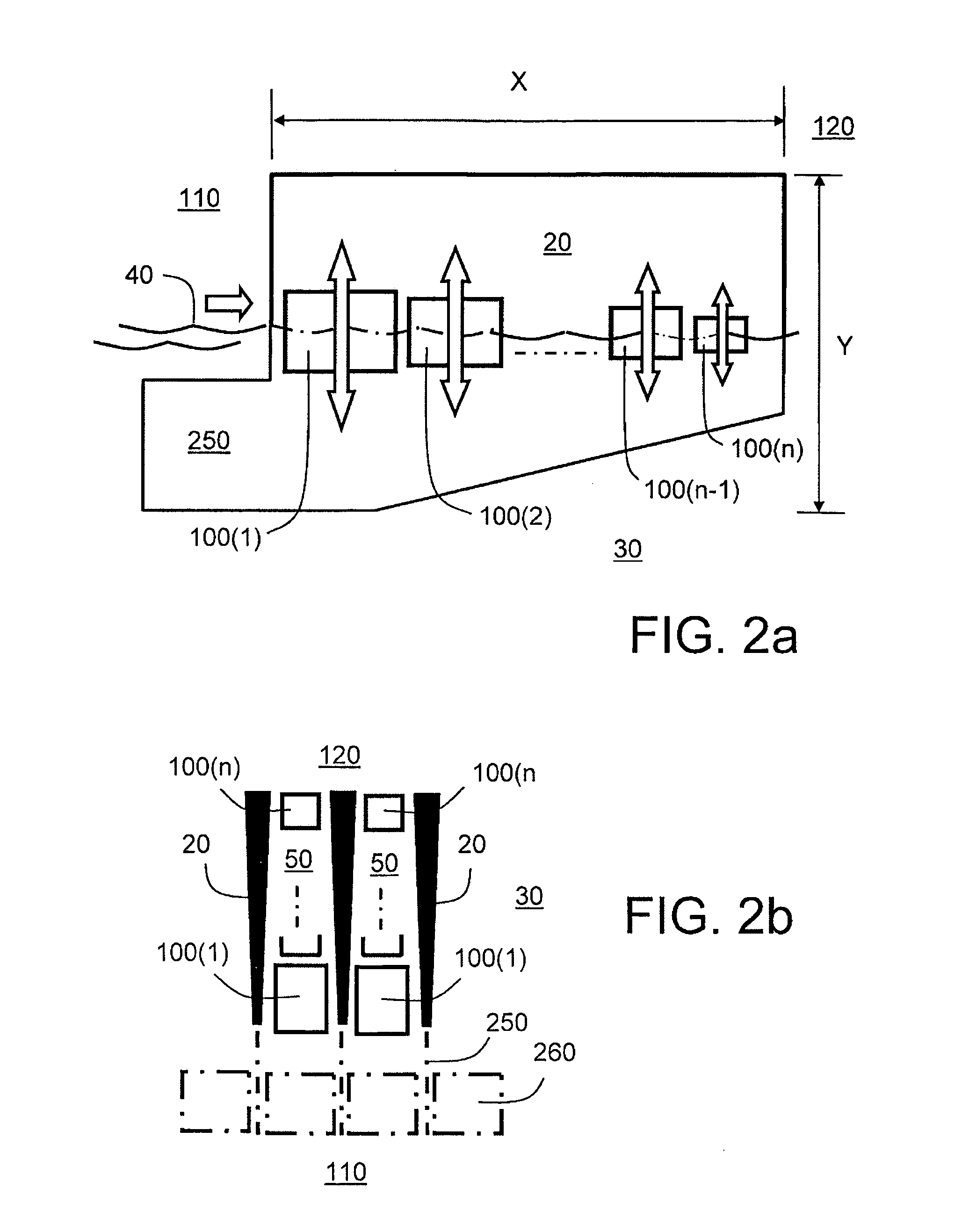

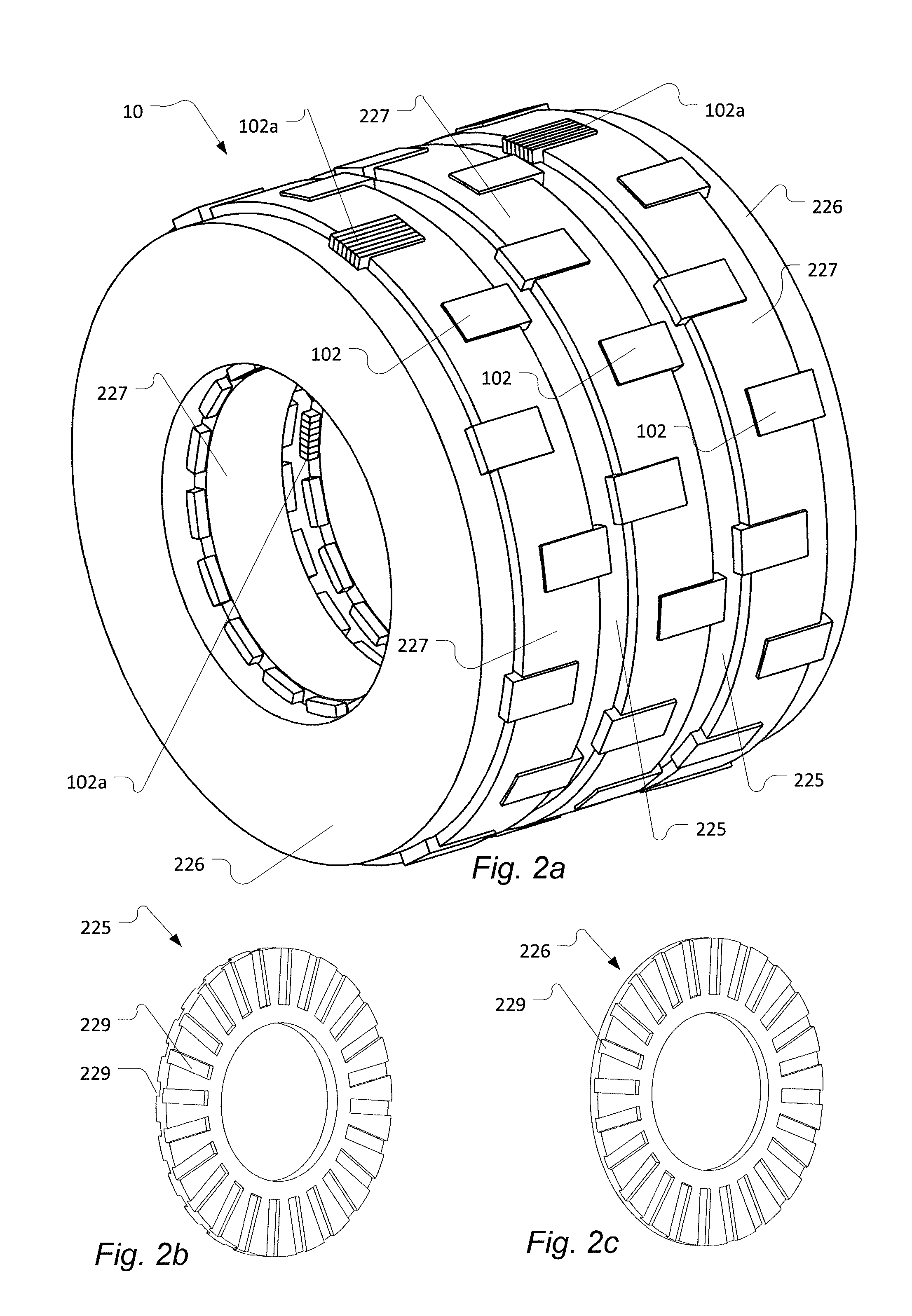

Stator and rotor for an electric machine

InactiveUS20150048708A1Robust constructionEasy constructionMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineCore component

A stator for an electric machine, the stator including a stator core and a winding. The stator core including an annular stator core back component providing a magnetic flux path in a circumferential direction and in an axial direction of the annular stator core back component; and a plurality of stator pole components each including a mounting part mounted to the stator core back component, an interface part defining an interface surface facing an active air gap between the stator and a rotor of the electrical machine; and a radially oriented tooth part extending radially from the annular stator core component and connecting the interface part with the mounting part.

Owner:HOGANAS AB

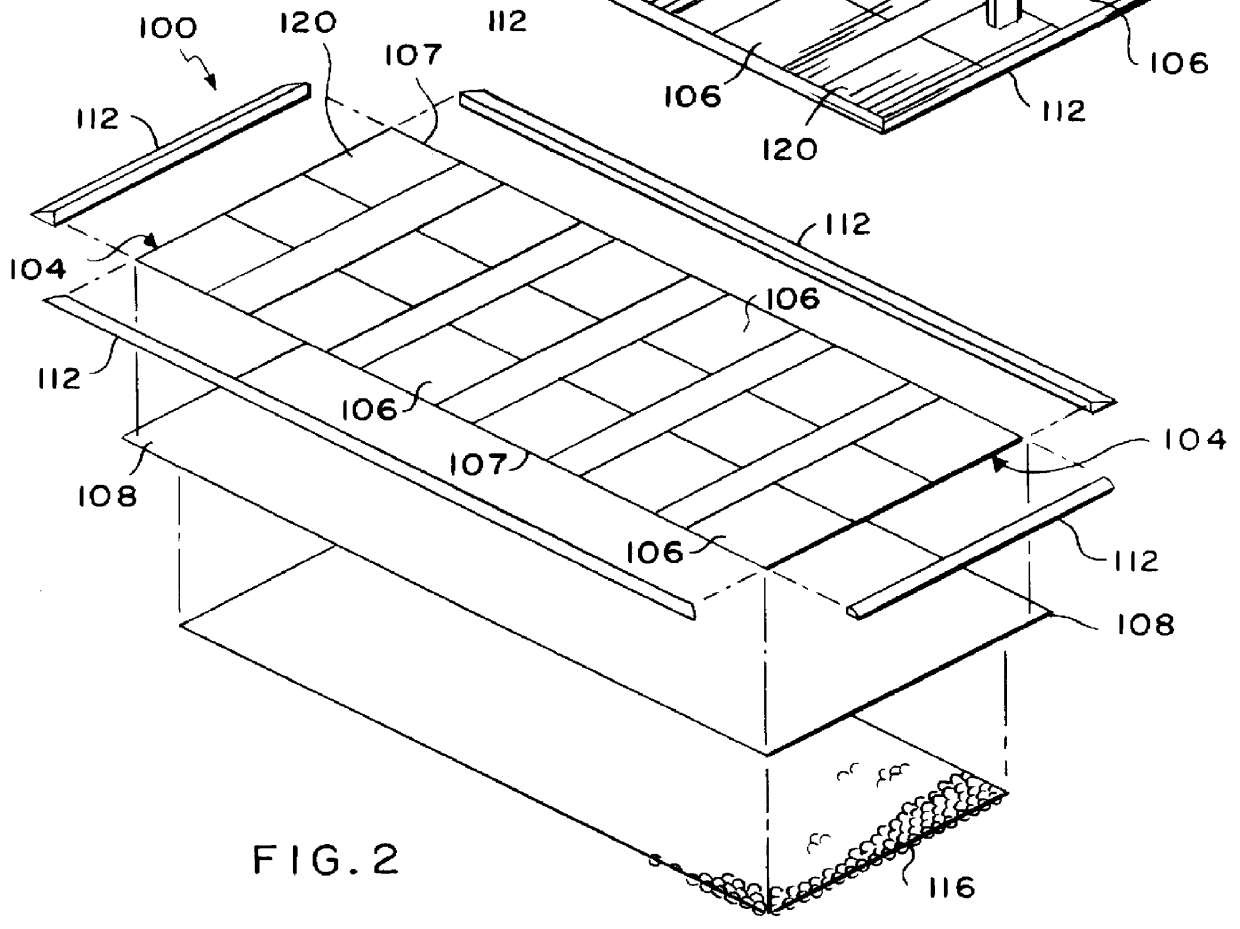

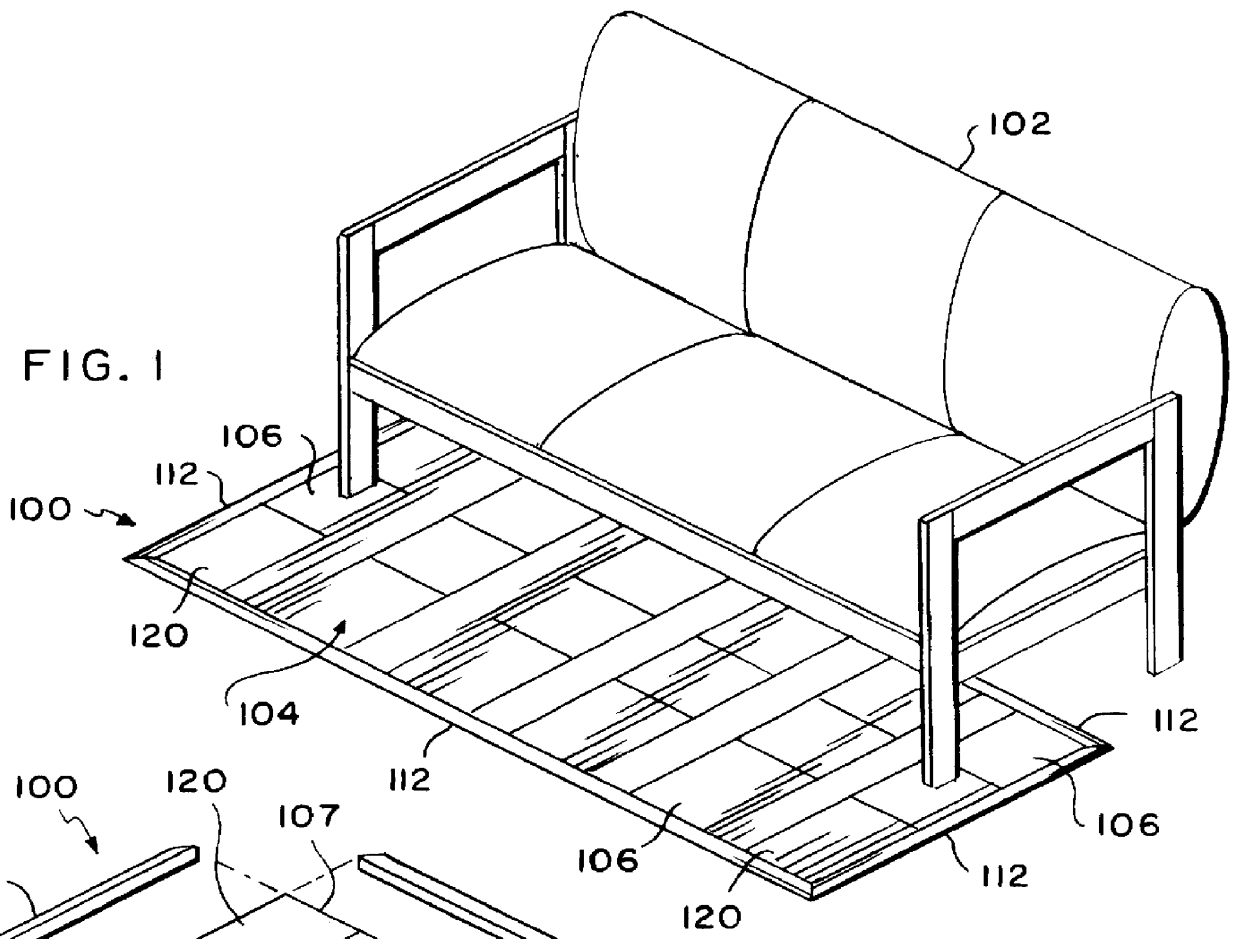

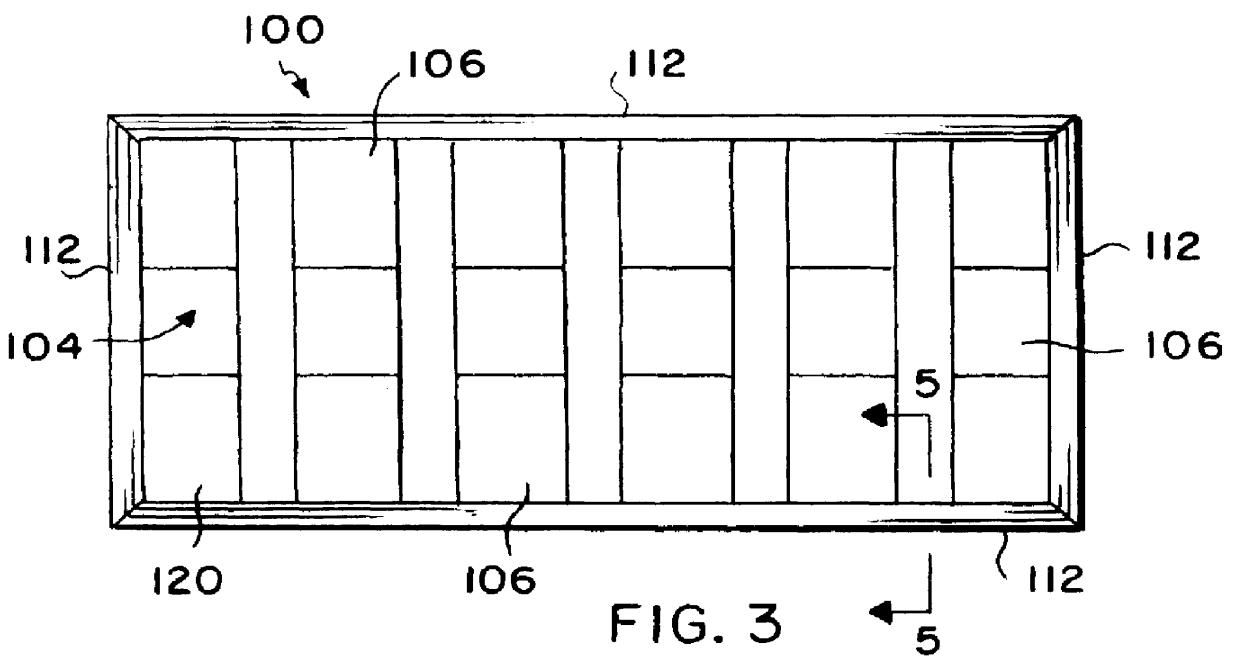

Portable area floor covering and method

InactiveUS6068904ARobust constructionSimple interfaceTreadsSynthetic resin layered productsWood veneerEngineering

A portable area floor covering and method is directed to a floor covering that is durable yet sufficiently flexible to facilitate portability, exhibits a robust construction and a very attractive and aesthetically pleasing appearance for use in residential and commercial environments. In its most fundamental embodiment, the portable area floor covering comprises a construction including a durable, flexible sheet layer formed of a plurality of sheet sections wherein each sheet section includes a plurality of outer edges. A flexible base layer is affixed to a bottom side of each of the sheet sections to form a backing for the durable, flexible sheet layer. A border reducer is fused to the flexible base layer and to the outer edges of the sheet sections. The border reducer is wedge-shaped which facilitates interfacing with a floor surface. Finally, a padding layer is secured to a bottom side of the flexible base layer to provide cushioning to the entire portable area floor covering. In lieu of the multiple sheet sections, the flexible sheet layer can be formed from a single continuous sheet section.

Owner:WESTLING DESIGN

Electronic seal with radio frequency identification

InactiveUS7696886B2Beautiful appearanceRobust constructionStampsBurglar alarm by hand-portable articles removalElectrical conductorEngineering

Owner:ALEXAN

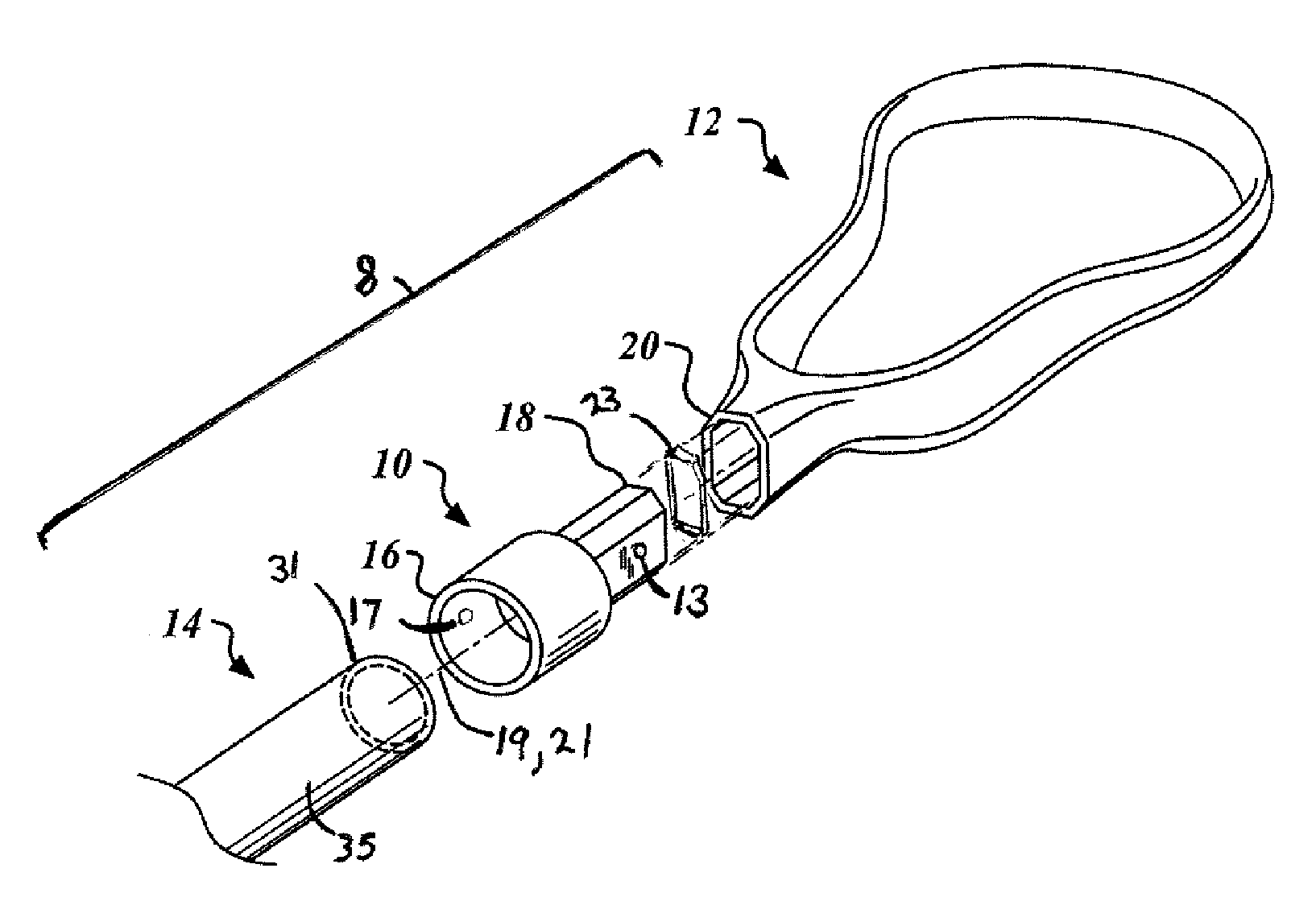

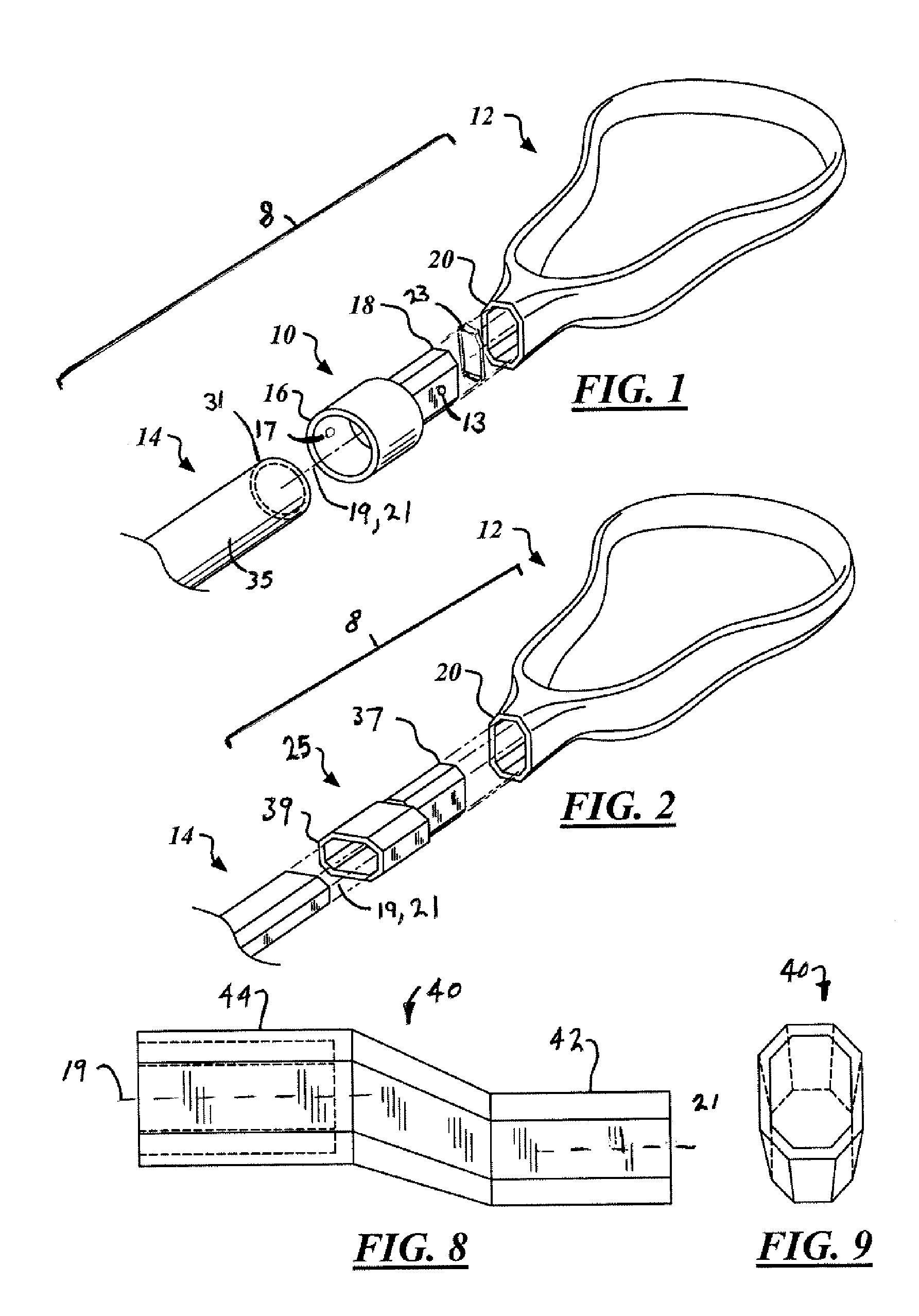

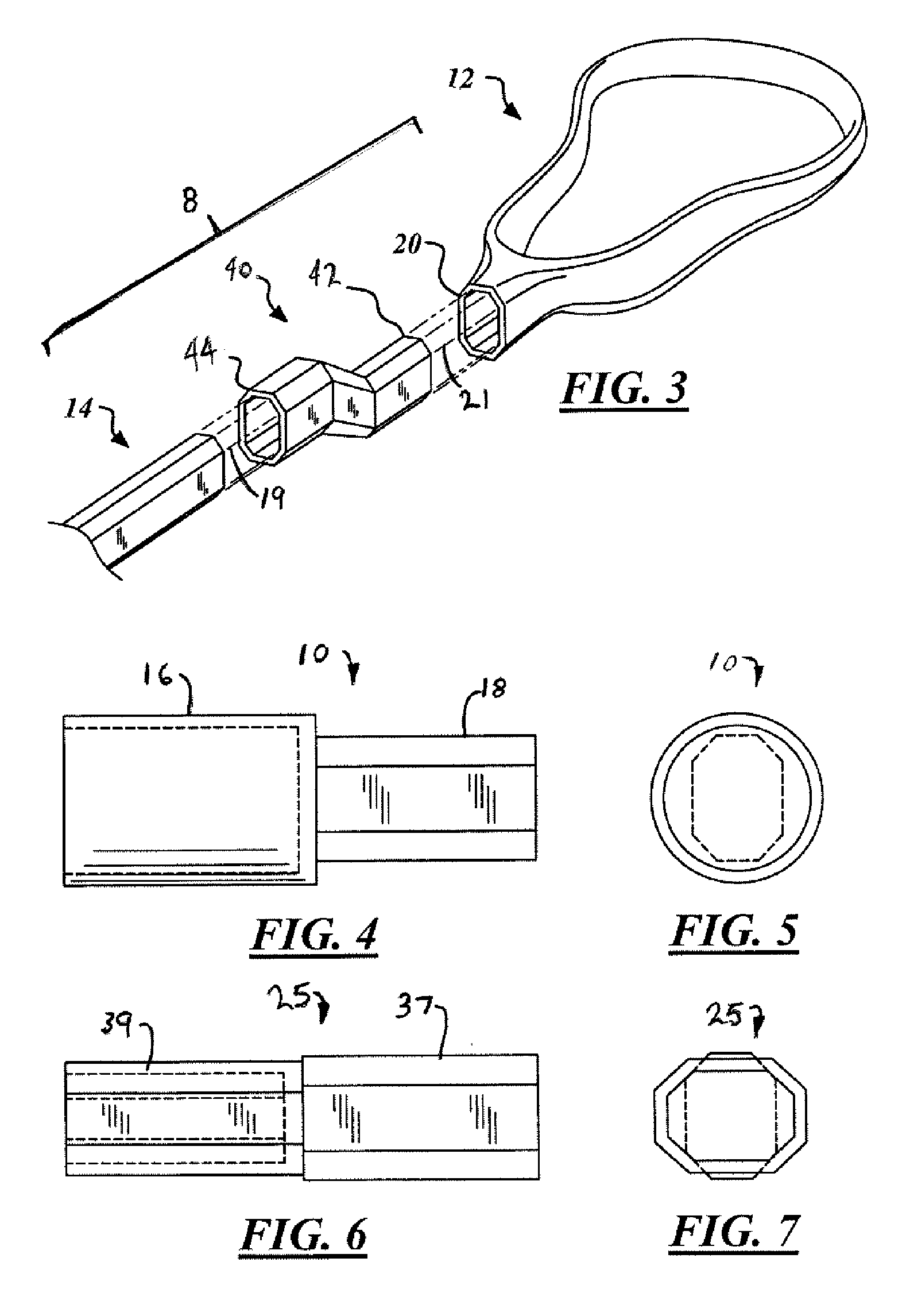

A coupling for attaching a lacrosse head to a lacrosse handle

A coupling for a lacrosse stick having a lacrosse handle and a lacrosse head includes a handle-mating portion receiving a portion of the lacrosse handle. The coupling also includes a head-mating portion sized for reception within a receiving portion of the lacrosse head. The head-mating portion couples to the handle-mating portion such that the handle-mating portion extends away from the head-mating portion.

Owner:WARRIOR LACROSSE

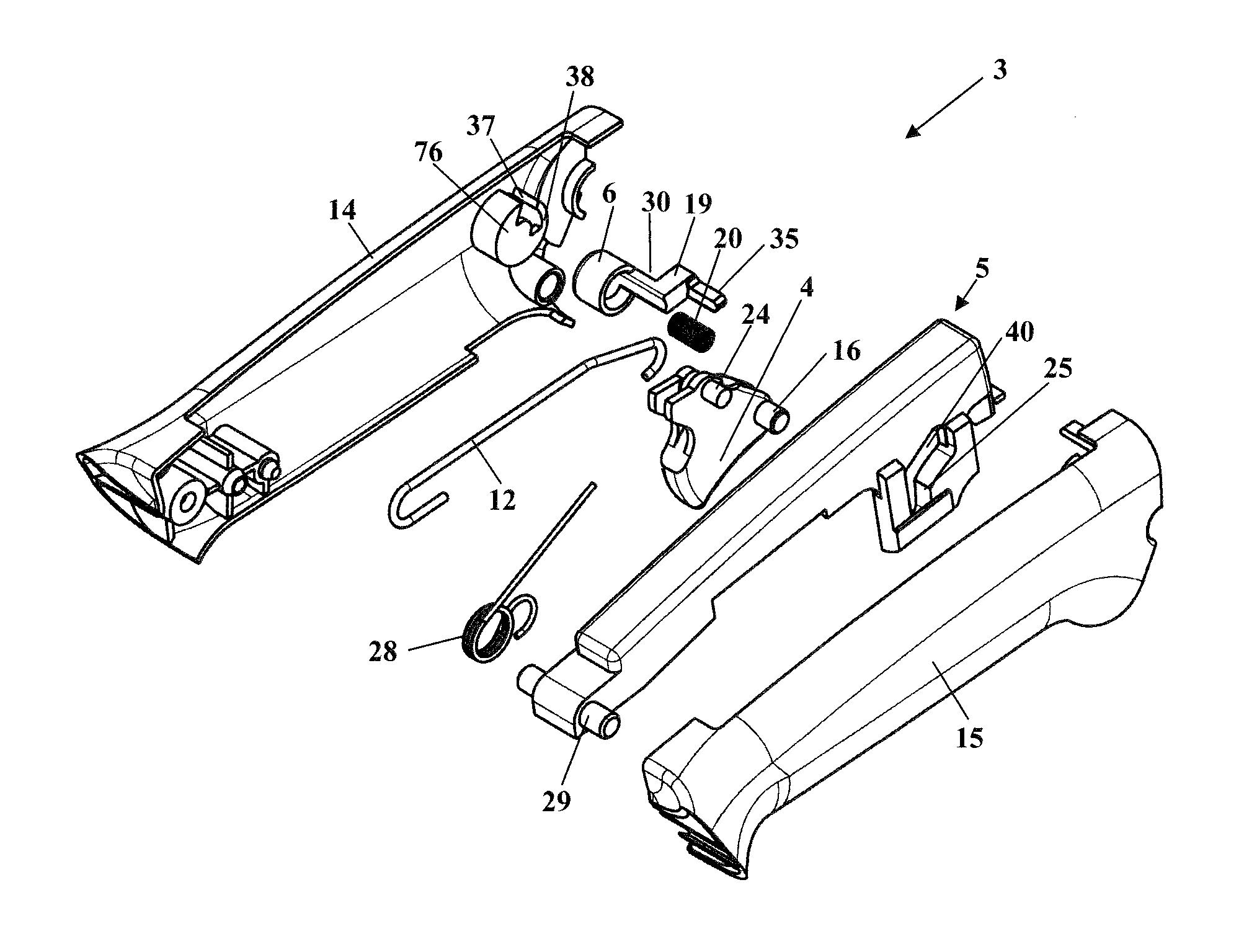

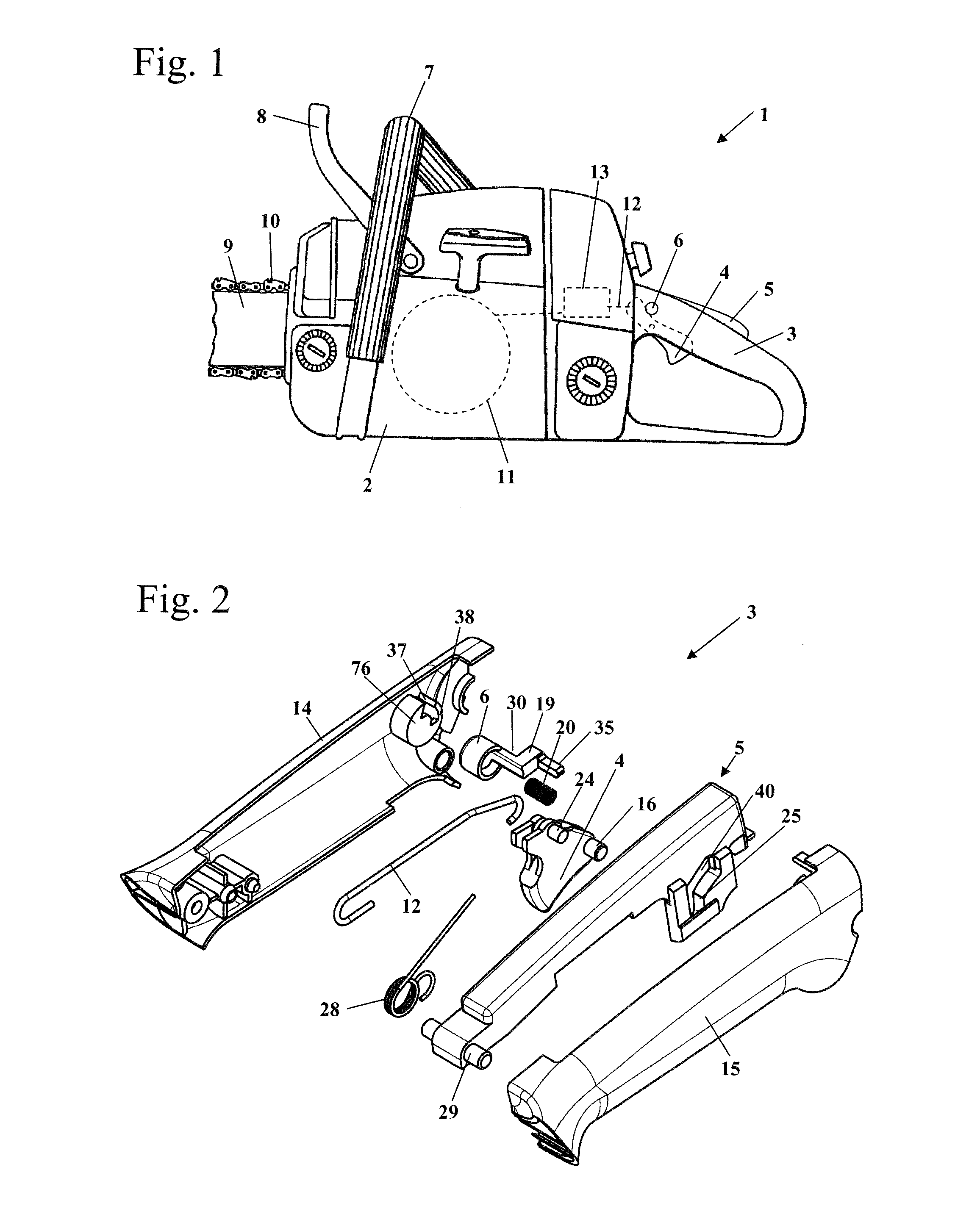

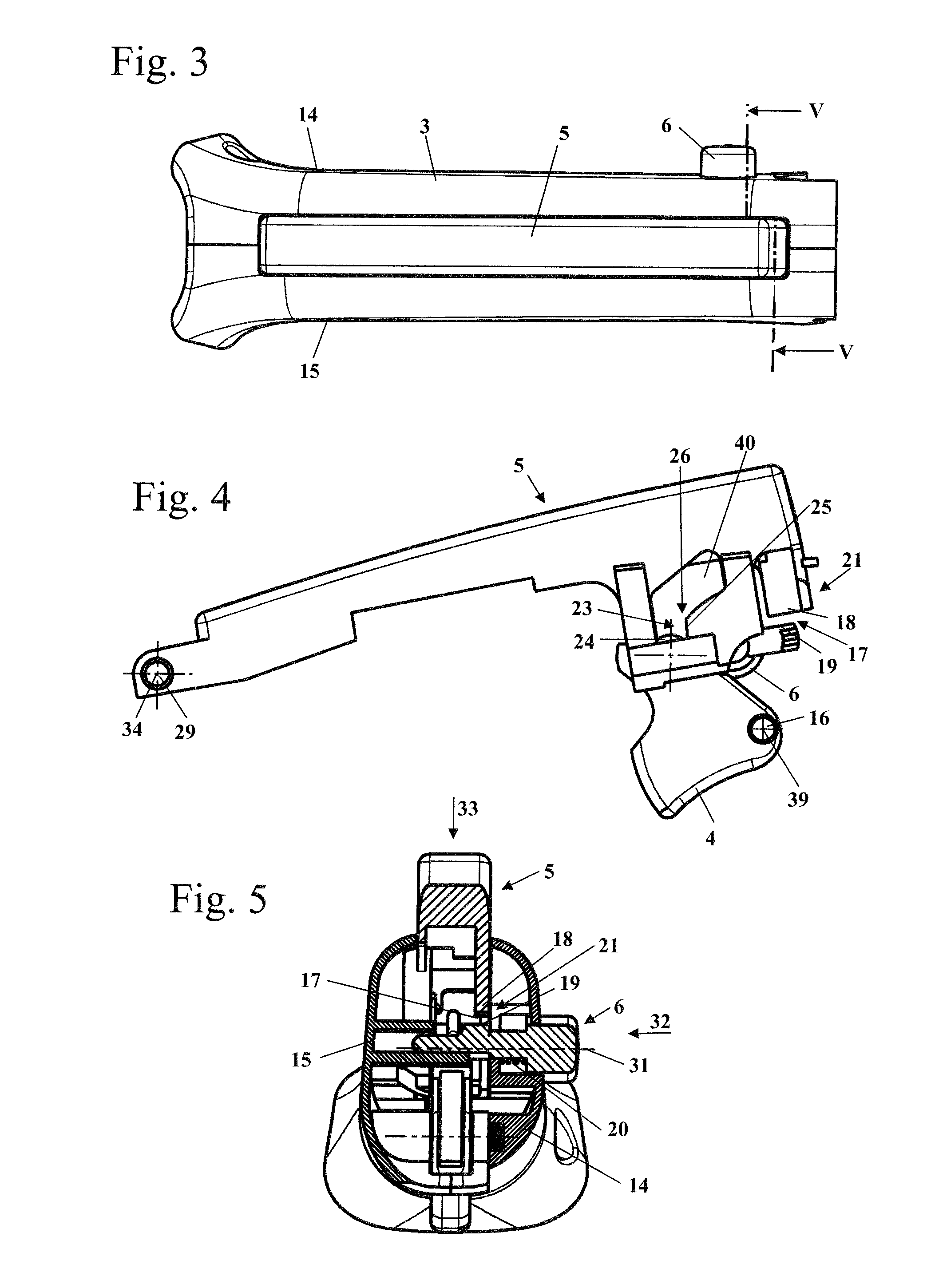

Handheld work apparatus having a drive motor for driving a work tool and method for operating said apparatus

ActiveUS20140174772A1Easy to operateSimple designOperator-supported drilling machinesChain sawsSoftware engineeringHand held

A handheld work apparatus has a drive motor for driving a tool, an operating element for operating the drive motor, a first inhibiting unit and a second inhibiting unit. Each inhibiting unit has a disable state and an enable state. The operating element is inhibited for operating the drive motor when at least one of the inhibiting units is in its disable state. The work apparatus further has a locking device which locks the first inhibiting unit in its enable state if the second inhibiting unit is in its enable state. A method for operating the work apparatus provides that the first inhibiting unit is locked in its enable state when the first inhibiting unit and the second inhibiting unit are situated in their enable states at the same time.

Owner:ANDREAS STIHL AG & CO KG

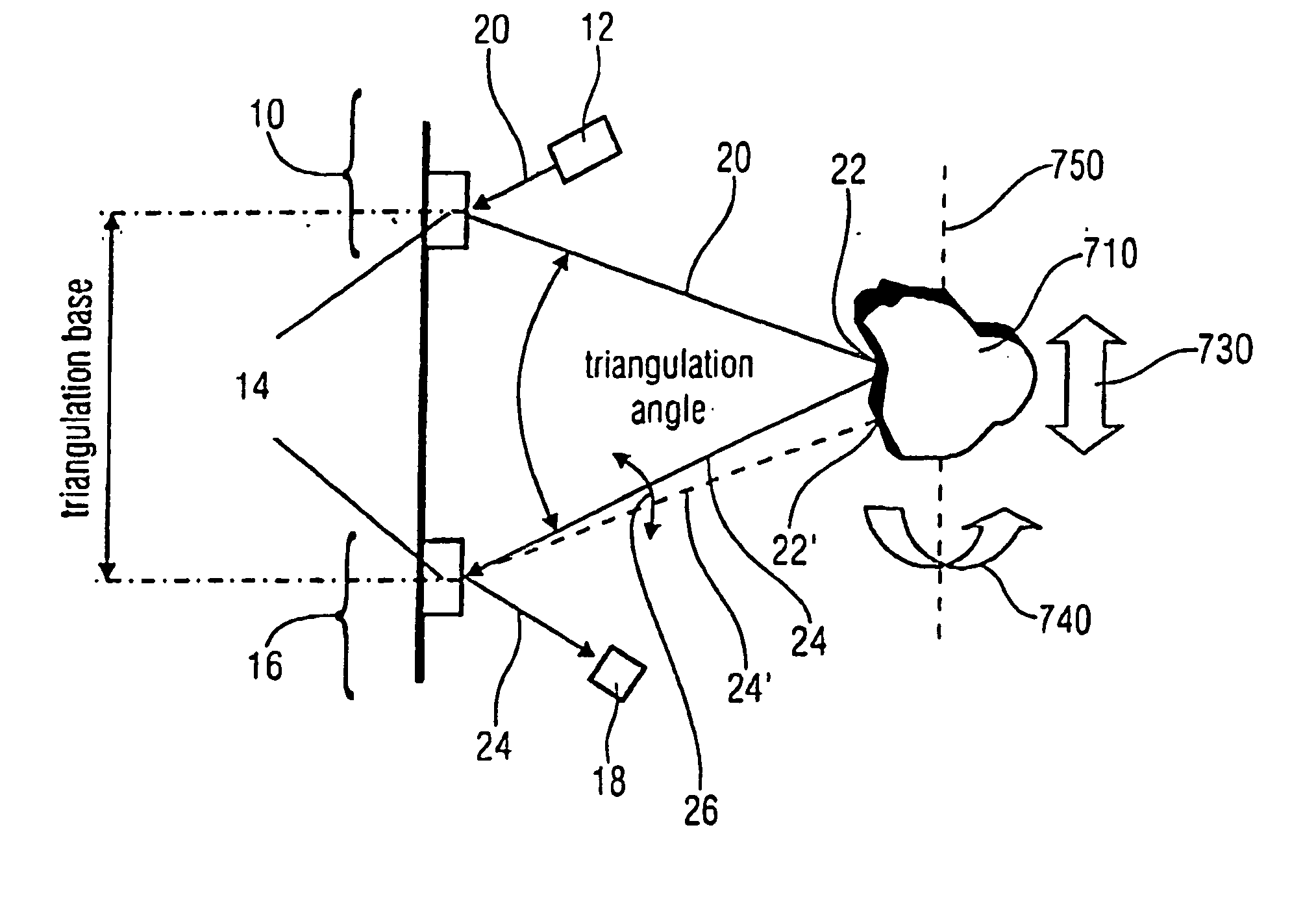

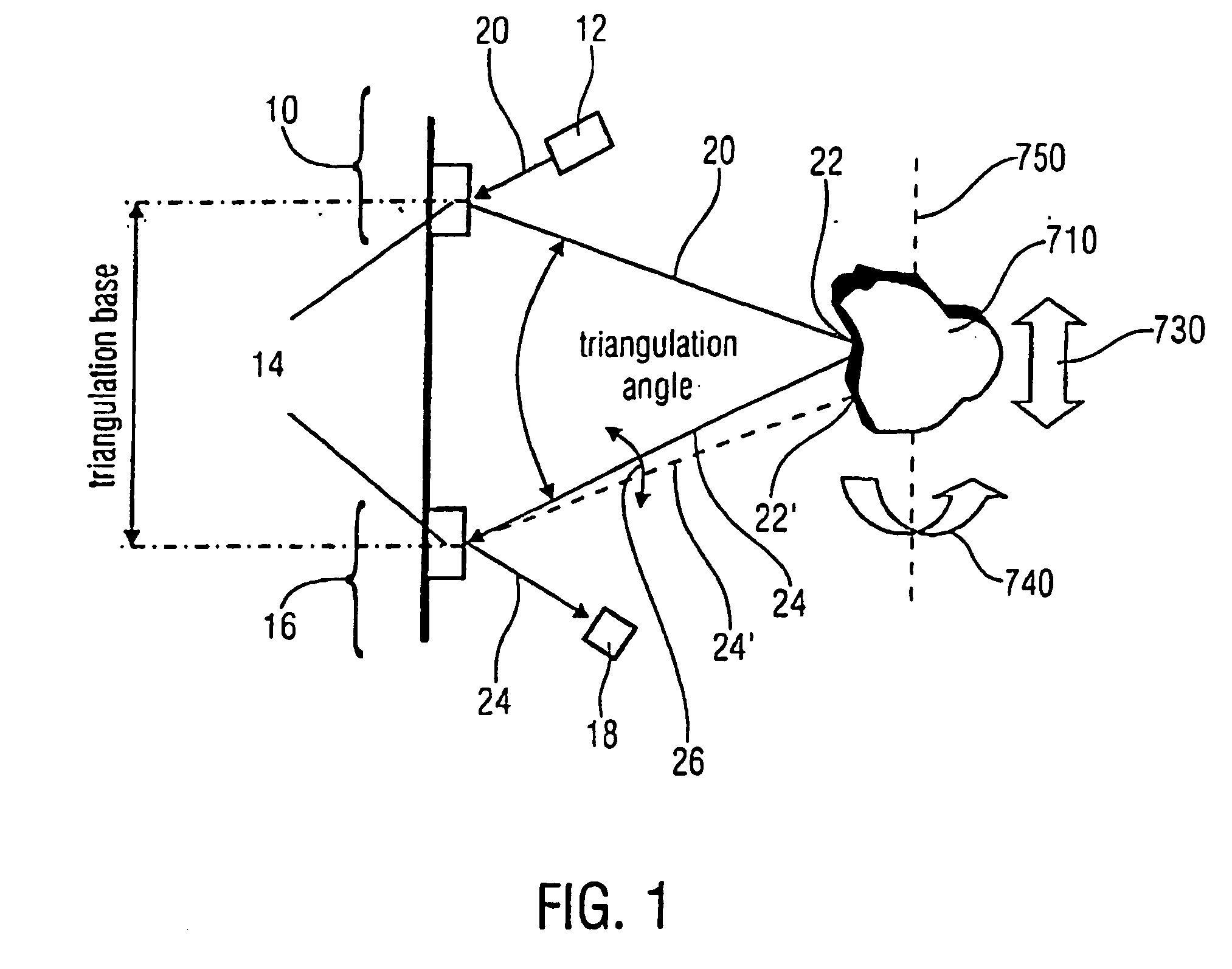

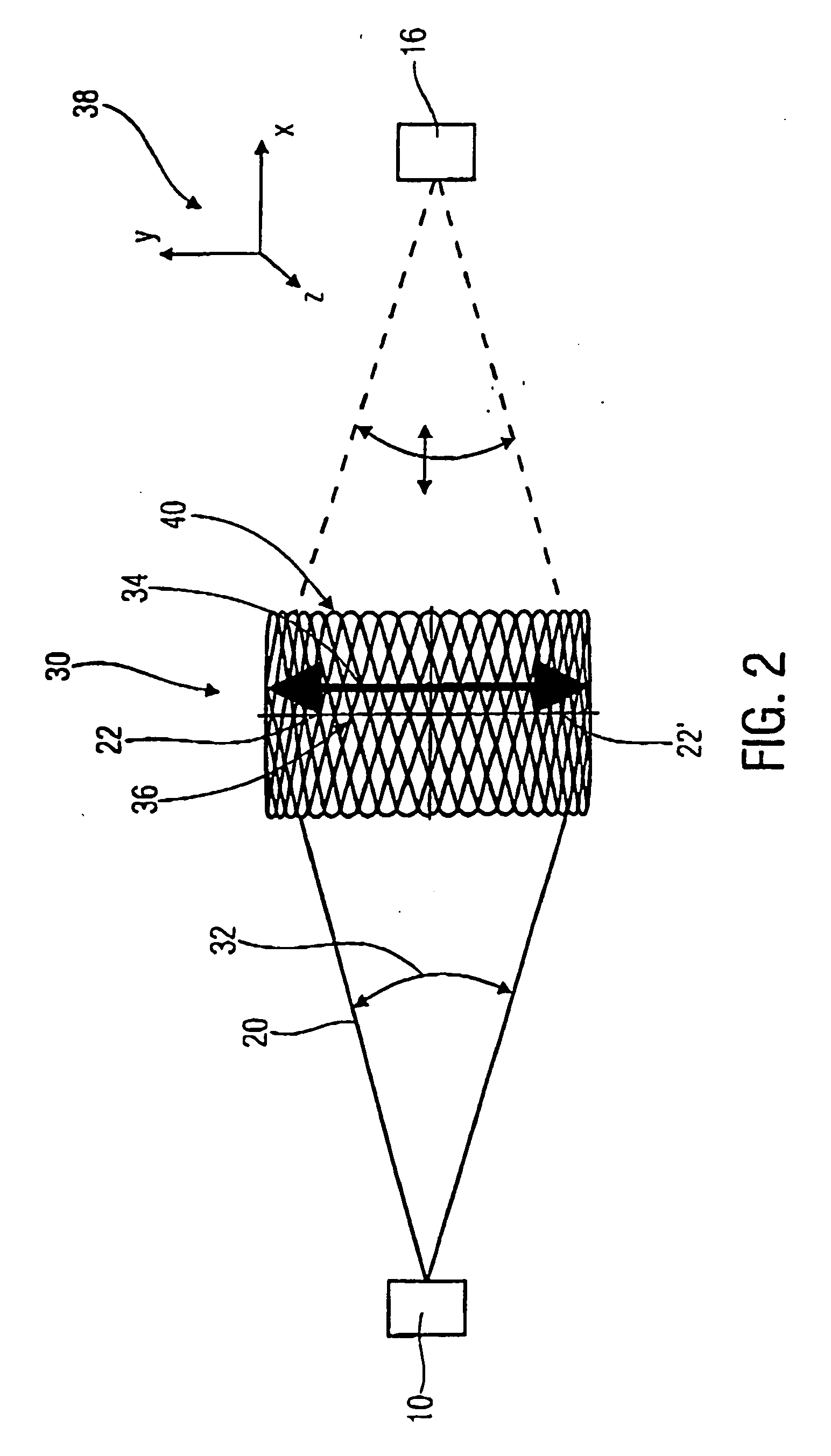

Scanner and method for operating a scanner

ActiveUS20060158662A1Manufacturing cost be reduceRobust constructionMirrorsCharacter and pattern recognitionSurface reliefLight beam

A scanner for providing a possibility of detecting a surface relief of an object includes a projector configured to guide a light beam in an illumination line over the surface relief to obtain an illuminated location on the surface relief, the projector being further configured to output a projection signal from which a position of the light beam in the illumination line is derivable. Additionally, the scanner includes a collector having a collector micro mirror stimulatable to oscillate in two dimensions and a point-shaped light detector, the collector micro mirror being oscillatingly arranged in a first direction of the illumination line and in a second direction differing from the first direction such that a reflection of the illuminated location within a scan area of the micro scanner mirror is imagable by it onto the point-shaped light detector, and the collector being configured to output a detection signal from which a position of the illuminated location in the first and second directions is derivable.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

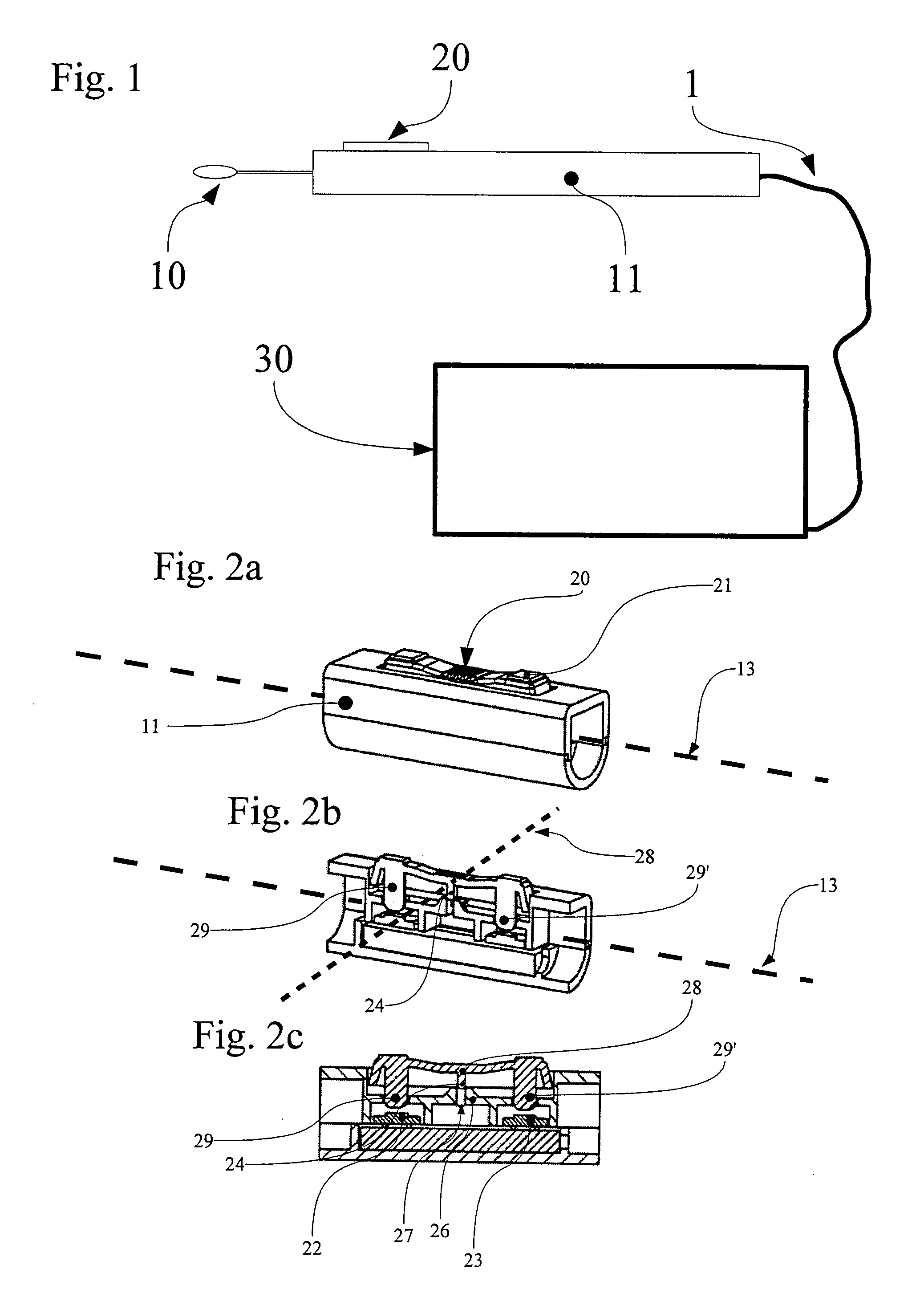

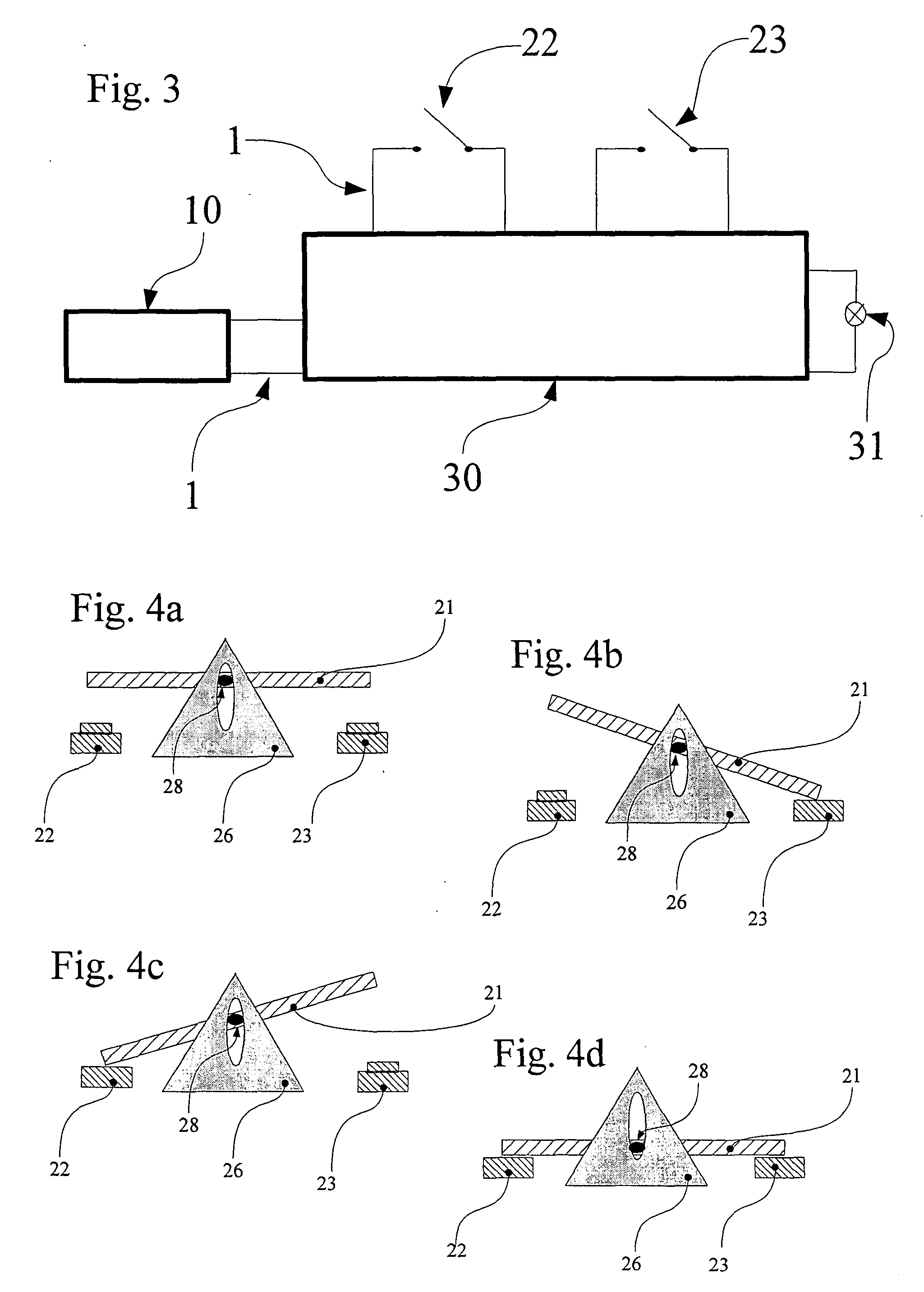

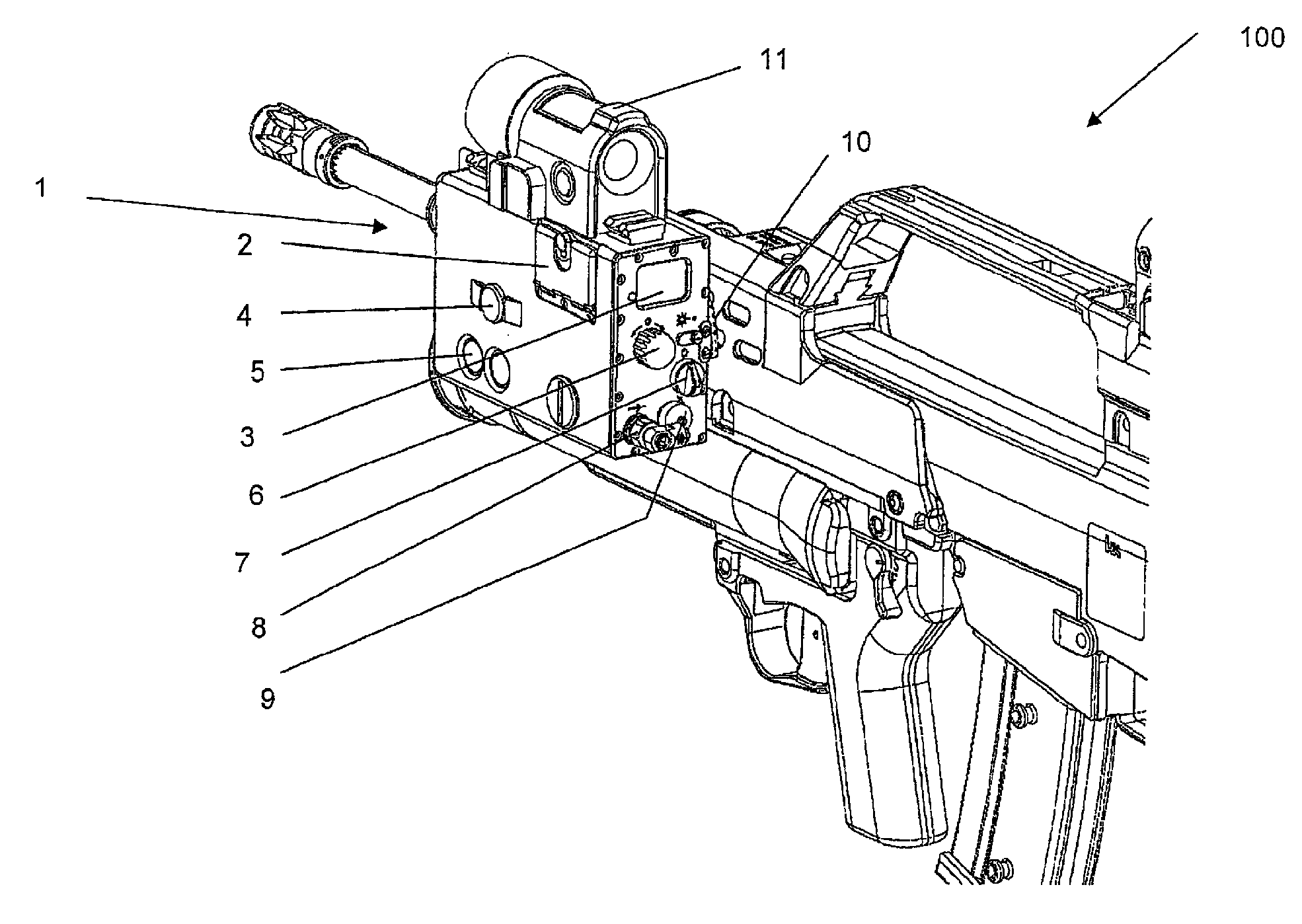

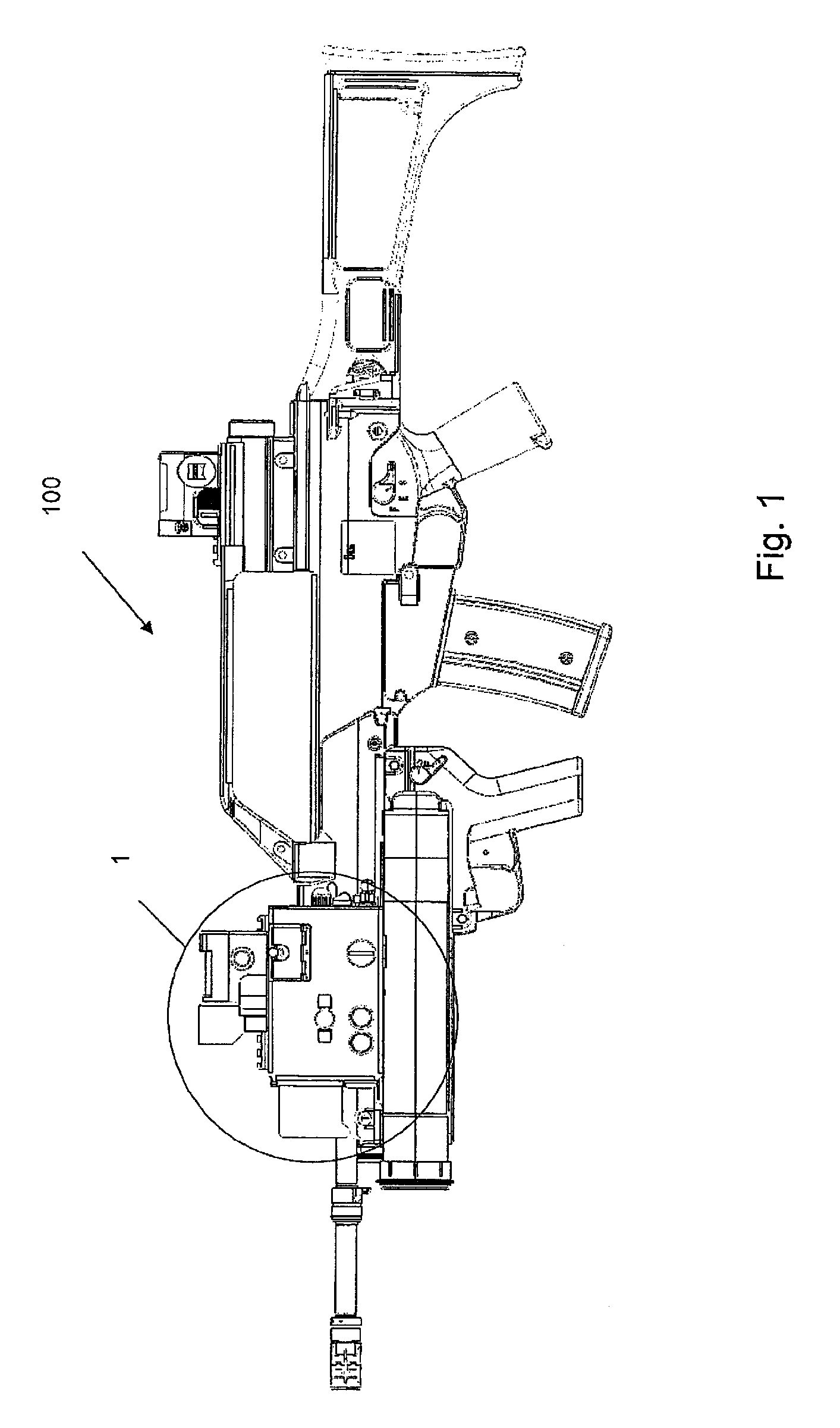

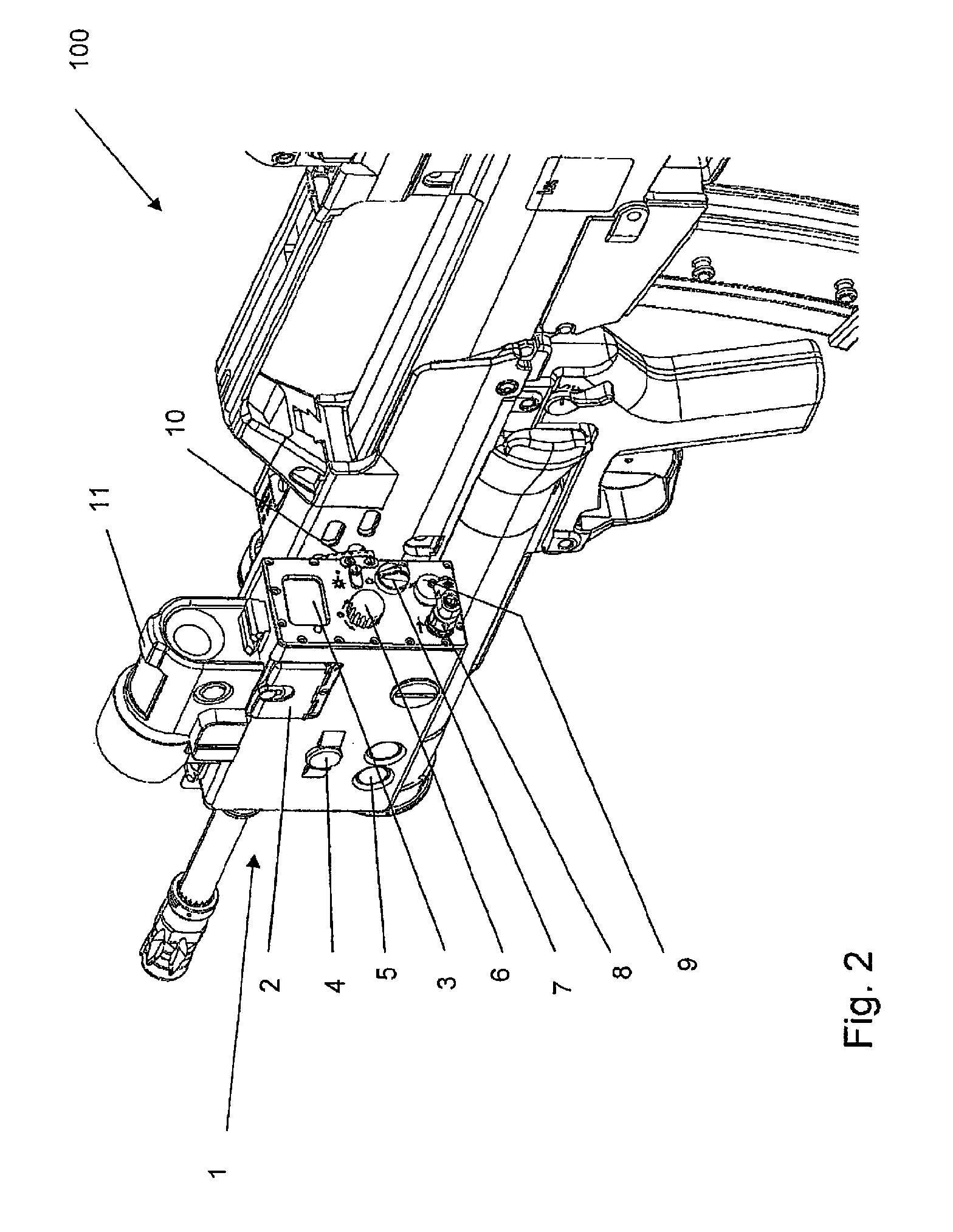

Fire guidance device for a hand fire weapon

ActiveUS20110010981A1Small sizeReduce weightSighting devicesWeapon control systemsLateral angleDisplay device

Owner:RHEINMETALL SOLDIER ELECTRONICS

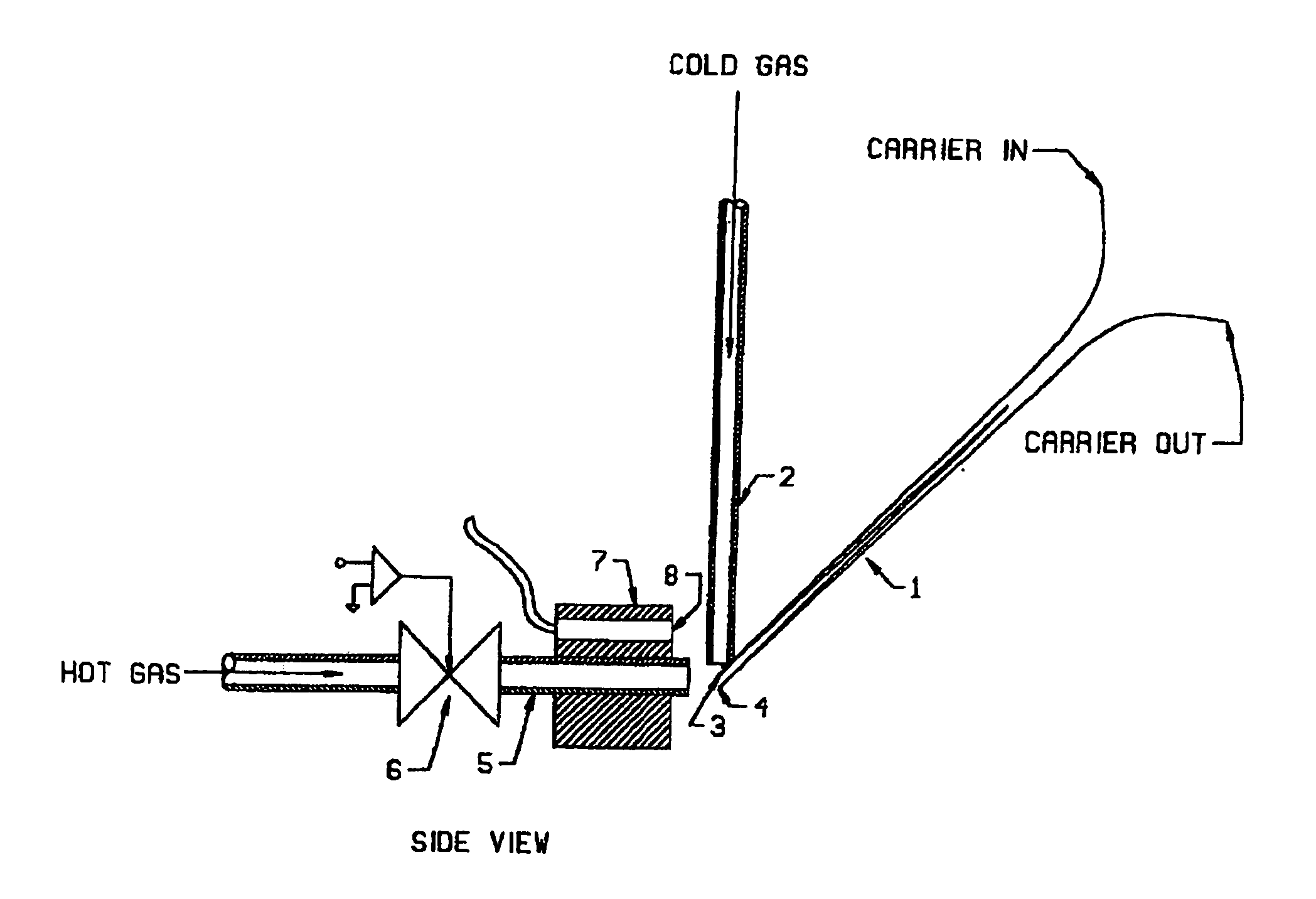

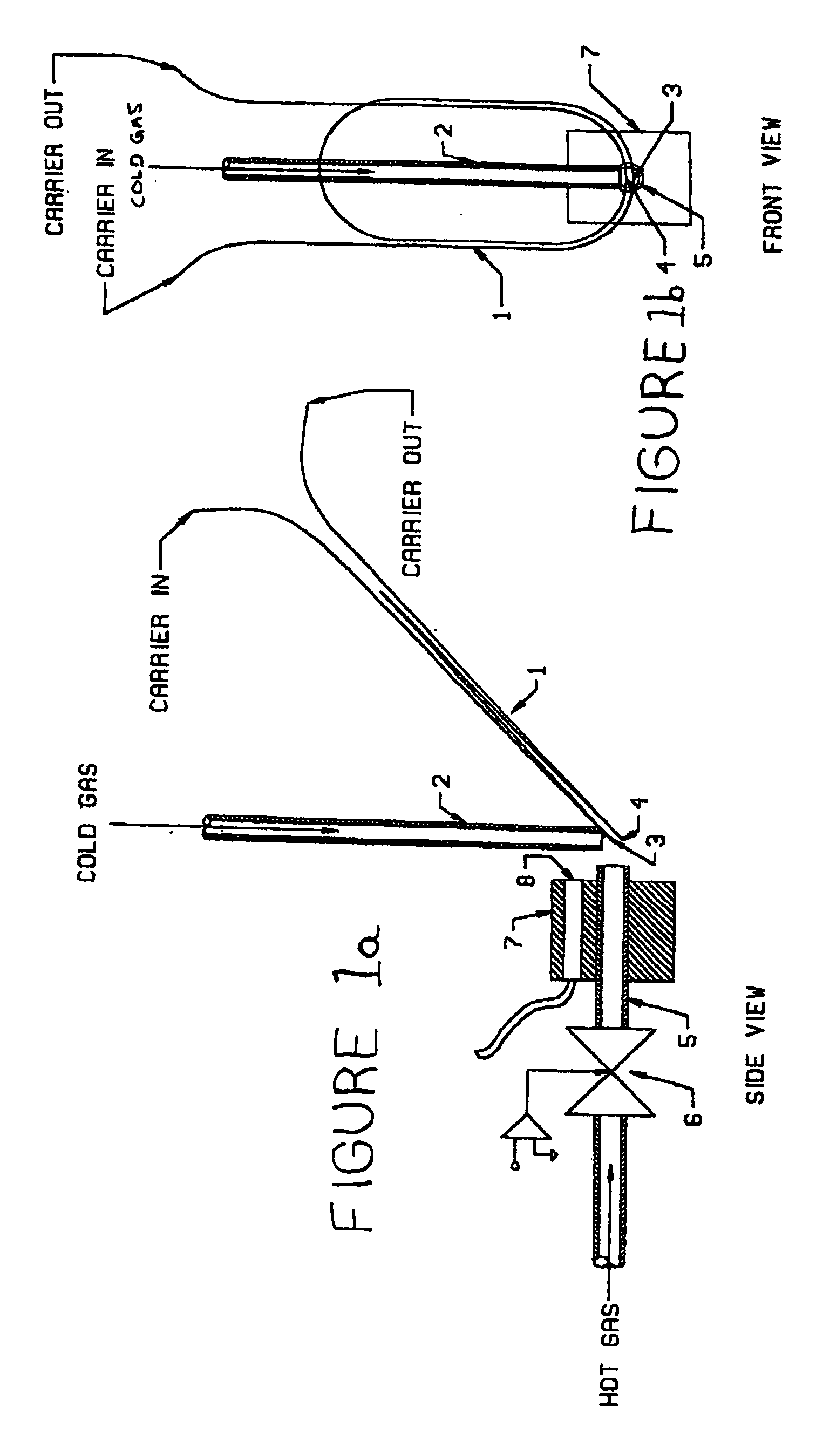

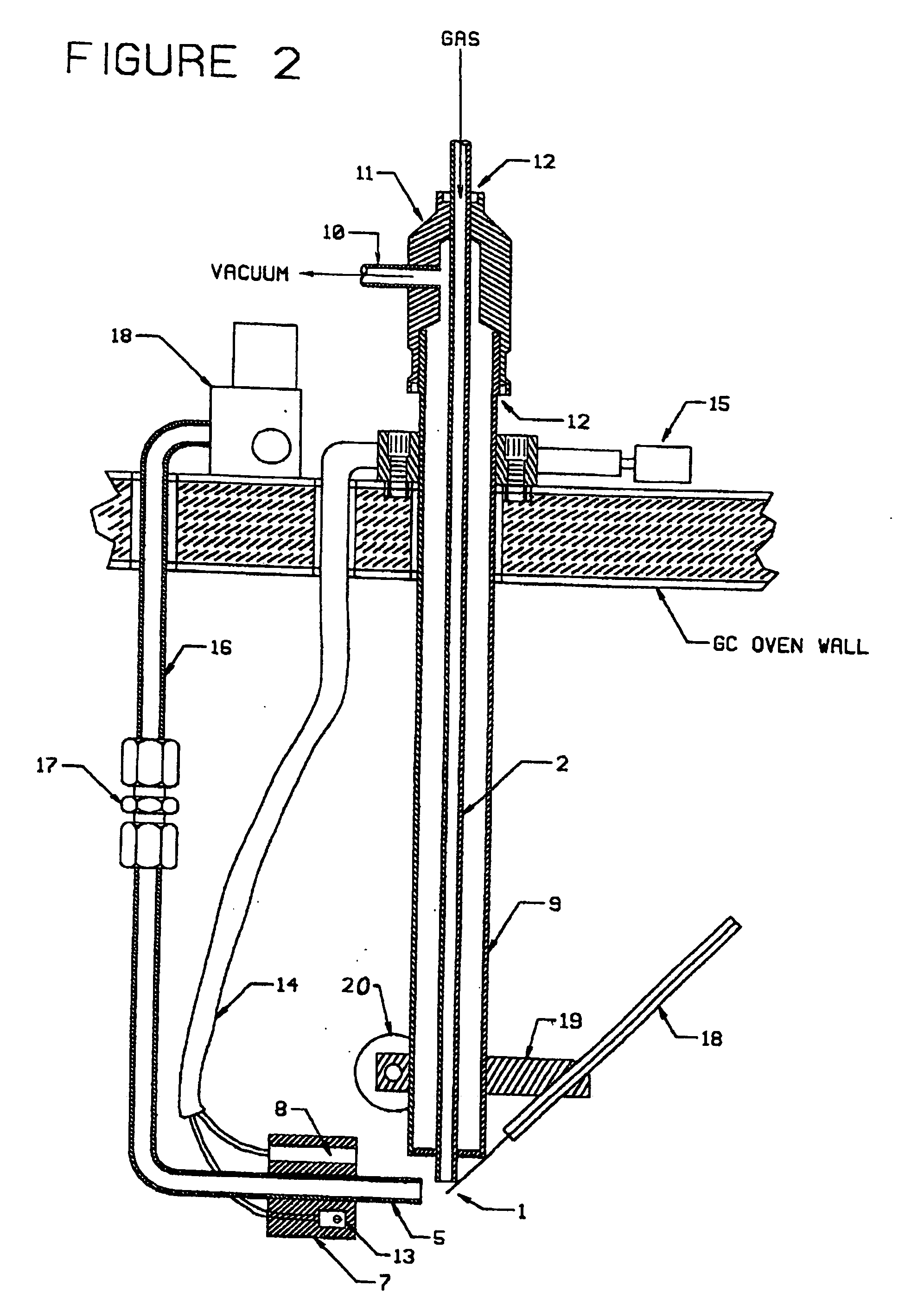

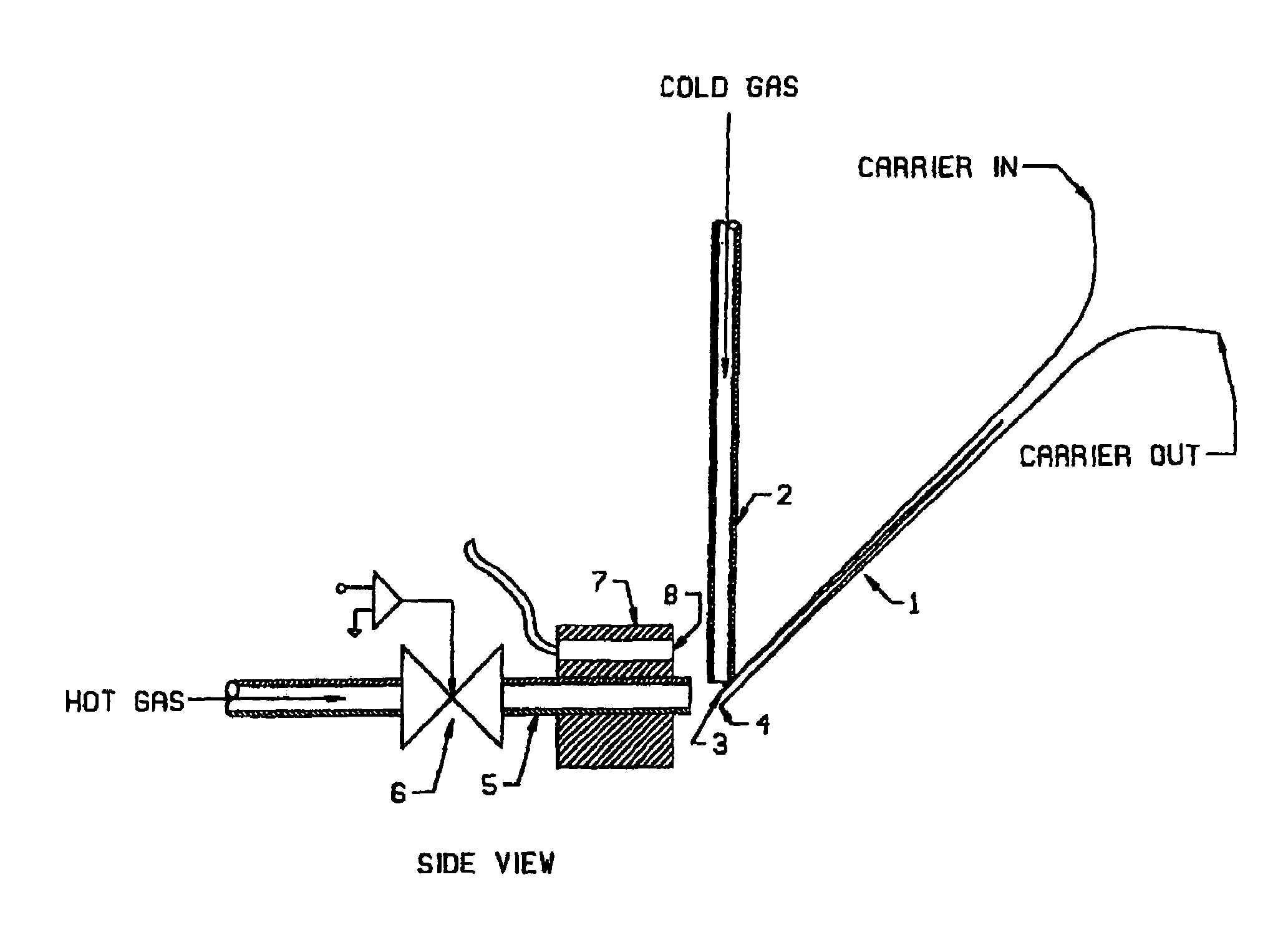

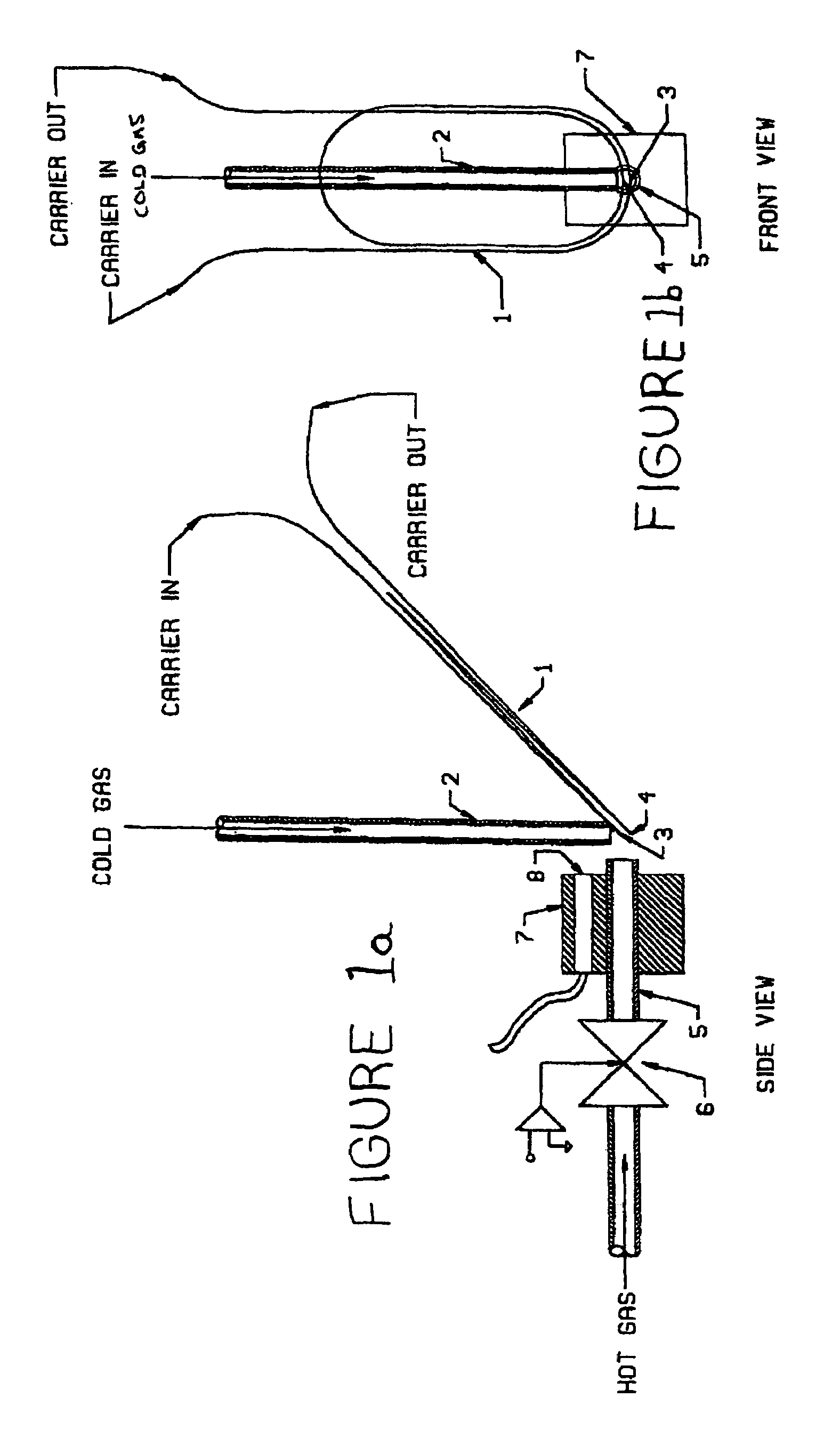

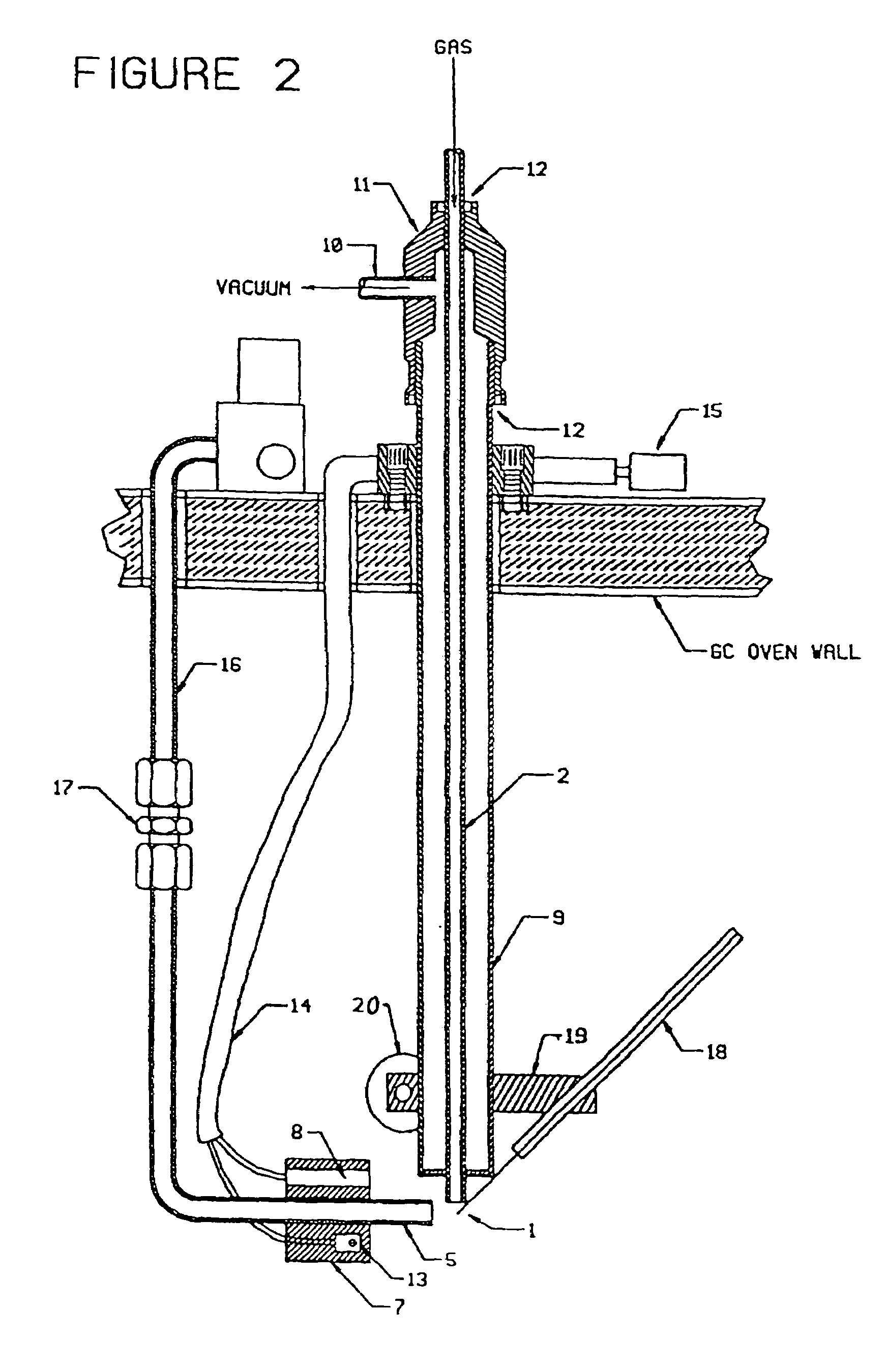

Method and apparatus for measuring velocity of chromatagraphic pulse

InactiveUS20050139076A1Robust constructionEasy to useIon-exchange process apparatusComponent separationChromatographic separationThermodynamics

An Apparatus and method for two-stage chromatographic separation uses thermal modulation. The chromatographic column or modulation tube (1) has a loop structure such that two portions of modulation tube (1) can be thermally modulated simultaneously by at least one thermal modulation device, which device can have a cold gas source, jet tube (2), and a hot gas source, hot jet tube (5), to modulate the temperature of the portions (3, 4) of modulation tube (1).

Owner:ZOEX

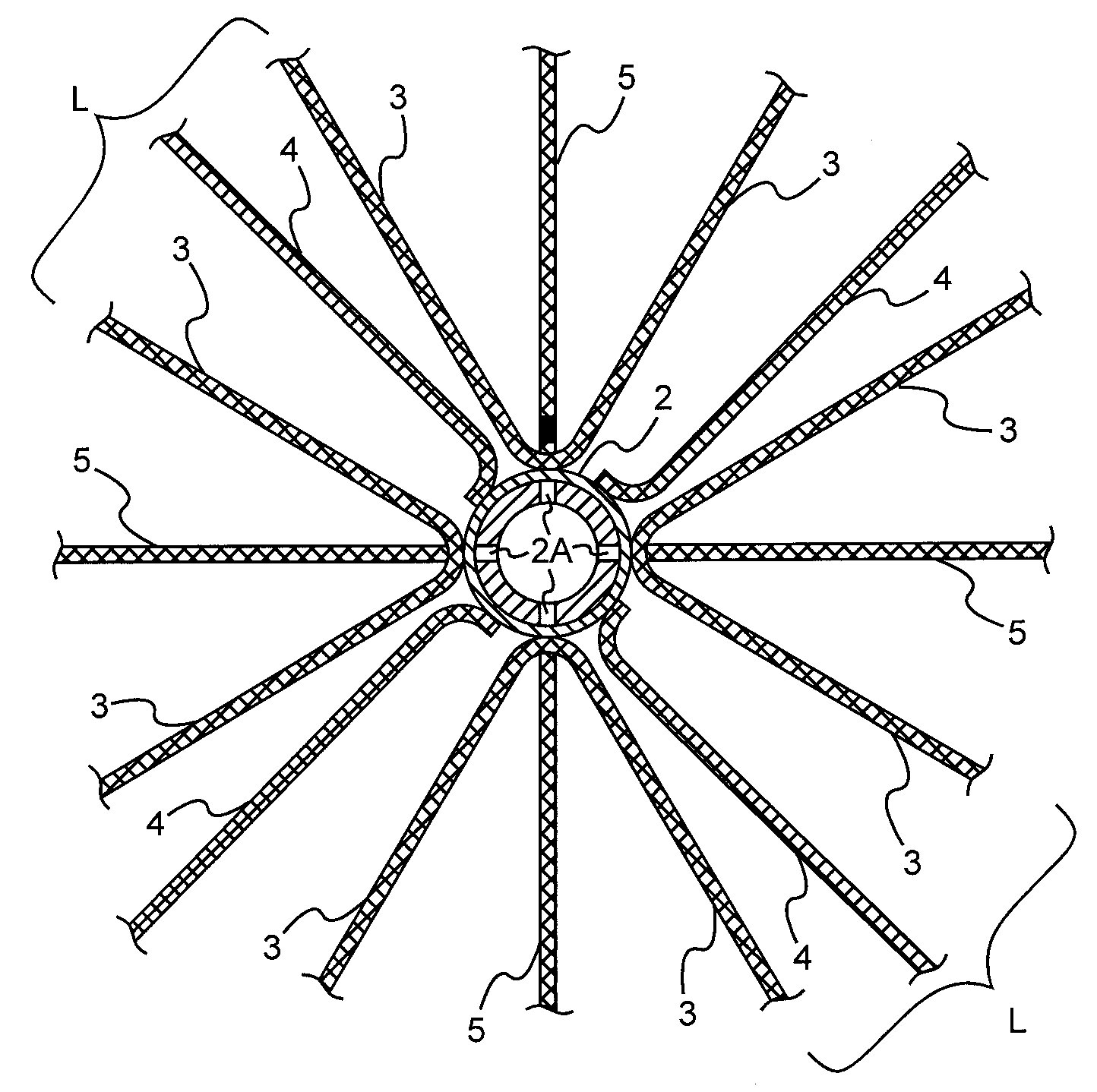

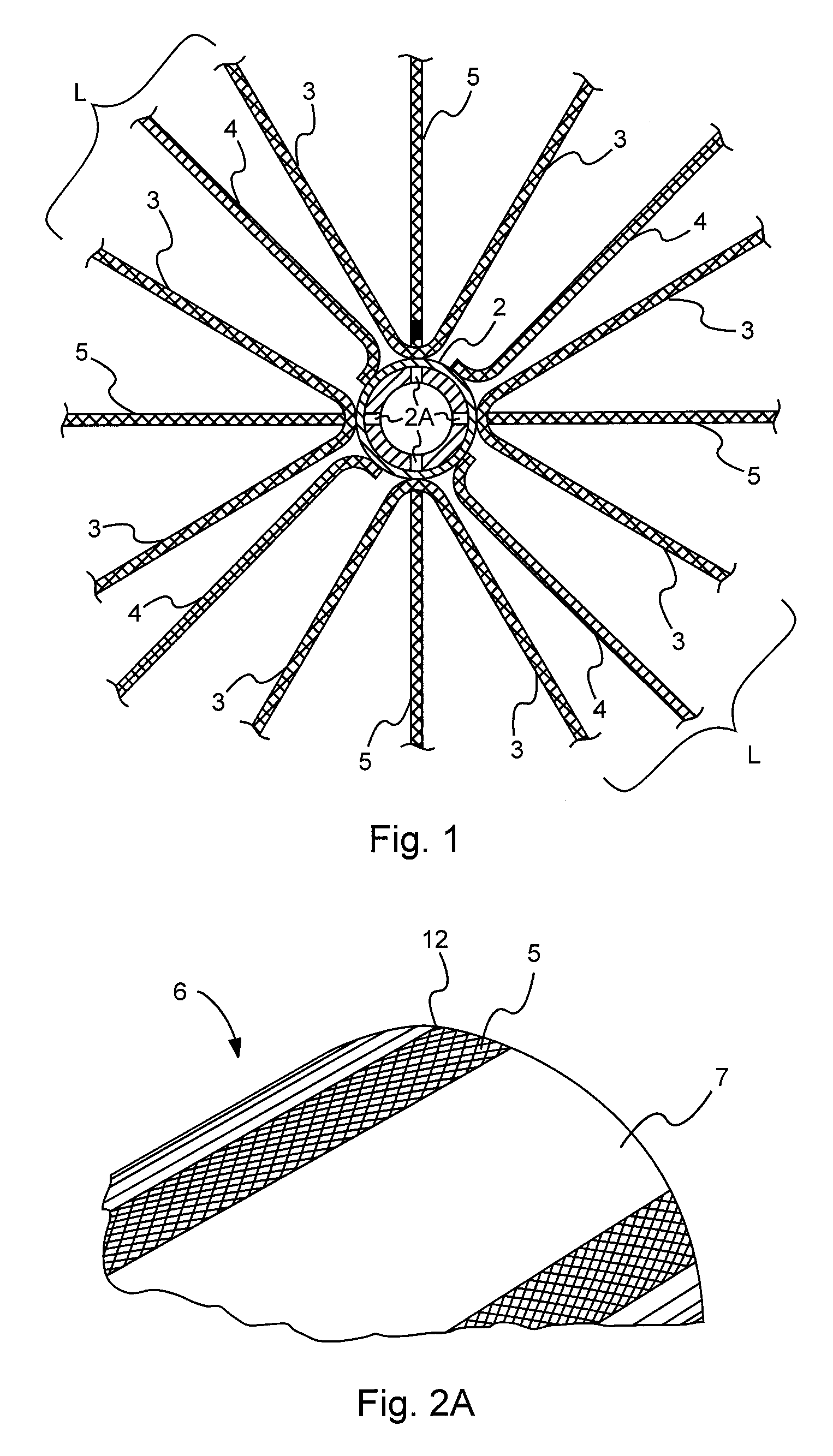

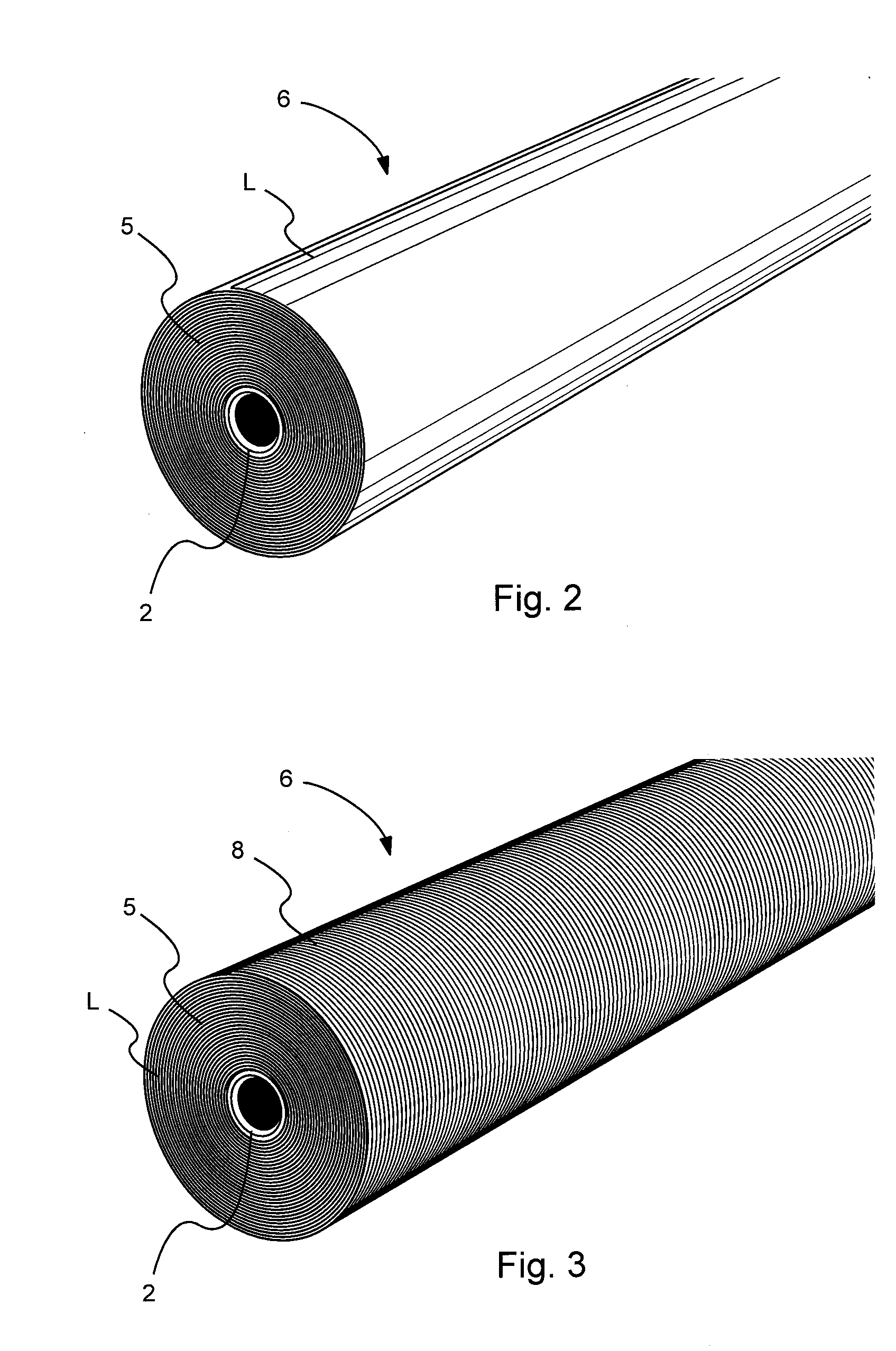

Sanitary spiral wound filtration cartridge

ActiveUS20090145838A1Facilitate rewindingRobust constructionMembranesSemi-permeable membranesCross-flow filtrationBiomedical engineering

Sanitary elements and cartridges of high performance are described which utilize a thin surrounding tubular shell with an exterior textured surface. Through the use of an overwrap material of particular design and by wrapping an assemblage of sheets of semipermeable membrane material, permeate carrier material and feed spacer material using a high tension, a spirally wound crossflow filtration element is constructed which has a substantially cylindrical outer surface of closely controlled OD that smoothly fits within such shell and which resists telescoping as a result of its radial compression.

Owner:MANNHUMMEL WATER & FLUID SOLUTIONS GMBH

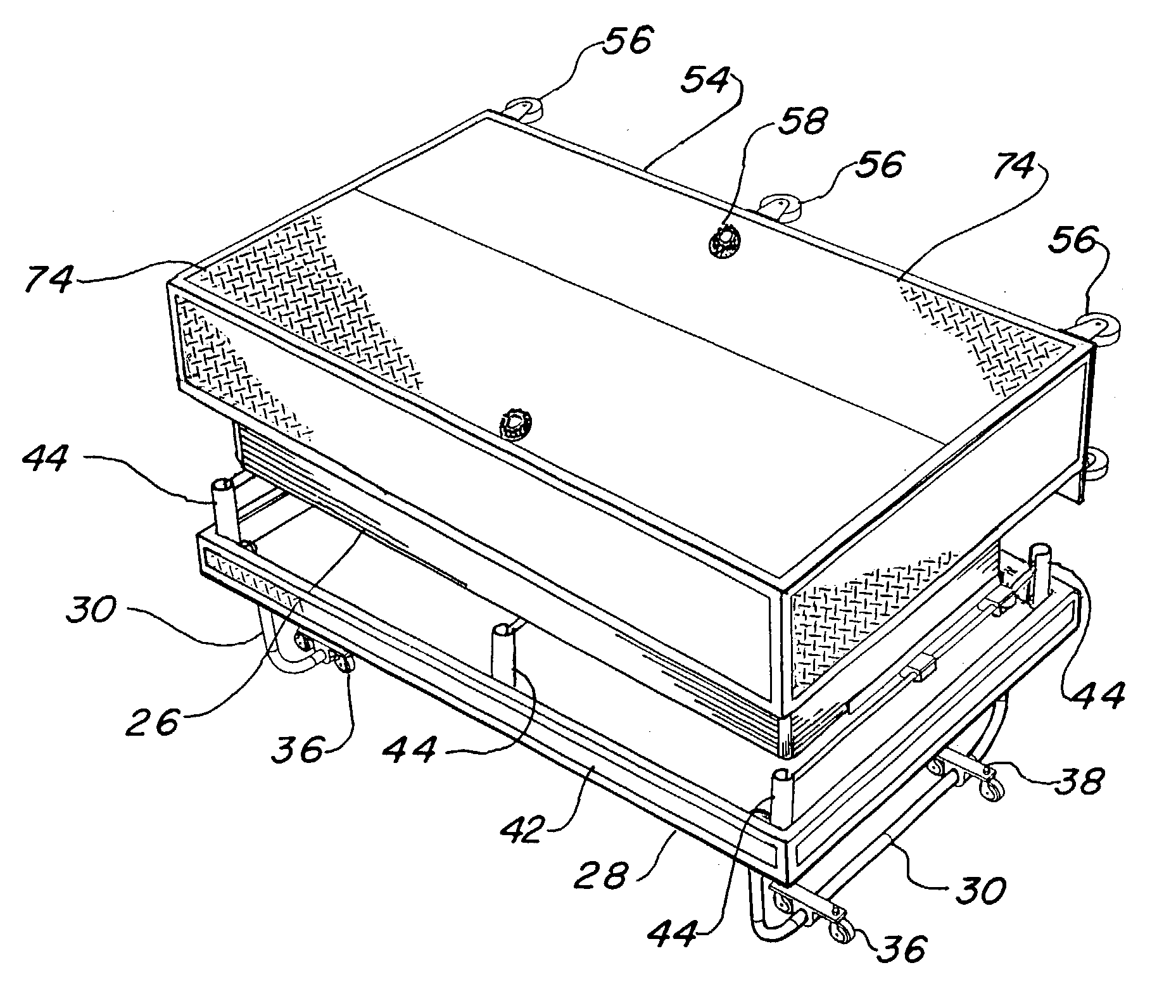

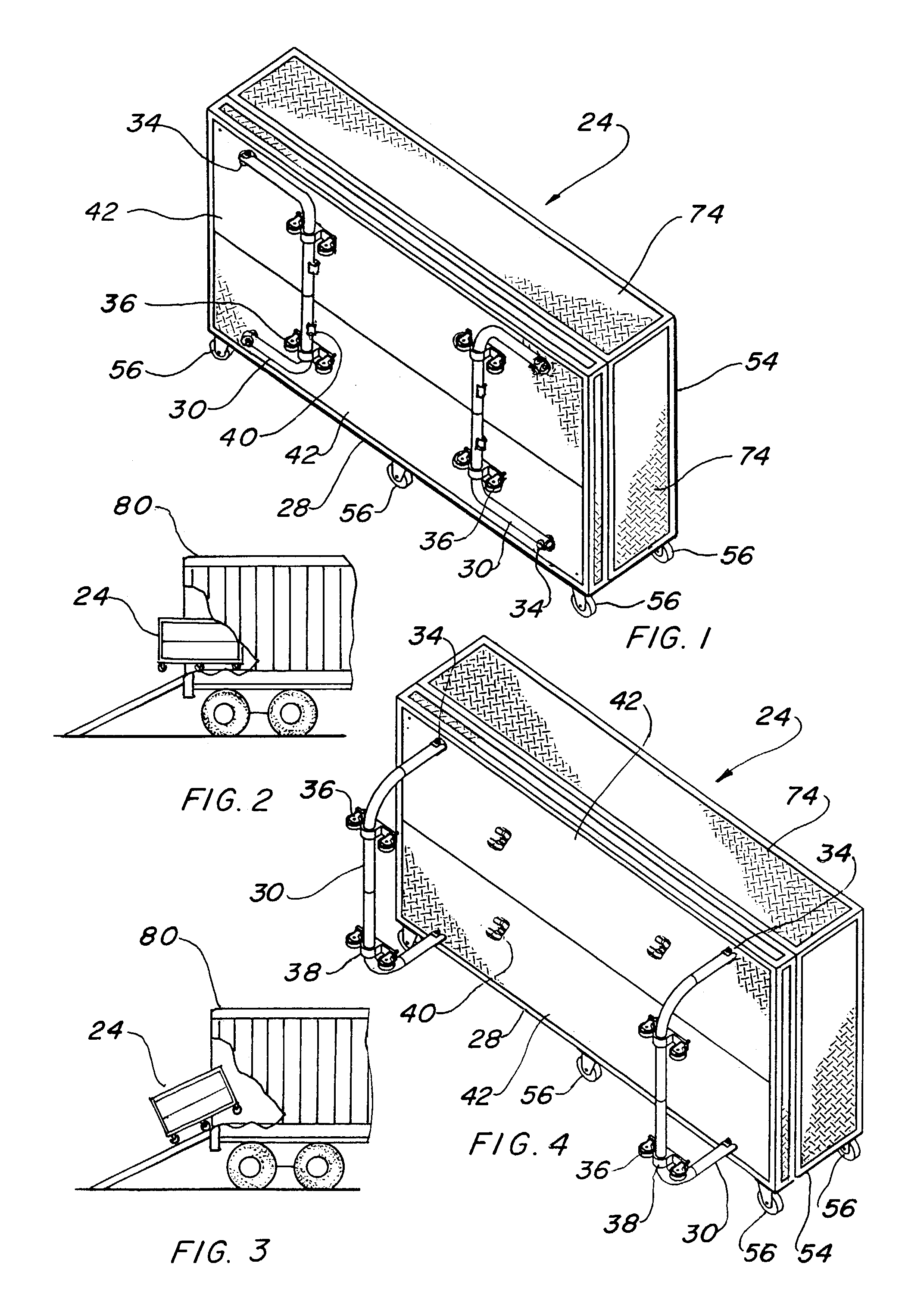

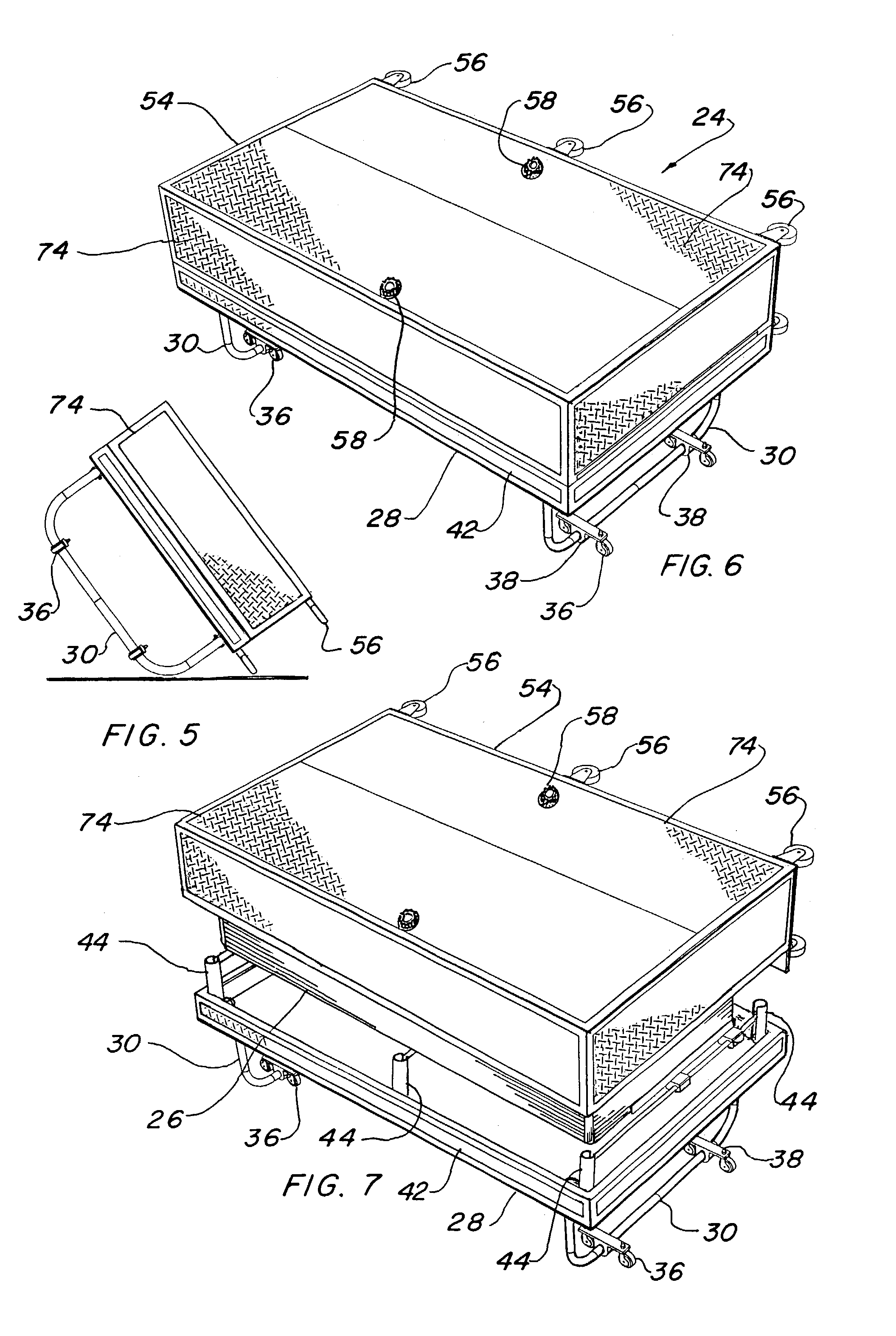

Audio mixing console flight case

InactiveUS6929268B1Equal delayEasy to slideCarriage/perambulator accessoriesCarriage/perambulator with multiple axesLocking mechanismEngineering

A flight case (24) for shipping and supporting an audio mixing console (26), having a main platform frame (28) that includes a pair of collapsible legs (30) each with reversible swivel casters (36) and a plurality of upright sockets having gas springs (48). When the flight case (24) is positioned on its side for transportation the casters (36) face outward; when positioned horizontally the casters (36) are rotated downward for resting on a hard surface. A sub frame (50) is located inside the frame (28) and is configured to receive the audio mixing console (26). A removable top (54), with side casters (56) and locking mechanisms (58) is placed over the frame (50). When the locking mechanisms are rotated, the frame (50) and the top (54) are elevated by the gas springs (48), permitting the top (54) to be removed leaving the frame (50) for supporting the audio mixing console (26) exposed ready for use. The frame (50) is then pulled outward forming a shelf creating room for a sound engineers legs.

Owner:OWENS OTIS

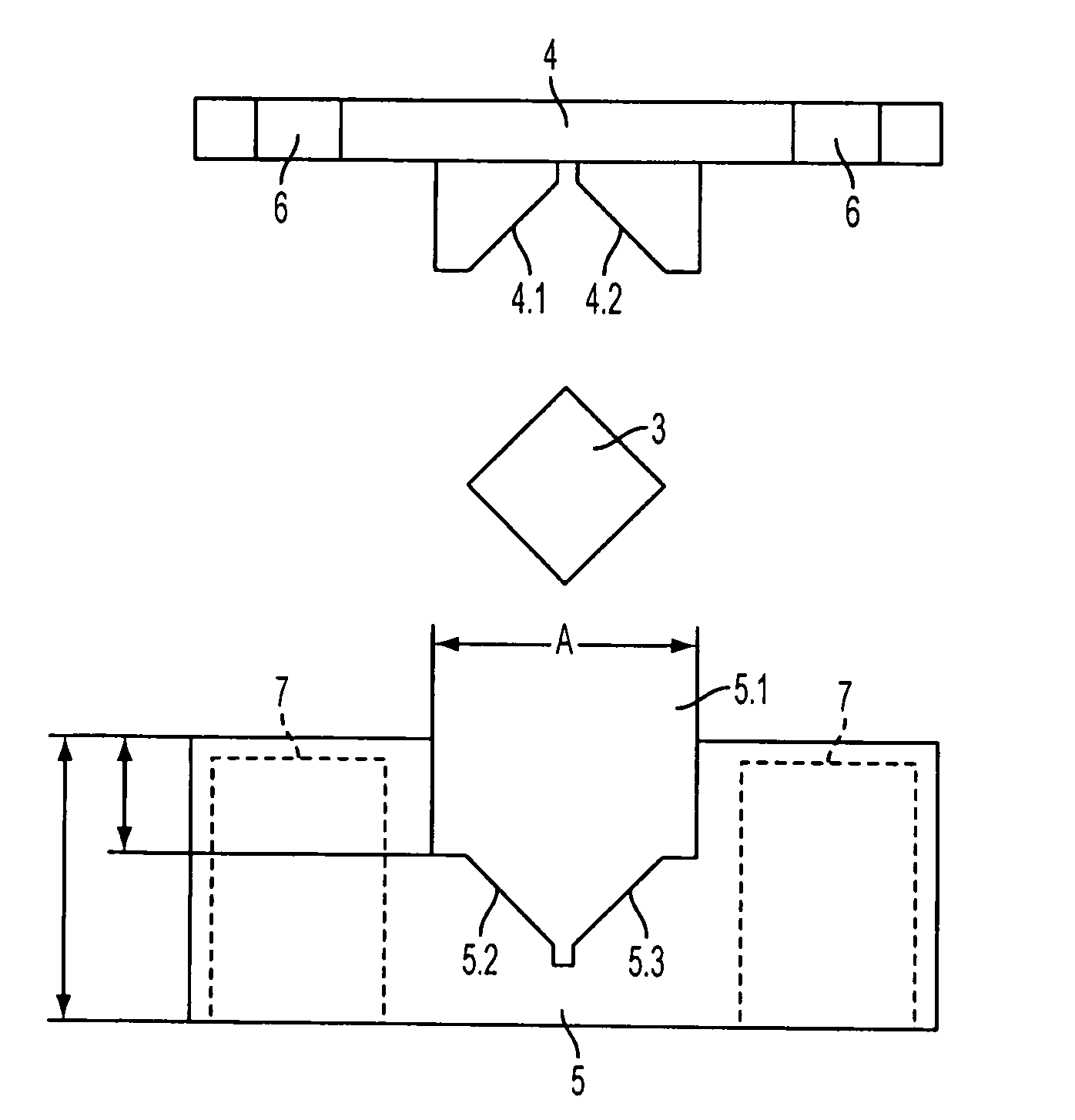

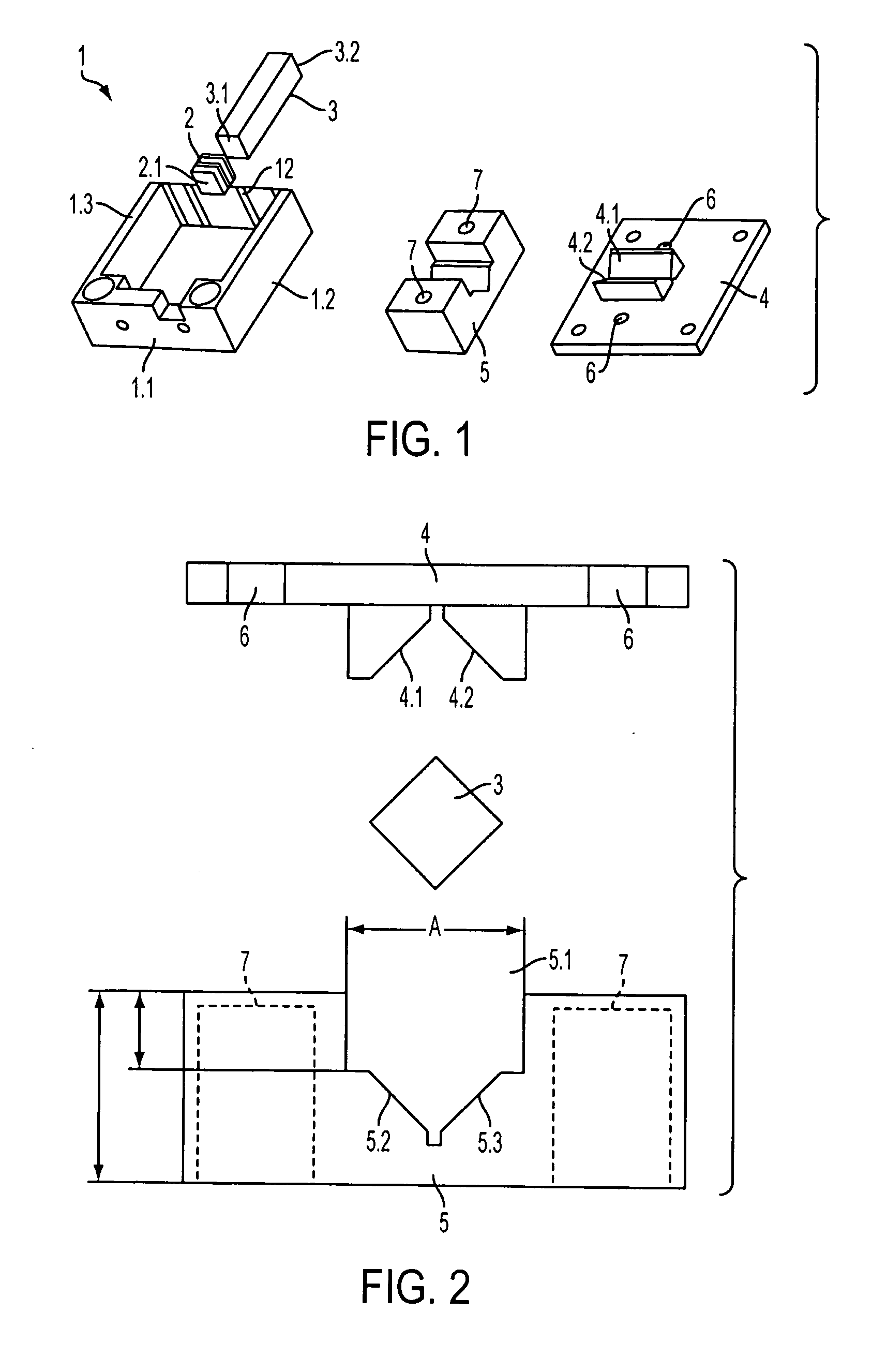

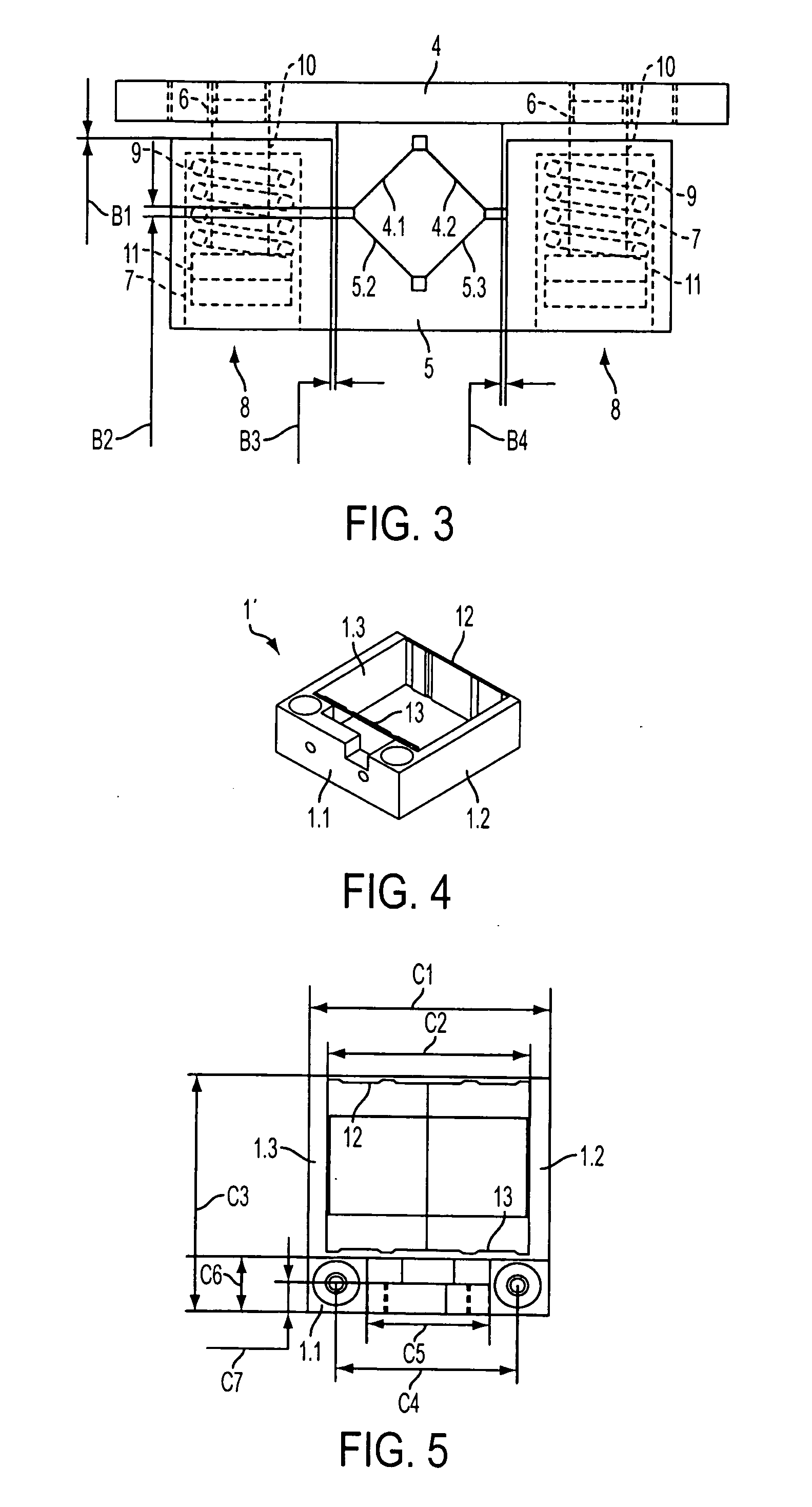

Positioning device with a solid-body joint

ActiveUS20080148589A1Easily fracturedRobust constructionMeasurement devicesPiezoelectric/electrostriction/magnetostriction machinesLateral displacementTranslatory motion

A positioning device has a first unit and a second unit arranged so as to be displaceable relative to the first unit. A slip-stick drive acts between the first unit and the second unit to produce a translatory movement (P) of the two units. The positioning device has a solid-body joint which is coupled to the first unit and the slip-stick drive and which mechanically protects a translation shaft of the slip-stick drive against rotation and / or lateral displacement.

Owner:ATTOCUBE SYST AG

Method and apparatus for measuring velocity of chromatographic pulse

InactiveUS7258726B2Robust constructionEasy to useIon-exchange process apparatusComponent separationChromatographic separationThermodynamics

Owner:ZOEX

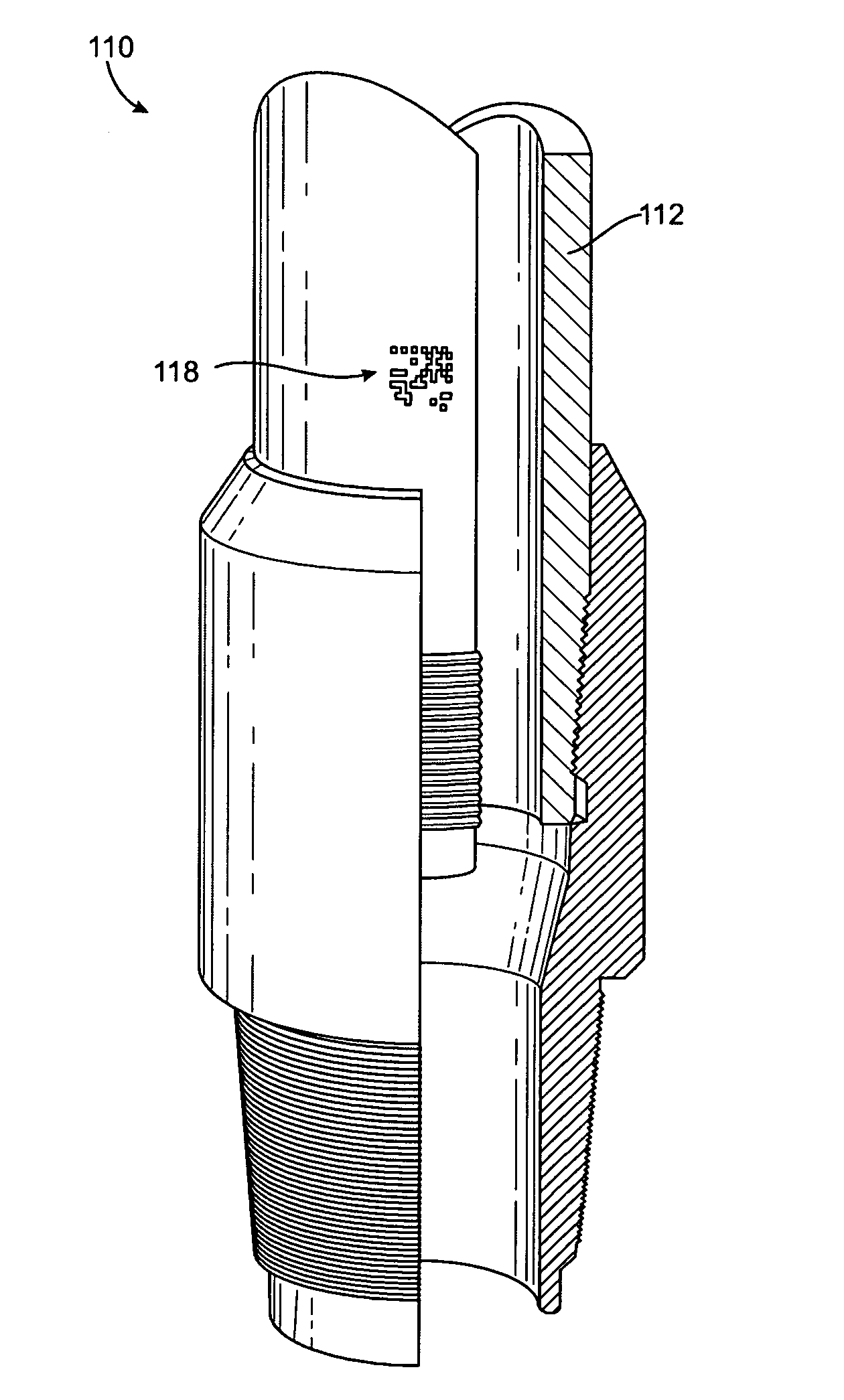

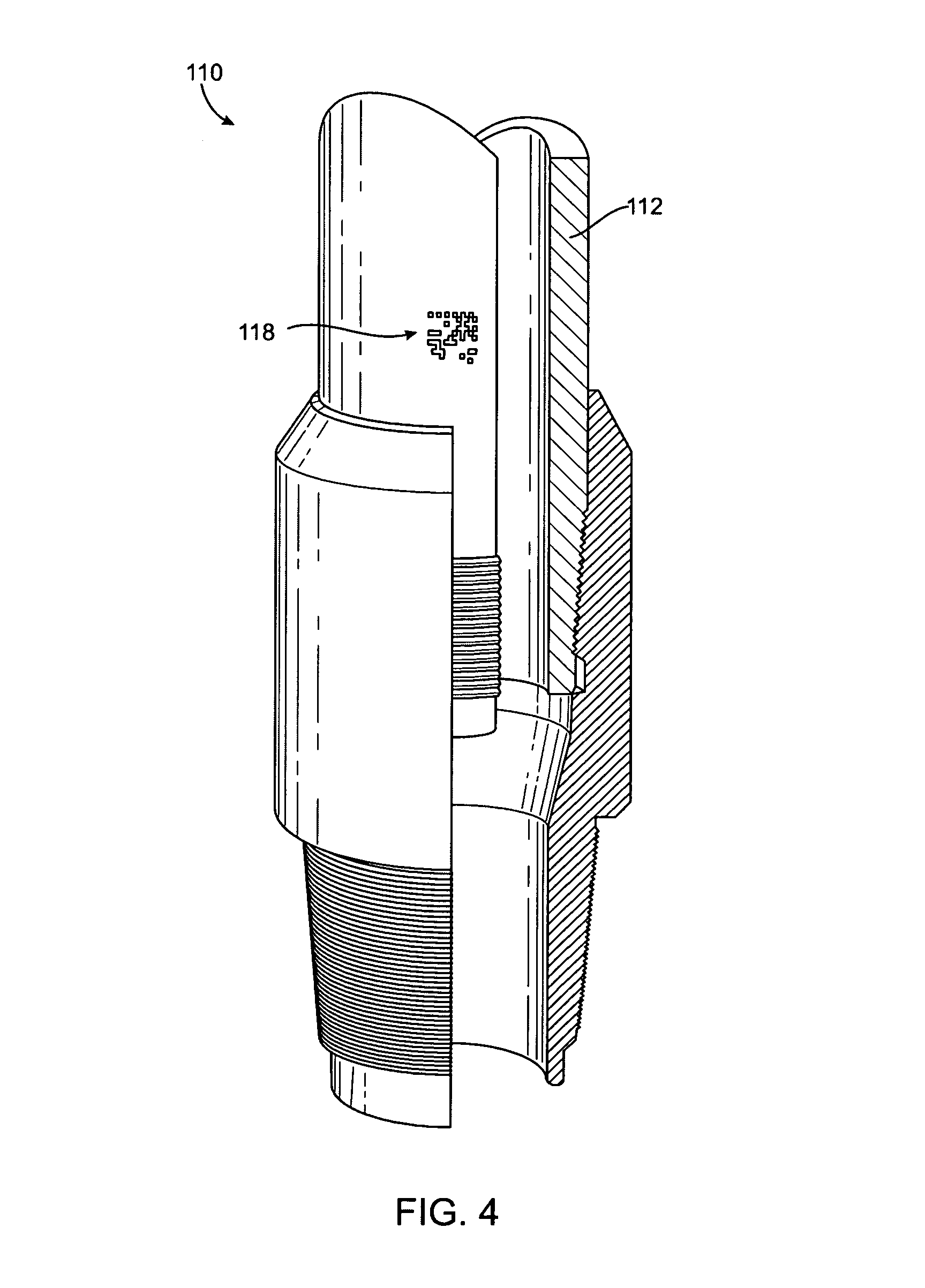

Labeled drill pipe

InactiveUS20110315261A1Minimize wearMinimize degradationDrilling rodsPipe elementsEngineeringMechanical engineering

A drill pipe including a tube having opposite ends. An internally threaded connector is provided at one of the opposite ends of the tube. An externally threaded connector is provided at the other one of the opposite ends of the tube. The externally threaded connector is adapted to mate with the internally threaded connector on a second drill pipe. A bar code is etched into either the tube, the internally threaded connector, or the externally threaded connector.

Owner:COLEMAN JAY B

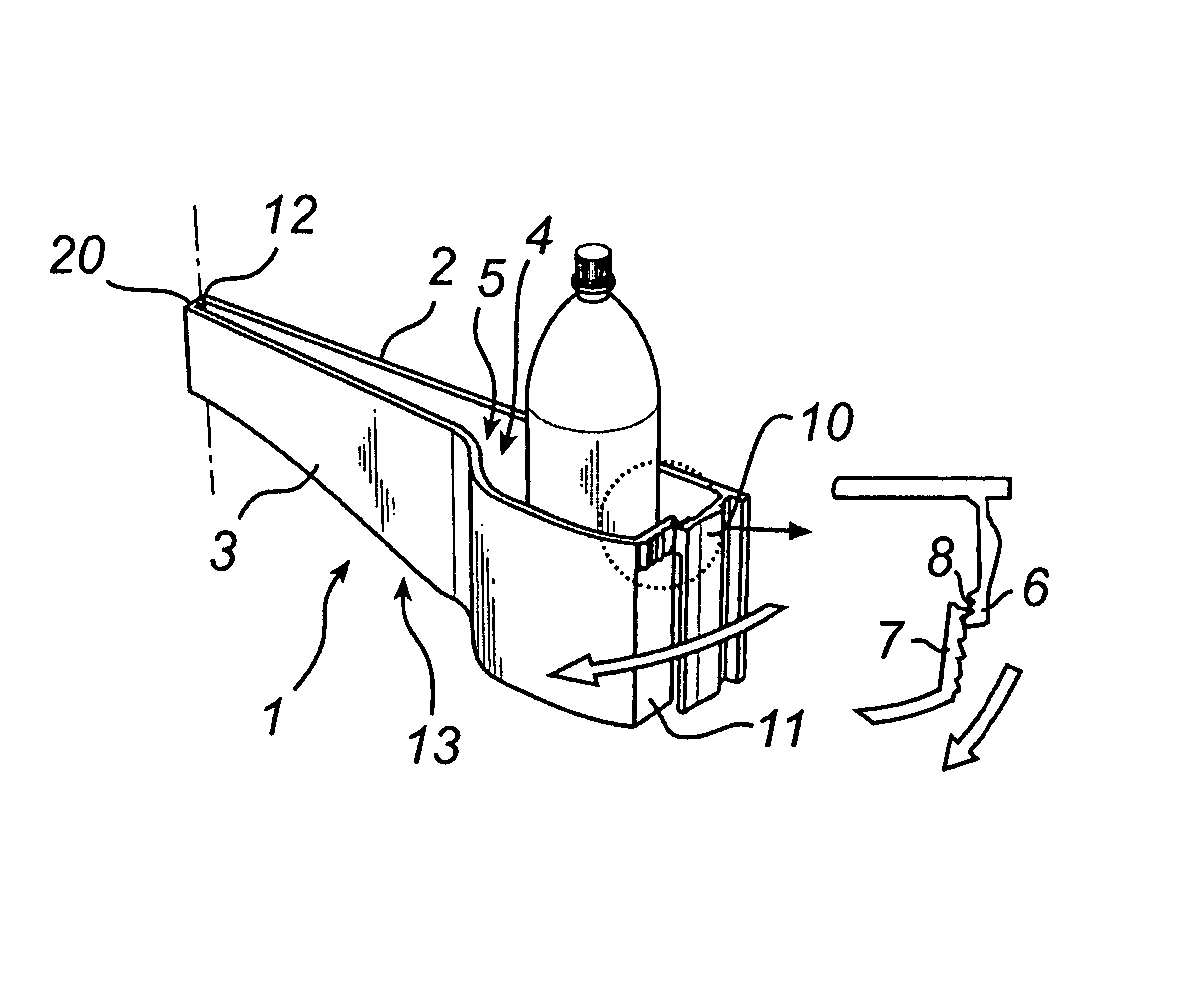

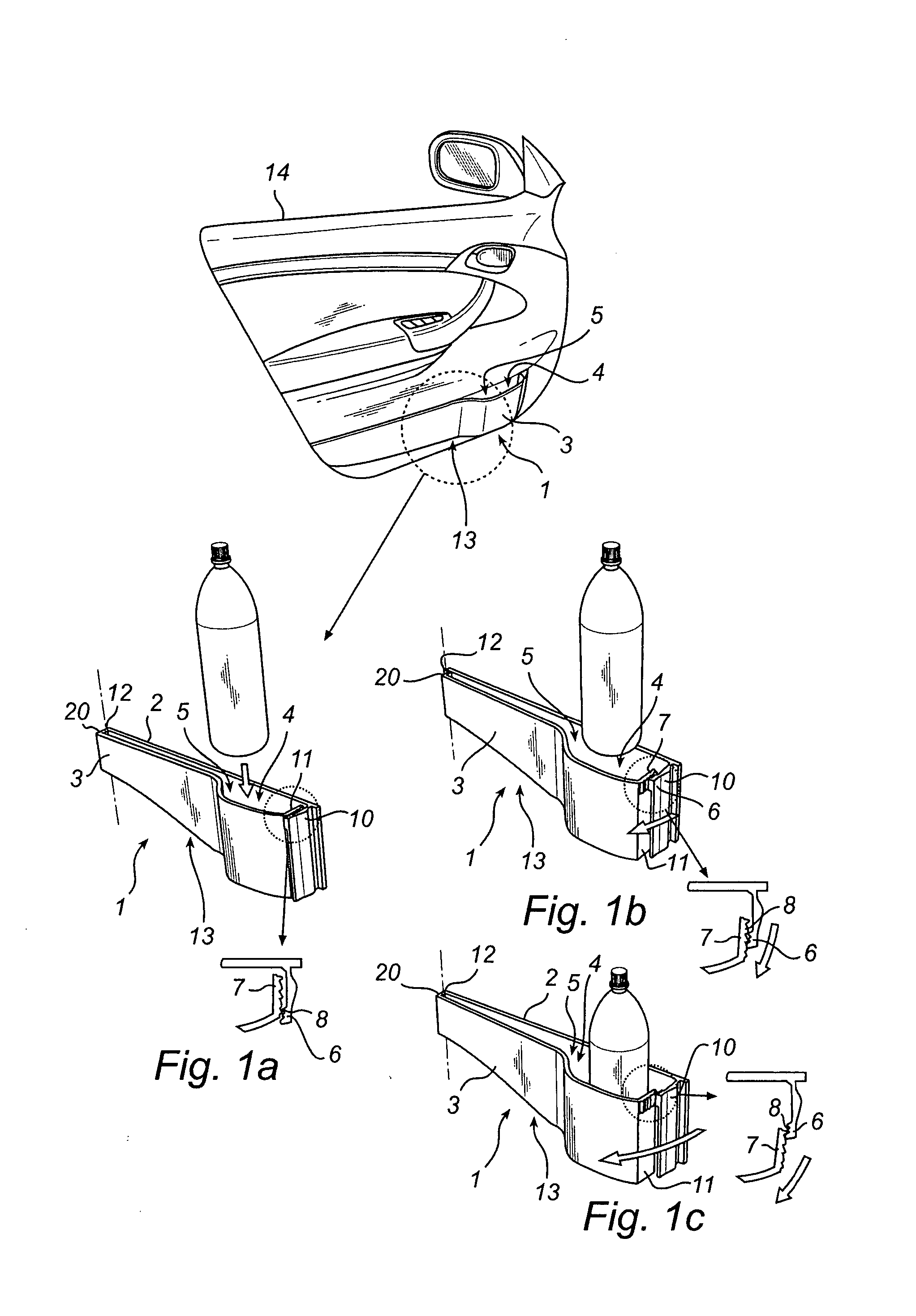

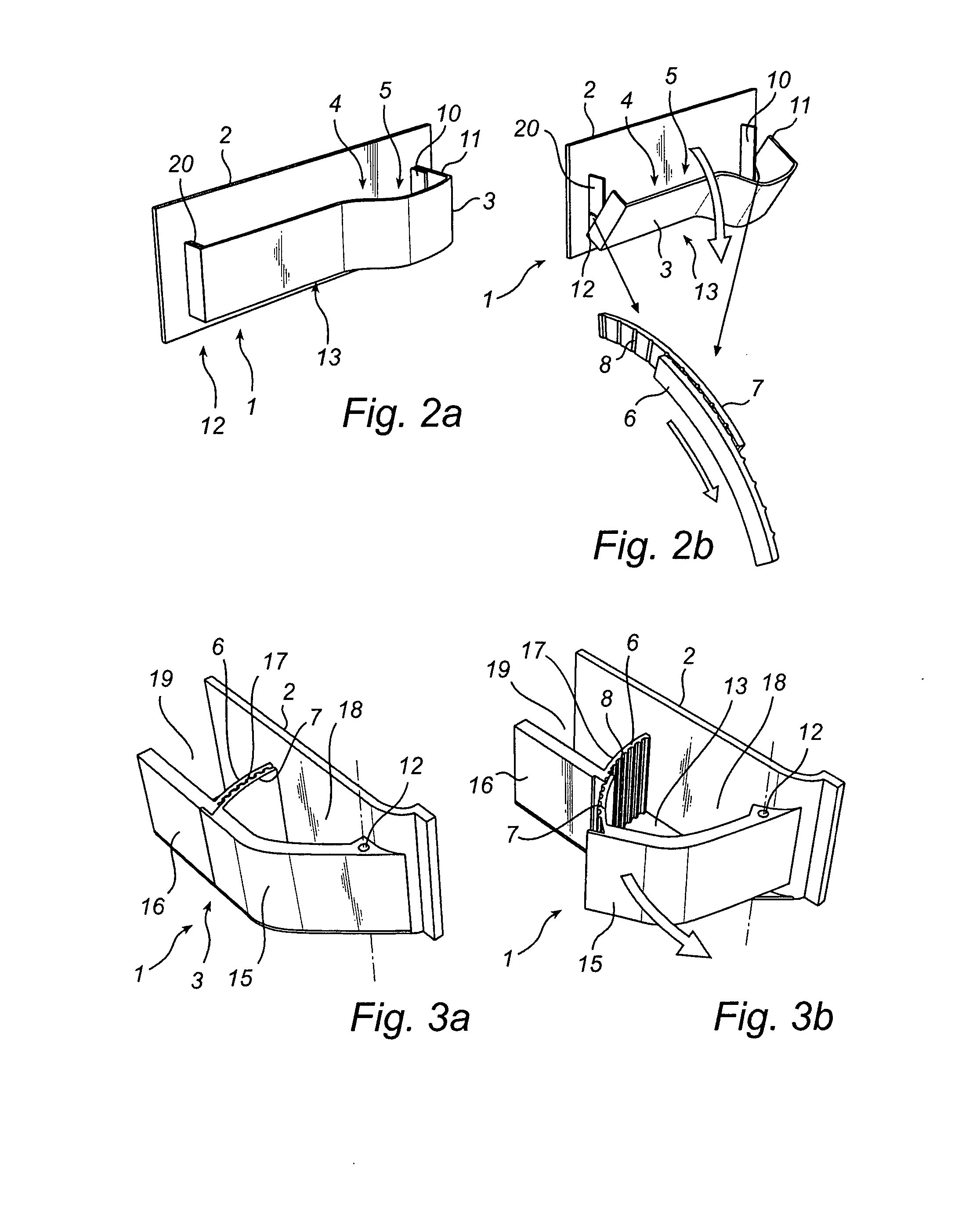

Storage arrangement

InactiveUS20070290109A1Good strengthRobust constructionPassenger spaceVehicle arrangementsEngineering

Owner:AHLBURG RALPH +1

V-belt continuously variable transmission for a vehicle engine

InactiveUS7207920B2Simple control processImprove operating conditionsGearing controlEngine controllersPower sensorDrive shaft

Owner:NORDSAMVERK HALLSTROEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com