Labeled drill pipe

a drill pipe and label technology, applied in the field can solve the problems of long service life of labeled drill pipe, and achieve the effects of long service life, long service life and robust construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

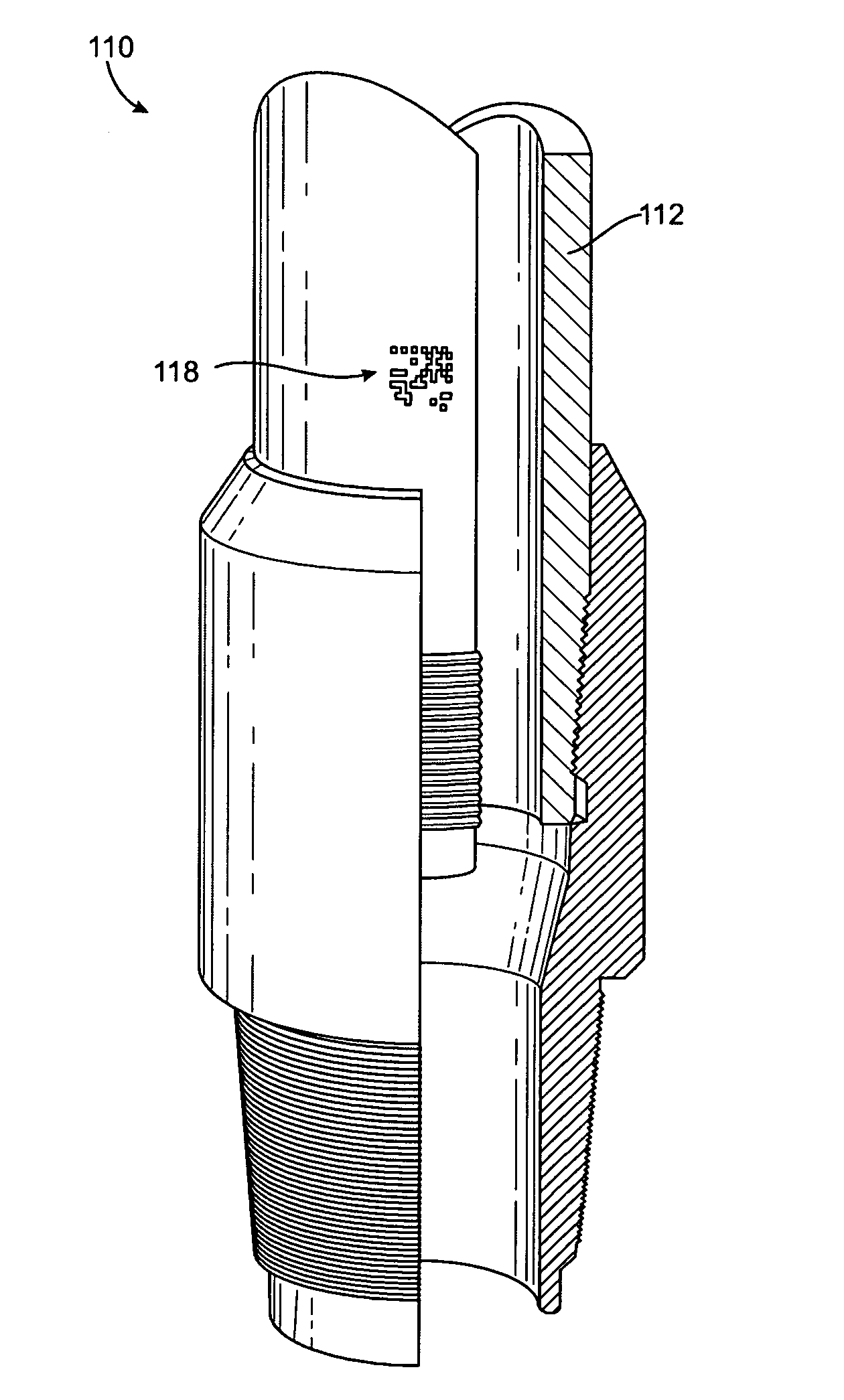

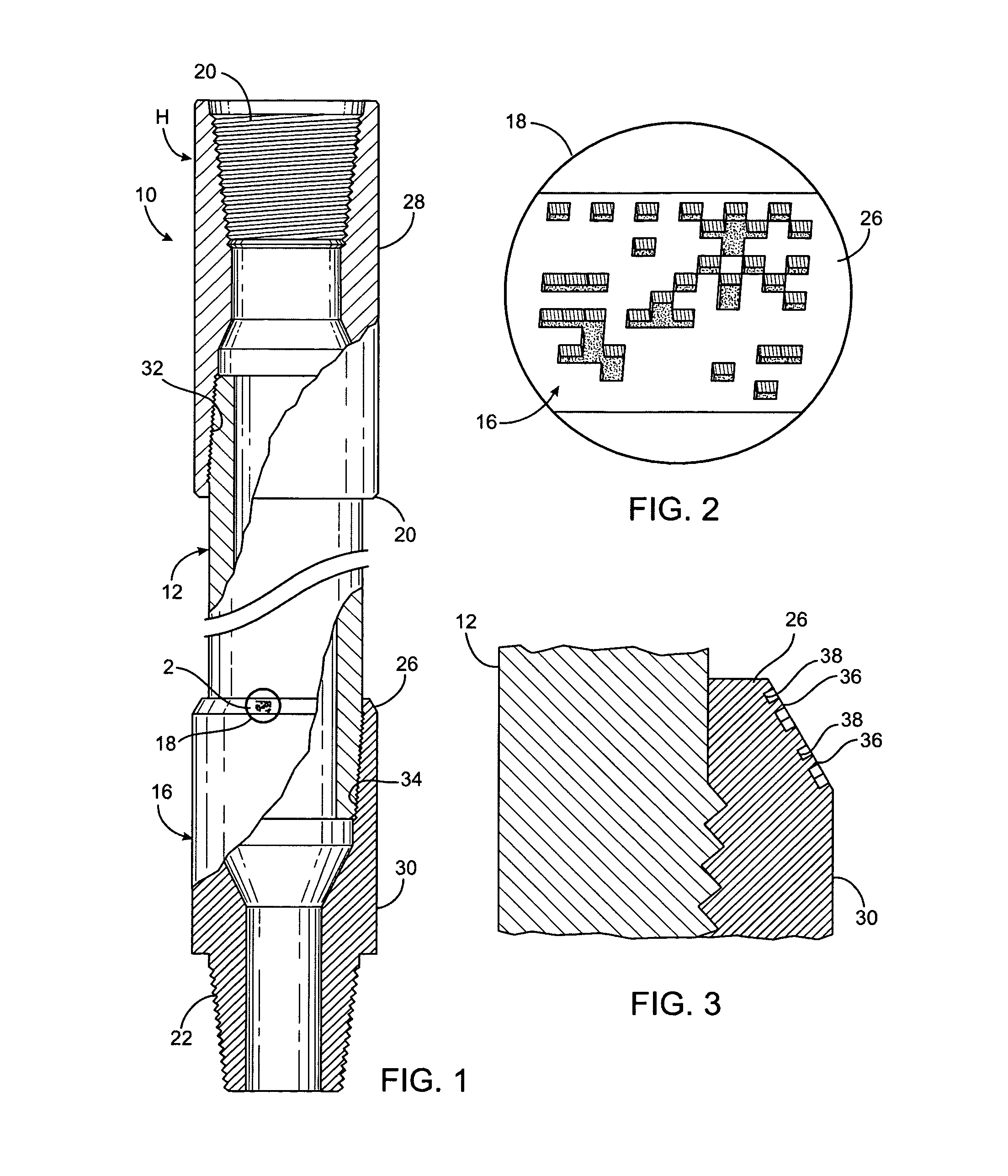

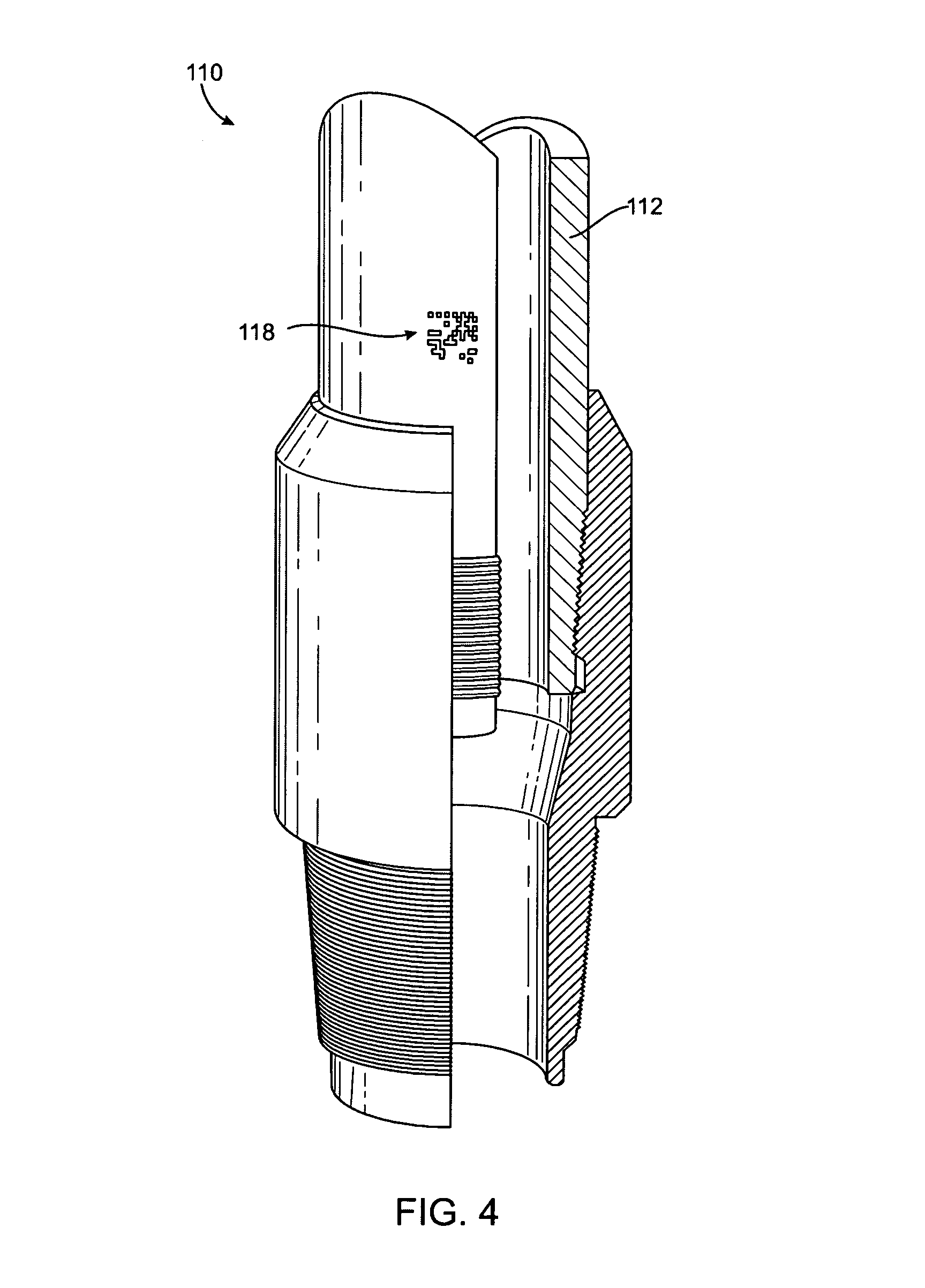

[0020]Referring now to the FIGS., a drill pipe constructed in accordance with my invention is shown at 10. The drill pipe 10 is a hollow, cylindrical, seamless tube 12 having a pair of connectors or tool joints 14 and 16 affixed to its opposite ends. The drill pipe 10 is labeled with a bar code 18 applied to the tool joint 16. The bar code 18 is unique to the drill pipe 10 and is used to identify the drill pipe 10 throughout its life.

[0021]The tube 12, and hence the drill pipe 10, is specified by its outside diameter, weight per foot, steel grade, and length. These parameters are a matter of design choice (and can vary widely), but are usually selected for an optimum combination of strength, hardness, and fatigue resistance. The American Petroleum Institute (API) has adopted standards meant to reinforce safe drilling practices by setting these parameters within fixed ranges. The tube 12 would normally be configured to meet API standards.

[0022]In selecting a tube 12 of appropriate si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com