Bi-metal layered hydroxide chelated Ti3C2 compound as well as preparation method and application thereof

A bimetallic layered and hydroxide technology, applied in the field of electrocatalysis, can solve the problems of cost barriers and high scarcity of platinum, and achieve the effects of low cost, large amount of hydrogen evolution, and low initial potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

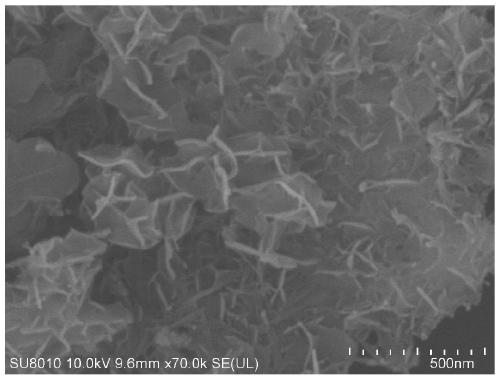

[0031] (1) FeCo-LDH / Ti 3 C 2 - Preparation of MXene

[0032] Including the following steps:

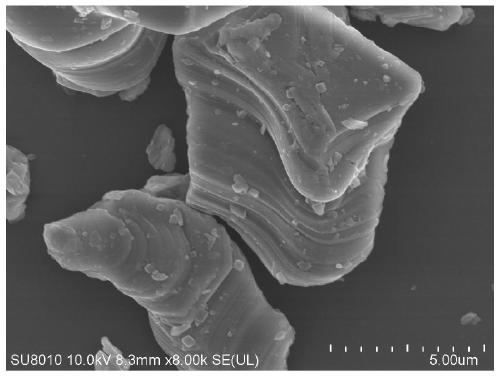

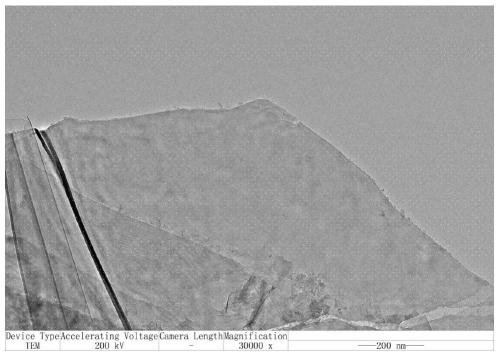

[0033] 1. Ti 3 C 2 - Preparation of MXene:

[0034] 1) Weigh 0.2g Ti in a 50mL centrifuge tube 3 AlC2 -MAX, slowly add 0.2g LiF and 2ml 98% hydrochloric acid, stir at room temperature for 72h, add deionized water, centrifuge the obtained reaction solution (10000rpm, 10min) 6 times, and discard the supernatant.

[0035] 2) Add 40 mL of deionized water to the sediment in the centrifuge tube, shake well to mix the sediment and deionized water evenly, put the centrifuge tube into a high-power ultrasonic machine for ultrasonic dispersion (750W, 10min), take it out and continue centrifuging ( 3500rpm, 10min) to collect the supernatant, filter and vacuum dry to obtain a small layer of Ti 3 C 2 -MXene.

[0036] 2. FeCo-LDH / Ti 3 C 2 - Preparation of MXene

[0037] 1) Weigh 0.0811g ferric chloride, 0.531g cobalt acetate and 0.336g potassium hydroxide, add 2mL deionized, ultrasonic ...

Embodiment 2

[0048] Example 2 Effects of Different Modified Electrodes on Electrocatalytic Anode Water Oxidation

[0049] (1) Electrode preparation

[0050] Get the FeCo-LDH / Ti that 4mg embodiment 1 prepares respectively 3 C 2 -MXene powder, Ti 3 C 2 -FeCo-LDH and Co(OH) prepared by MXene powder and comparative example 1 2 For the catalyst, add 995 μl absolute ethanol and 5 μl Nafion respectively, ultrasonically disperse for 5 minutes, and stir for 1 hour. The resulting mixture was transferred to glassy carbon electrodes in 5 μl using a pipette gun, and dried at room temperature to completely evaporate the solvent to obtain glassy carbon electrodes coated with different materials.

[0051] (2) Electrochemical performance testing

[0052] All the tests in this experiment were performed on the CHI660E electrochemical workstation of Shanghai Chenhua Company.

[0053] Detect linear sweep voltammetry (LSV) with a rotation rate of 1600rpm and a scan rate of 10mV s -1 . The glassy carbon...

Embodiment 3

[0055] Example 3 FeCo-LDH / Ti 3 C 2 - Catalytic stability test of MXene as a catalytic hydrogen evolution material

[0056] (1) Preparation of electrodes

[0057] Get the FeCo-LDH / Ti that 4mg embodiment 1 prepares respectively 3 C 2 - MXene powder and FeCo-LDH prepared in Comparative Example 1 were added with 995 μl of absolute ethanol and 5 μl of Nafion, ultrasonically dispersed for 5 min, and stirred for 1 h. Transfer 5 μl of the obtained mixture to a glassy carbon electrode with a pipette gun, and dry at room temperature to completely evaporate the solvent to obtain FeCo-LDH / Ti 3 C 2 -MXene modified electrode and FeCo-LDH modified electrode.

[0058] (3) Electrochemical performance test

[0059] FeCo-LDH / Ti 3 C 2 -MXene modified electrode and FeCo-LDH modified electrode as working electrode, Pt wire as counter electrode, Ag / AgCl as reference electrode to form a three-electrode system, with 1M KOH solution as electrolyte, using standard three electrodes on CHI760D el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com