Method for preparing lactic acid and feedstuff concurrent with crop straw fermentation

A technology of crop straw and lactic acid, applied in the direction of animal feed, animal feed, fermentation, etc., can solve the problem of not being able to produce feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

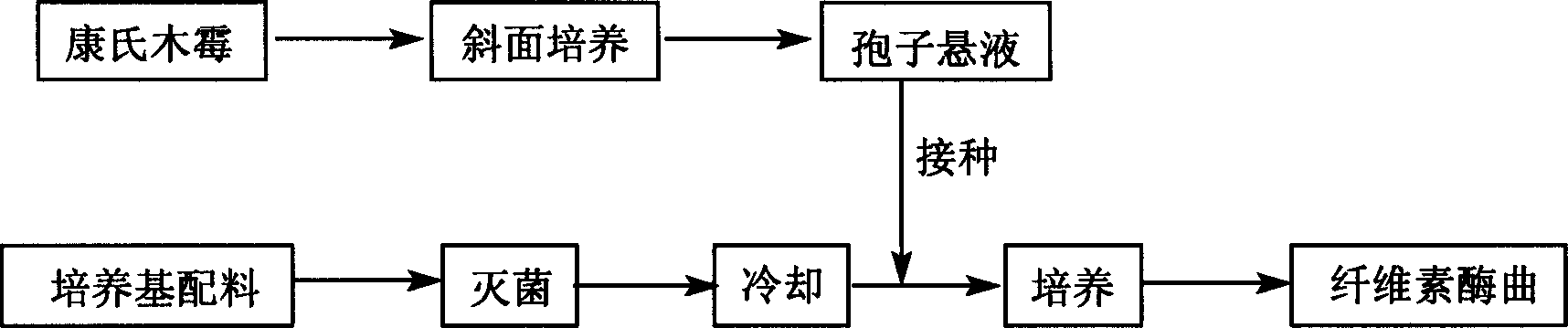

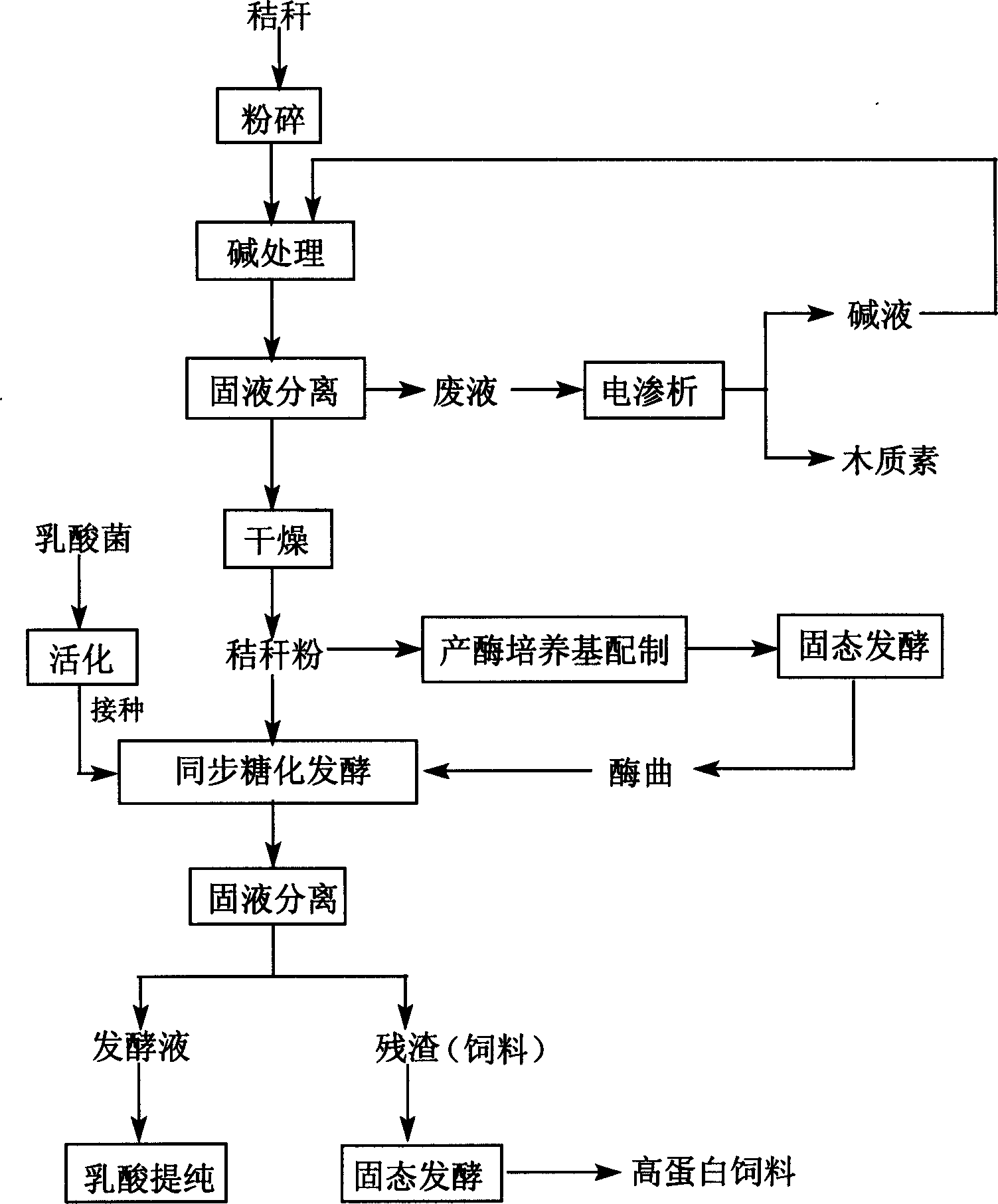

[0005] Specific implementation mode one: (see figure 1 , figure 2 ) This embodiment is realized according to the following steps: (1) Pretreatment of crop stalks: after the stalks are crushed to 80-140 mesh, soaked in dilute lye for 12-36 hours, filtered, and washed until the washing liquid is neutral. The waste liquid produced by pretreatment is recovered lignin and lye by bipolar membrane electrodialysis. (2) Preparation of cellulase koji by solid-state fermentation: Trichoderma and fungi producing cellulase are selected as starting strains, and solid-state fermentation is carried out at 25-30°C for 60-108 hours, and the cellulase koji produced by fermentation is directly used Subsequent simultaneous fermentation. The specific steps for preparing cellulase koji are as follows: a. Inoculate the cellulase-producing bacterial strain into the slant medium for culture, scrape a few ring spores from the activated slant and insert them into sterile water with glass beads, shake ...

specific Embodiment approach 2

[0006] Specific implementation mode two: (see figure 1 , figure 2 ) This embodiment is realized according to the following steps: (1) After crushing the soybean stalks to 140 mesh, soak them in 10% ammonia water at room temperature for 24 hours, filter, and wash until the washing liquid is neutral. The waste liquid produced by pretreatment is separated from lignin and lye by bipolar membrane electrodialysis. (2) Trichoderma konshii is inoculated into the slant medium and cultivated until the mycelia grow vigorously, scrape a few rings of spores from the slant and insert them into sterile water with glass beads, vibrate, disperse the spores, measure the spore concentration, and make the spore suspension concentration reach 10 7 individual / mL. (3) Add straw powder, bran, acetic acid-sodium acetate buffer solution, etc. to the container to prepare a culture medium, so that the weight ratio of straw powder and bran is 1:1, the solid-liquid weight ratio is 2:5, and the acetic a...

specific Embodiment approach 3

[0008] Specific implementation mode three: (see figure 1 , figure 2) This embodiment is realized according to the following steps: (1) crush the corn stalks, pass through an 80-mesh sieve, soak them with 8% ammonia water for 24 hours at room temperature, and the solid-to-liquid ratio is 1:10, then filter and wash until washing Liquid is neutral. The waste liquid produced by pretreatment is separated from lignin and lye by bipolar membrane electrodialysis. (2) Trichoderma konshii is inoculated into the slant medium and cultivated until the mycelia grow vigorously, scrape a few rings of spores from the slant and insert them into sterile water with glass beads, vibrate, disperse the spores, measure the spore concentration, and make the spore suspension concentration reach 10 7 individual / mL. (3) Add pretreated straw powder, bran, water, and ammonium sulfate in the container, so that the weight ratio of straw powder and bran is 1:1, the solid-liquid weight ratio is 1:3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com