Protective coating for high-voltage and high-frequency power equipment

A technology for protective coatings and power equipment, applied in anti-corrosion coatings, fire-resistant coatings, radiation-absorbing coatings, etc., can solve the problems of coating stability and film-forming effect, high production cost, poor dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

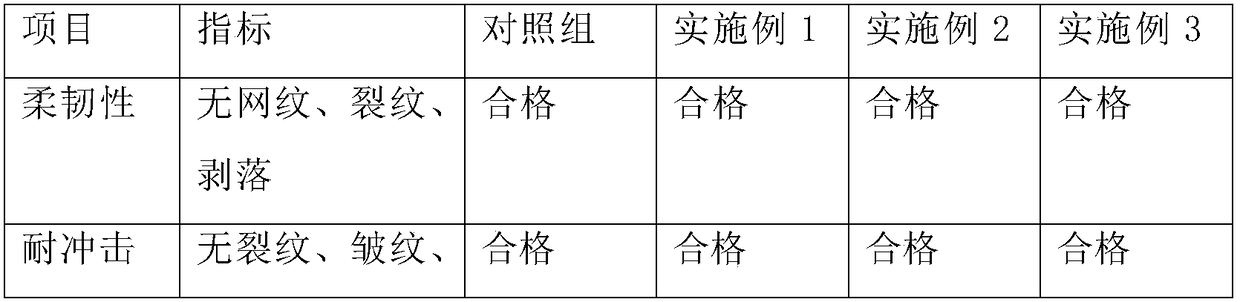

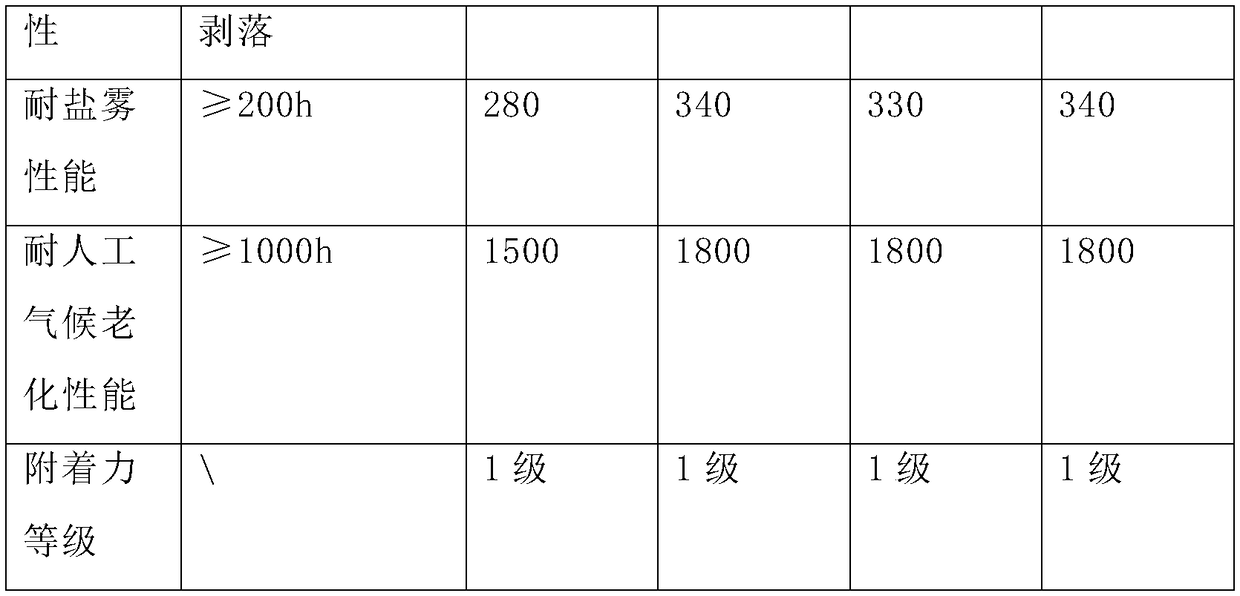

Examples

preparation example Construction

[0026] The preparation method of anti-radiation additive comprises the steps:

[0027] (1) Prepare inorganic fillers according to the number of parts by mass: 45 parts of α-alumina, 37 parts of nano-silicon dioxide, 8 parts of nano-silicon carbide, and 15 parts of nano-calcium carbonate. The above inorganic filler components are added to the ball mill for ball milling and mixing. Add modifier dropwise to the mixture during ball milling. The amount of modifier added dropwise is 6% of the mass of the mixed filler. After ball milling, the solvent is evaporated at a temperature of 88°C to obtain the required superhard core;

[0028] (2) According to the mass ratio of 2:1:1:5:4, the nanoscale particles of lanthanum oxide, samarium oxide, thulium oxide, yttrium oxide and strontium carbonate are added to the hydrochloric acid solution for dissolution, and the amount of particles added is 4% of the hydrochloric acid solution. %, add 3.6wt% polyvinyl alcohol to the solution to dissolve...

Embodiment 1

[0033] A protective coating for high-voltage and high-frequency power equipment, characterized in that, according to the parts by mass, the components of the protective coating include: 60 parts of pure acrylic emulsion, 13 parts of fluorosilicone resin, 11 parts of polyvinylpyrrolidone, 12 parts of filler, 4 parts of radiation additives, 1.3 parts of sodium nitrite, 0.6 parts of hydroxypropyl methyl cellulose ether, 0.2 parts of nonylphenol polyoxyethylene ether, 0.1 part of antiseptic and antibacterial agent, and 0.1 part of defoamer.

[0034] Wherein, the filler component contains titanium dioxide, lithium-based bentonite and palygorskite powder, and the mass ratio of the three is 5:2:1.

[0035] The preservative is isothiazolinone; the defoamer is a silicone defoamer.

[0036] The preparation method of the protective paint provided by the present embodiment is:

[0037] In parts by mass, add pure acrylic emulsion and polyvinylpyrrolidone into the dispersing tank and stir ...

Embodiment 2

[0039] A protective coating for high-voltage and high-frequency power equipment, characterized in that, according to the mass parts, the components of the protective coating include: 70 parts of pure acrylic emulsion, 18 parts of fluorosilicone resin, 16 parts of polyvinylpyrrolidone, 15 parts of filler, anti 8 parts of radiation additives, 1.7 parts of sodium nitrite, 1.4 parts of hydroxypropyl methylcellulose ether, 0.6 parts of nonylphenol polyoxyethylene ether, 0.3 parts of antiseptic and antibacterial agent, and 0.7 part of defoamer.

[0040] Wherein, the filler component contains titanium dioxide, lithium-based bentonite and palygorskite powder, and the mass ratio of the three is 5:2:1.

[0041] The preservative is thiophanate-methyl; the defoamer is a mineral oil defoamer.

[0042] The preparation method of the protective paint provided by the present embodiment is:

[0043] In parts by mass, add pure acrylic emulsion and polyvinylpyrrolidone into the dispersing tank a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com