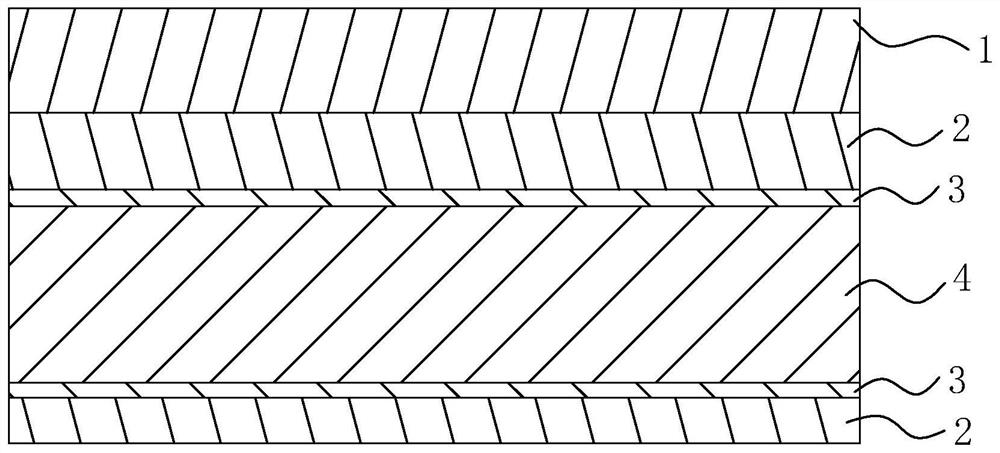

A kind of pcm board for elevator and its production process

A technology for elevators and substrates, which is used in elevators, polyurea/polyurethane coatings, anti-corrosion coatings, etc. To achieve the effect of increasing stability, improving salt spray corrosion resistance, improving salt spray corrosion resistance and acid and alkali corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

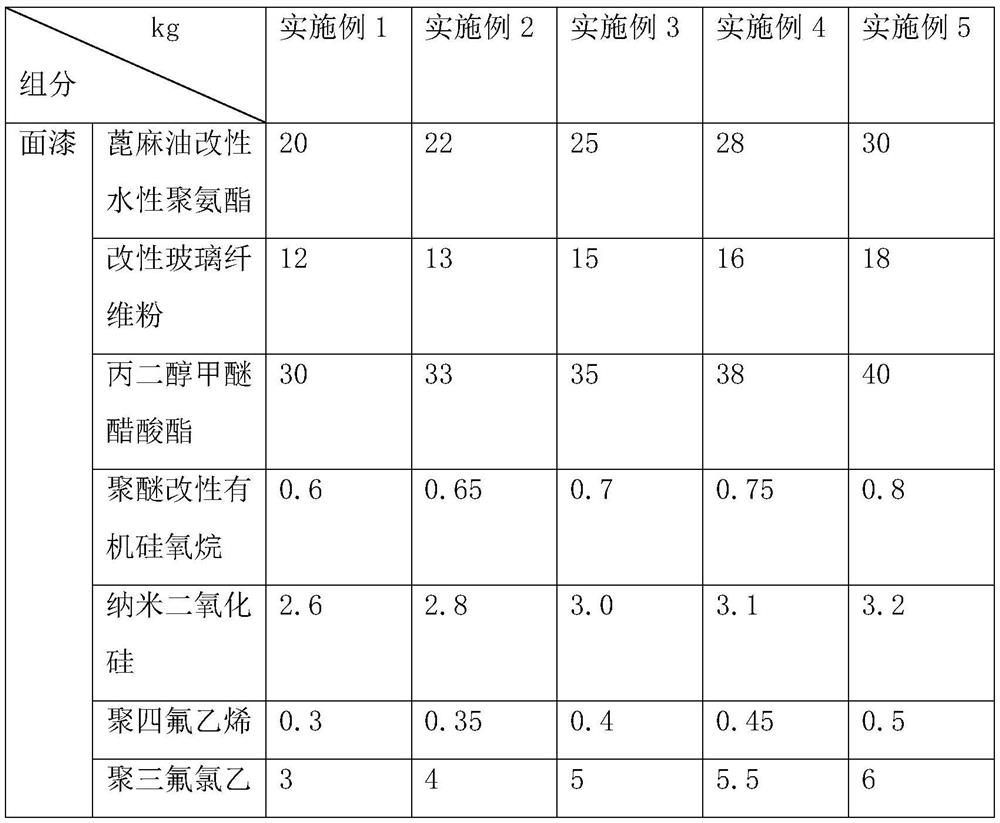

Examples

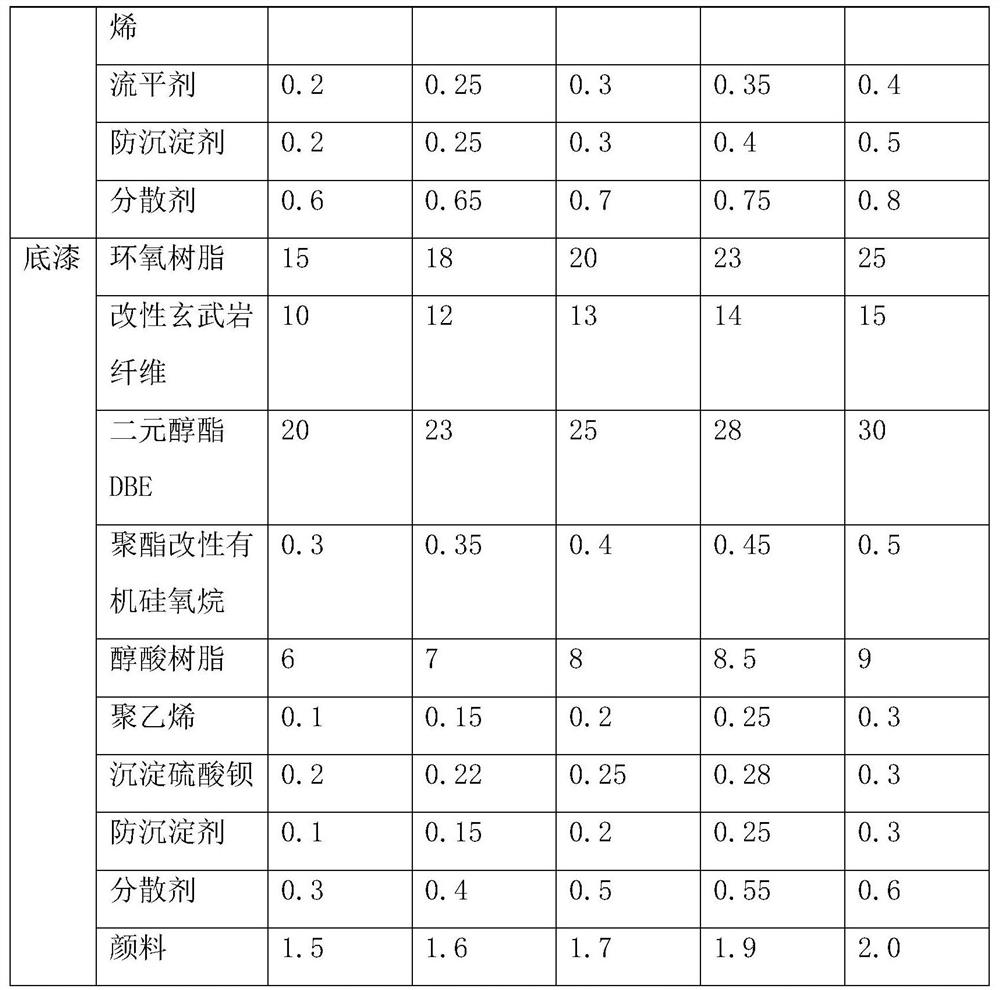

preparation example 1-3

[0050] In the preparation example 1-3, the glass fiber is selected from the glass fiber sold by Binzhou Anrun Chemical Fiber Rope Net Co., Ltd. with the article number AR-1116, and the graphene oxide is selected from the article number TF-12055 sold by Suzhou Carbonfeng Graphene Technology Co., Ltd. The graphene oxide and bisphenol A vinyl resin are selected from the bisphenol A vinyl resin sold by Changzhou Kainuosi Composite Material Co., Ltd. with the brand name VER-2.

preparation example 1

[0051] Preparation Example 1: (1) Burn the glass fiber in a muffle furnace at 600°C for 1.5 hours, and wash it twice with deionized water;

[0052] (2) Place the glass fibers in a dopamine solution with a concentration of 2 g / L and a pH value of 8.5, stir and react for 20 hours at room temperature, wash with deionized water for 3 times after filtration, and vacuum-dry at 65°C. The mass ratio of dopamine solution is 1:4;

[0053] (3) Mix graphene oxide, nanoparticles and styrene, add the dopamine solution with a concentration of 2g / L and a pH value of 8.5, then add the glass fiber prepared in step (2), stir for 1h, and then mix it at 3000r / min Centrifuge at a rotating speed of 5min, place in bisphenol A vinyl resin to solidify for 1.5h, and grind into powder to obtain modified glass fiber powder; the mass ratio of glass fiber, graphene oxide, nanoparticles, styrene and dopamine solution 1:0.1:0.8:0.5:1.1:6, the mass ratio of bisphenol A vinyl resin to the centrifuged mixture i...

preparation example 2

[0054] Preparation Example 2: (1) Burn the glass fiber in a muffle furnace at 630°C for 1.3 hours, and wash it with deionized water for 3 times;

[0055] (2) Put the glass fiber in a dopamine solution with a concentration of 2.2g / L and a pH value of 8.6, stir and react for 22 hours at room temperature, wash it with deionized water for 4 times after filtering, and dry it in vacuum at 63°C. The mass ratio with dopamine solution is 1:5;

[0056] (3) Mix graphene oxide, nanoparticles and styrene, add concentration to be 2.2g / L and in the dopamine solution that pH value is 8.6, add the glass fiber that step (2) makes again, stir 1.1h, with 3300r / min speed centrifugation for 4.5min, placed in bisphenol A vinyl resin for curing for 1.8h, ground into powder, and prepared modified glass fiber powder; glass fiber, graphene oxide, nanoparticles, styrene and dopamine solution The mass ratio of the mixture is 1:0.2:0.9:0.6:1.2:7, the mass ratio of bisphenol A vinyl resin to the centrifug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com