Novel chemical nickel-plating method for magnesium alloy

A technology for electroless nickel plating and magnesium alloy plating, which is applied in the field of metal surface treatment and electroless nickel plating for magnesium alloys. It can solve problems such as the need to improve the bonding force of the plating layer, poor bonding force of the plating layer, and complicated process, so as to improve the salt spray corrosion resistance. Good coating performance and the effect of overcoming high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

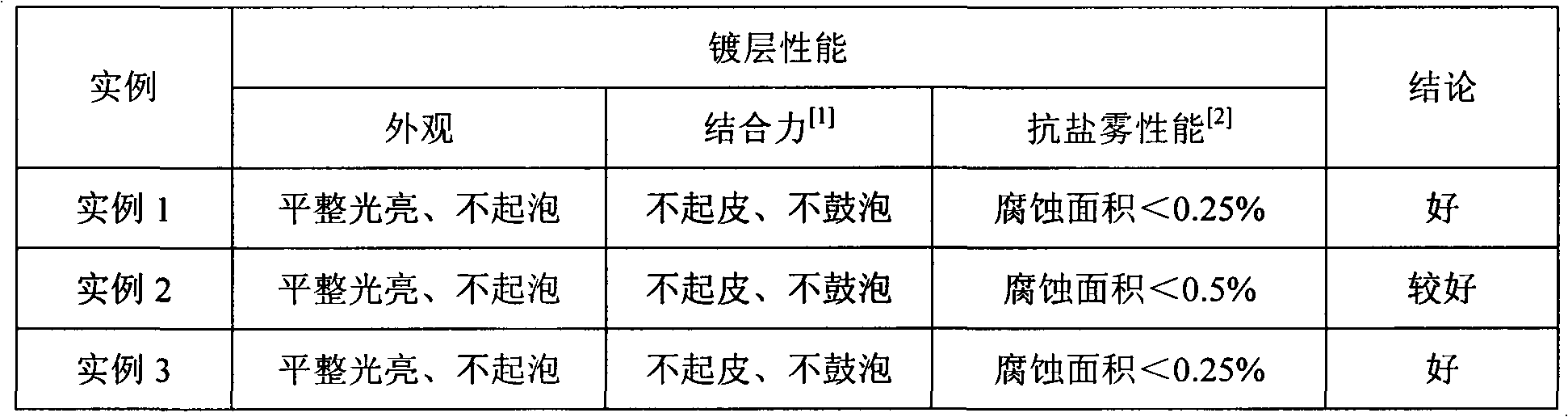

Examples

example 1

[0025] Example 1: Extruded profile with domestic AZ31B magnesium alloy, cut into 100×50×4mm 3 Samples, according to the following steps for electroless nickel plating treatment:

[0026] 1. Alkaline washing: dissolve 15g of industrial grade sodium hydroxide (99%) in 100ml distilled water, dissolve 15g of industrial grade trisodium phosphate in 100ml distilled water; dissolve 1g of analytically pure sodium lauryl sulfate in 100ml distilled water ; Pour the above three solutions into a 1000ml beaker, add 700ml of distilled water, and mix completely to form a 1000ml alkali washing solution. Heat the alkali washing solution to 70°C in a constant temperature water bath, and immerse the sample in the alkaline washing solution for 7 minutes; after taking out the sample, rinse it with a large amount of distilled water at room temperature.

[0027] 2. Pickling: Dissolve 50ml of analytically pure acetic acid into 100ml of distilled water, 5g of potassium sodium tartrate into 100ml of d...

example 2

[0031] Example 2: Using domestic AZ91 magnesium alloy ingot, cut into 100×50×4mm 3 For the samples, perform electroless nickel plating according to the following steps.

[0032] The processing method is the same as Example 1.

example 3

[0033] Example 3: Cast ingot with domestic ZK60 magnesium alloy, cut into 100×50×4mm 3 For the samples, perform electroless nickel plating according to the following steps.

[0034] 1. Alkaline washing: dissolve 15g of industrial grade sodium carbonate in 100ml distilled water, dissolve 10g of industrial grade trisodium phosphate in 100ml distilled water; dissolve 1g of analytically pure OP-10 in 100ml of distilled water; Dissolve 1g of sodium in 100ml of distilled water; pour the above three solutions into a 1000ml beaker, add 600ml of distilled water, and mix completely to form 1000ml of alkali washing solution. Heat the alkali washing solution to 70°C in a constant temperature water bath, and immerse the sample in the alkaline washing solution for 7 minutes; after taking out the sample, rinse it with a large amount of distilled water at room temperature.

[0035] 2. Pickling: the same as item 2 in Example 1;

[0036] 3. Activation: Dissolve 10ml of analytically pure sulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com