Device for salt mist tolerance test of aluminum alloy workpiece and test method using device

A technology of aluminum alloy and spraying device, which is applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as inability to effectively complete salt spray tolerance test, imperfect structure, simple design, etc., to achieve safety and effectiveness The effect of treating the environment, improving the ability to resist salt spray corrosion, and improving the structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following, the present invention will be further explained through specific embodiments in conjunction with the drawings:

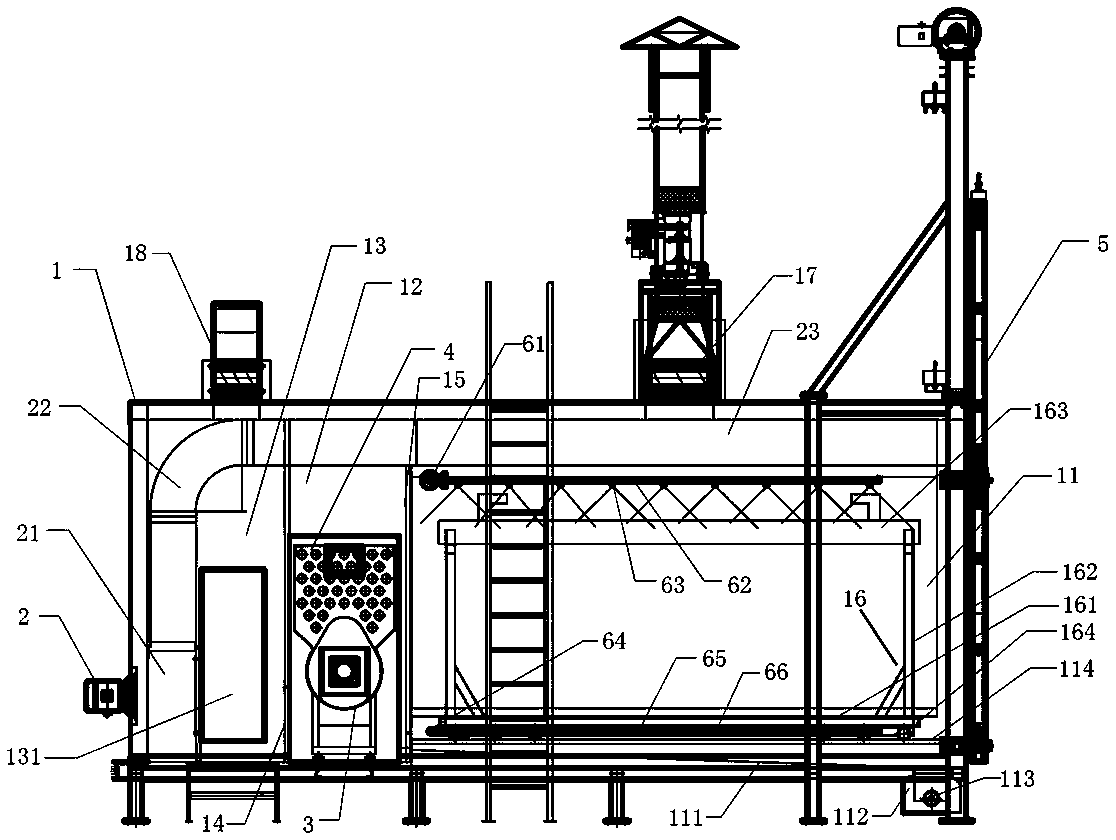

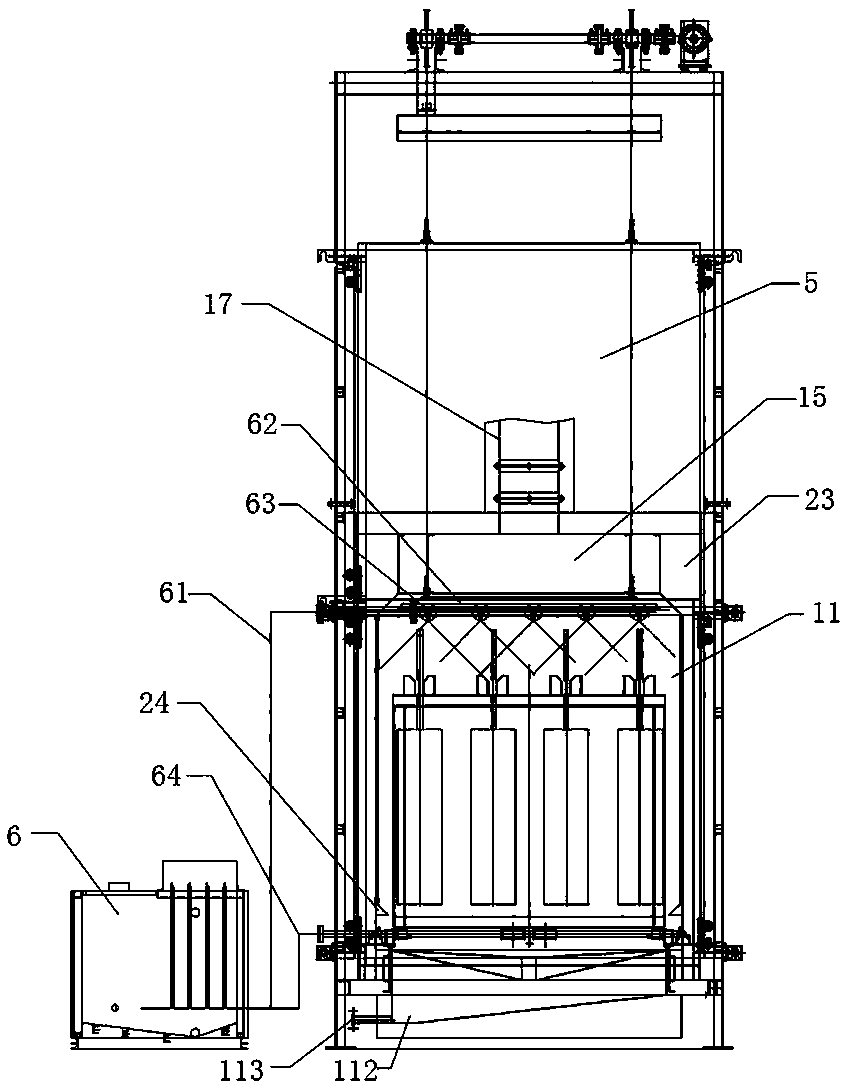

[0028] see figure 1 , figure 2 , A device for salt spray resistance test of aluminum alloy workpieces, including steam box 1, fan 2, burner 3, heat exchanger 4, vertical lift door 5 and heatable water tank 6, steam box 1 includes workpiece steaming chamber 11. The return air chamber 12 and the air supply chamber 13; the fan 2 is fixedly connected to the outer wall of the air supply chamber 13, and the air supply chamber 13 is provided with an induced air box 21, an air supply pipe 22 connected to the induced air box 21, and an induced air box 21 The deflector, the air supply pipe 22 extends from the air supply chamber 13 into the return air chamber 12 and then into the workpiece steam chamber 11; the burner 3 is fixedly connected to the outer wall of the return air chamber 12, and the heat exchanger 4 is arranged in the return air chamber In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com