Patents

Literature

77results about How to "Safe and efficient handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

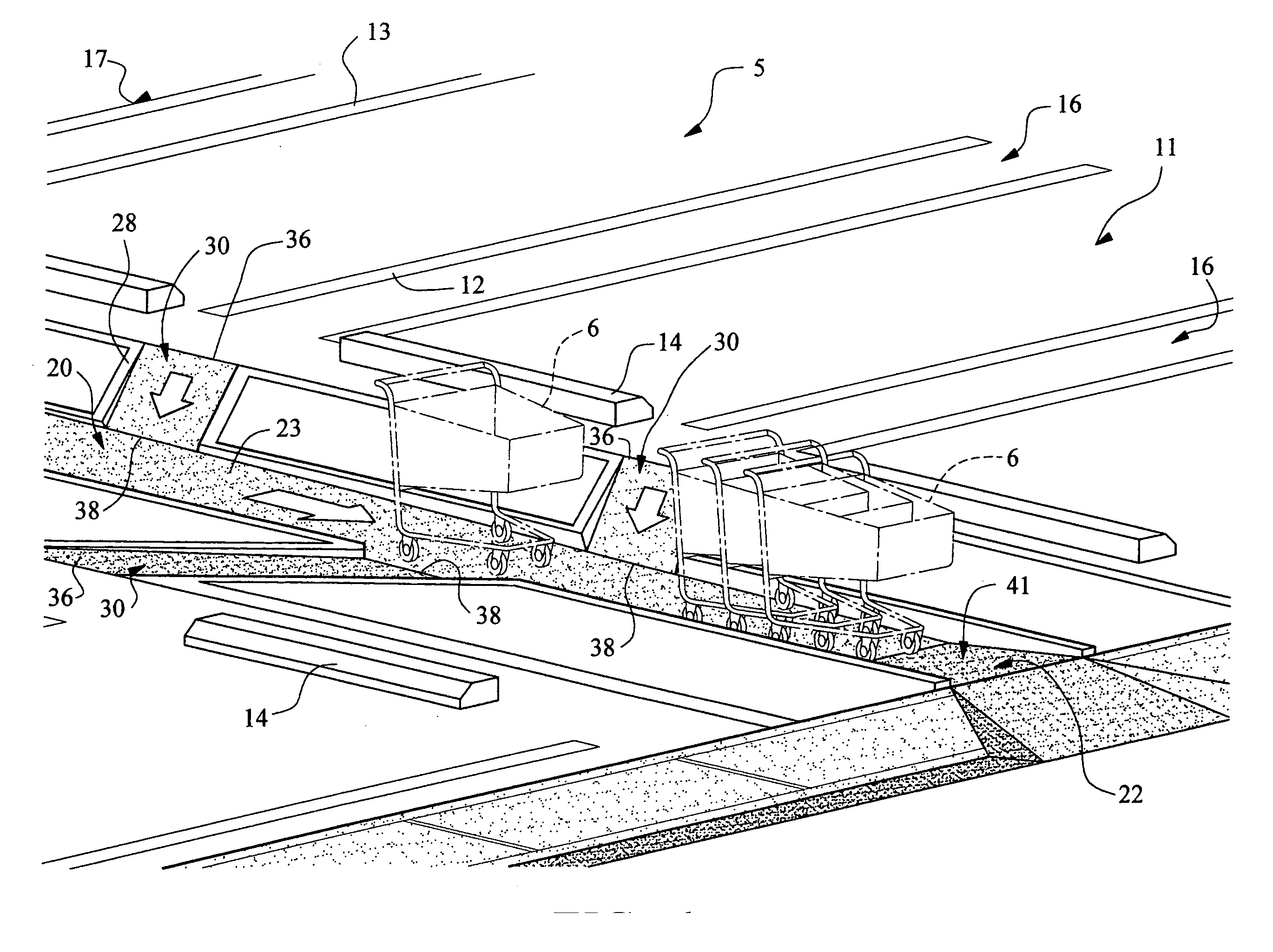

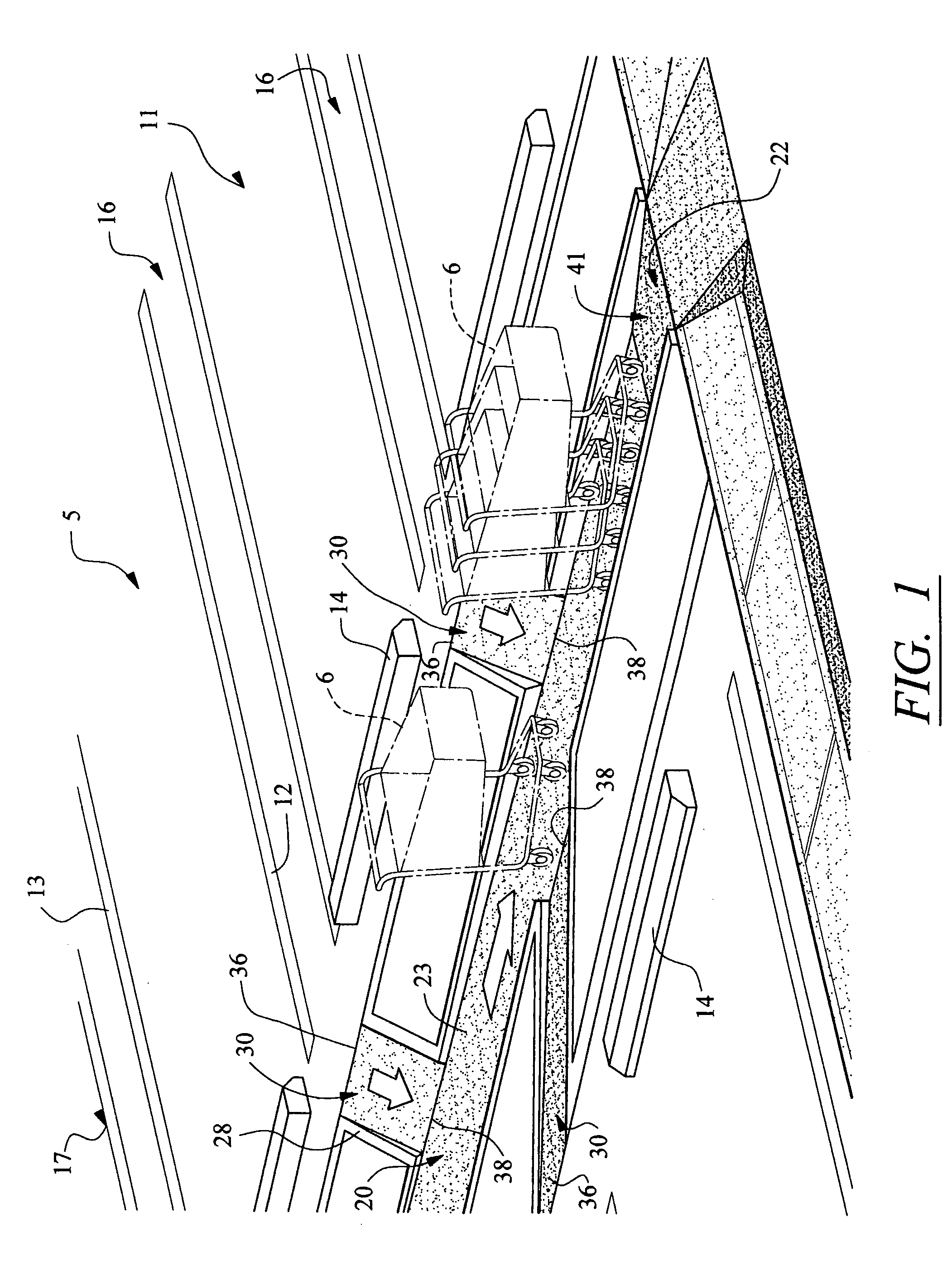

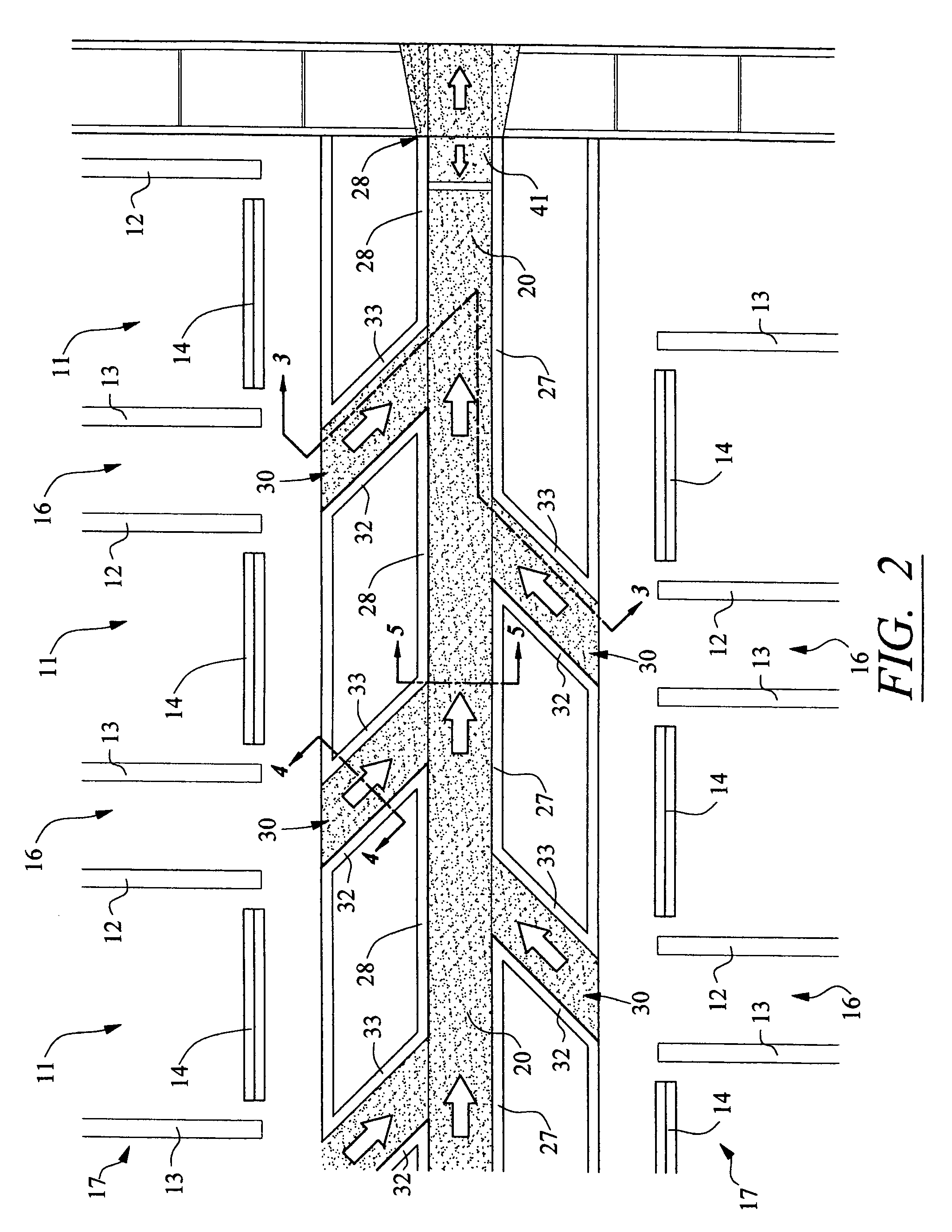

Shopping cart collection, storage, and retrieval system

InactiveUS6910828B1Safe and efficient handlingEncourage useService system furnitureTraffic signalsCartSelf guided

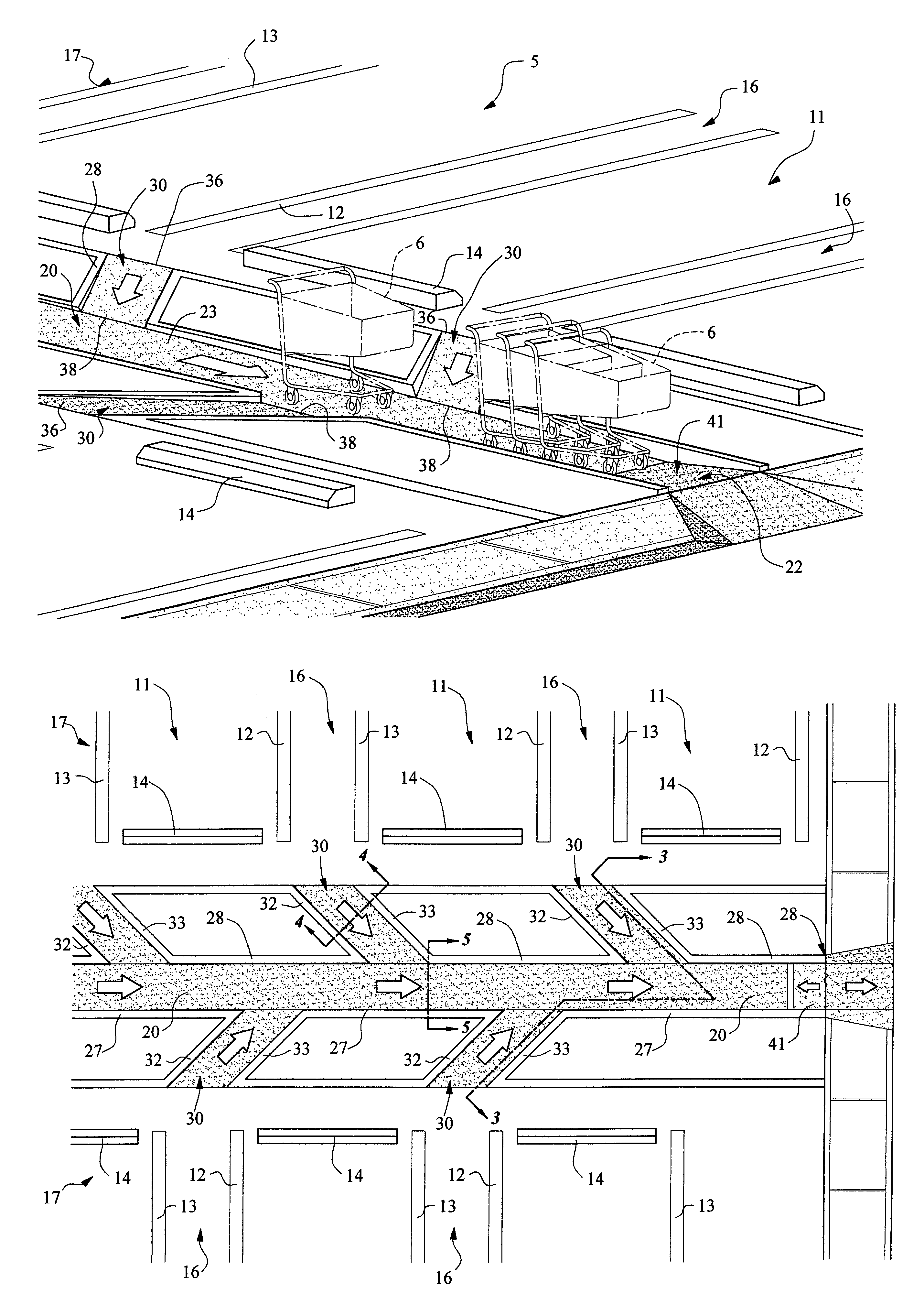

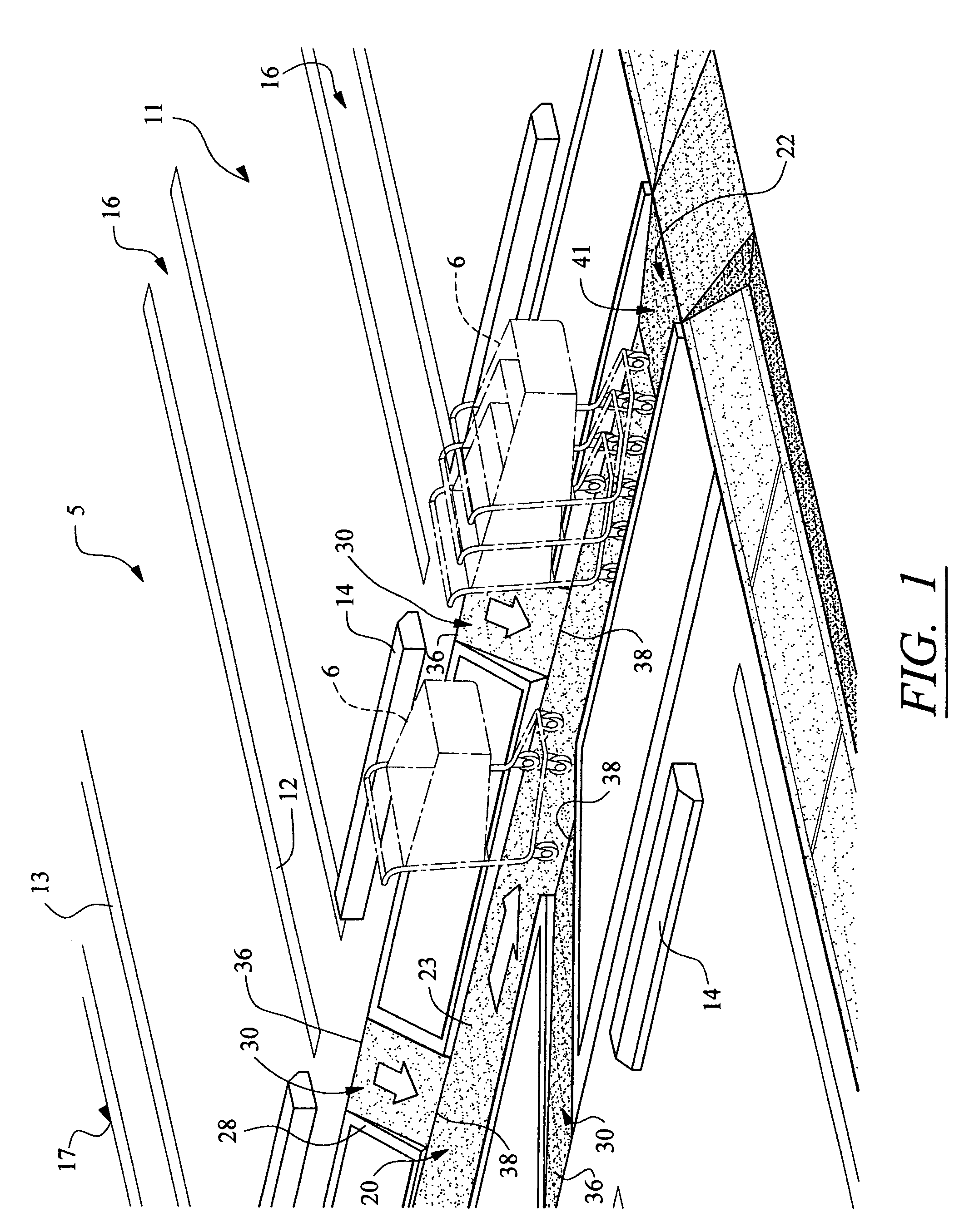

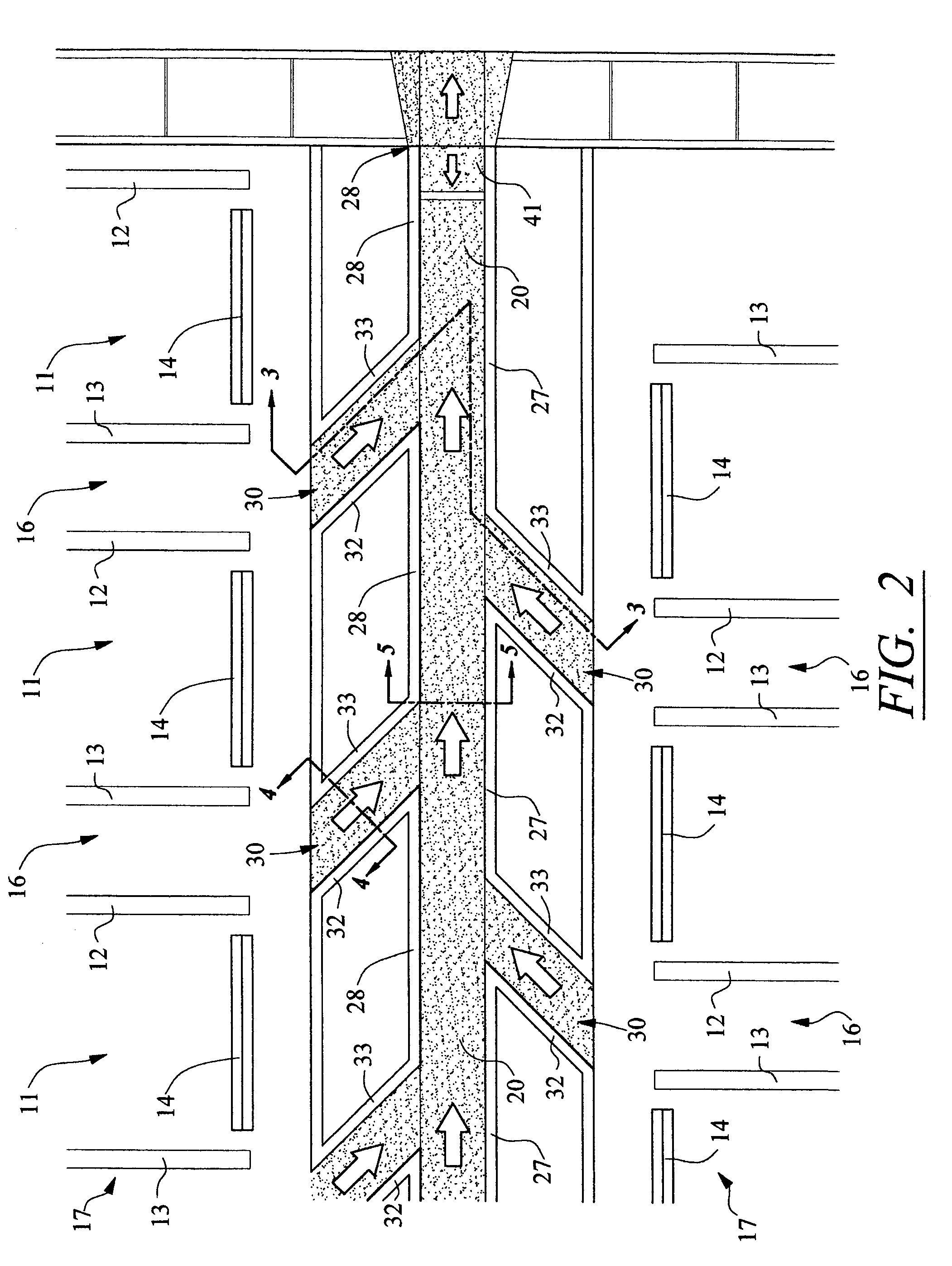

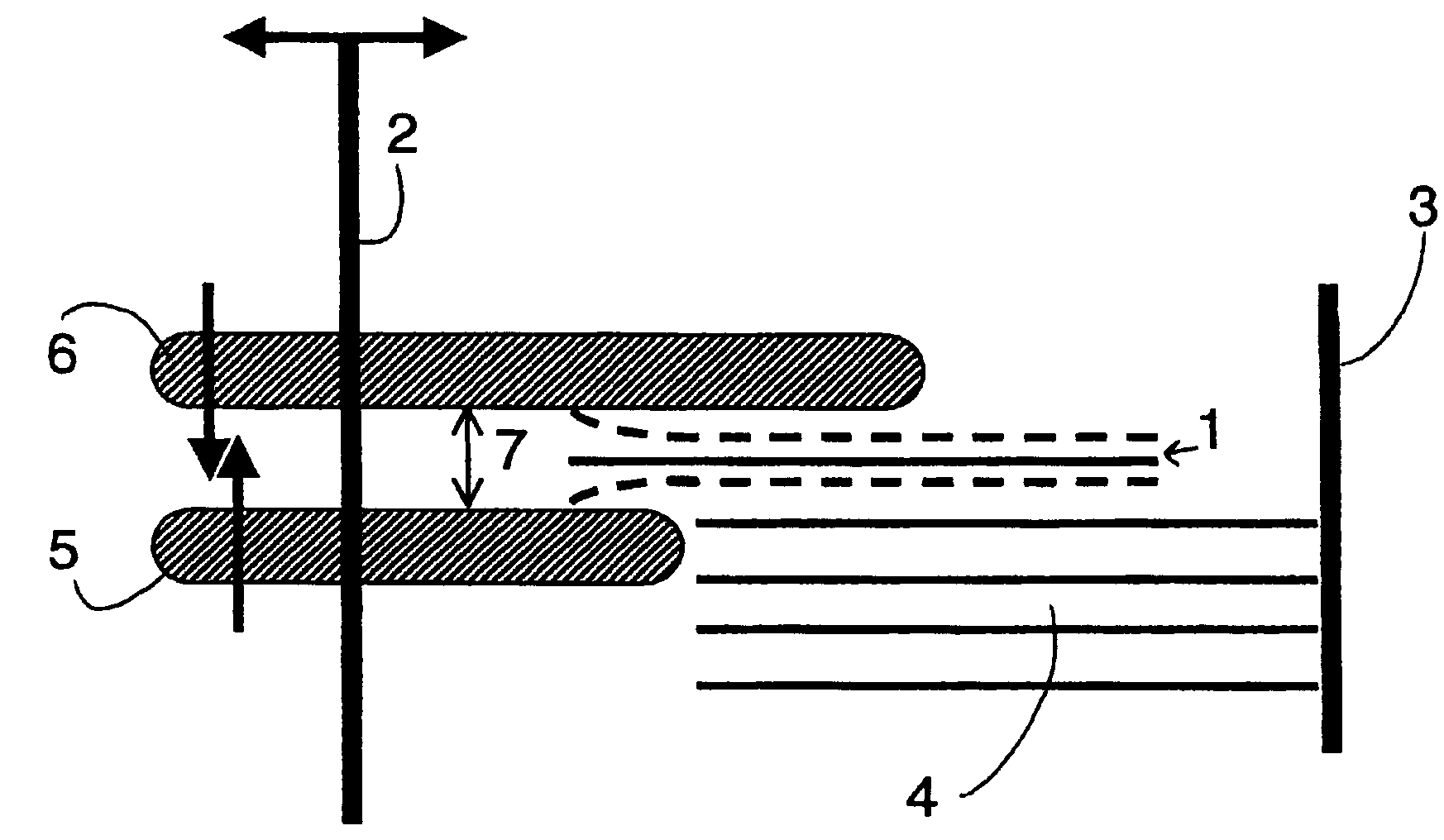

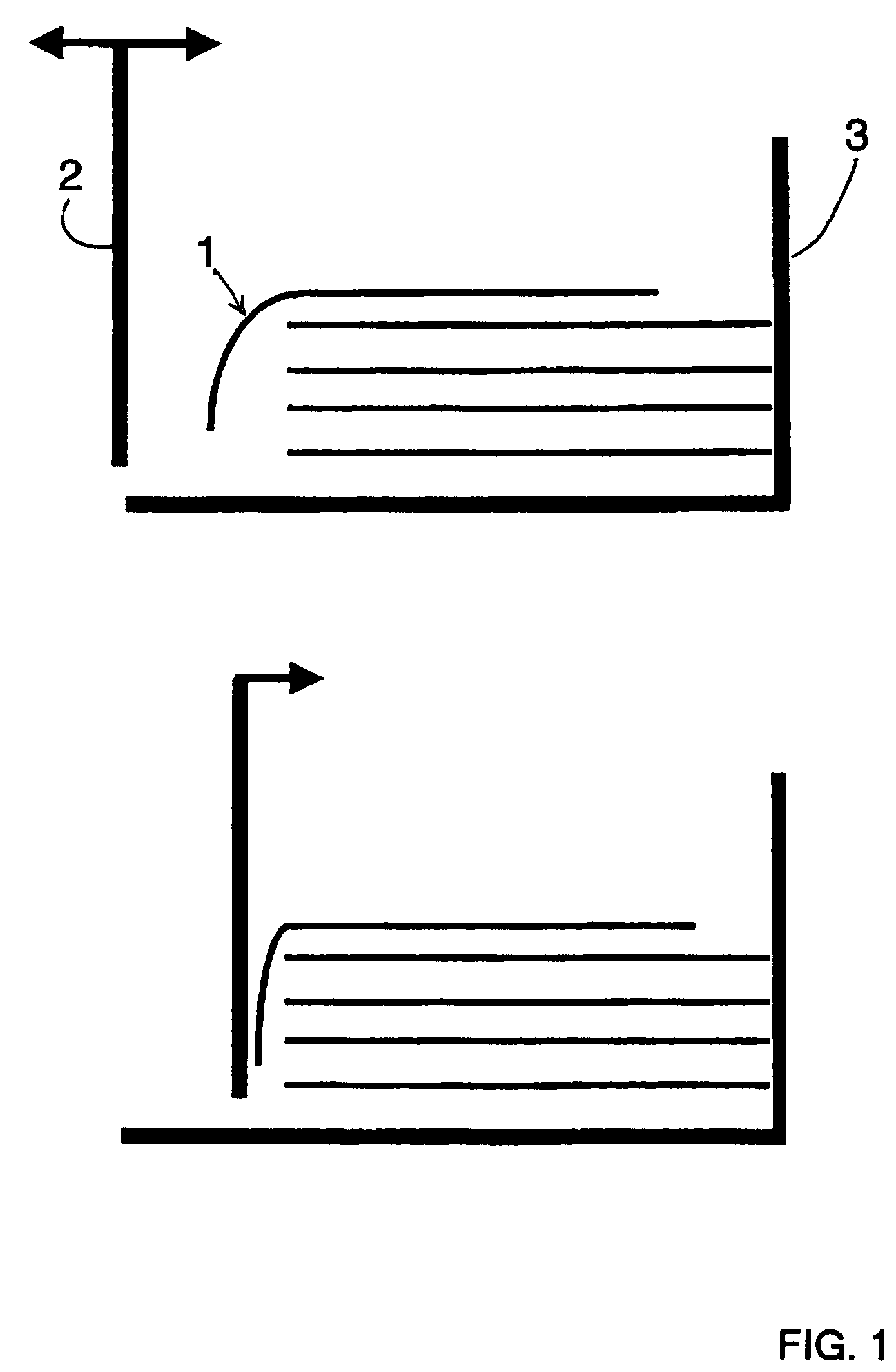

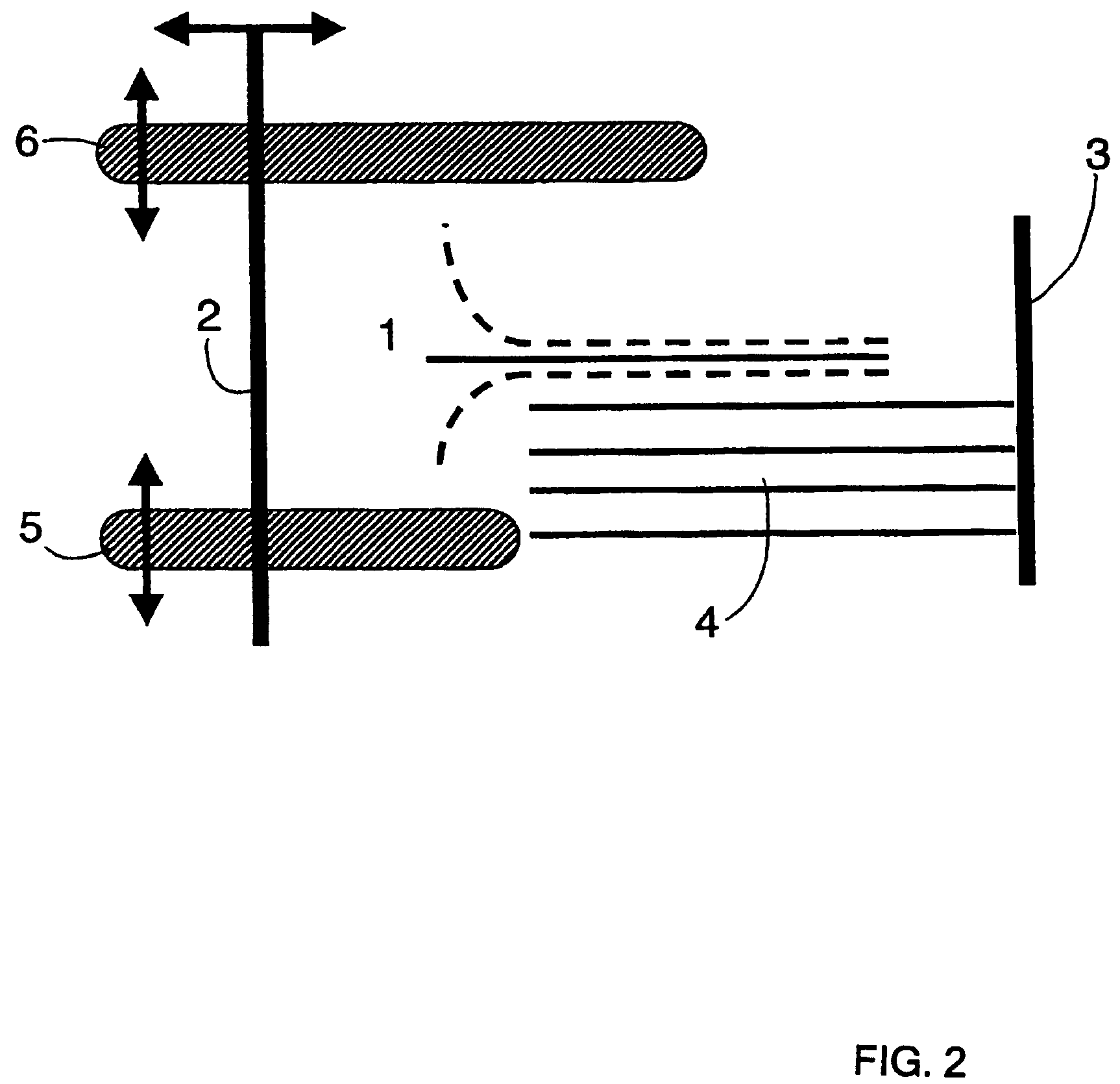

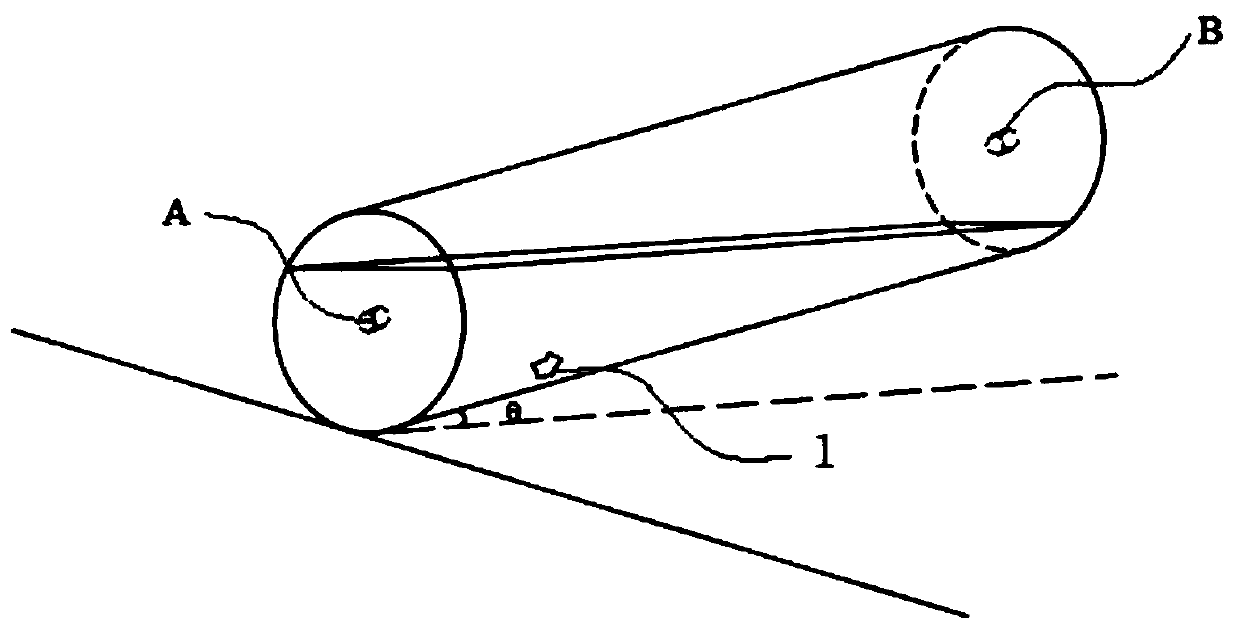

A self-guiding shopping cart collection, storage, and retrieval system is provided which is integrated into the parking lot construction. A collection channel is adjacent and parallel to a row of parking spaces which is formed as an inset trough configured to allow rolling translation of a shopping cart to a collection end. The collection channel has a generally planar floor and at least one inclined side bank with the floor being downwardly linearly inclined toward the collection end. Lateral feed channels intersect with the collection channel which are configured to allow rolling translation of a shopping cart from the parking lot into the collection channel. Thus, shopping carts from the parking lot are introduced into the lateral feed channels at the parking lot level and guided therethrough into the collection channel.

Owner:HUGHES METRA

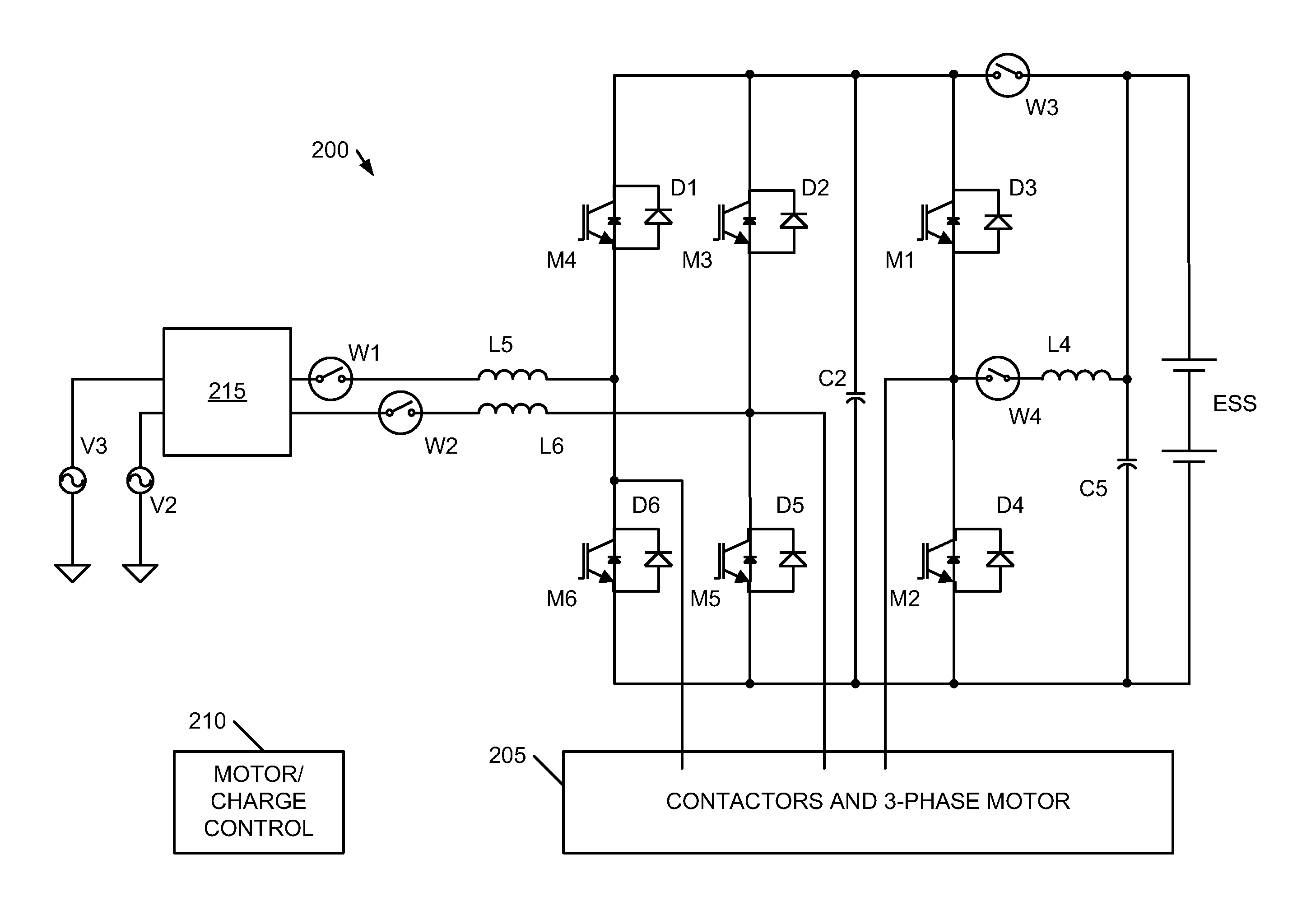

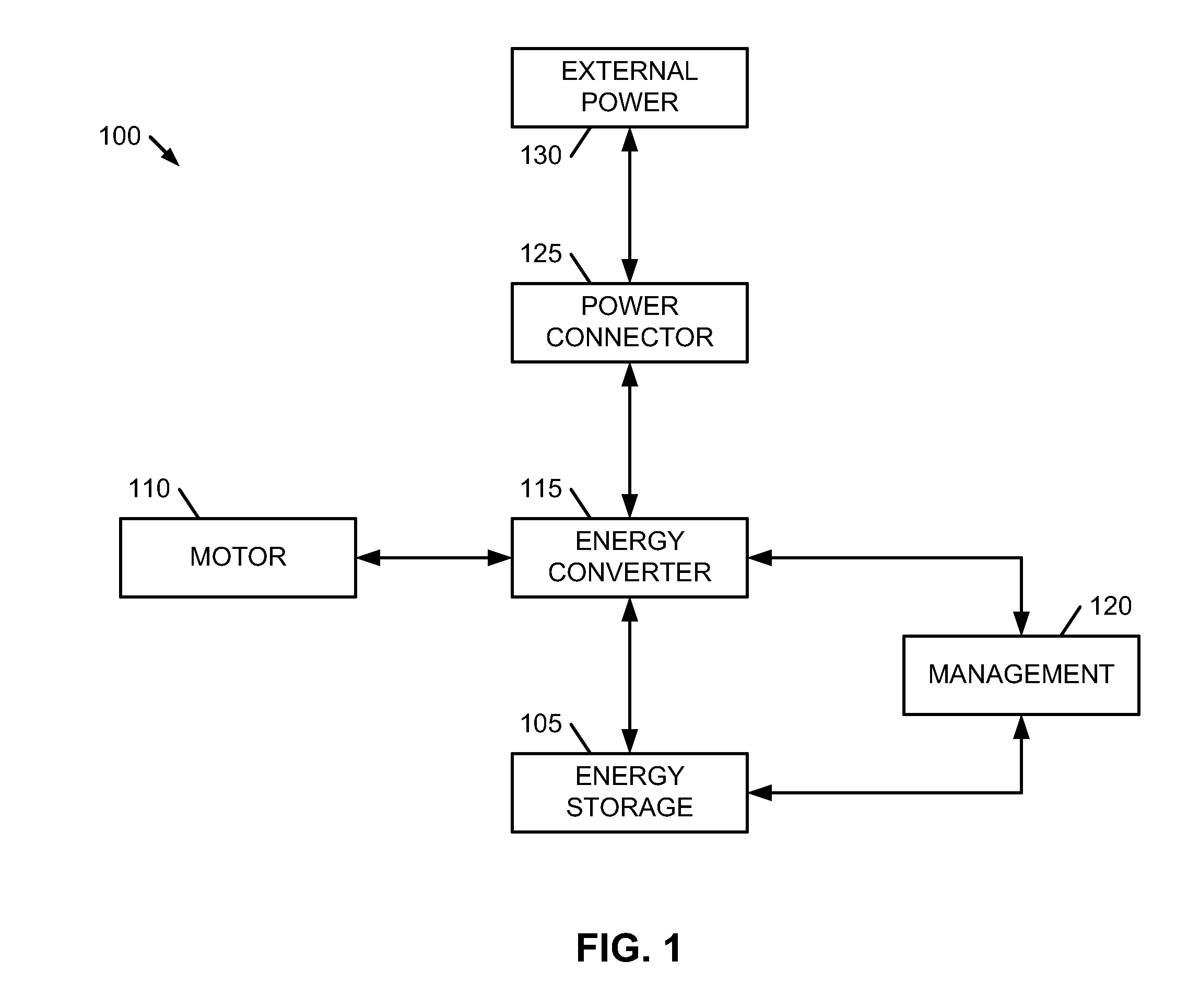

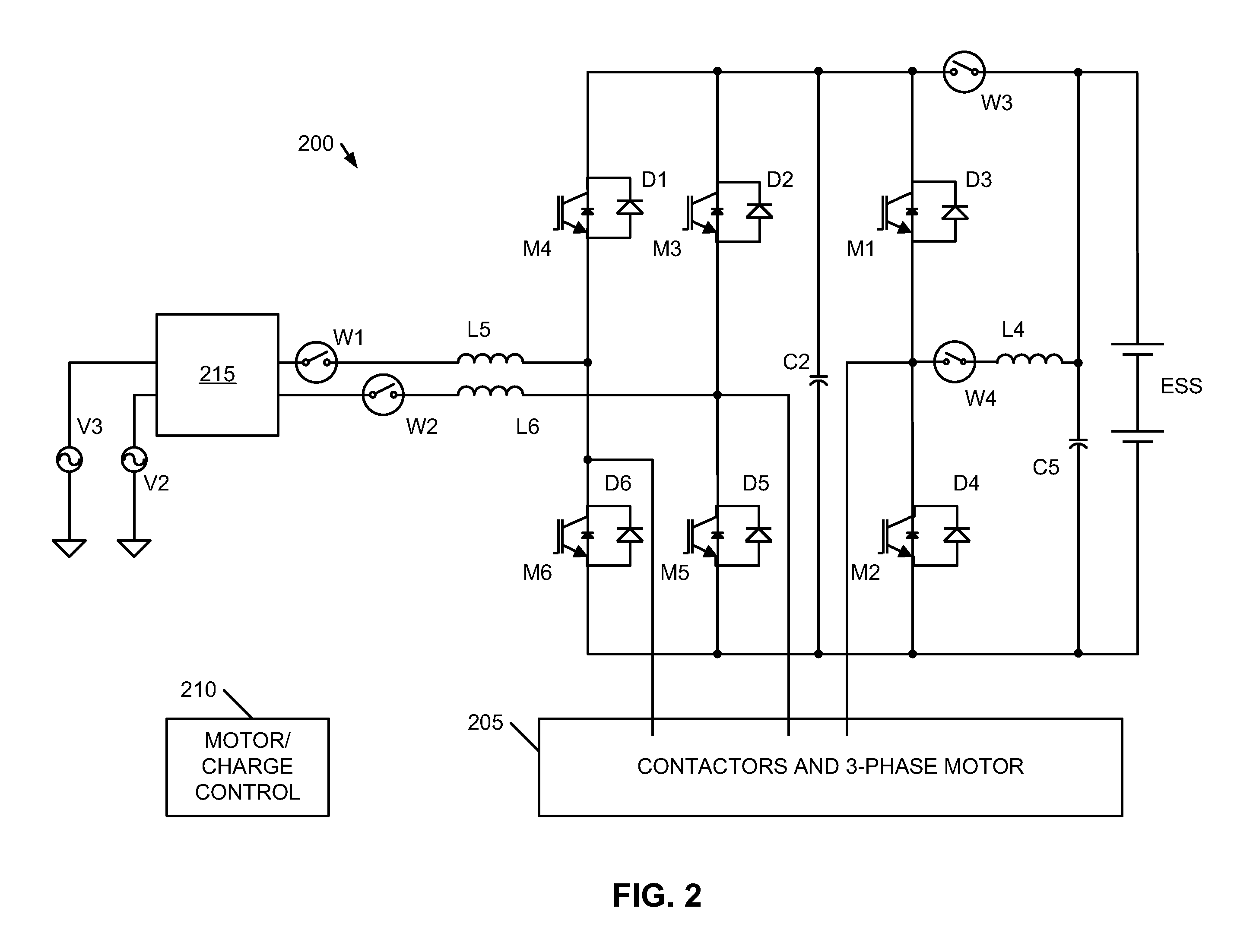

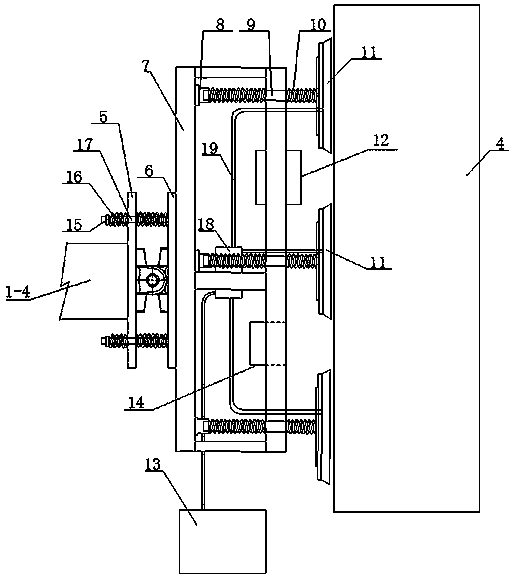

Bidirectional polyphase multimode converter including boost and buck-boost modes

ActiveUS20120019212A1High energySafe and efficient handlingSecondary cells charging/dischargingElectric powerDriver circuitMotor drive

A charging method using a multiphase line voltage for charging an energy storage system (ESS) using a polyphase motor drive circuit communicated to a polyphase motor, the polyphase motor drive circuit including a plurality M of driver stages, one driver stage for each phase of the polyphase motor with each driver stage coupled across the energy storage system, the method including the steps of: (a) determining a charge mode responsive to a comparison of the multiphase line voltage to a voltage of the energy storage system, the determined charge mode including a boost mode when the voltage of the energy storage system has a first predetermined relationship to the multiphase line voltage and the determined charge mode including a boost-buck mode when the voltage of the energy storage system has a second predetermined relationship to the multiphase line voltage; (b) converting, when the charge mode includes the boost mode, the multiphase line voltage to a first charging voltage using a first set of N number of the plurality of driver stages, with N less than M, wherein the first charging voltage is communicated to the energy storage system, and wherein the first charging voltage is greater than the multiphase line voltage; and (c) converting, when the charge mode includes the boost-buck mode, the multiphase line voltage to a second charging voltage using a second set of P number of the plurality of driver stages when in the boost-buck mode, with P greater than N, wherein the second charging voltage is communicated to the energy storage system, and wherein the second charging voltage is less than the multiphase line voltage.

Owner:TESLA INC

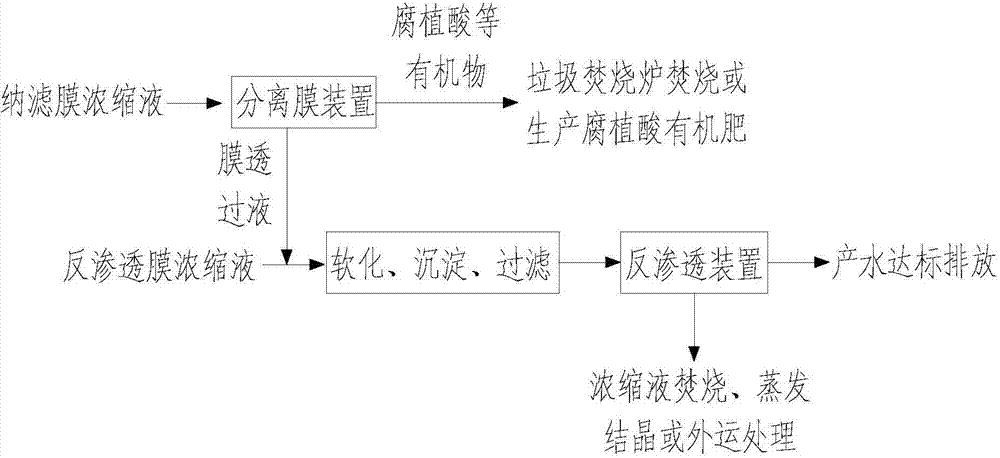

Treatment method for garbage leachate membrane concentrated solution

InactiveCN104496079AEasy to handleOrganic matter such as humus that is easy to process and recover has been safely and effectivelyMultistage water/sewage treatmentExisting TreatmentReverse osmosis

The invention discloses a treatment method for a garbage leachate membrane concentrated solution. The treatment method comprises the following steps: feeding the garbage leachate membrane concentrated solution into a membrane separating device to remove degradation-resistant organic substances such as humic acid in the concentrated solution, mixing the outlet water of the concentrated solution with a reverse osmosis concentrated solution, then removing scaling ions such as Ca<2+> and Mg<2+> and other inorganic substances in the concentrated solution by softening, precipitating and filtering, introducing the outlet water into the reverse osmosis membrane to further concentrate, and realizing up-to-standard release of produced water; and finally, spraying back the concentrated water back to an incinerator for incineration, evaporative crystallization or outward processing. The treatment method can be used for realizing efficient treatment of the garbage leachate membrane concentrated solution, and has the advantages of being stable in operation, high in treatment efficiency, low in operation cost, convenient to maintain and manage, and the like in comparison with the existing treatment method for the garbage leachate membrane concentrated solution.

Owner:BEIJING SOUND ENVIRONMENTAL ENG +1

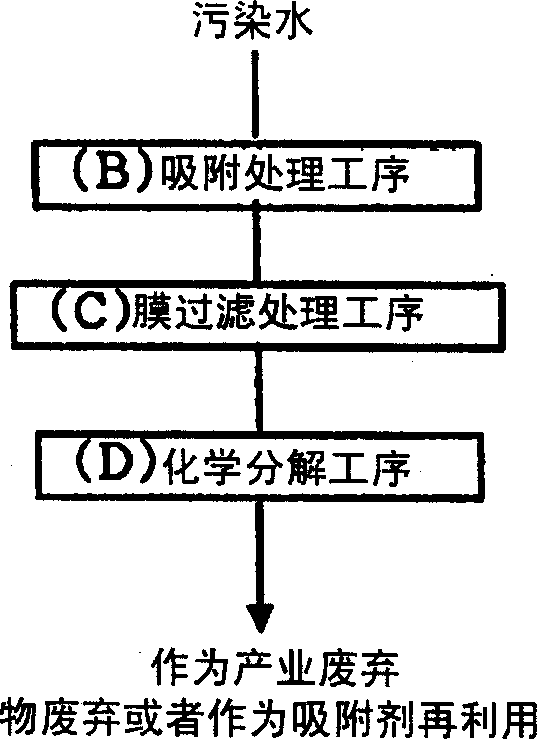

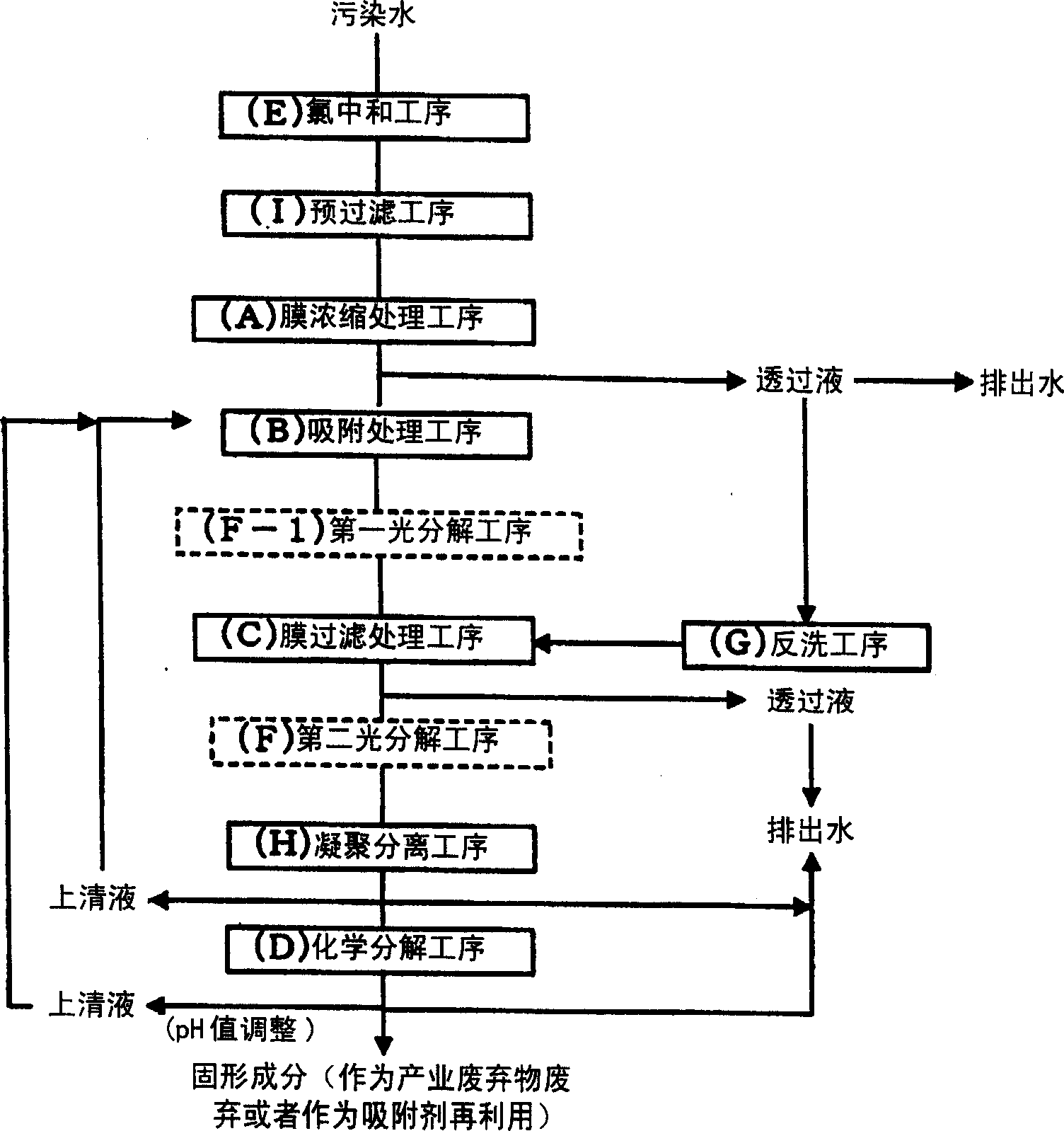

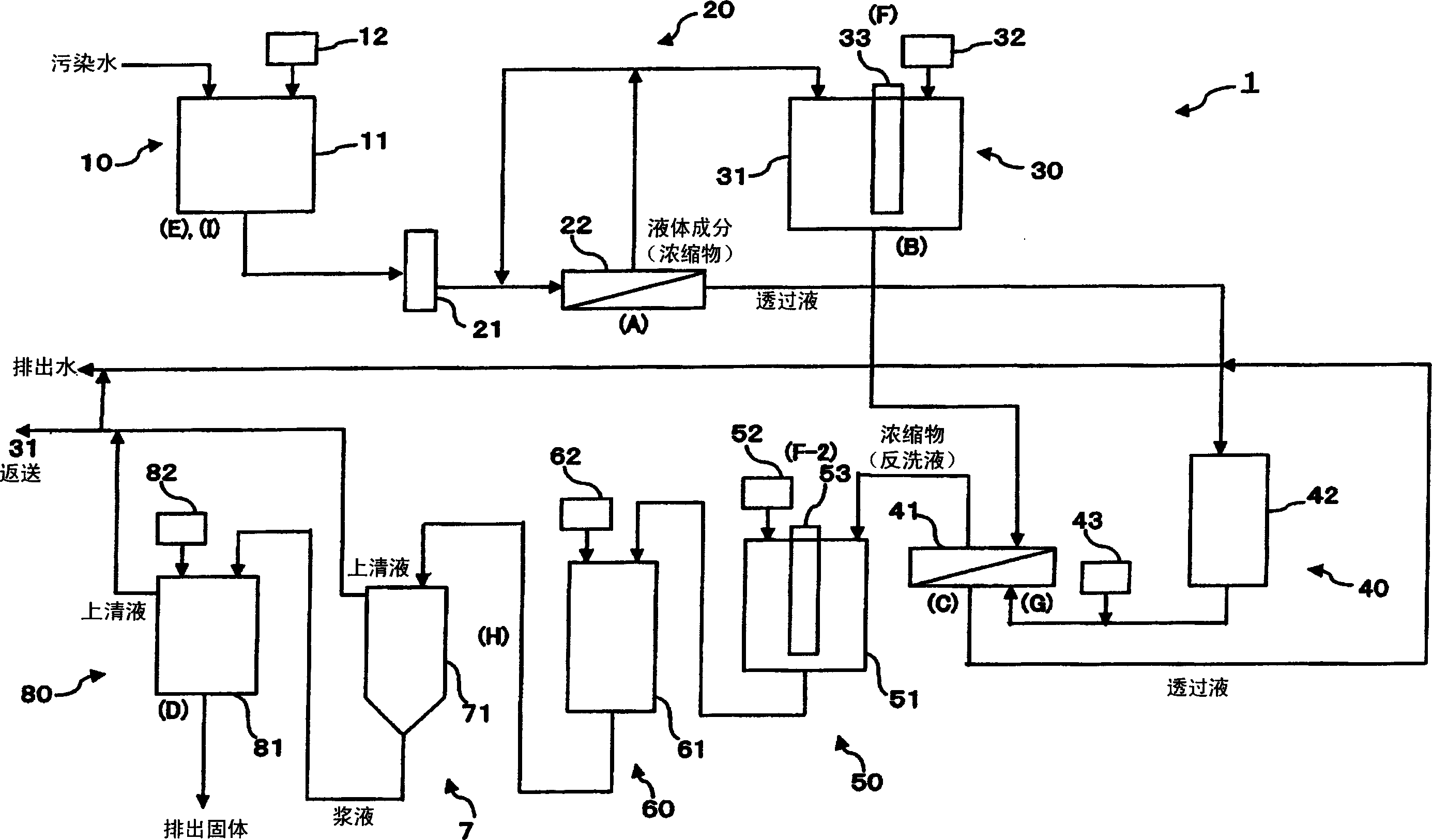

Method for treating raw water containing hardly decomposable substance

InactiveCN1910116ASafe and efficient handlingNo harmful effectsOrganic chemistryWater/sewage treatment by irradiationFiltrationDesorption

A method for treating a raw water containing a hardly decomposable substance, which comprises the following steps: a step (B) of adding an adsorbing agent to a raw water containing a hardly decomposable substance (a raw water to be treated) to allow said adsorbing agent to adsorb the hardly decomposable substance (an adsorption treatment step), a step (C) of separating a permeated liquid by the use of a filtration film, to concentrate the adsorbing agent having absorbed said hardly decomposable substance (a film filtration treatment step), and (D) a step of chemically decomposing the hardly decomposable substance being adsorbed in the concentrated adsorbing agent by a peroxide, without the operation for desorption from said adsorbing agent (a chemical decomposition step), and, by the above steps, concentrates hardly decomposable substances such as dioxins contained in a contaminated water (the raw water to be treated) and converts the hardly decomposable substances to harmless substances. The above method can be applied also to a raw water containing a reducing substance such as a hydrogensulfite for neutralizing free chlorine, the application thereof is not limited by the properties of hardly decomposable substances being contained, and also it allows conversion of hardly decomposable substances to harmless ones with good efficiency at a low cost.

Owner:IDEMITSU KOSAN CO LTD +1

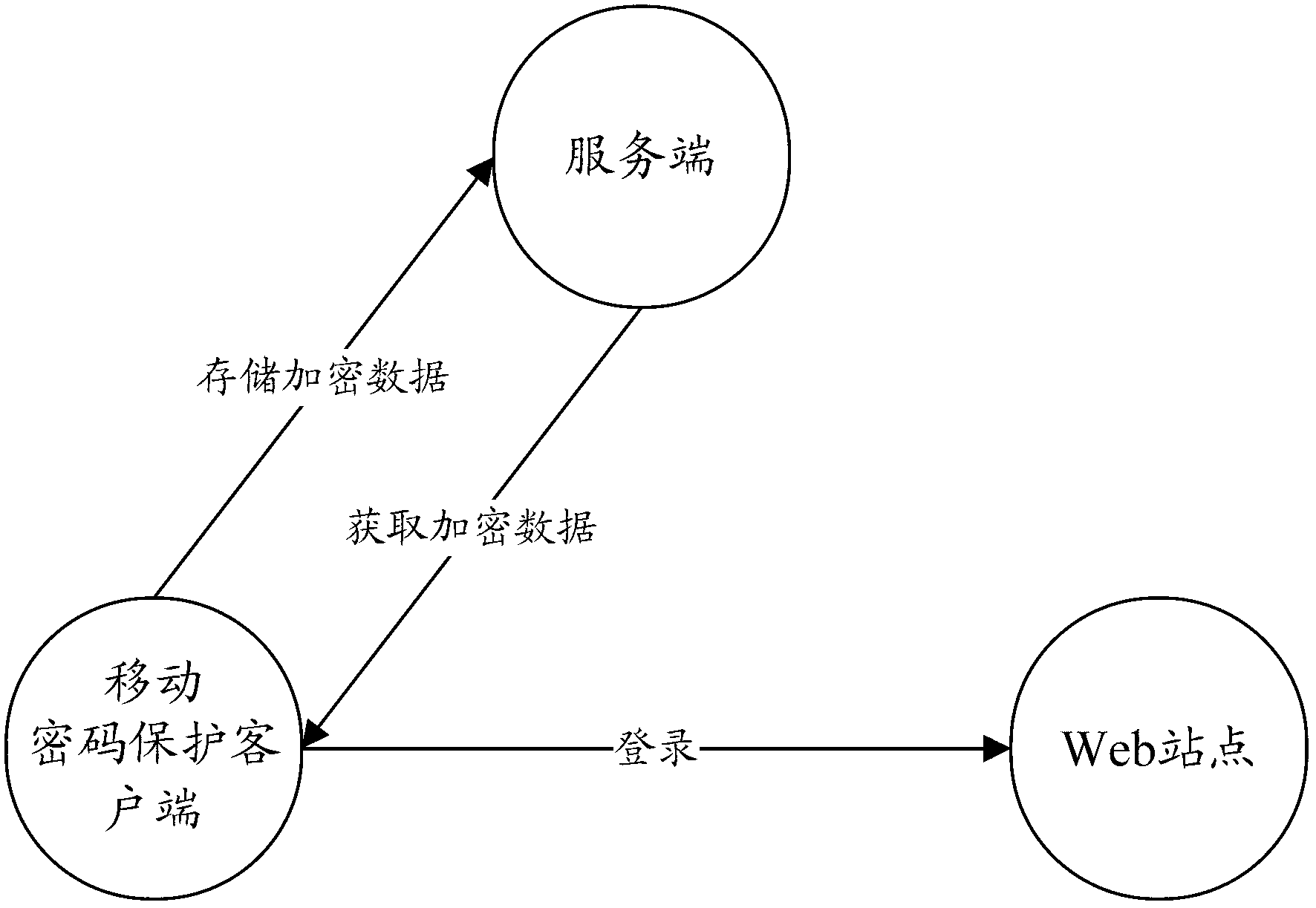

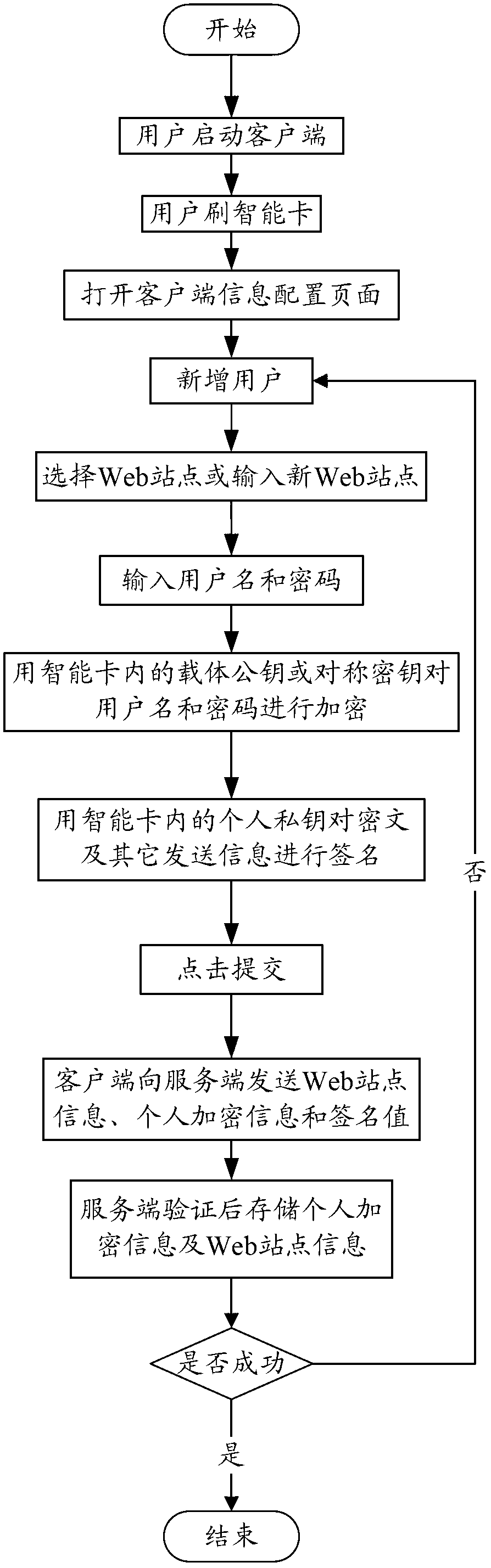

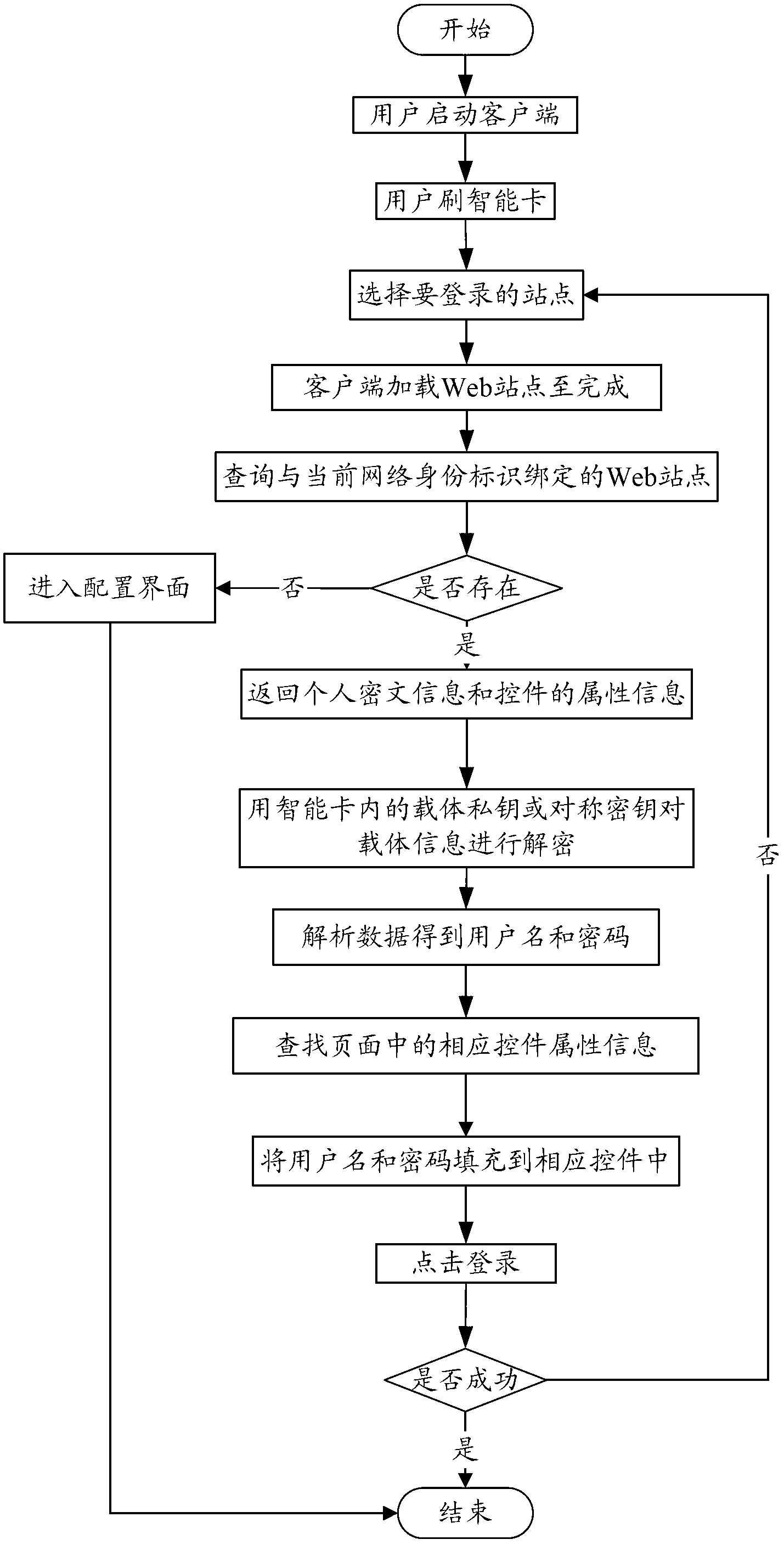

Password protection method for smart card on mobile terminals

ActiveCN103237305AImplement secure loginGuaranteed confidentialityTransmissionSecurity arrangementCiphertextConfidentiality

The invention relates to a password protection method for a smart card on mobile terminal devices. An NFC (near field communication) chip is internally arranged in the mobile terminal devices, and a password protection client module is further arranged in the mobile terminal devices. The password protection method includes controlling and disposing individual user information configuration and visits to a Web site. By the password protection method for the smart card on the mobile terminal devices, confidentiality and completeness of data are guaranteed; cipher texts are stored on remote servers, so that risks of leakage of user's private information are reduced, and safety degree is high; the user does not need to remember too much account information, and usability is high; by an NFC technology, the user does not need to carry an external card reader, so that user's burden is eased; individual user private information protection is guaranteed when the user logs in, and secure logon on the Web site is realized; processing procedures are safe and effective, working performance is stable and reliable; and the NFC technology has a wide scope of application.

Owner:THE THIRD RES INST OF MIN OF PUBLIC SECURITY

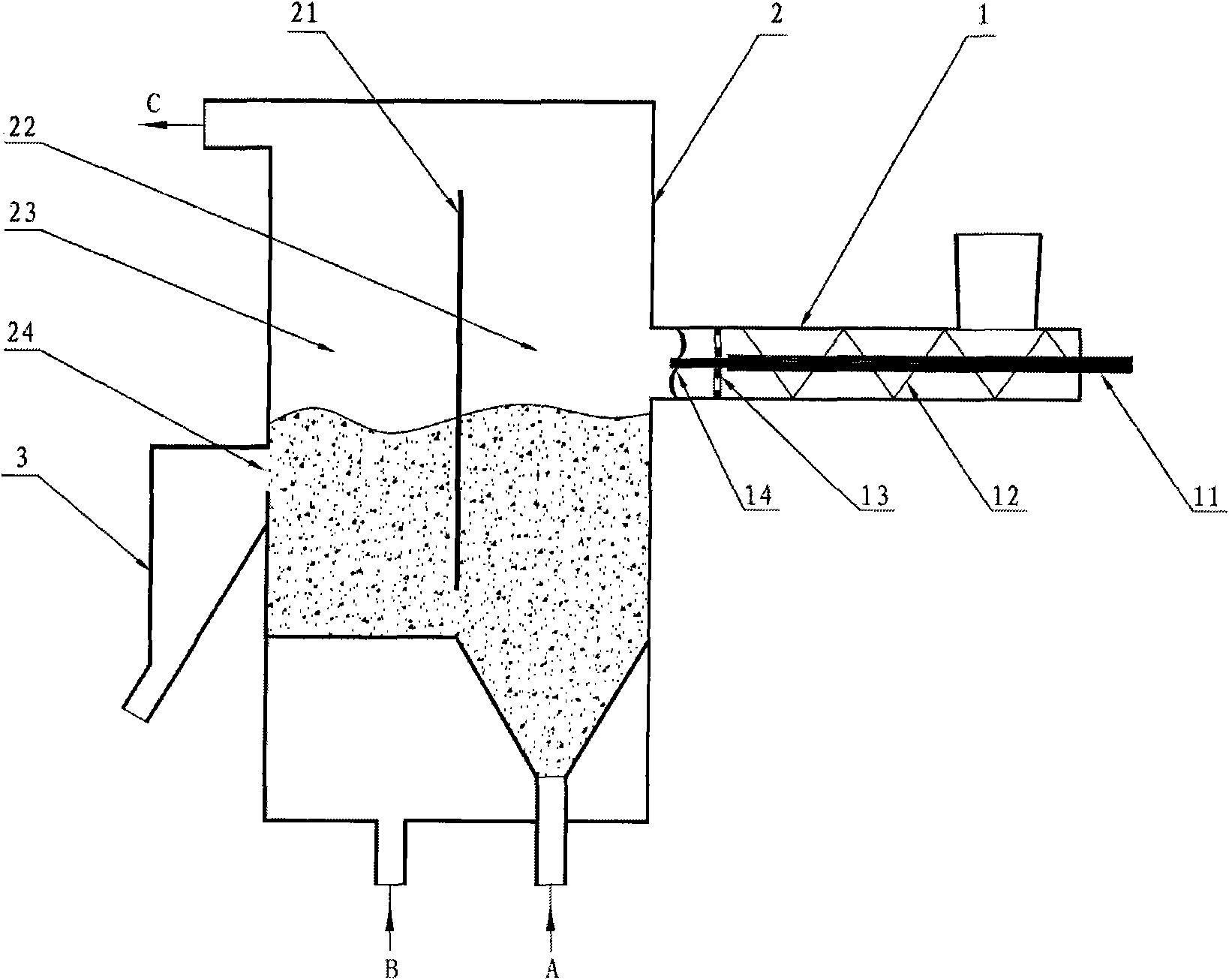

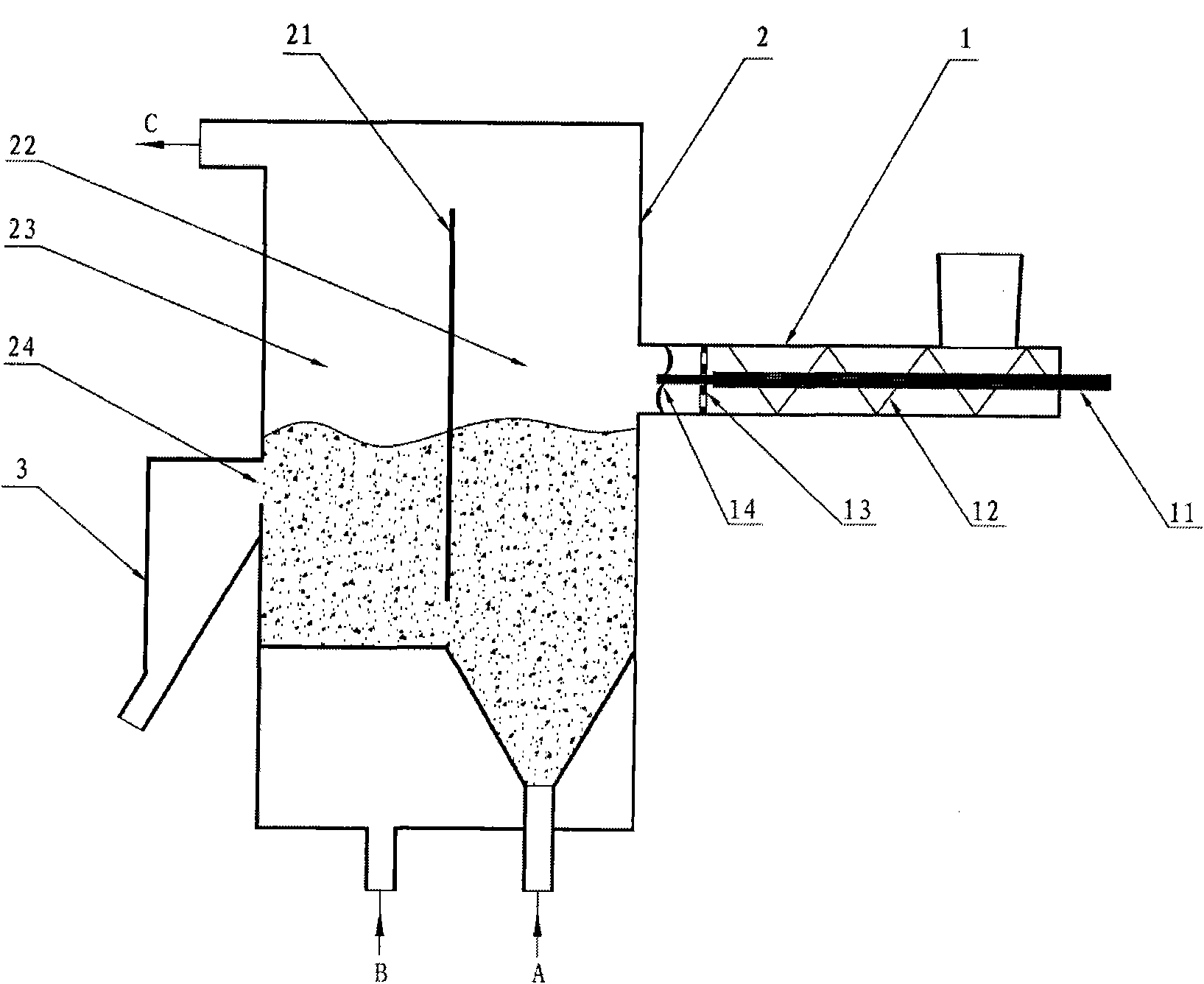

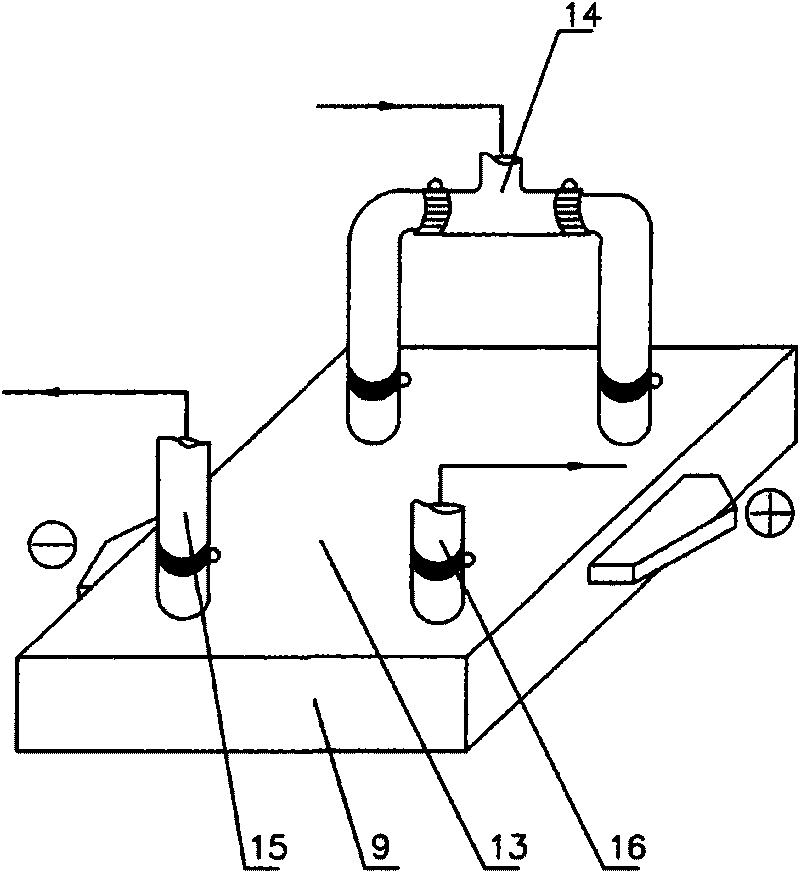

Sludge granulation and drying device and method

InactiveCN101913750APromote the development and utilization of resourcesSafe and efficient handlingSludge treatment by de-watering/drying/thickeningGranulation by material expressionResource developmentDrive shaft

The invention relates to sludge granulation and drying device and method, which can safely and effectively treat wet sludge of a sewage treatment plant so as to facilitate the subsequent resource development and utilization of sludge. The device comprises a screw extrusion granule forming machine, a spout fluidized bed and a dried sludge granule stock bin, and the screw extrusion granule forming machine comprises a drive shaft, a screw feeder, a sludge extrusion forming pore plate and a rotating cutter. The method comprises the following steps of: dividing the spout fluidized bed into an upper spout bed area and a lower fluidized bed area, which are communicated, by using a middle partition board; loading the wet sludge granules from the screw extrusion granule forming machine downward into the spout bed from the bed surface of the spout bed; leading the primarily dried sludge granules to flow to the bottom of the fluidized bed from the bottom opening of the spout bed, and leading theother part of hot gas medium to enter the fluidized bed from a fluidized air inlet to deeply dry the sludge granules; enabling the dried sludge granules to move upward from the bottom of the fluidized bed to the bed surface of the fluidized bed; and finally, overflowing the dried sludge granules out from the fluidized bed to enter the dried sludge granule stock bin.

Owner:SOUTHEAST UNIV

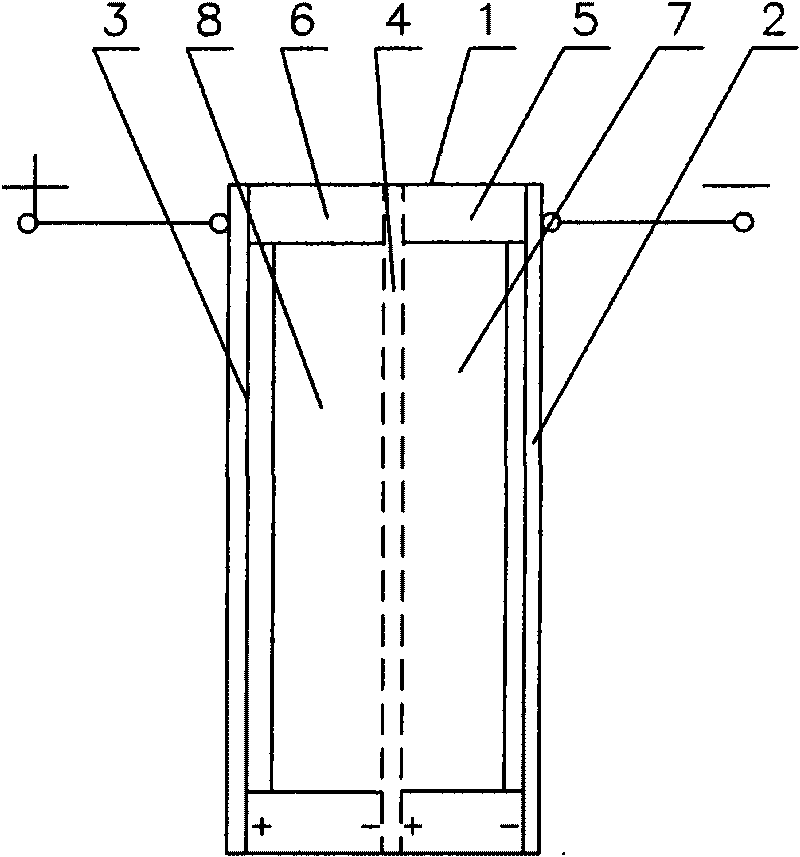

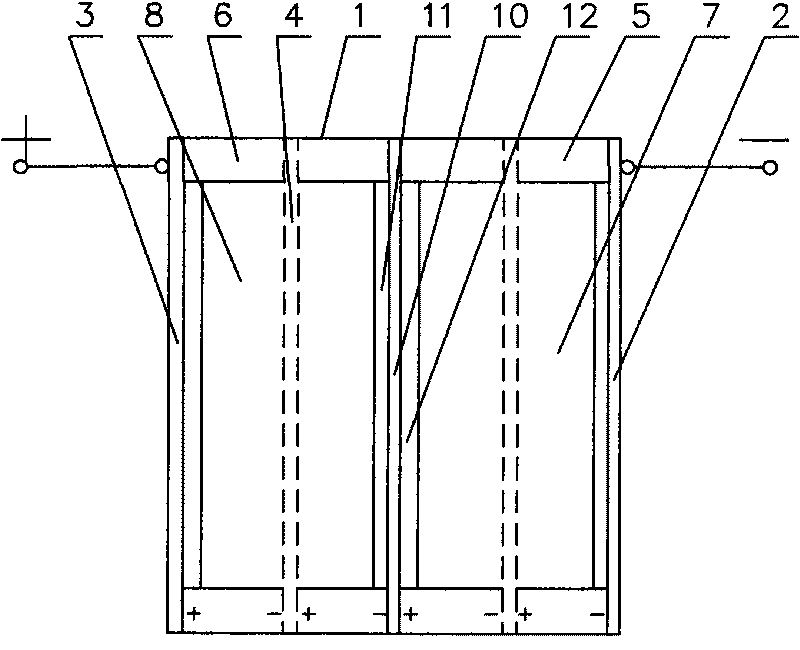

Bipolar membrane dual-liquid flow type hydroxyl radical generator

InactiveCN101748418ALow costEasy to manufactureCellsChemical industryHigh concentrationSemiconductor electrode

The invention relates to a bipolar membrane dual-liquid flow type hydroxyl radical generator, belonging to the technical field of electrochemistry electrolytic oxidation. The bipolar membrane dual-liquid flow type hydroxyl radical generator is composed of a cathode, an anode and a bipolar membrane located between the cathode and the anode. A cathode liquid chamber is formed between the bipolar membrane and the cathode; an anode liquid chamber is formed between the bipolar membrane and the anode; both the cathode and the anode adopt a single face electrode with a panel structure; and the cathode, the anode and the bipolar membrane are parallel to each other. The invention ensures that high-concentration hydroxyl radical strong oxidant solution can be generated by very low voltage and very high electricity efficiency, the effects of water sterilization, disinfection, decoloration, deodorization, and the like are superior to that of ozone, chlorine and other oxidants, has no toxicity, residue and secondary pollution. The invention has a plurality of innovations that bipolar membrane energy-saving dissociation molecules are inserted between electrolytic cells to supply OH to produce .HO, lead-free tin oxide semiconductor electrode is supplied for a cavity (h+) without lead to pollute water body, and a dual-liquid stream structure is used so that the concentration of .HO is never saturated.

Owner:薛廷芳

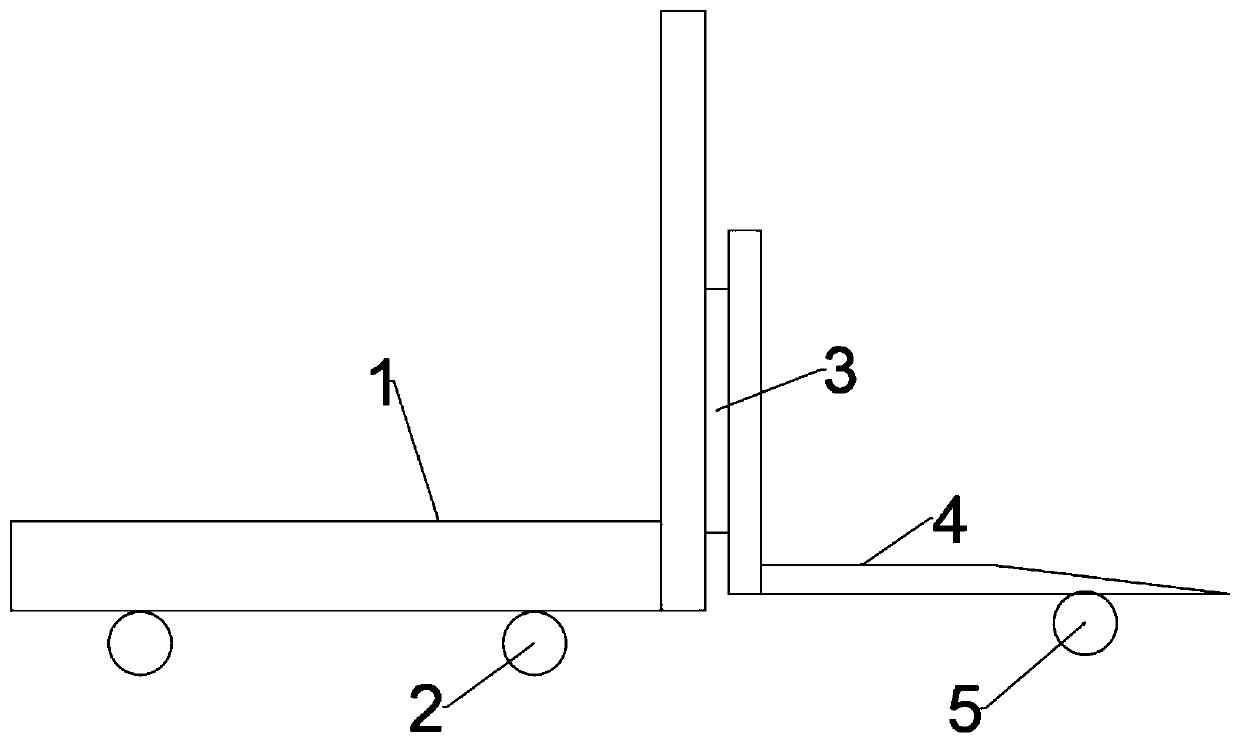

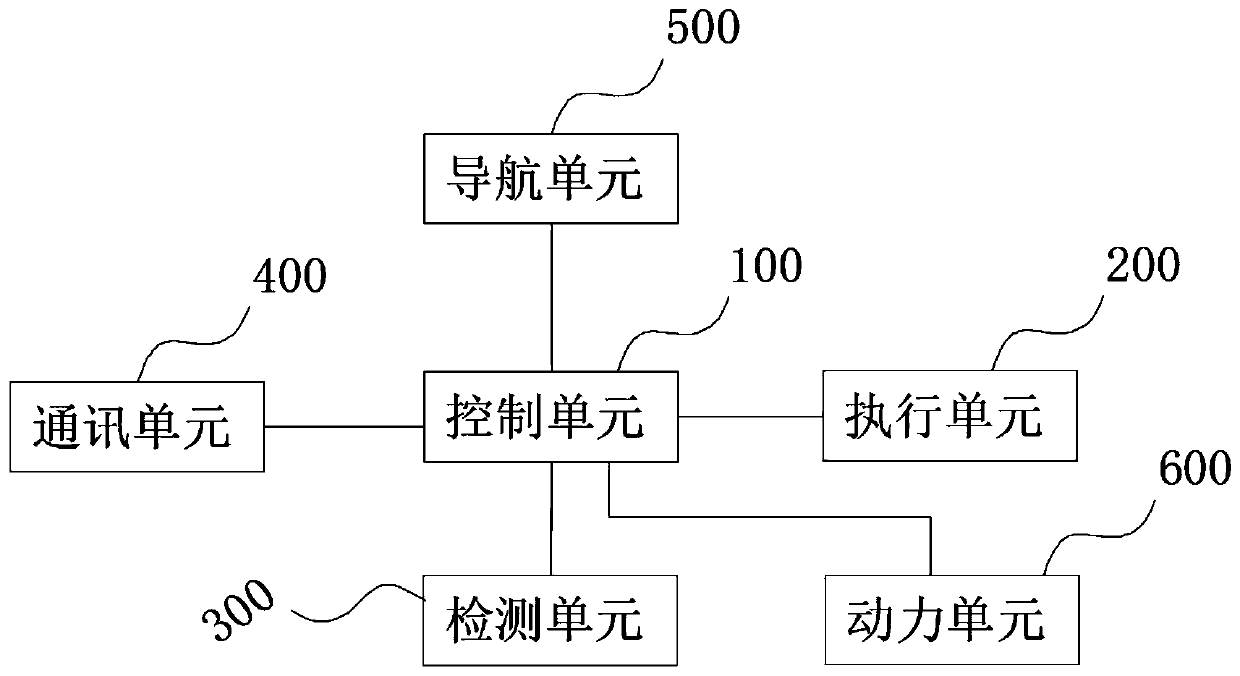

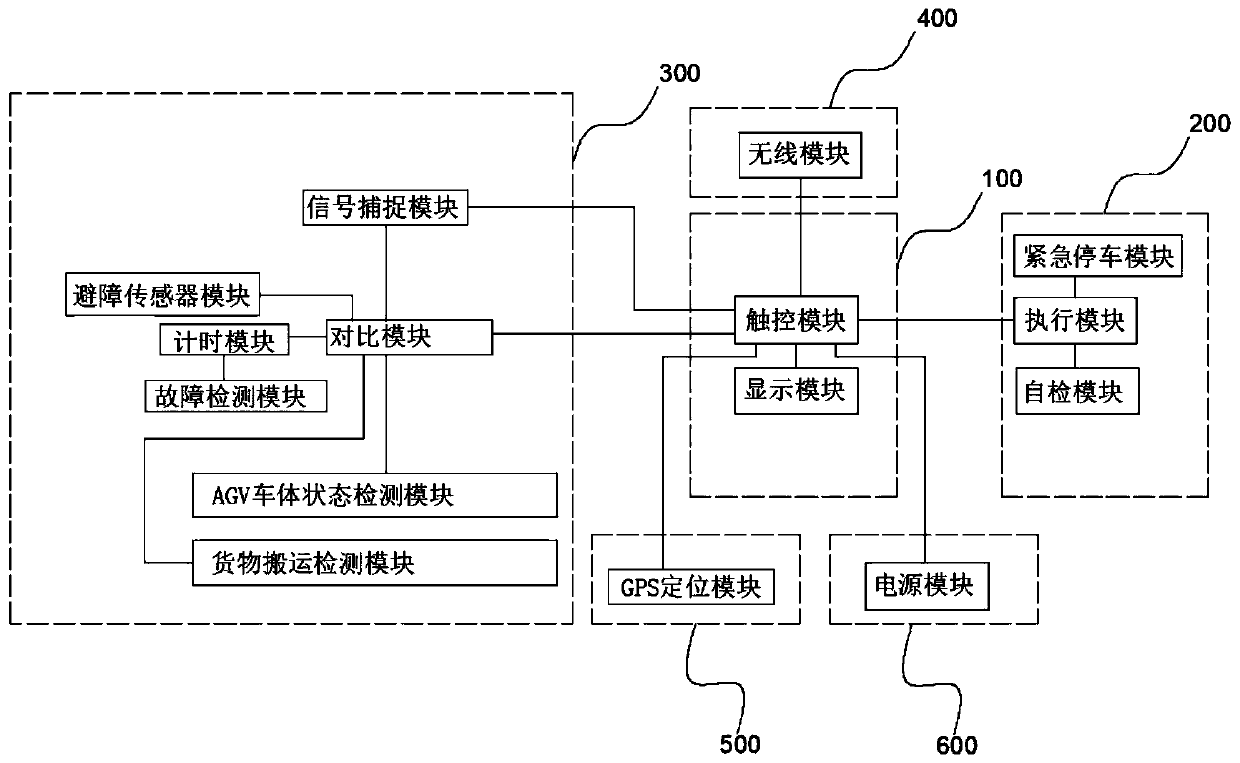

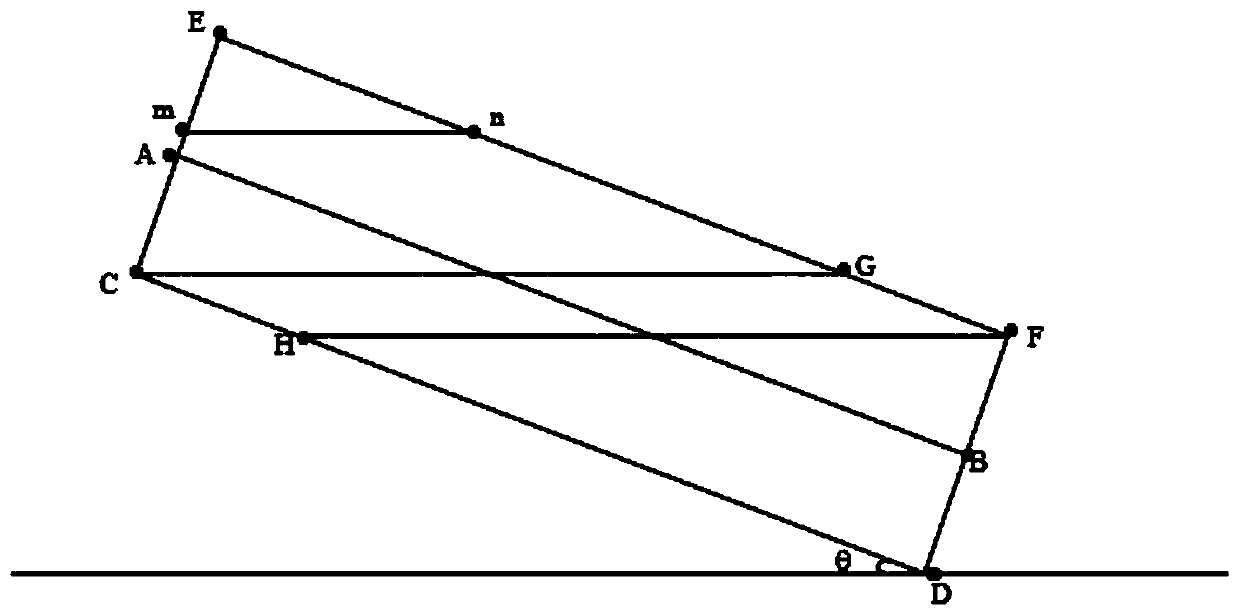

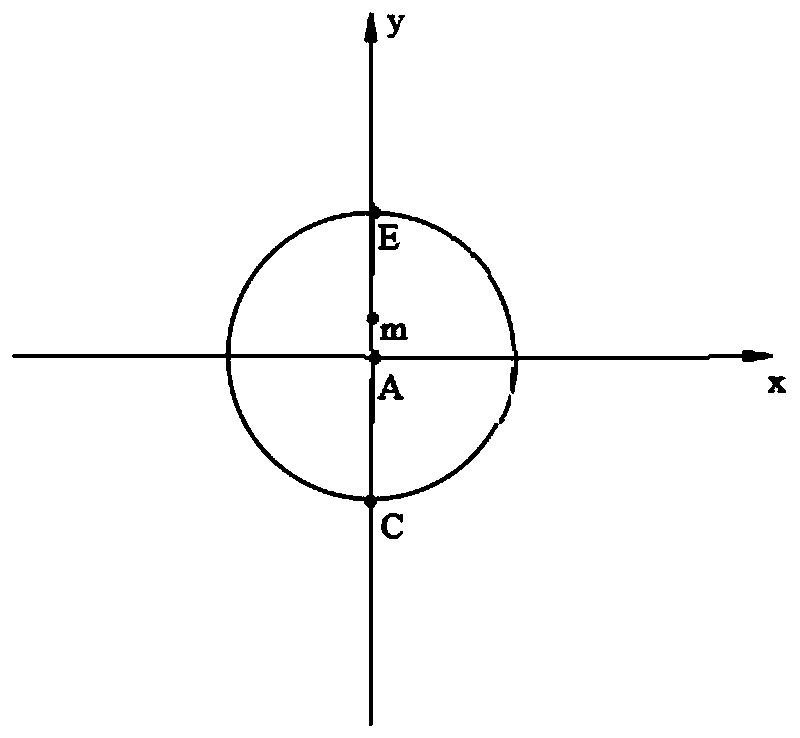

Method of transferring forklifts to operate and lift

ActiveCN109809334ASafe and efficient handlingAccurate acquisitionSafety devices for lifting equipmentsPosition/course control in two dimensionsCommand and controlParking space

The invention discloses a method of transferring forklifts to operate and lift. The method comprises the following steps: S0, preparing a plurality of AGV forklifts and an upper computer; S1, carryingout path planning on the AGV forklifts by the upper computer according to cargo stacking information to acquire running route information; S2, sending starting commands to AGV vehicle bodies by the upper computer according to the running route information and receiving the starting commands and controlling the running states of the AGV bodies by a control unit; S3, acquiring deceleration distances and parking distances of the AGV bodies; and S4, when the AGV bodies arrive the positions of the deceleration distances, controlling the AGV bodies to start to decelerate at a first preset acceleration, and when the AGV bodies are decelerated to the position of the parking distances, controlling the AGV bodies to start to decelerate at a second preset acceleration; and judging whether cargoes are detected or not within a set time period after parking, and carrying the cargoes according to positions of the cargoes and the detection result. According to the method, the cargoes can be carried in definite space.

Owner:航天通用技术(北京)有限公司 +1

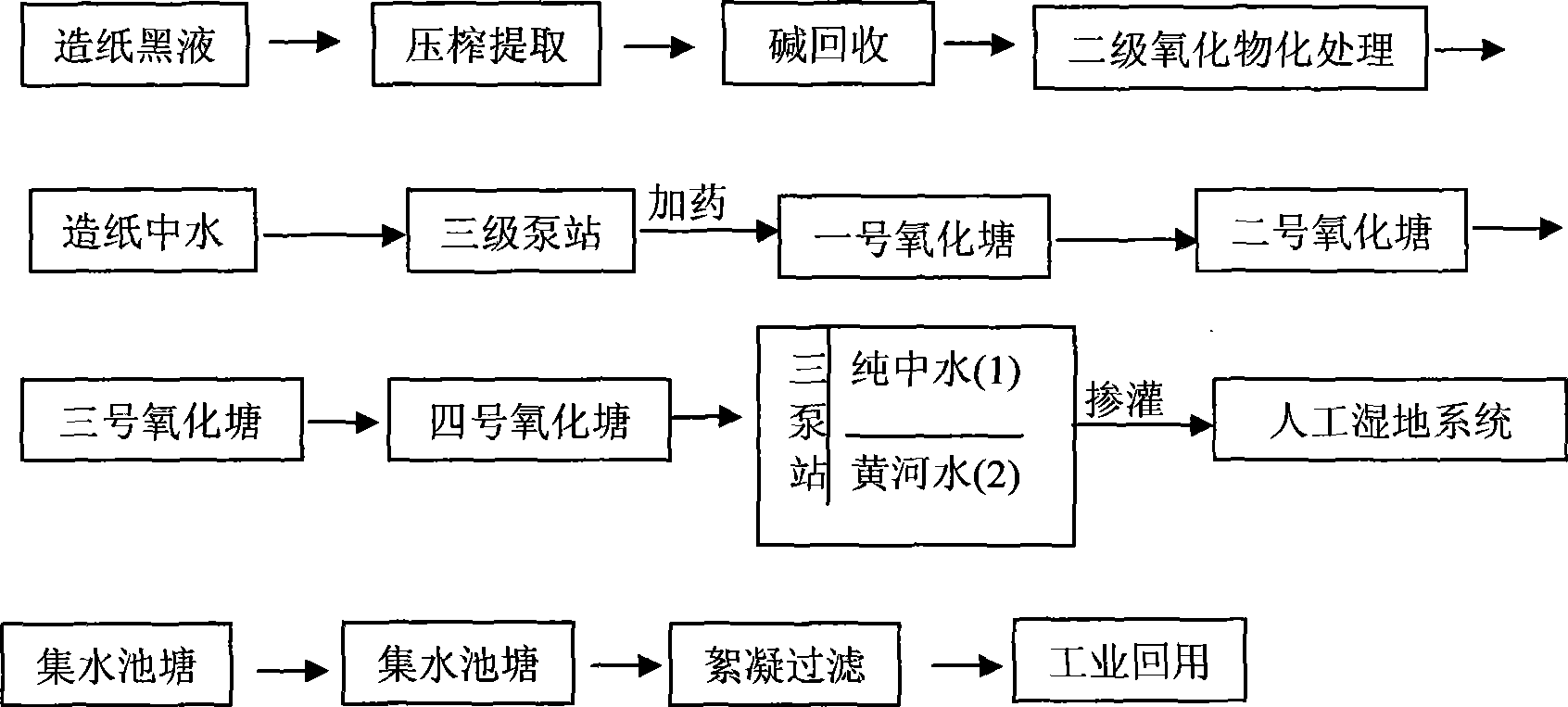

Method for deeply treating papermaking wastewater

InactiveCN101445297AImprove the rate of removalReduce power consumptionTreatment with aerobic and anaerobic processesEnergy based wastewater treatmentConstructed wetlandMedicine

The invention relates to a method for deeply treating papermaking wastewater. The invention comprises the following steps: conducting anaerobic treatment, facultative treatment and aerobic treatment to papermaking waste water which reaches standard after alkali recovery and middle part water treatment and is distributed in a multistage oxidation pond treatment unit through manual redeploy; and leading the treated water to a manual ground bed with certain area, certain gradient and certain size designed according to treatment load requirements by a corresponding drainage and irrigation system after the water achieves primary treatment effect. the invention establishes a typical model of 'lagoon-constructed wetlands', creates a new technique of papermaking waste water ecologic treatment bases on low power consumption, low cost and high elimination rate, and enables that large amount of rough purified middle part papermaking waste water of papermaking enterprises after alkali recovery and middle part water treatment truly realizes the aims of safe and efficient treatment and resource cyclic utilization.

Owner:中冶纸业集团有限公司

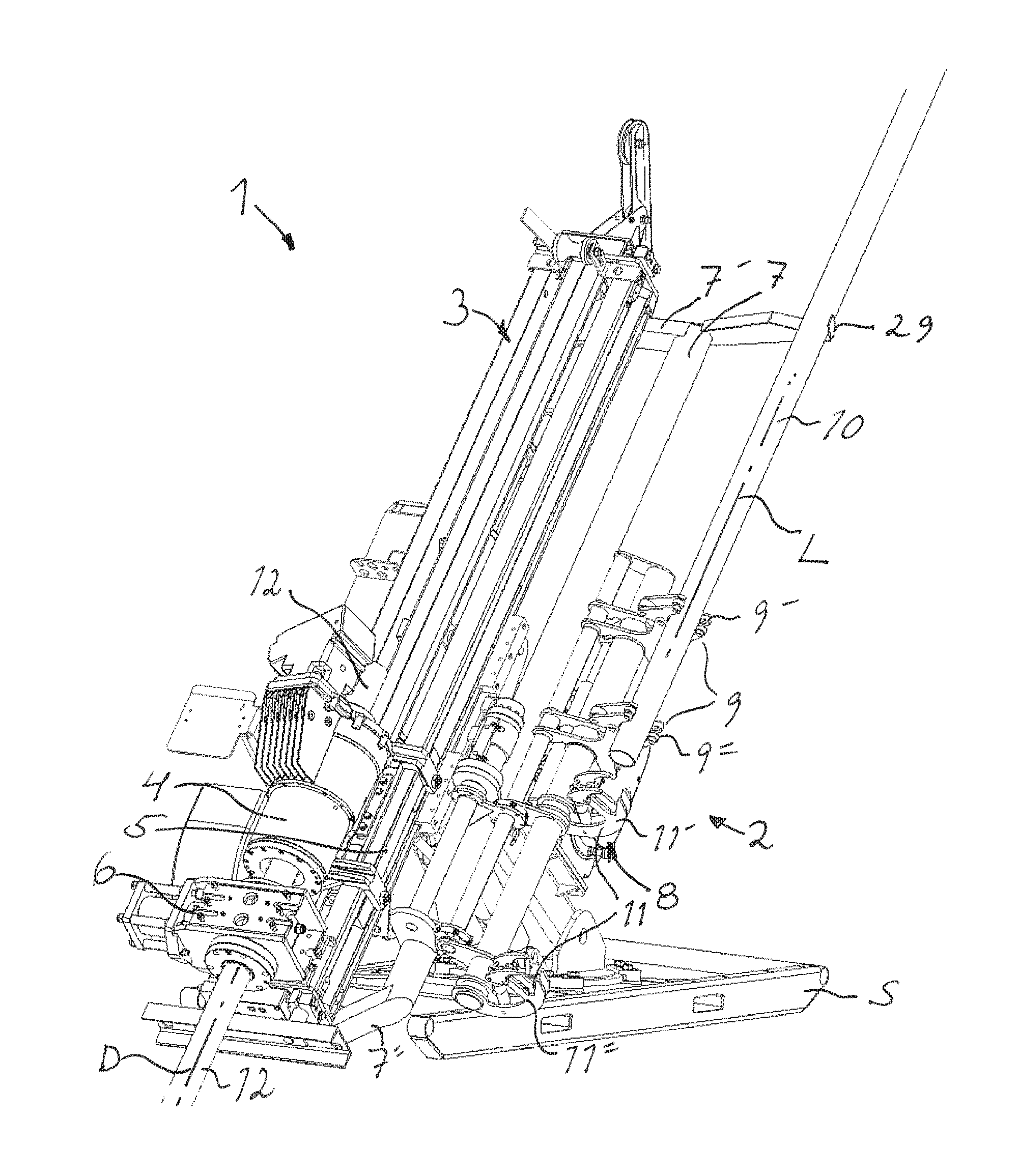

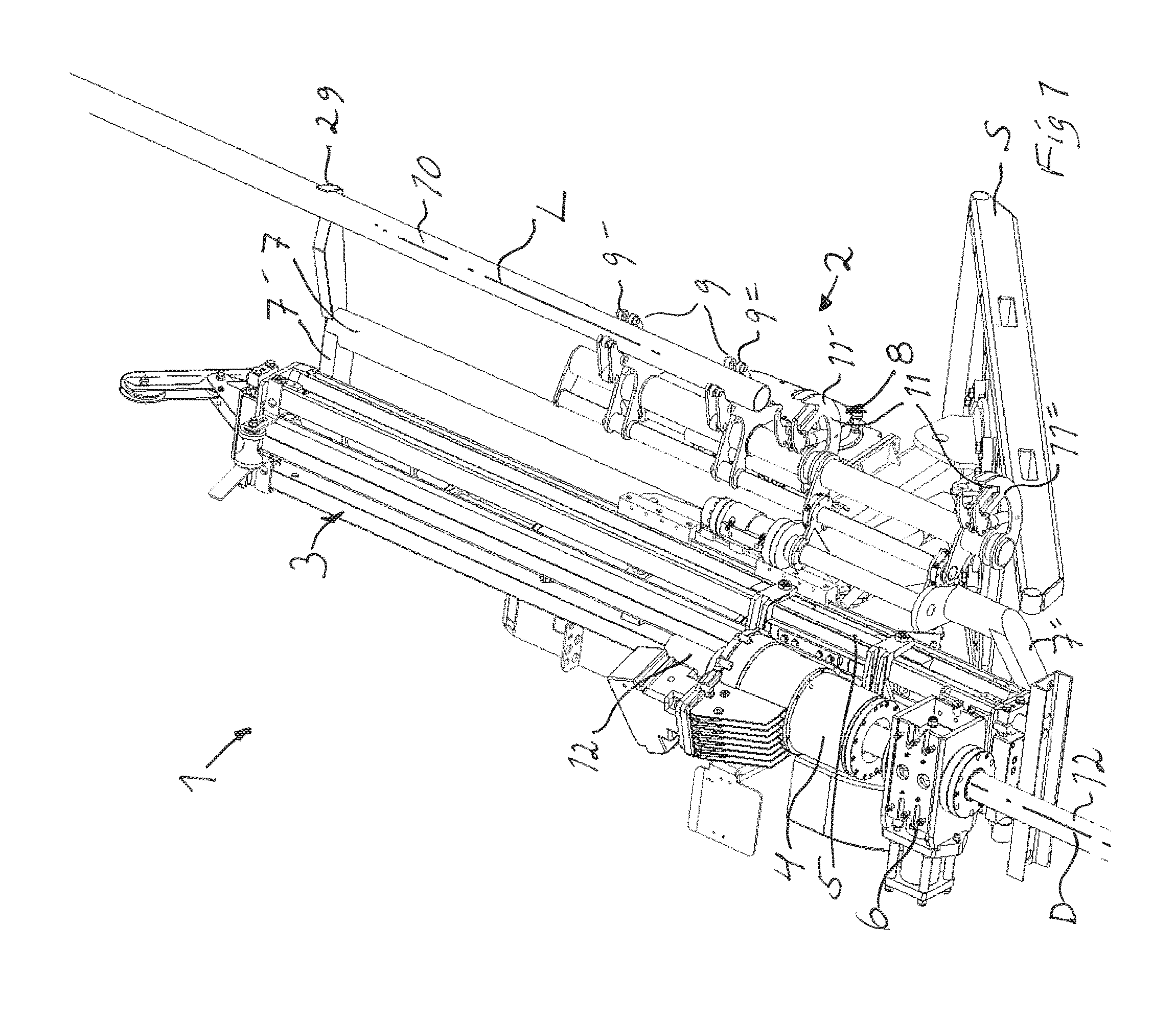

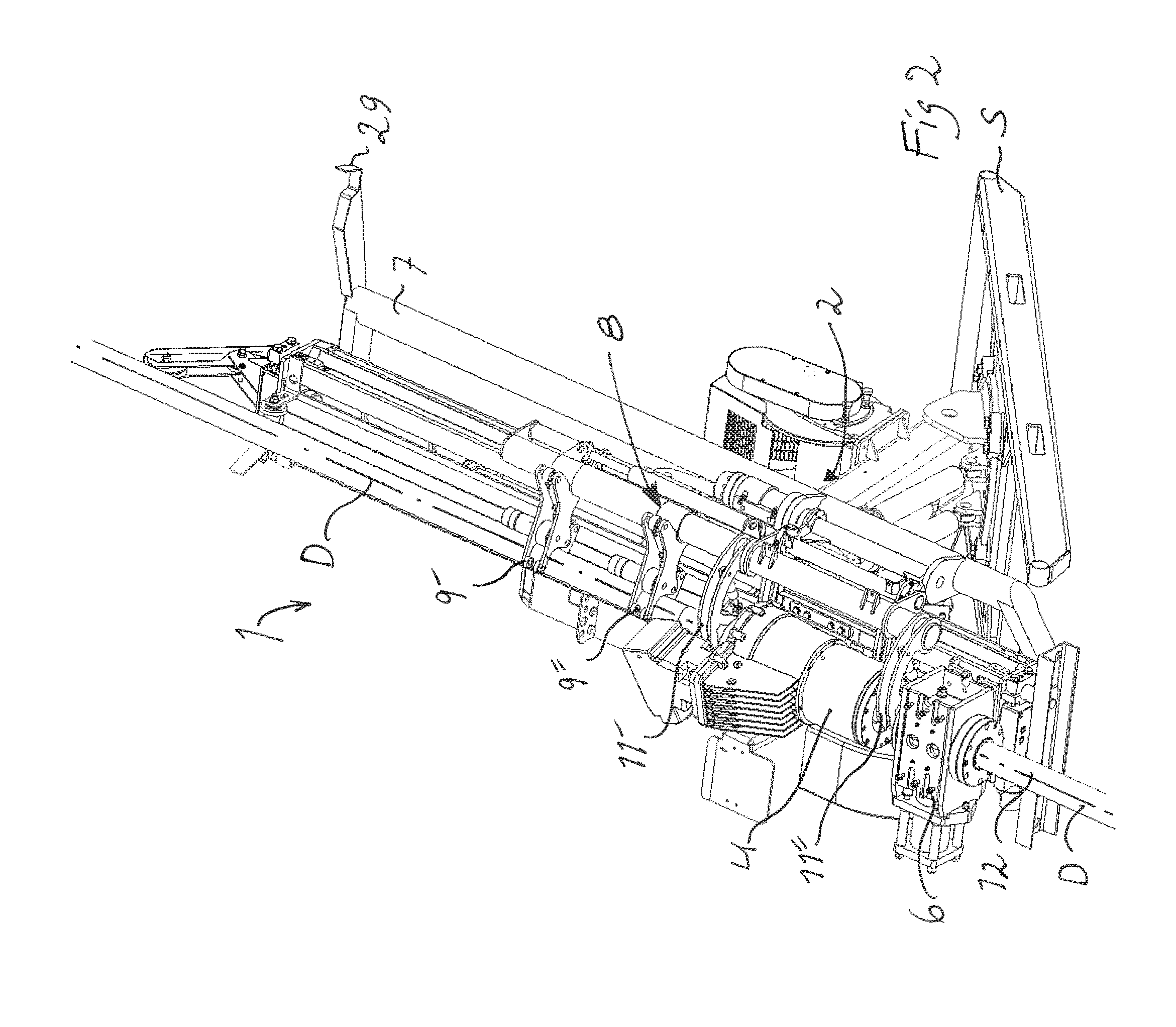

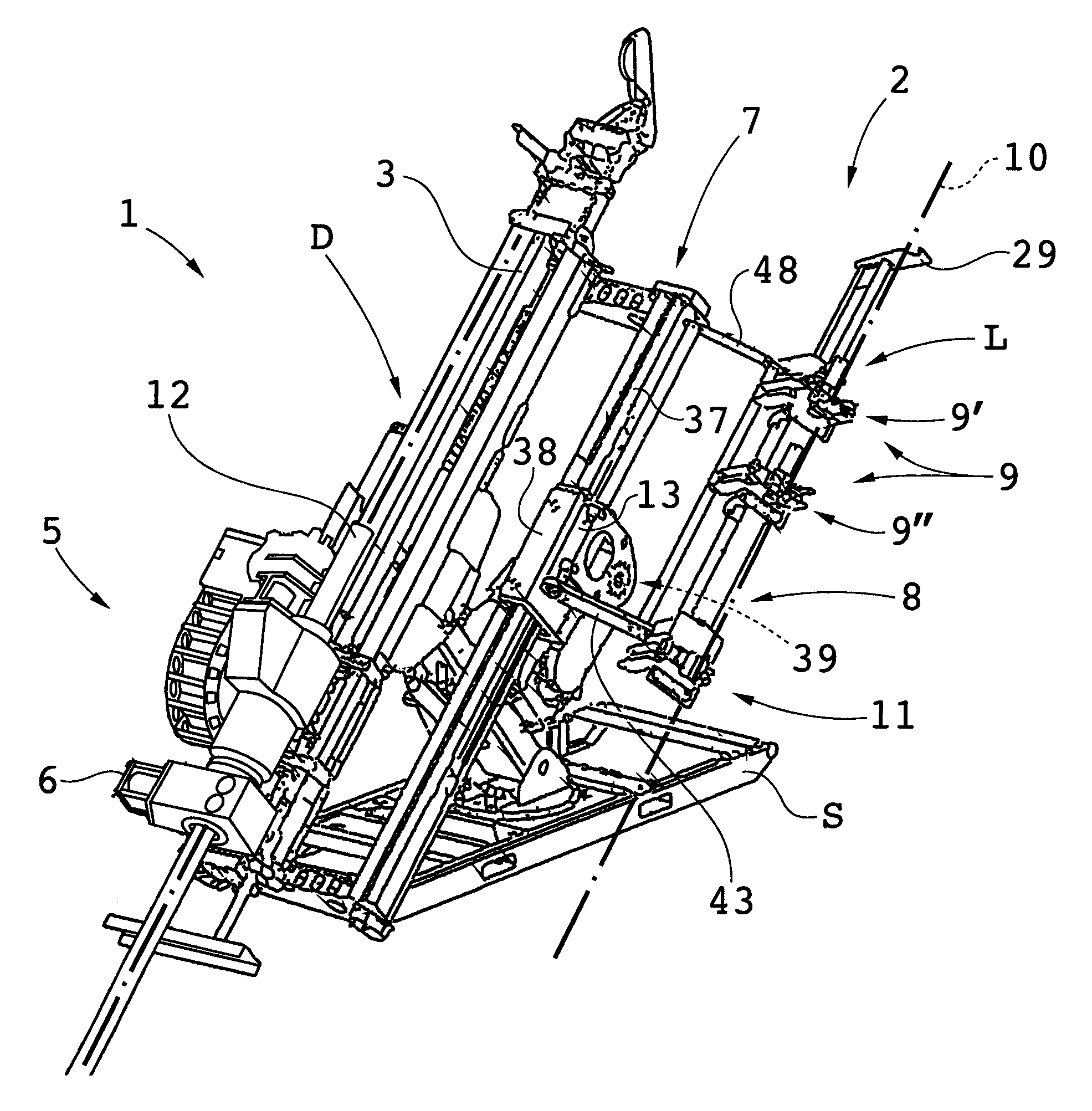

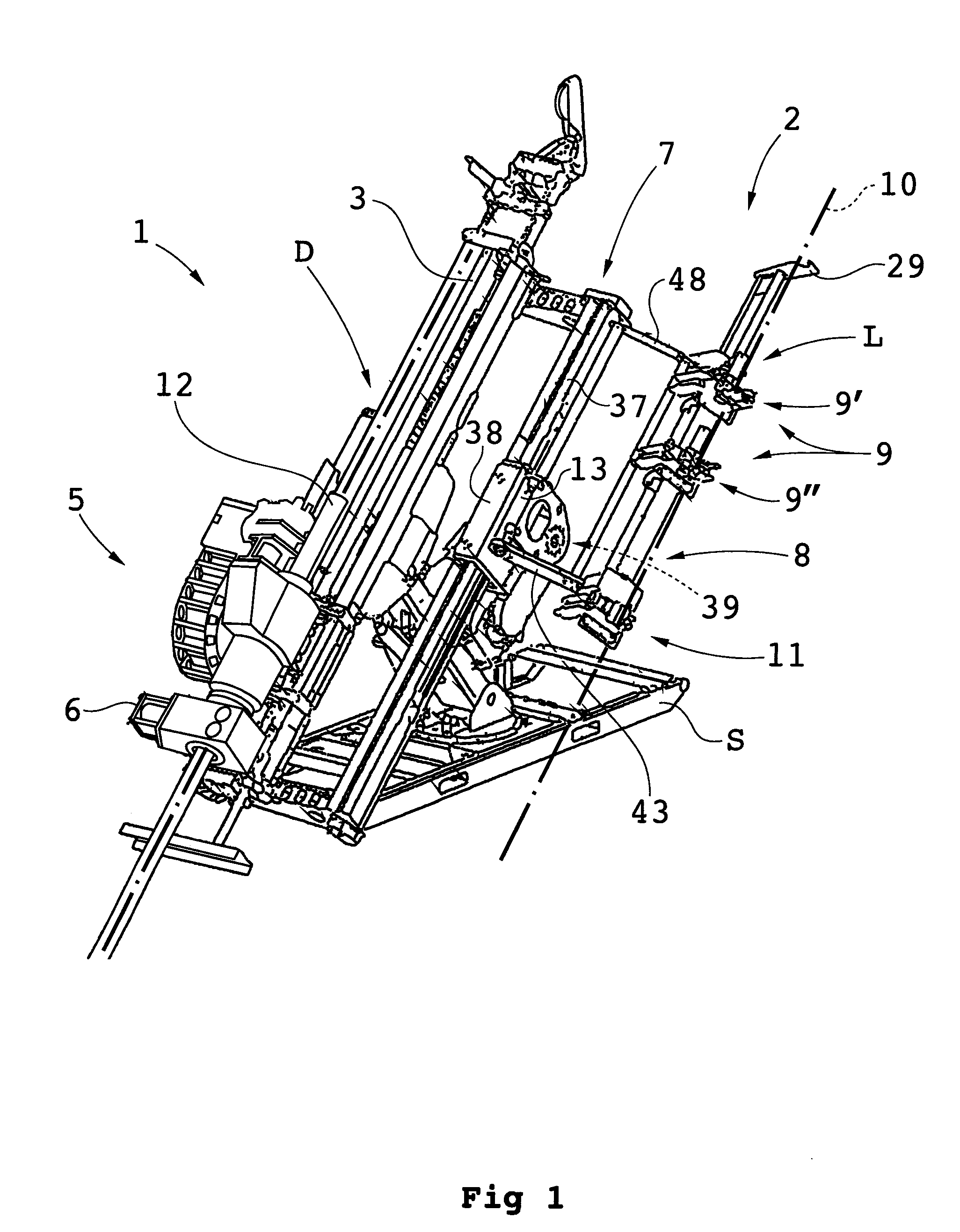

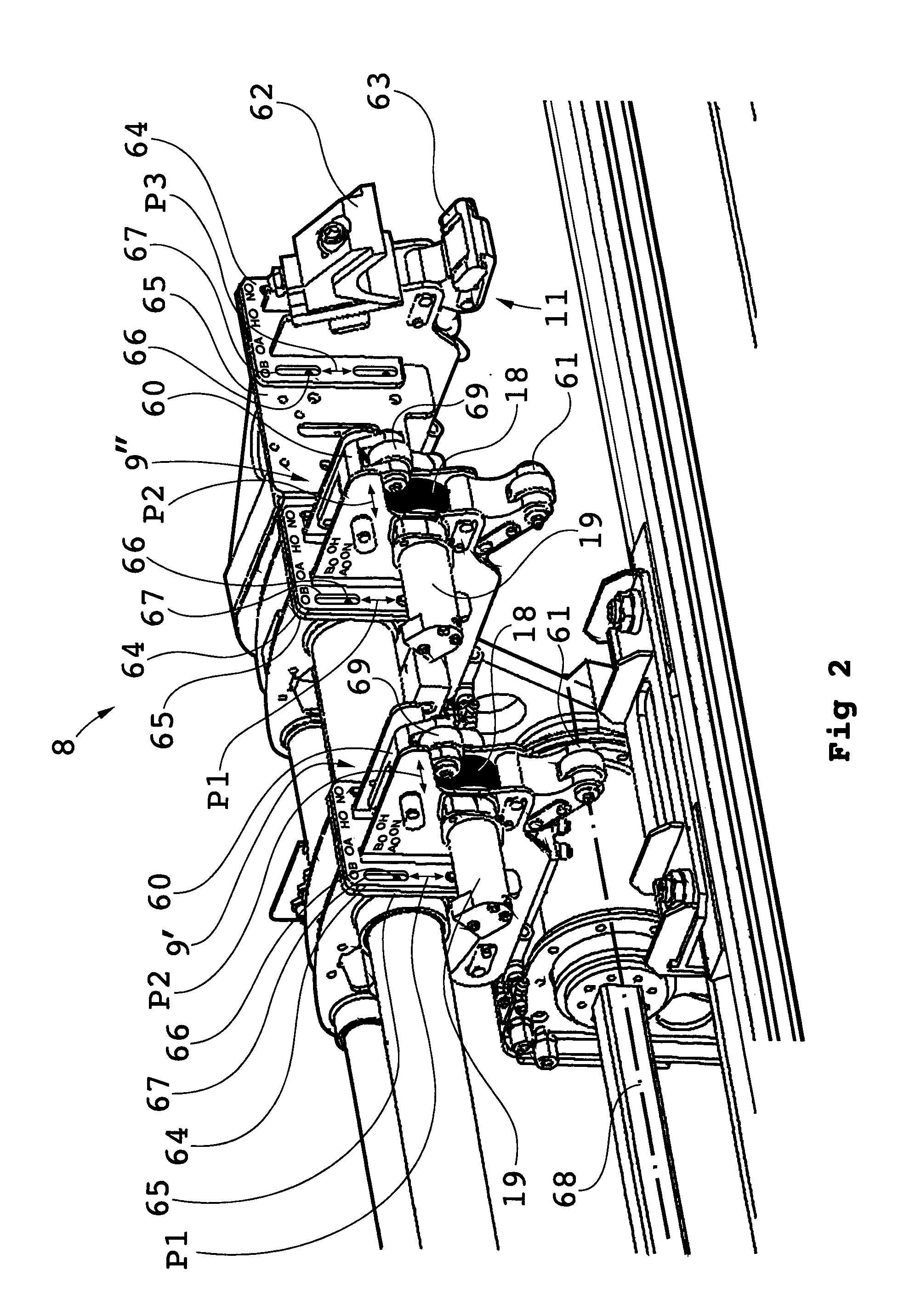

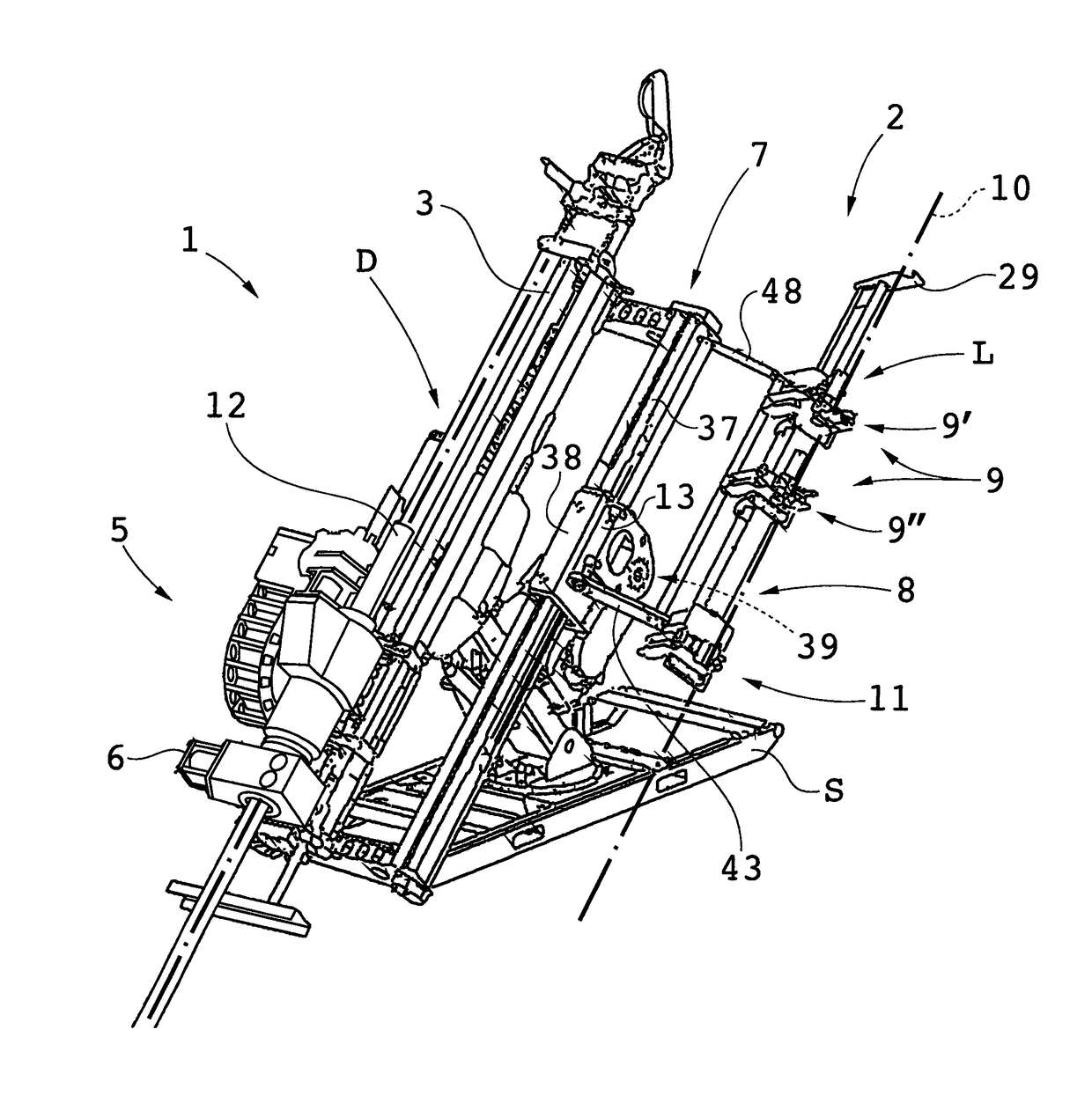

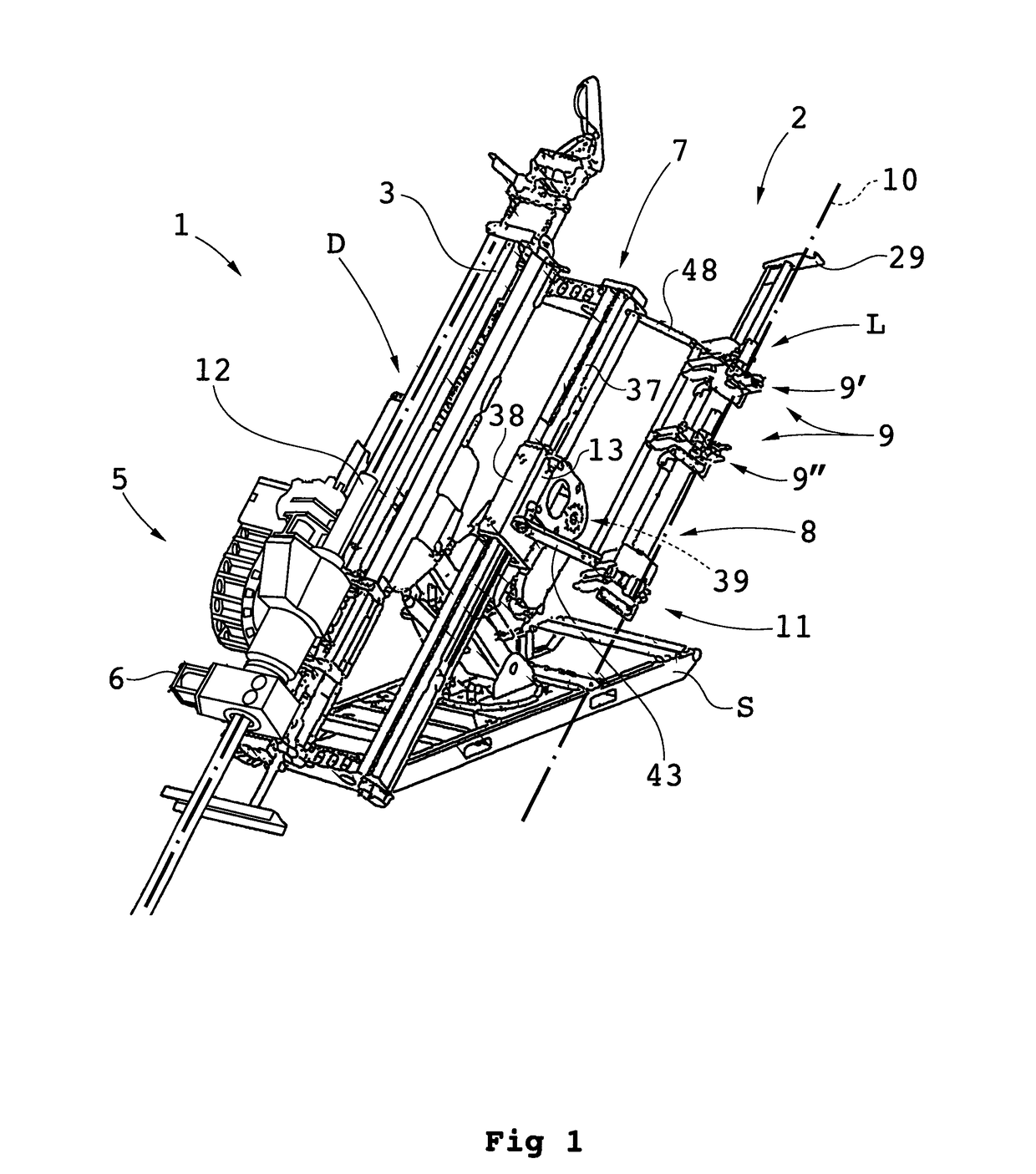

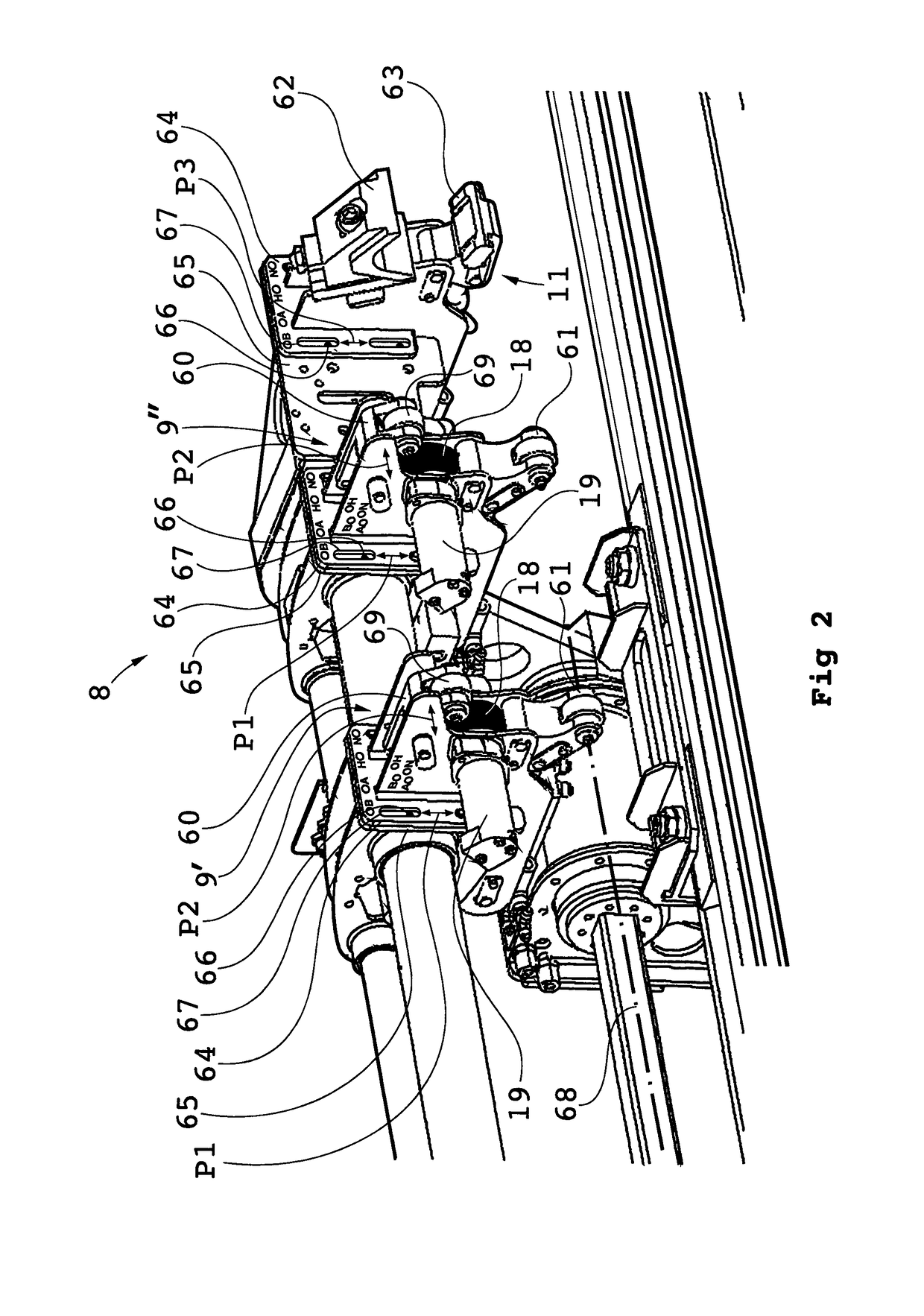

Device and method for handling drill string components in a drill rig and drill rig

ActiveUS20150136420A1Safe and efficient handlingSubject to problemDrilling rodsDerricks/mastsPetroleum engineeringDrill string

A device for handling drill string components in respect of a drill rig. A gripper is configured to grip a first drill string component to be threaded on to or off from a second drill string component being partly drilled into a rock formation. A support is configured to fasten the device onto the drill rig. A handling unit is movably connected to the support. The handling unit includes the gripper and is movable between a drill string position and a loading position. The handling unit includes an auxiliary engagement unit configured to engage the second drill string component in the drill string position and an angle variation unit configured to vary an angle of the gripper and thereby the gripped first drill string component in order to allow the alignment in the drill string position. Also a method and a drill rig.

Owner:EPIROC AB

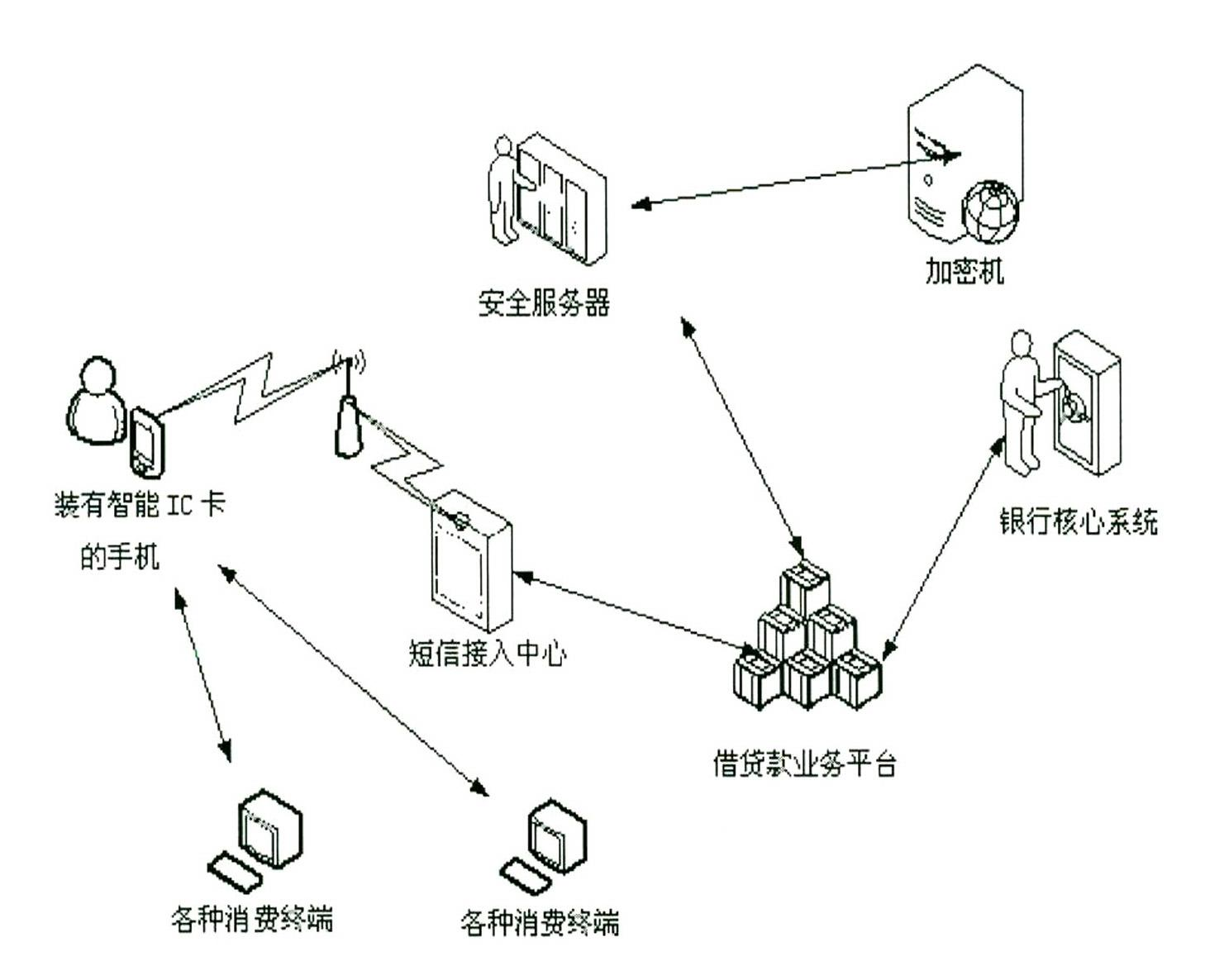

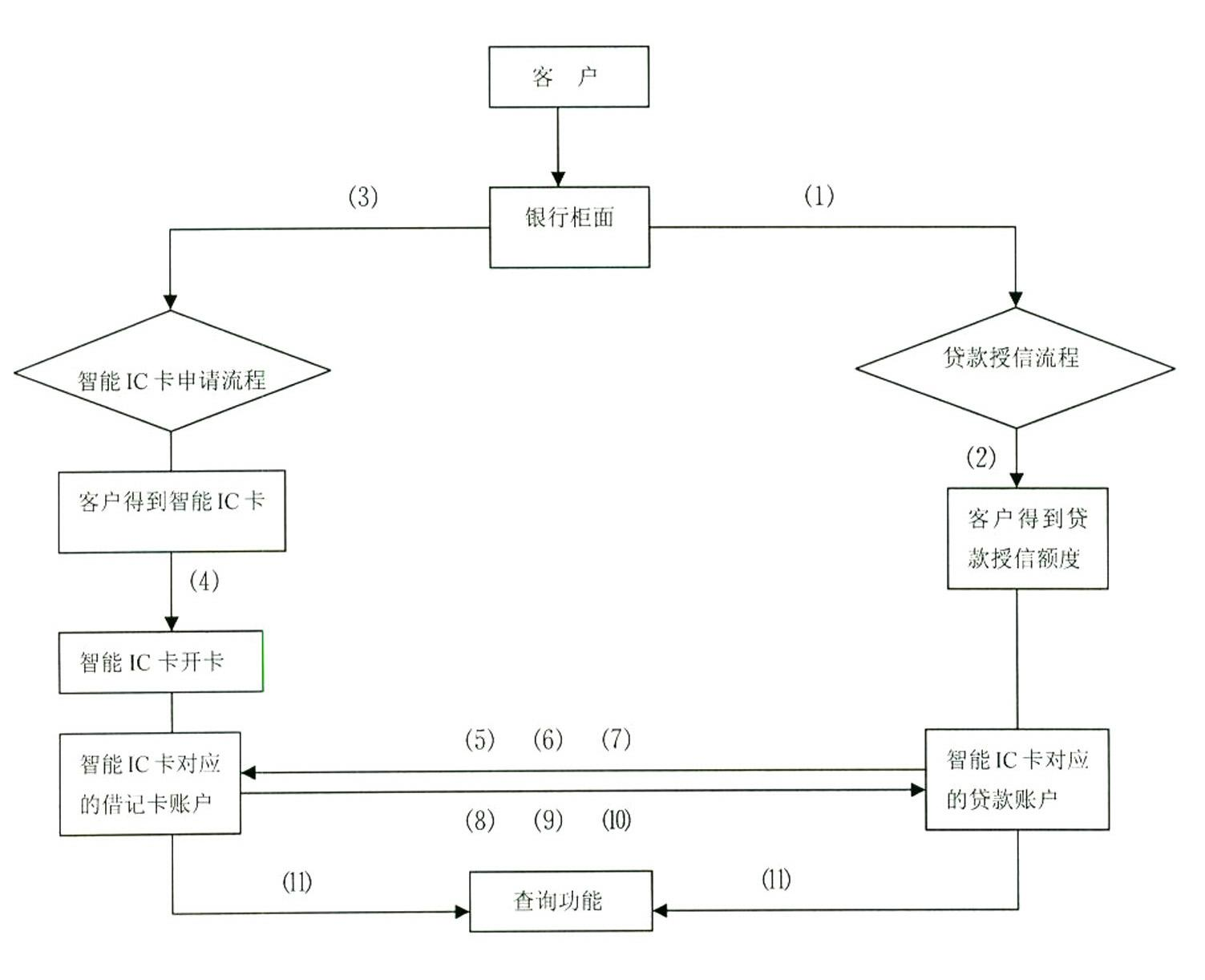

System for performing loan transaction service based on mobile phone short message

InactiveCN102131164ASafe and efficient handlingSimple structurePayment architectureMessaging/mailboxes/announcementsTransaction serviceComputer terminal

The invention discloses a system for performing a loan transaction service based on a mobile phone short message. The system comprises a mobile phone provided with an intelligent IC card, a security server, a loan transaction platform, a short message access center and a bank core system, wherein the mobile phone provided with an intelligent IC consists of a client mobile phone terminal and an intelligent IC card; the load transaction service comprises card registration, actual loan withdrawing, loan repayment and information inquiry. By the system, the financial function of a financial IC card is combined with the communication function of a mobile phone communication card; the client can make the loan transaction safely and efficiently by the mobile phone short message, and the loan transaction service comprises loan withdrawing, account transfer, repayment and related information inquiry. The system has characteristics of simplicity of structure, safety of use and convenience for service.

Owner:宁波征信金电信息技术有限公司

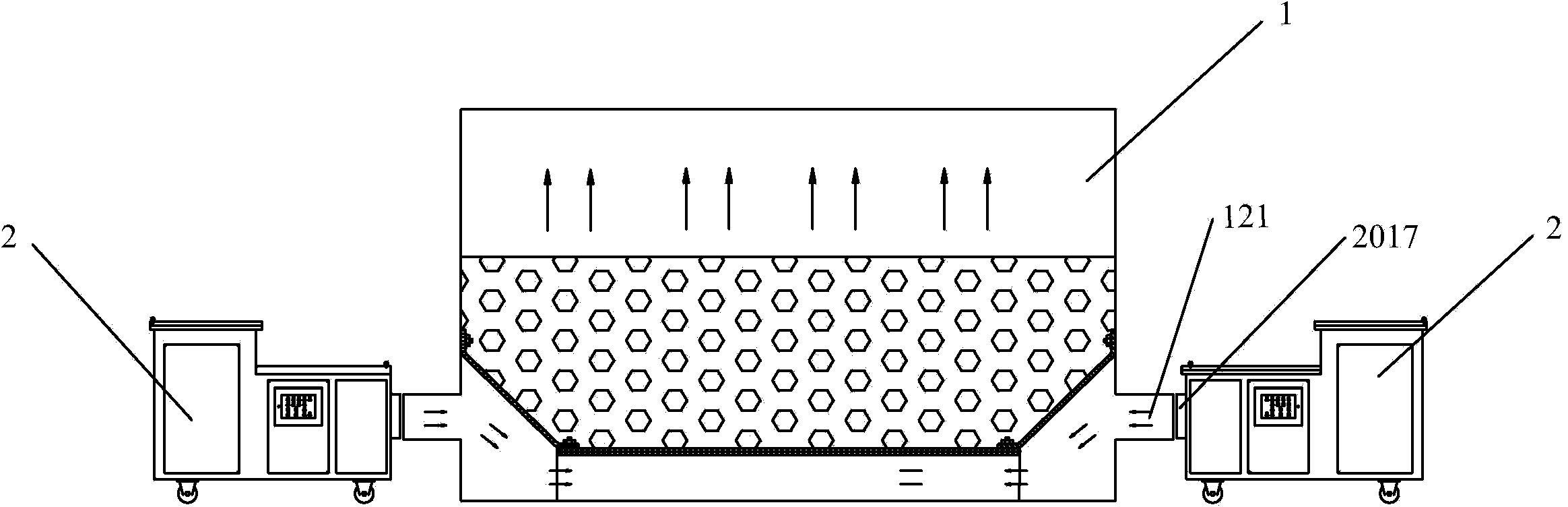

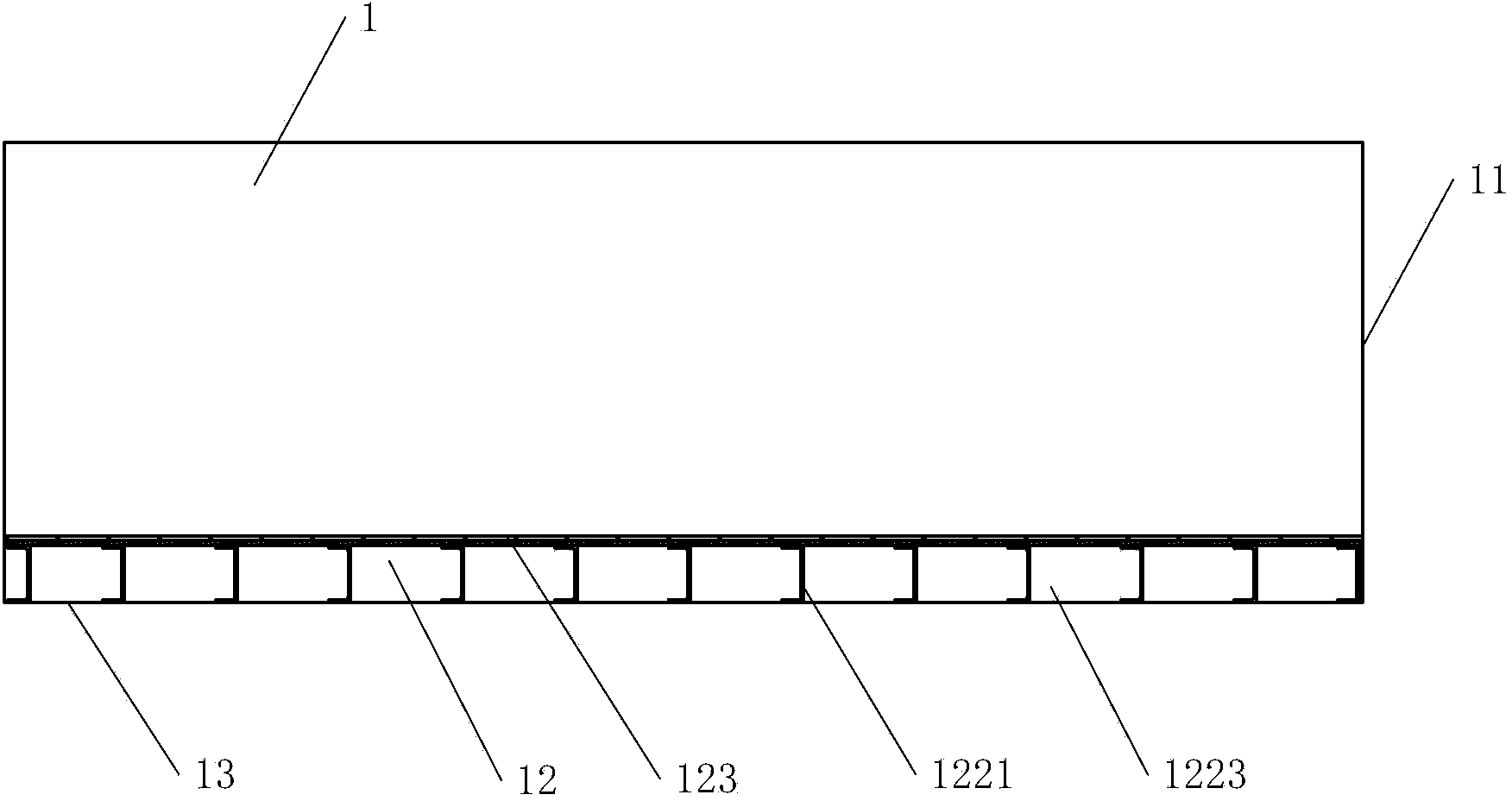

Whole bin whole-base ventilation low-speed drying grain storage system

InactiveCN104034130AMaintain commodity valueNo mildew lossDrying gas arrangementsSeed preservation by dryingLow speedPesticide residue

The invention relates to a whole bin whole-base ventilation low-speed drying grain storage system which comprises a grain bin and a grain bin treatment device. The system is characterized in that the grain bin is a whole-base ventilation grain bin, a ventilation structure is arranged on a base plate of the grain bin, the ventilation structure is connected with a ventilation inlet formed in the grain bin, and the ventilation structure is communicated with an inner cavity of the grain bin. The grain bin treatment device comprises a shell, and an air inlet and an air outlet are formed in the shell. The air outlet of the grain bin treatment device is connected with the ventilation inlet of the grain bin. According to the whole bin whole-base ventilation low-speed drying grain storage system, no drying pipelines exist in the grain bin, drying efficiency and the drying effect are greatly improved, the system can adapt to unprocessed grain conditions and climatic features in different areas, and the commodity value of the grain is ensured through low-temperature low-speed drying. In addition, by the adoption of technology application of ozone mould prevention and sterilization and pesticide residue degradation, it is ensured that no mould loss is produced in the treatment process, and meanwhile the drying season can be prolonged.

Owner:中机天安(北京)粮储安全技术研究院

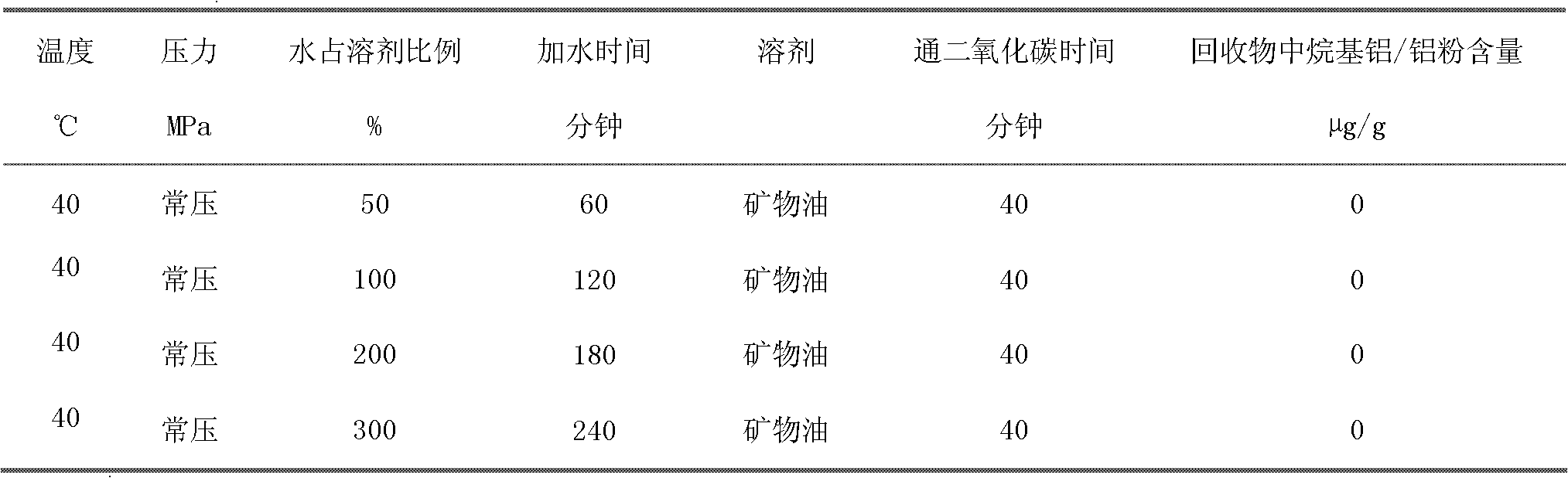

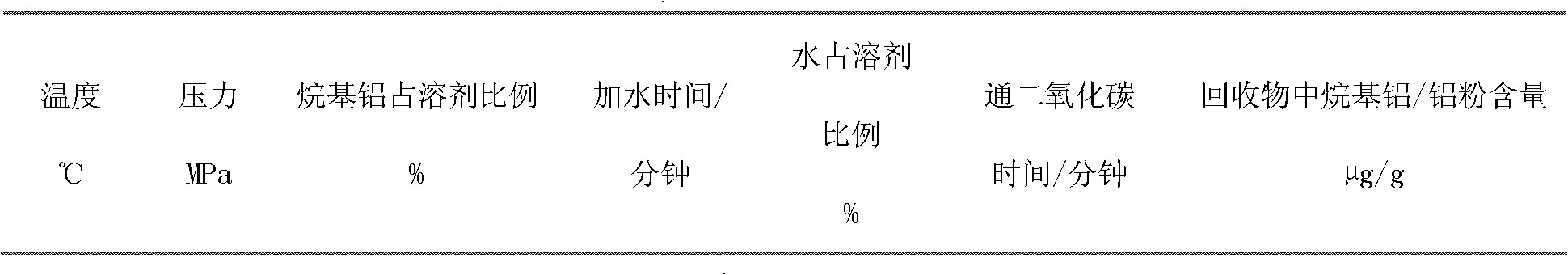

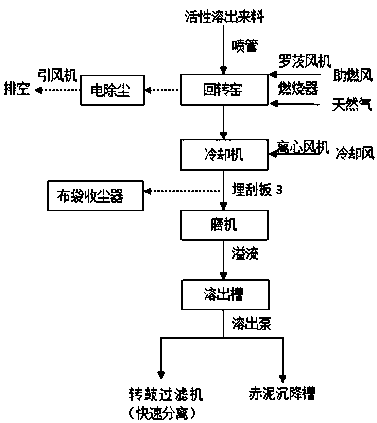

Recovery and treatment method for hazardous waste in production of aluminum alkyl

ActiveCN103182156ASafe and efficient handlingHydrocarbon purification/separationHydrocarbonsReaction temperatureSystem pressure

The invention relates to a recovery and treatment method for hazardous waste in production of aluminum alkyl. The method comprises the following steps: adding a solvent containing aluminum alkyl and aluminum powder into a reaction vessel after displacement of the reaction vessel with nitrogen and starting stirring; introducing carbon dioxide for 1 to 40 min, with an introduction speed controlled to be 5 L / min; when a temperature is lower than 40 DEG C, maintaining system pressure to be in a range of normal pressure to 0.1 Mpa and stopping introduction of carbon dioxide; adding water accounting for 50 to 300% by volume of the volume of the solvent, controlling a reaction temperature to be 10 to 60 DEG C and a pressure in a reaction to be 0.01 to 0.1 Mpa and carrying out full stirring and mixing; and filtering a mixture solution obtained after the reaction, collecting a separated oil-water mixture and carrying out standing and layering to obtain supernatant liquid which is a recovered solvent. The method provided in the invention is applicable to recovery and treatment of waste solvents containing different amounts of aluminum alkyl and aluminum powder and can effectively treat a solvent containing no more than 15 wt% of aluminum alkyl and o more than 10 wt% of aluminum powder.

Owner:PETROCHINA CO LTD

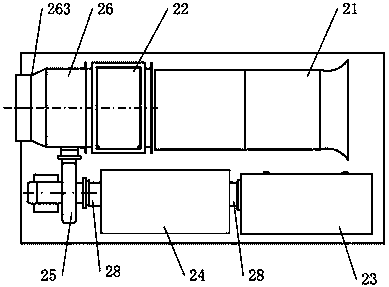

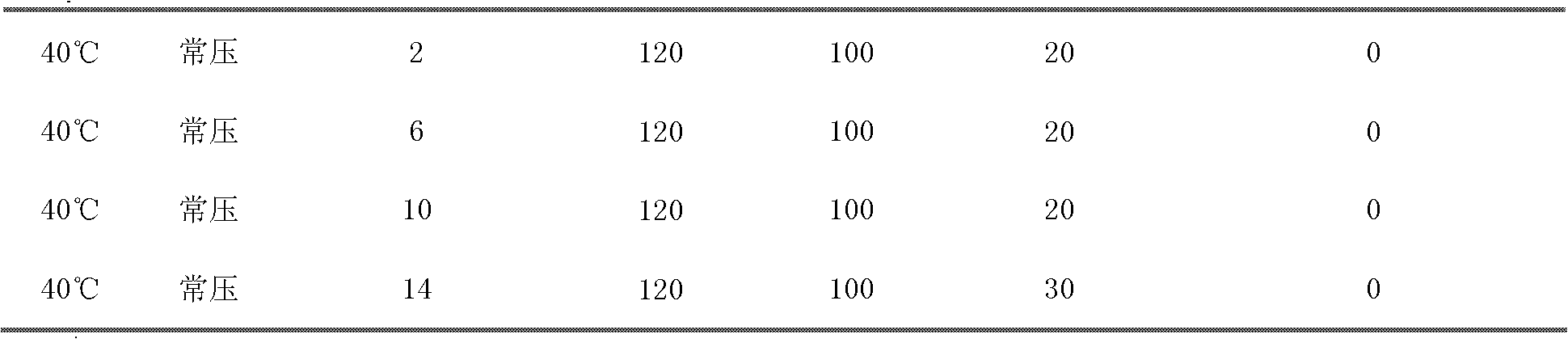

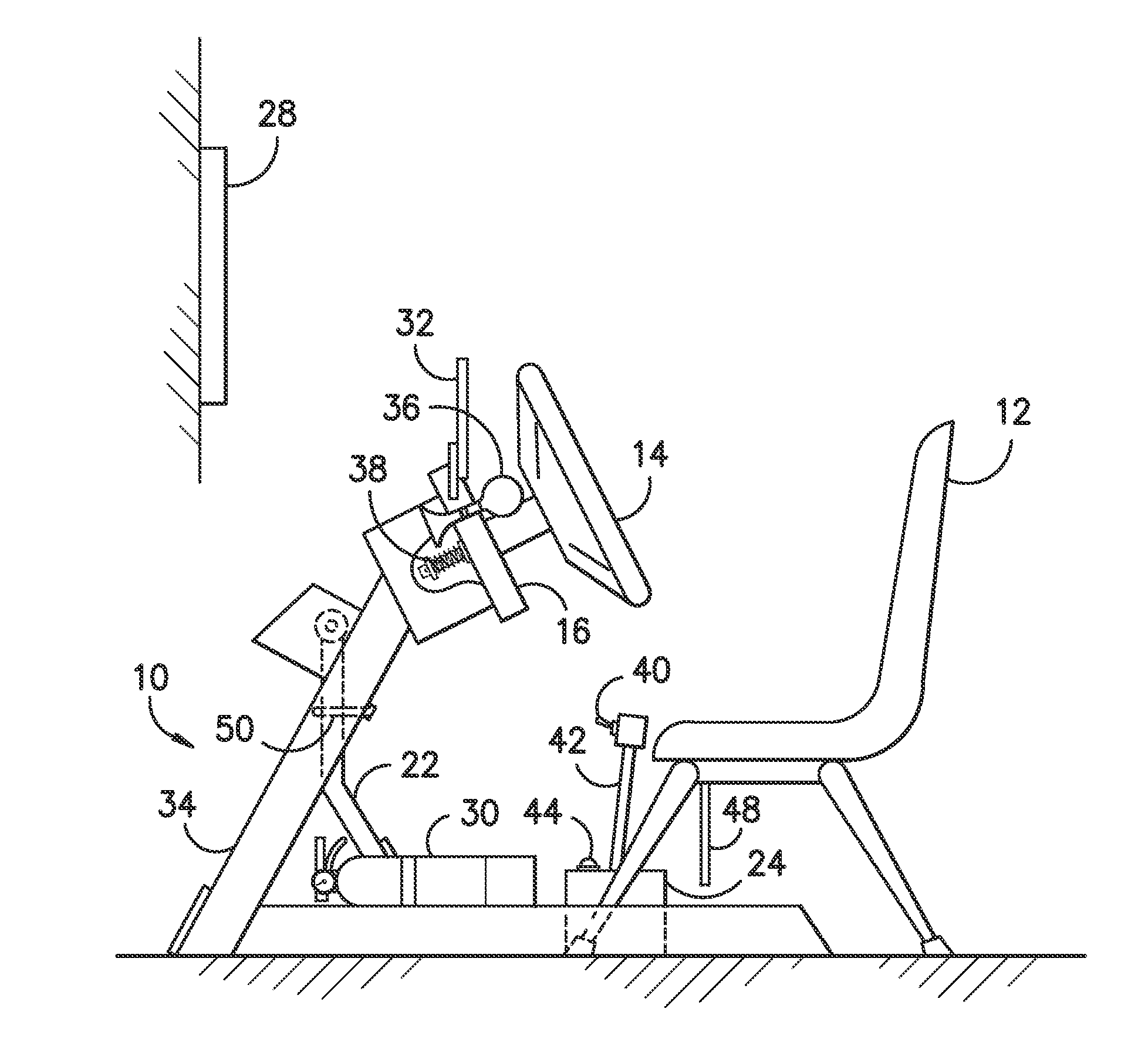

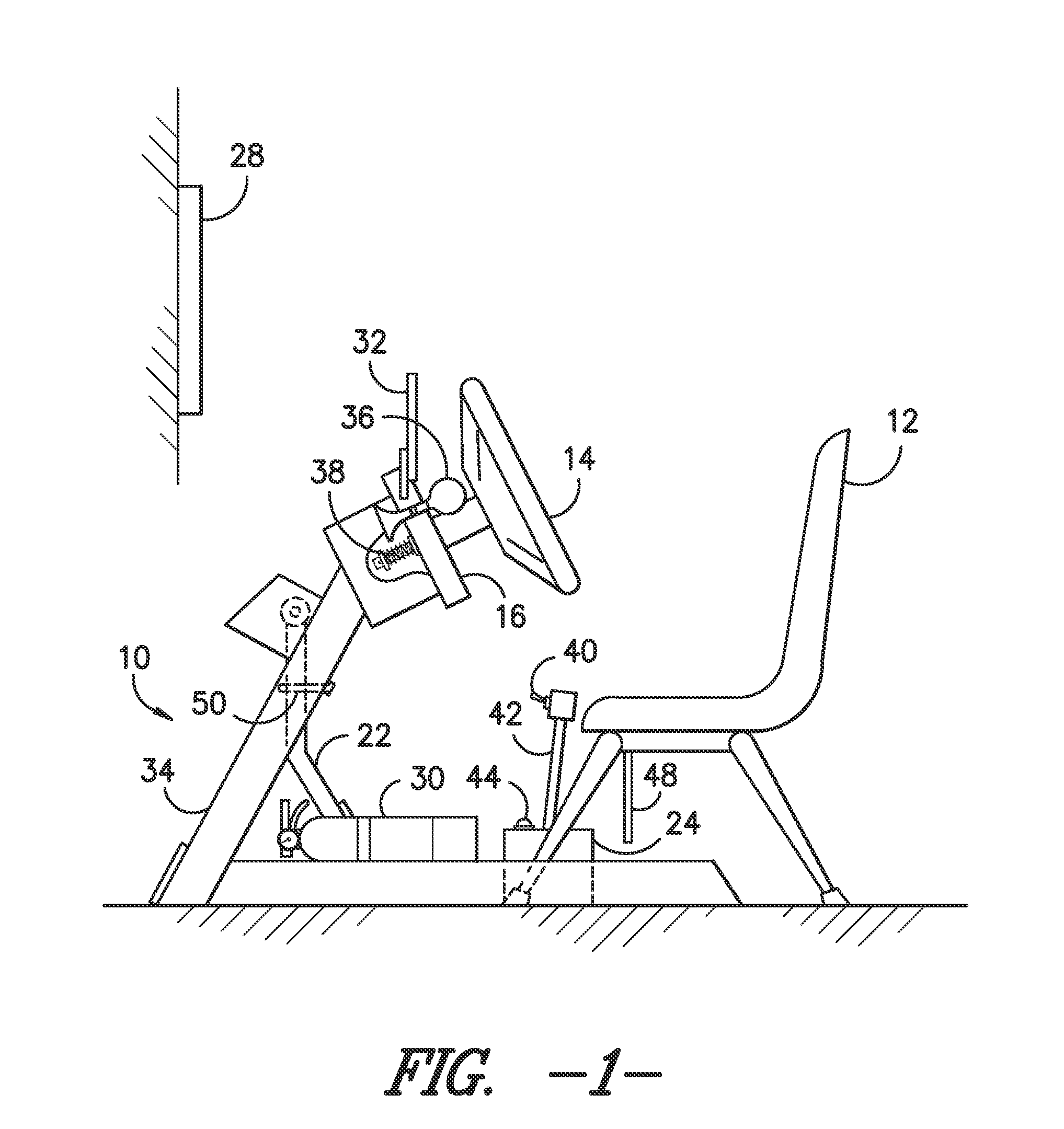

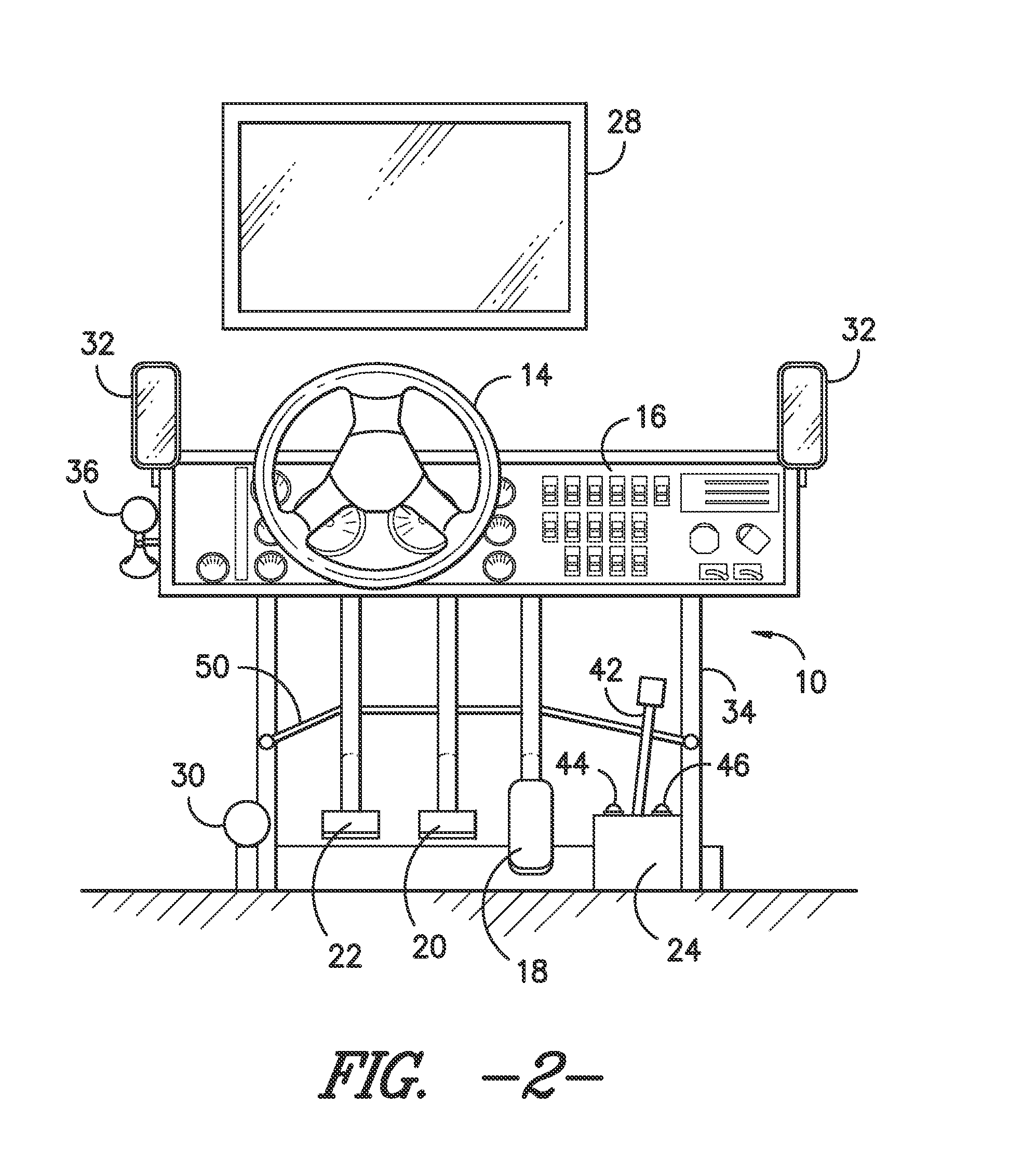

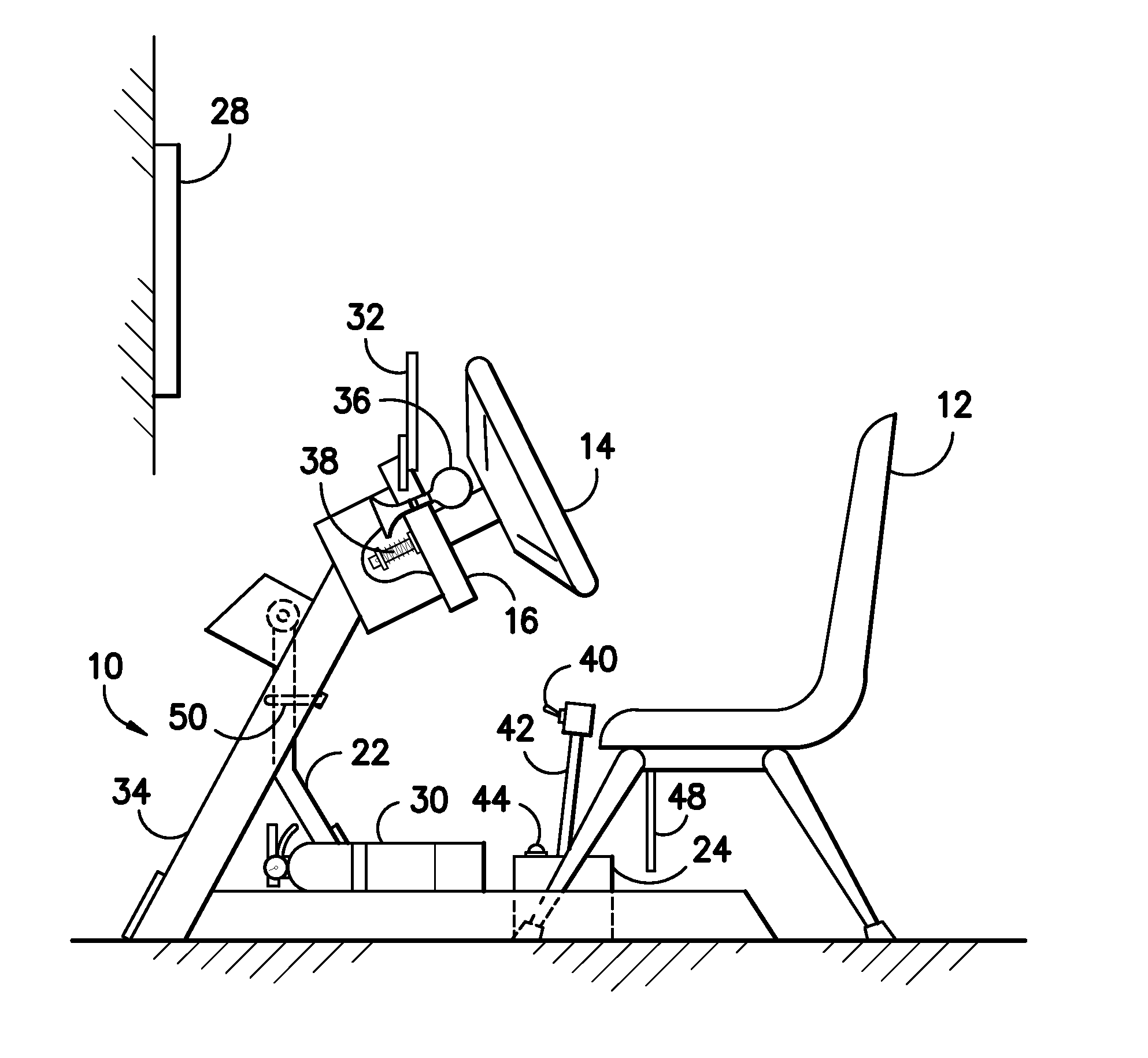

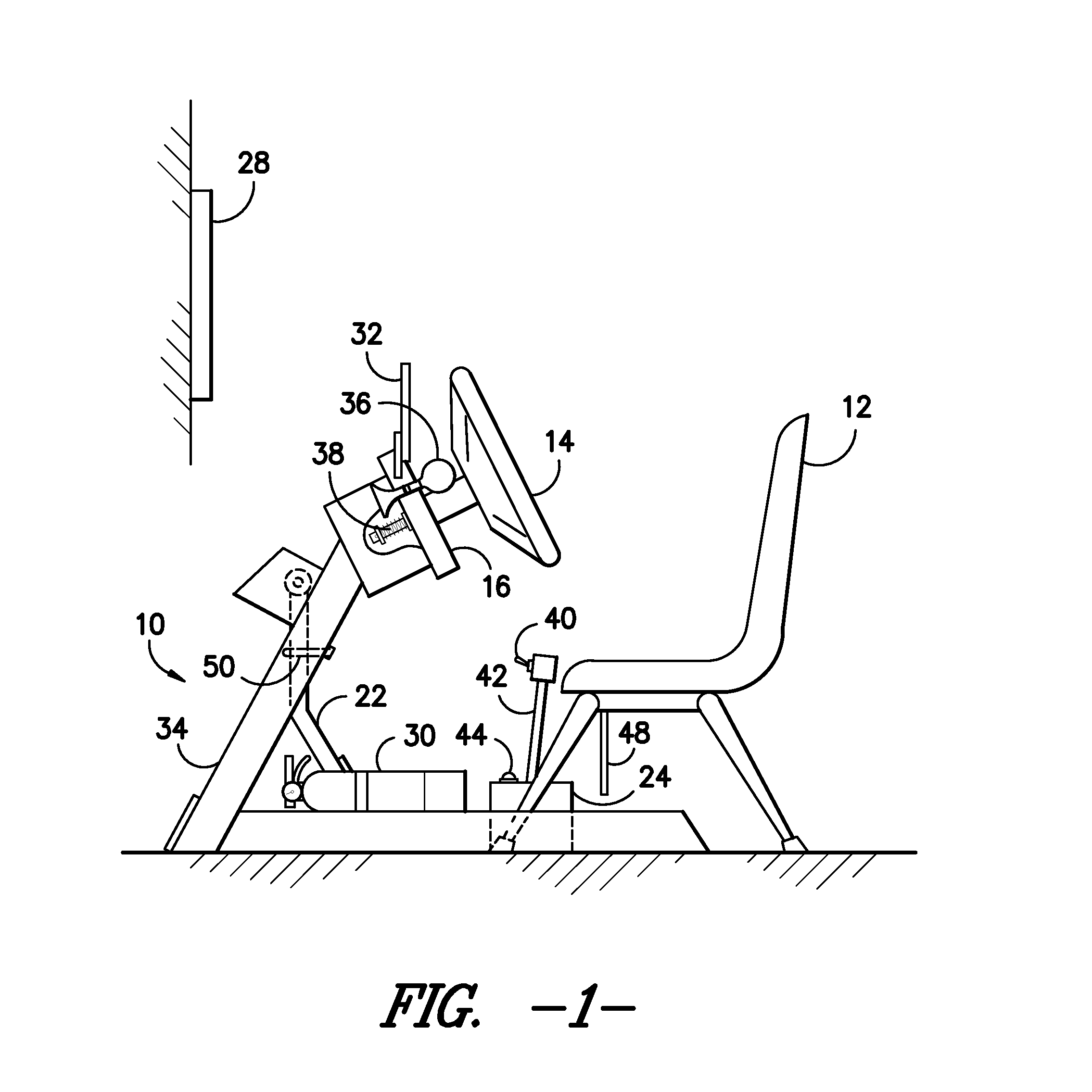

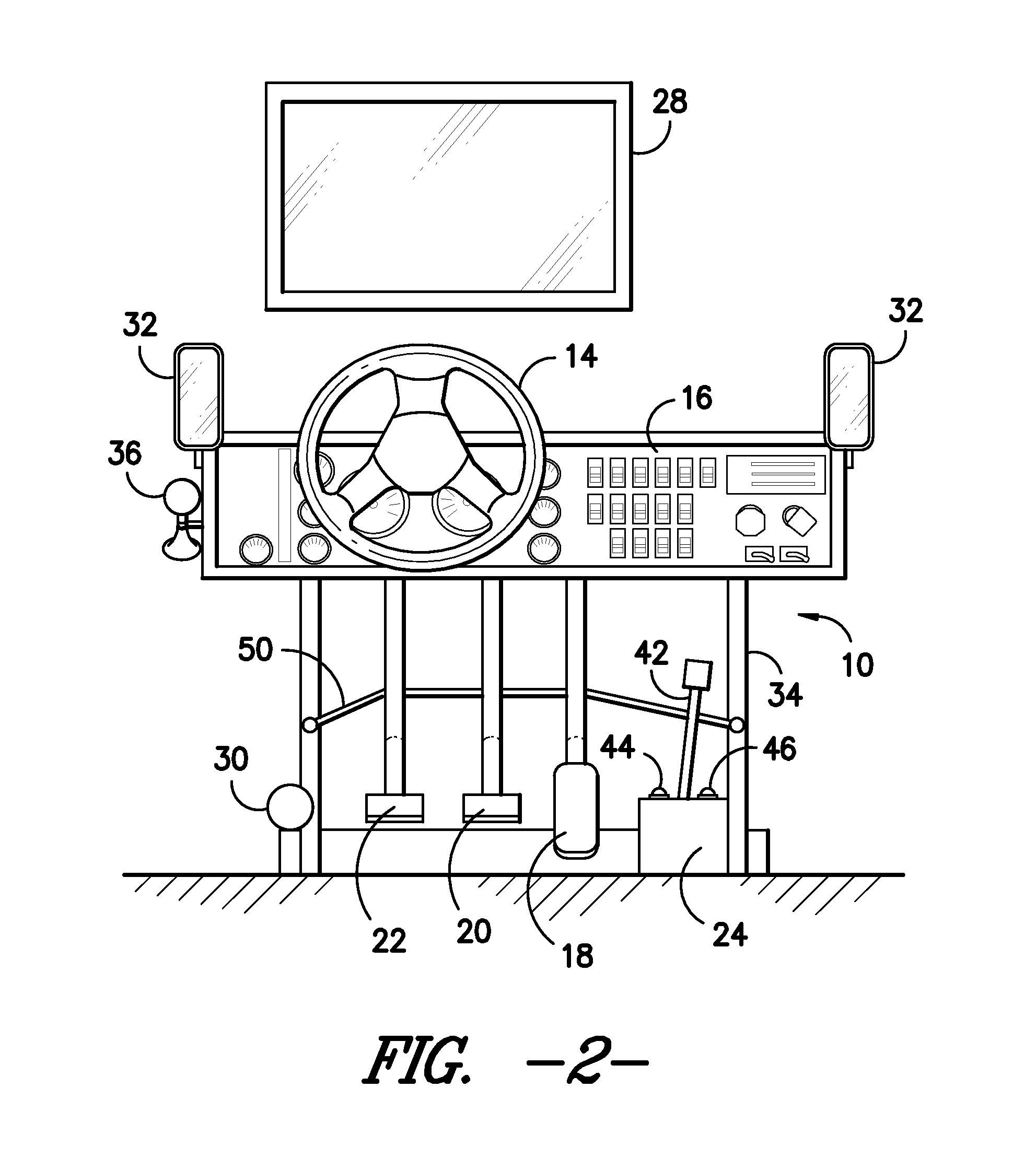

Truck driving simulator and training method

InactiveUS20130149673A1Effective instructionSafe and efficient handlingCosmonautic condition simulationsSimulatorsDashboardDriver/operator

A truck driving simulator is provided, comprising a simulated cab with a steering wheel and dashboard layout, foot pedals (accelerator, clutch, brake), gear shifting mechanism, and a video screen. In another embodiment, a series of such simulators may be placed in a classroom together with a single large screen video monitor or television at the front of the class, so that multiple students can follow along with the video simulation under the supervision of a teacher or instructor. The video monitor(s) may be used to show video footage of the actual route that will be used to test the drivers for their trucker's license. This arrangement allows students to repeatedly practice driving the actual course used for their driver's license test, and to learn concepts like clutching, double clutching and switching gears without risking damage to an actual truck and transmission.

Owner:VERATHON

Truck driving simulator and training method

InactiveUS20120009547A1Effective instructionSafe and efficient handlingCosmonautic condition simulationsSimulatorsDashboardSteering wheel

A truck driving simulator is provided, comprising a simulated cab with a steering wheel and dashboard layout, foot pedals (accelerator, clutch, brake), gear shifting mechanism, and a video screen. In another embodiment, a series of such simulators may be placed in a classroom together with a single large screen video monitor or television at the front of the class, so that multiple students can follow along with the video simulation under the supervision of a teacher or instructor. The video monitor(s) may be used to show video footage of the actual route that will be used to test the drivers for their trucker's license. This arrangement allows students to repeatedly practice driving the actual course used for their driver's license test, and to learn concepts like clutching, double clutching and switching gears without risking damage to an actual truck and transmission.

Owner:MILLER JAMES E

Method for treating inert aluminum ash in aluminum ash treatment technology

InactiveCN108640137AWon't pile upSafe and efficient handlingAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationFlue gasSlurry

The invention discloses a method for treating inert aluminum ash in an aluminum ash treatment technology. A mixture of aluminum ash and raw slurry is fired through a rotary kiln, is cooled through a cooling machine and is finally subjected to clinker leaching in a ball grinding mill in sequence. A device provided by the invention can be used for safely and efficiently treating the inert aluminum ash in the aluminum ash; lime milk is prepared and reacts with F<-> to generate CaF2, so that harmful elements and harms caused by the fact that the F<-> enter flue gas are eliminated; meanwhile, organic matters accumulated by a Bayer process can be treated. The rotary kiln is arranged and materials with different grain diameters can be uniformly mixed; the calcination efficiency and effect are improved.

Owner:YUNNAN WENSHAN ALUMINUM

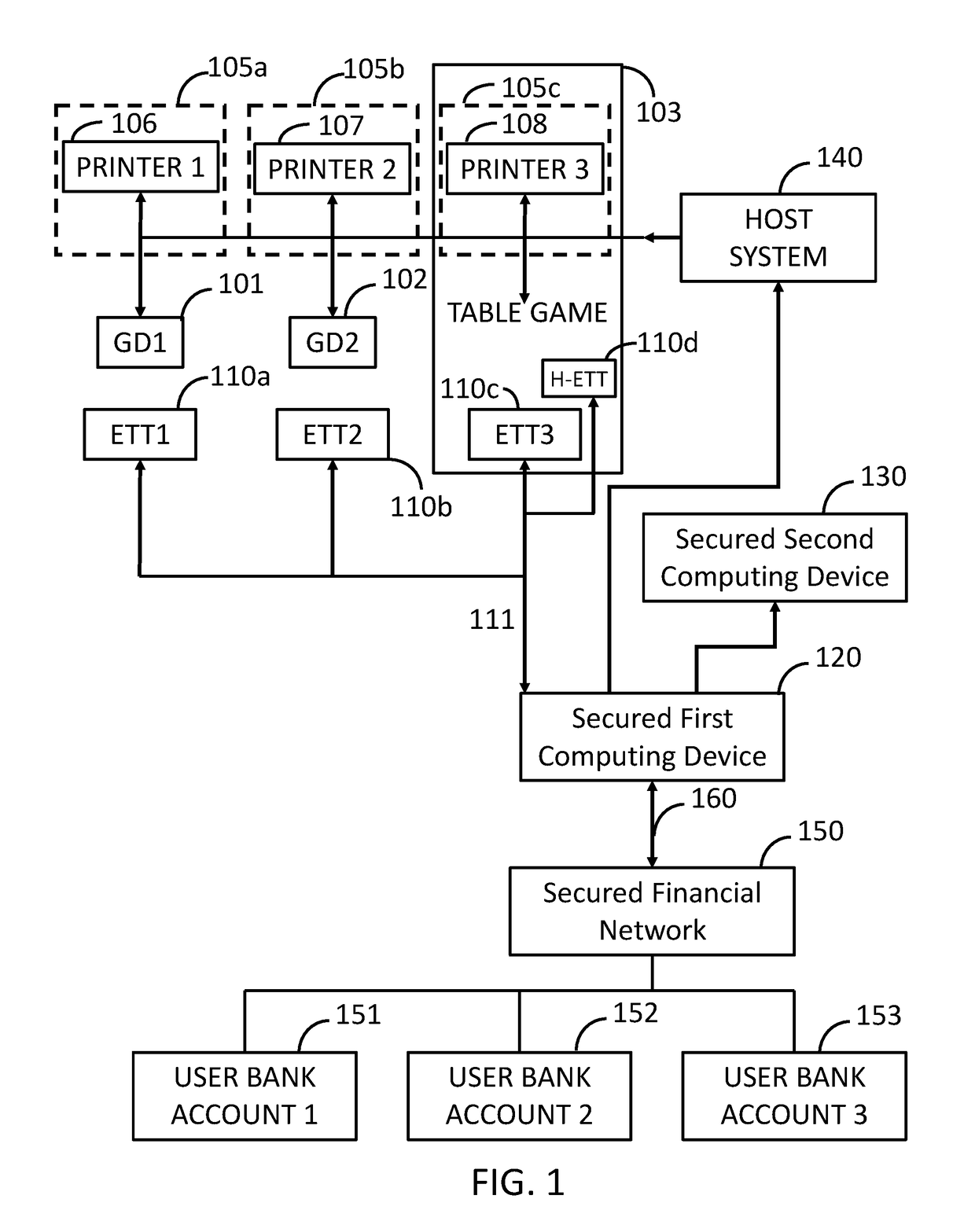

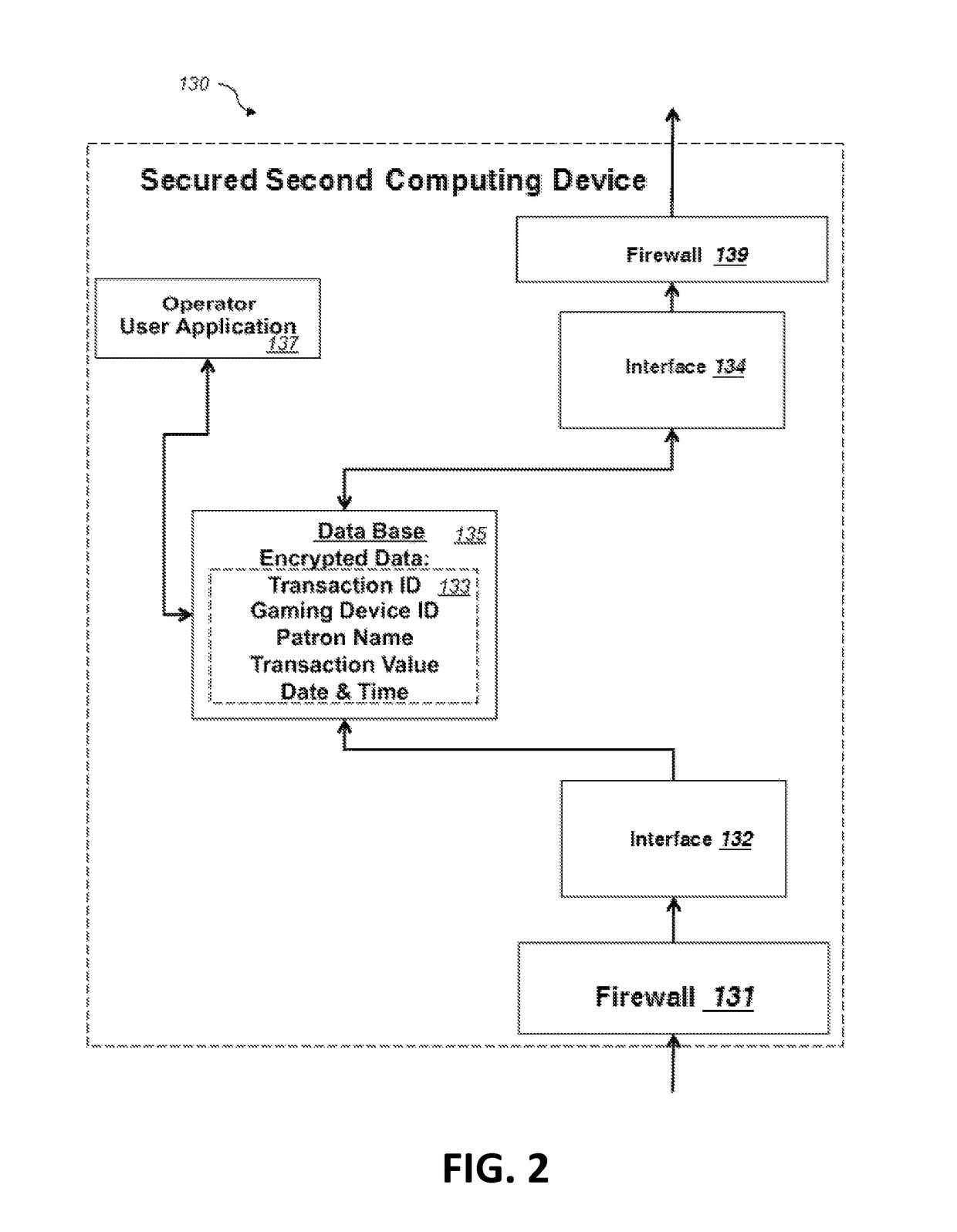

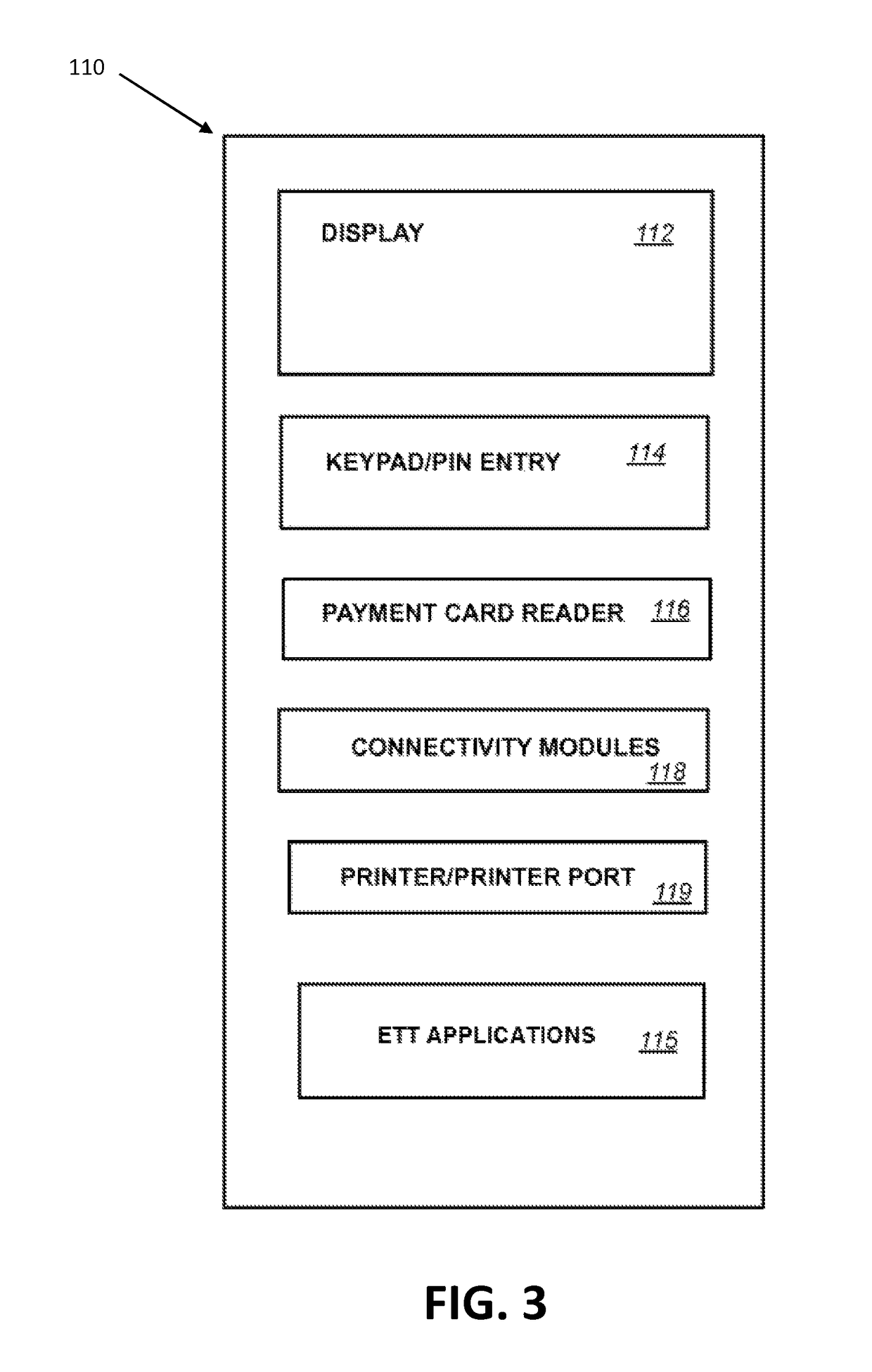

Electronic transaction systems and methods for gaming or amusement credit purchases

ActiveUS10223866B2Efficient retrievalImprove integrityFinanceApparatus for meter-controlled dispensingDisplay deviceDebit card

Systems, and methods are provided for the electronic purchase of gaming or amusement credits using a transaction device at a patron's location to apply funds from a financial account to the purchase of credits for use with an amusement or gaming device, system, or point of other wagering activity. Such credits are provided at the patron's location in the form of a printed ticket or other physical indicia of equivalent value, credits appearing in the credit meter and on the display of a gaming device, credit issued to a player card confirmed at the patron's location, credit issued to a debit card confirmed at the patron's location, and / or cash or other monetary-equivalents. In addition, physical confirmation of the completed electronic transaction from the patron's financial account may be concurrently provided to the patron in the form of a receipt.

Owner:AUTOMATED CASHLESS SYST INC

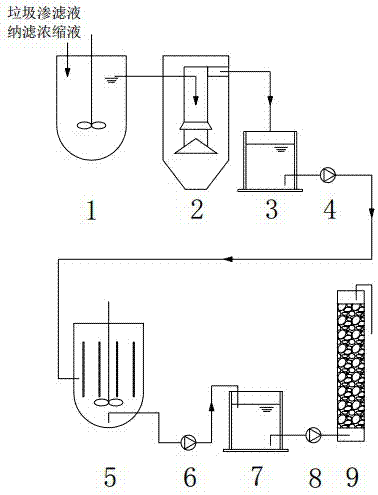

Safe and high-efficiency combined technology for landfill leachate nanofiltration concentrated solution treatment

ActiveCN107540135AImprove settlement performanceEfficient removalWater contaminantsMultistage water/sewage treatmentElectrolysisTwo step

The invention provides a safety and high-efficiency combined technology for landfill leachate nanofiltration concentrated solution treatment. The combined technology comprises three processes of iron-based flocculent precipitation treatment, electricity-like Fenton advanced oxidation and activated carbon adsorption treatment. The iron-based flocculent precipitation treatment can achieve a flocculent appropriate pH by controlling an adding mount of ferric salt to enhance a flocculation effect; in the electricity-like Fenton advanced oxidation, residual Fe<3+> of flocculation supernatant is utilized as a catalyst precursor, and an organic matter degrading effect is obviously improved compared with ordinary electrolysis; by means of arranging the activated carbon adsorption process, residuallow-molecular-weight organic matters after the former two steps and toxic and side byproducts generated in the electricity-like Fenton process can be adsorbed at the same time in high efficiency; finally safe and high-efficiency treatment on a concentrated solution is achieved; thus, the problems that the landfill leachate nanofiltration concentrated solution is difficult to treat and effluent hashigh toxicity in the field of water pollution control are solved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

Method for treating high-arsenic contaminated acid

ActiveCN107265690ANothing producedReduce CODWater contaminantsMultistage water/sewage treatmentCalcium hydroxideLiquid product

The invention provides a method for treating high-arsenic contaminated acid. The method comprises the following steps: 1) adding a calcium compound into high-arsenic contaminated acid until the pH value is 3 to 6, adding an oxidizing agent and soluble iron salt to perform reaction until precipitate is not generated any more, and performing solid and liquid separation to obtain a first precipitate and an intermediate liquid product; 2) adding the calcium compound into the intermediate liquid product to perform reaction, controlling the pH value to be 7 to 9 until precipitate is not generated any more, and performing solid and liquid separation to obtain a second precipitate and waste liquid, wherein the calcium compound is selected from at least one of calcium hydroxide and calcium oxide. By the treatment method, the waste liquid and the waste residues reach the discharge standard at the same time.

Owner:中城华宇(北京)矿业技术有限公司

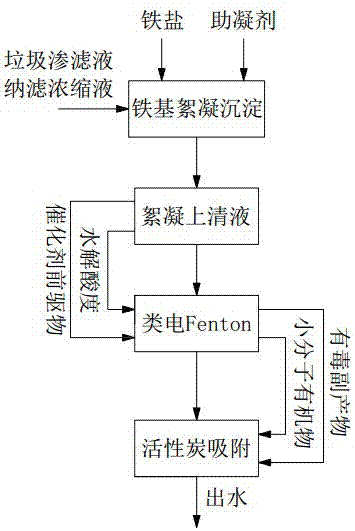

OS combined hair follicle extraction device and extraction method thereof

InactiveCN105877792AEasy to separateEfficient resectionSurgeryDiagnostic recording/measuringHair transplantingEyelash

The invention relates to an OS combined hair follicle extraction device and an extraction method thereof. The OS combined hair follicle extraction device comprises a hollow tube and a hair push rod, wherein the hair push rod is arranged in a hollow cavity of the hollow tube, a needle is arranged at the lower end of the hair push rod and extends out of the hollow tube, a groove is formed in one side of the needle, and the hair push rod is controlled through a control button. The length of the hollow tube is 11-13 cm, the tube diameter is 1 cm, the exposure length of the needle is 5-25 mm, the needle diameter is 0.8-1.8 mm, and the extraction method comprises the steps of routine examination before transplantation, hair follicle detection, image design, angle customization, hair follicle extraction, hair follicle separation, hair follicle planting and care after planting. By the adoption of the extraction device and the extraction method, the speed of hair follicle extraction can be effectively improved, hair loss, cicatricial alopecia and scant eyebrows, eyelashes, beards and other parts can be safely and efficiently handled, and the hair transplanting process is achieved by adopting a reasonable technology and using the shortest time.

Owner:林凤飞

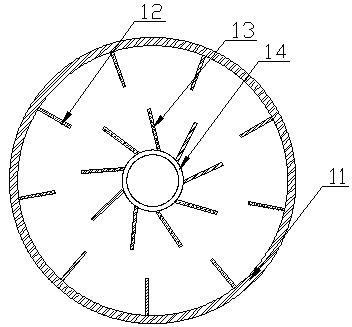

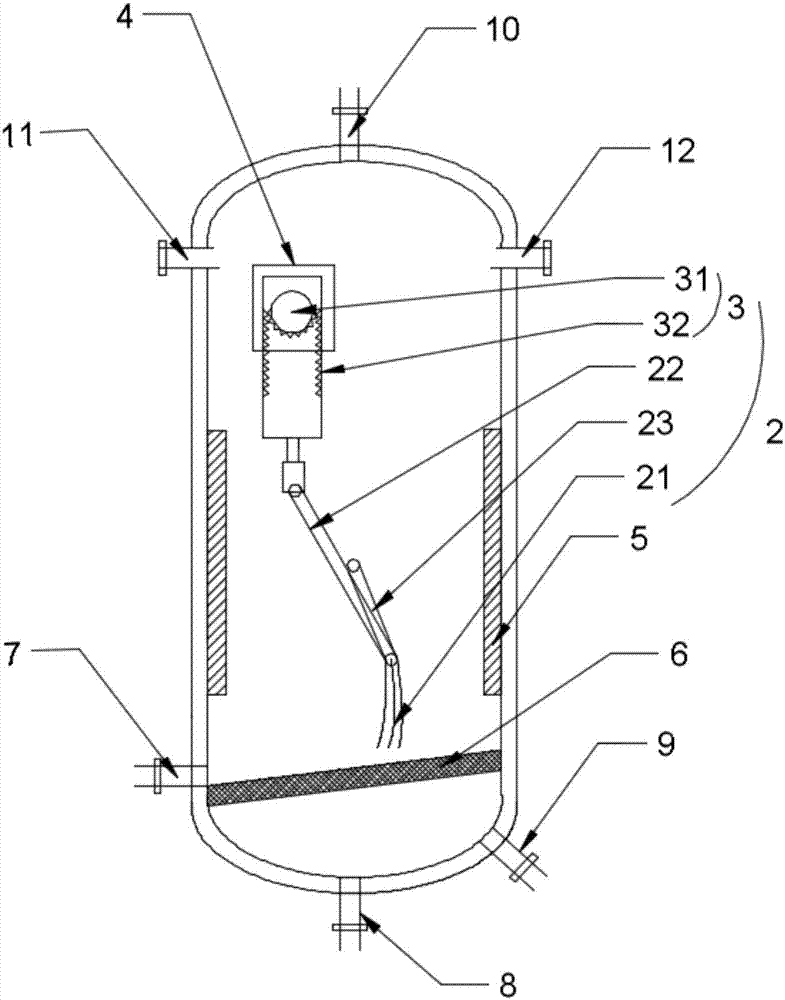

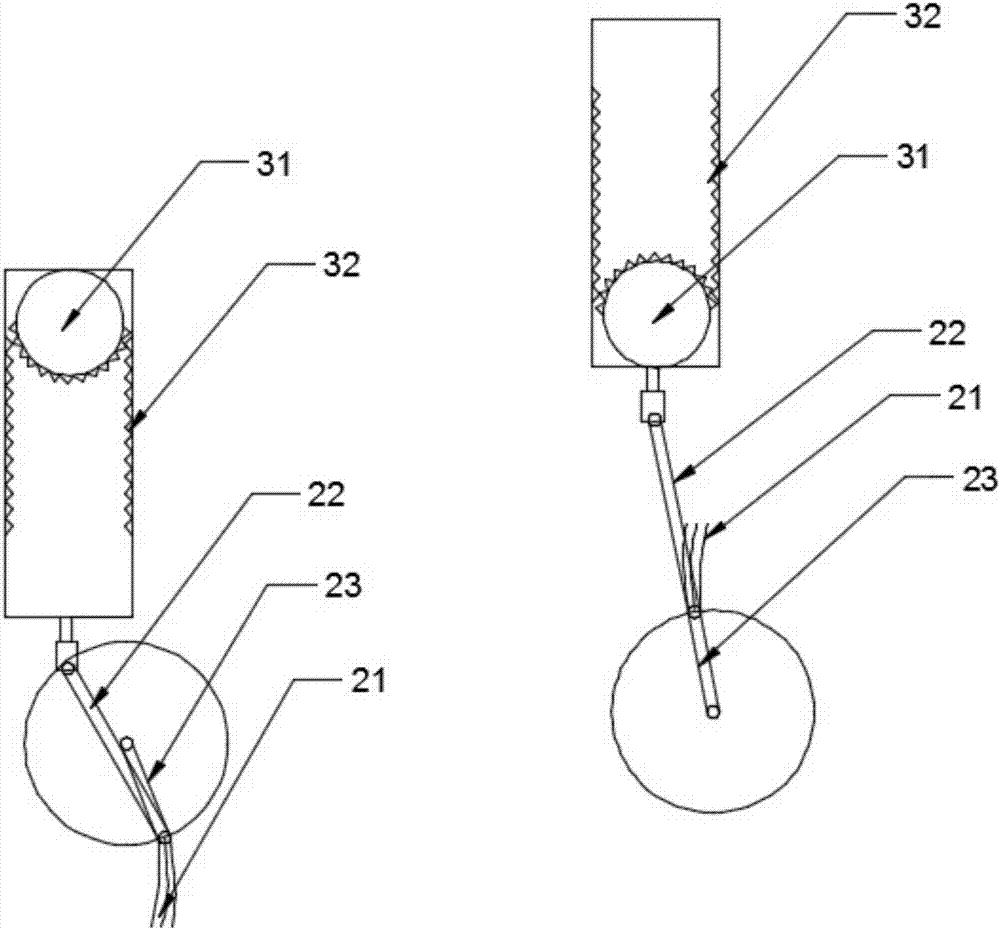

Activated carbon desorption reusing device

InactiveCN107362786AEasy to take outReduce manufacturing costOther chemical processesCombustible gas purificationActivated carbonMicrowave

The invention discloses an activated carbon desorption reusing device, and relates to the technical field of absorbent regeneration. The activated carbon desorption reusing device comprises a tank body and a stirring device fixed inside the tank body and is characterized in that the stirring device comprises a stirring grabber, a connecting rod structure for driving the stirring grabber and a rotating motor for driving the connecting rod structure; the stirring device is vertically arranged inside the tank body; a microwave generator assembly is fixed on the inner wall of the tank body; an inclined vibrating sieve is arranged below the stirring grabber; a gas outlet is formed at the upper part of the tank body; an activated carbon outlet, a sewage draining exit and a steam inlet are formed at the lower part of the tank body; the activated carbon outlet is positioned at the lower side of the inclined vibrating sieve. A conventional activated carbon processing device is high in processing cost and poor in processing effect. The activated carbon desorption reusing device disclosed by the invention has the advantages of simple structure, low operation cost and high desorption efficiency.

Owner:弘毅天承知识产权股份有限公司

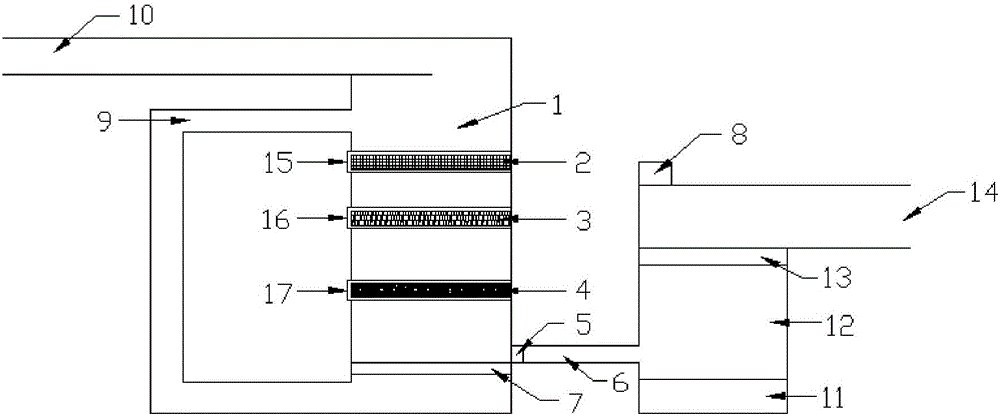

Domestic sewage treating and recycling device

InactiveCN106746104ARaise the gradeSafe and efficient handlingTreatment involving filtrationMultistage water/sewage treatmentSiphonDrinking straw

The invention discloses a domestic sewage treating and recycling device. The domestic sewage treating and recycling device is characterized in that an asbestos net filtering layer is arranged in a first slot; a quartz sand filtering layer is arranged in a second slot; an anthracite filtering layer is arranged in a third slot; a sewage monitor is arranged at the bottom end of the third slot; a heater is arranged at the bottom end of a water purifier; a distilled water adsorber is arranged at the top end of the heater; a reflux siphon is arranged at the bottom end of the sewage monitor; a pure water pipe is arranged on one side of a filter; a pure water valve is arranged at the inner end of the pure water pipe and electrically connected with the sewage monitor. The domestic sewage treating and recycling device is suitable for urban life and can safely and effectively recycle domestic sewage, the treated water resource is safe and healthy and can be domestically used again, so that water resource waste is greatly reduced, and repeating utilization factor of the water resource is increased.

Owner:WUHAN XINGTIANYU ENVIRONMENTAL ENG

Device for handling drill string components in respect of a rock drill rig and rock drill rig

ActiveUS20160130891A1Safe and efficient handlingAvoid less flexibilityDrilling rodsConstructionsPetroleum engineeringDrill string

A device for handling drill string components with respect to a drill rig. A gripper is configured to grip a first drill string component to be threaded on to or off from a second drill string component being part of a drill string which is partly drilled into a rock formation. A handling unit includes the gripper is movable between a drill string position and a loading position wherein a drill string component can be brought into or taken out from the gripper. The handing unit includes auxiliary engagement unit configured to align the gripped first drill string component to essentially in line with an axial direction defined by the second drill string component. The gripper and the auxiliary engagement unit are adjustable for gripping drill string components of different dimensions with maintained alignment of gripped drill string components. A rock drill rig including the device.

Owner:EPIROC ROCK DRILLS AB

Device for handling drill string components with respect to a rock drill rig and a rock drill rig

ActiveUS10100592B2Safe and efficient handlingAvoid less flexibilityDrilling rodsConstructionsPetroleum engineeringDrill string

A device for handling drill string components with respect to a drill rig. A gripper is configured to grip a first drill string component to be threaded on to or off from a second drill string component being part of a drill string which is partly drilled into a rock formation. A handling unit includes the gripper is movable between a drill string position and a loading position wherein a drill string component can be brought into or taken out from the gripper. The handing unit includes auxiliary engagement unit configured to align the gripped first drill string component to essentially in line with an axial direction defined by the second drill string component. The gripper and the auxiliary engagement unit are adjustable for gripping drill string components of different dimensions with maintained alignment of gripped drill string components.

Owner:EPIROC ROCK DRILLS AB

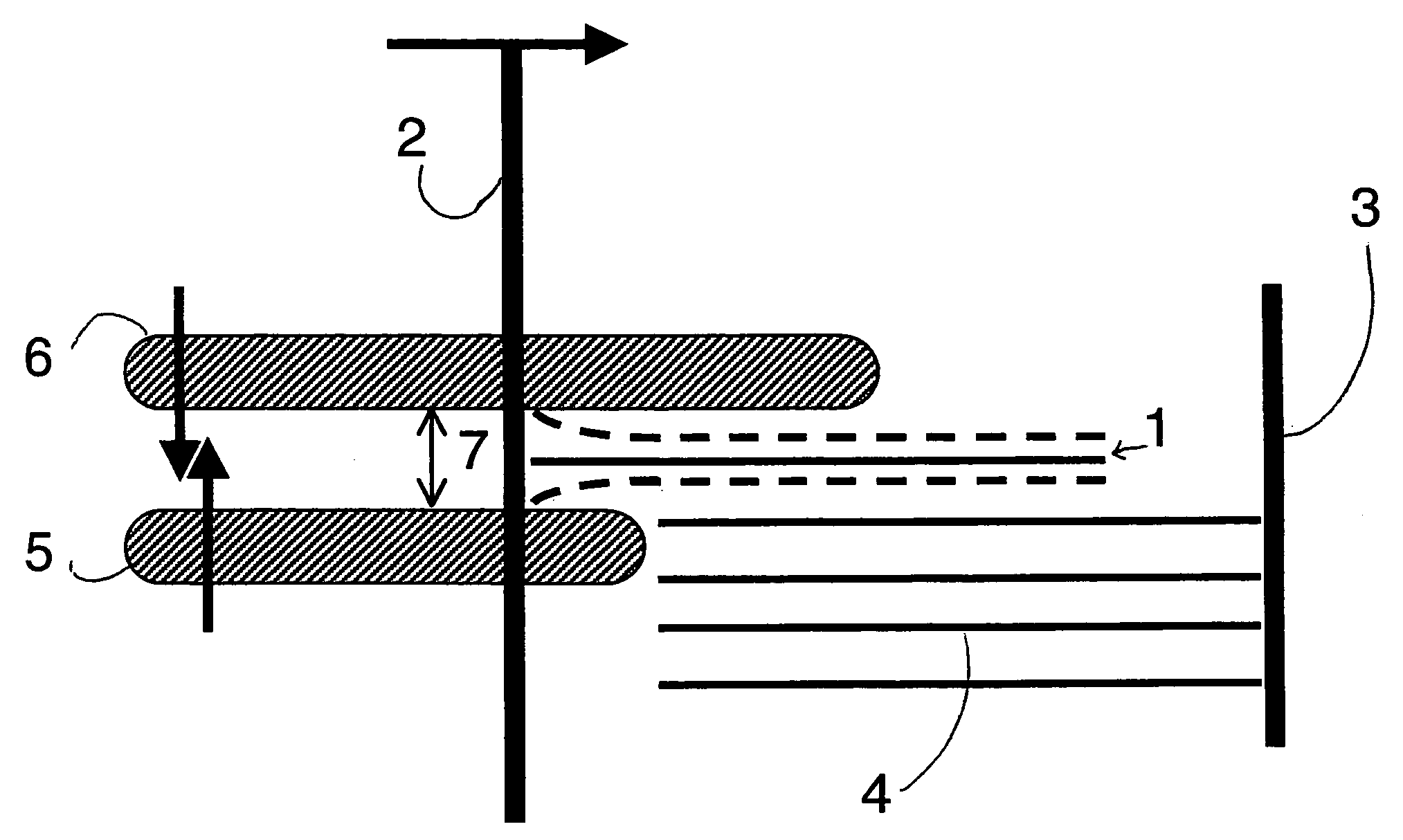

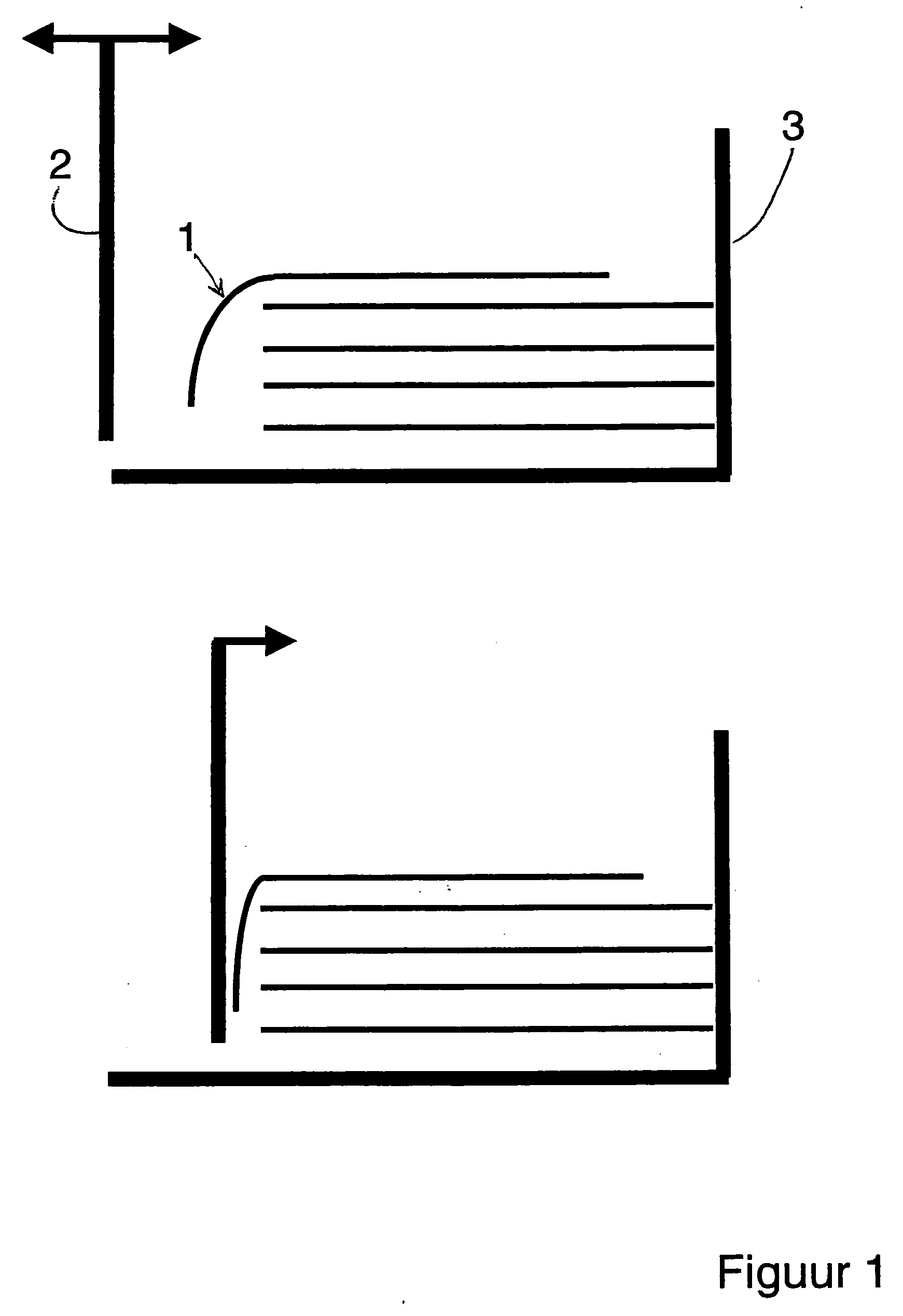

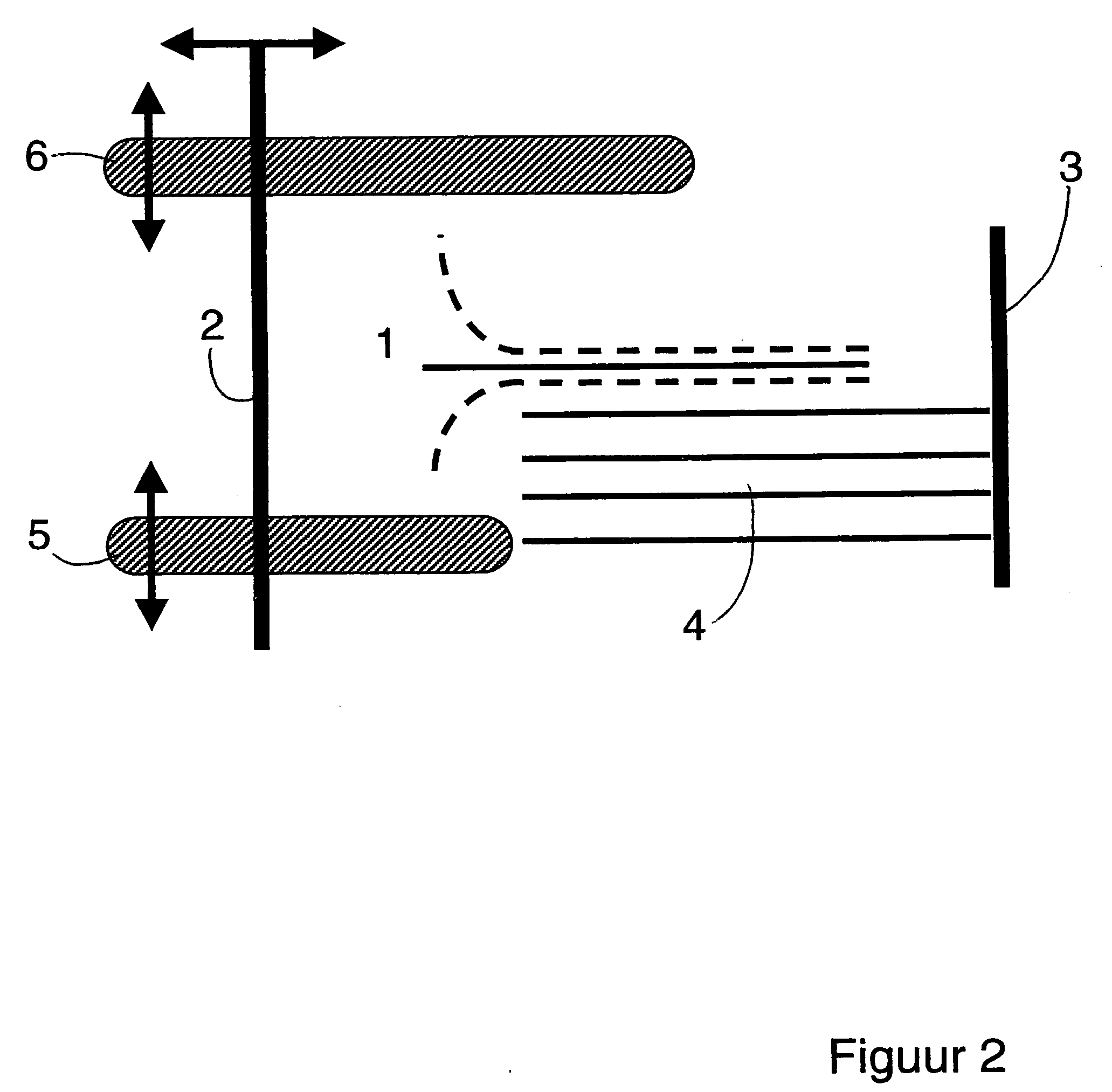

Device and method for forming a stack of sheets on a delivery surface

ActiveUS20050248079A1Prevent movementMinimize the risk of damagePile receiversArticle deliverySheet material

Owner:OCE TECH

Device and method for forming a stack of sheets on a delivery surface

ActiveUS7708272B2Safe and efficient handlingControl freedomPile receiversArticle deliveryEngineeringSheet material

Owner:OCE TECH

Contaminated soil thermal decomposition tail gas treatment method

InactiveCN104056530AEasy to handleSafe and efficient handlingDispersed particle filtrationIncinerator apparatusCombustion chamberIncineration

The invention discloses a contaminated soil thermal decomposition tail gas treatment method. The contaminated soil thermal decomposition tail gas treatment method comprises the steps of dust removal treatment, catalytic combustion, cooling treatment and absorption treatment, wherein according to the catalytic combustion, tail gas without particles is fed into a catalytic combustion chamber to be subjected to catalytic combustion, the combustion process is a process with catalytic combustion through catalysts, the temperature of catalytic combustion ranges from 200 DEG C to 600 DEG C, and the time of catalytic combustion is two seconds or longer. Compared with an existing tail gas high-temperature incineration method, the contaminated soil thermal decomposition tail gas treatment method has the advantages that due to the fact that the tail gas is treated with a catalytic combustion method, the damage and removal rate of organic pollutants is more than 99%, and the tail gas is treated efficiently, safely and effectively; due to the fact that tail gas treatment is carried out at low temperature, energy consumed in the tail gas treatment process is about only half of the energy consumed in high-temperature incineration, the treatment cost of thermal decomposition is remarkably reduced, and the contaminated soil thermal decomposition technology can be widely applied easily.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

Detection system for rollover leakage parameters of tank truck and detection method of detection system

ActiveCN110450699ARealize detectionSafe and efficient handlingMeasurement of fluid loss/gain rateTank vehiclesRolloverComputer module

The invention discloses a detection system for rollover leakage parameters of a tank truck and a detection method of the detection system, and belongs to the technical field of automobile safety. Thedetection system is provided with a rollover monitoring module and a leakage detection module, the rollover monitoring module is adopted for judging the operating state of the tank truck, when it is judged that the tank truck is in a rollover risk state, the leakage monitoring module is used for monitoring the liquid level of liquid in a liquid tank and the slip angle of a tank body, whether the liquid tank is in leakage or not is judged according to liquid level data and slip angle data, the liquid leakage amount in the tank and the flow of the leaking liquid are calculated, and therefore theleakage parameters are detected. Then the rescue risk is reduced through the accurate leakage parameters, the rescue efficiency is improved, and it is guaranteed that accidents are safely and efficiently treated.

Owner:HUAIAN COLLEGE OF INFORMATION TECH +1

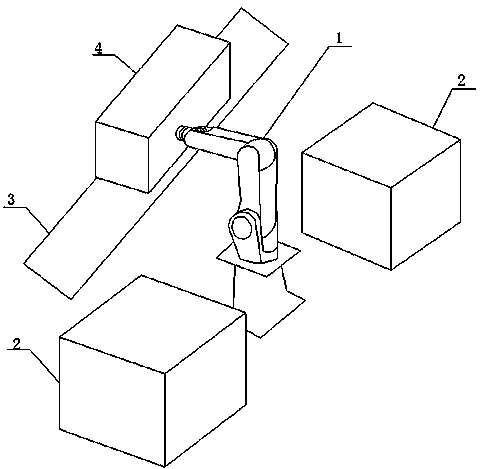

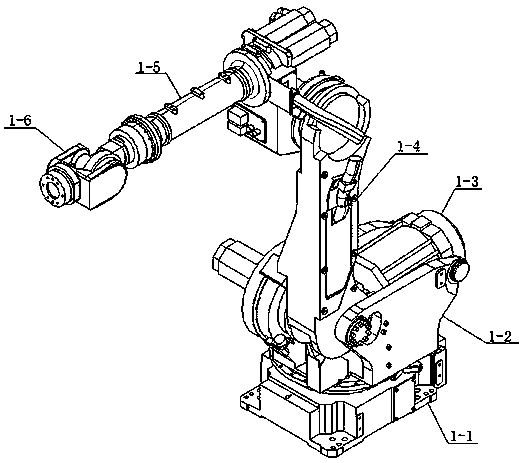

Robot system for grasping waste refrigerator

ActiveCN109093611ARealize handlingSafe and efficient handlingProgramme-controlled manipulatorGripping headsRobotic systemsEngineering

The invention discloses a robot system for grasping a waste refrigerator. The robot system comprises two storing boxes, a conveying belt, a grasping device and a controlling device. The two storing boxes are respectively arranged on two sides of the grasping device. The conveying belt is arranged in front of the grasping device. The grasping device comprises a base, a grasping arm and a suction cup assembly. The grasping arm sequentially comprises a rotation seat, a first arm body, a second arm body and a third arm body. A grasping suction cup comprises a fixing bracket, a suction cup and a vacuumizing mechanism. The fixing bracket is hinged to the end of the third arm body. The suction cup is connected with the fixing bracket. The suction cup communicates with the vacuumizing mechanism. The vacuumizing mechanism comprises a vacuumizing pump, a vacuumizing pipe and an electromagnetic valve. The electromagnetic valve is connected with the controlling device. The controlling device comprises a controller and a pressure sensor arranged in the suction cup. The controller controls and is connected with the grasping arm. Automatic waste refrigerator grasping and conveying are achieved. Labor efficiency is improved, and the working process is accurate, safe and reliable.

Owner:河南省睿卡机器人制造有限公司

Shopping cart collection, storage, and retrieval system

InactiveUS20050214073A1Safe and efficient handlingEncourage useSingle unit pavingsPaving detailsParking spaceEngineering

Owner:HUGHES METRA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com