Sludge granulation and drying device and method

A drying device and sludge technology, applied in dewatering/drying/concentrating sludge treatment, raw material extrusion and granulation, etc., can solve the problem of wet sludge cohesion and agglomeration, unfavorable sludge granulation and drying, and poor particle bed structure. problems of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

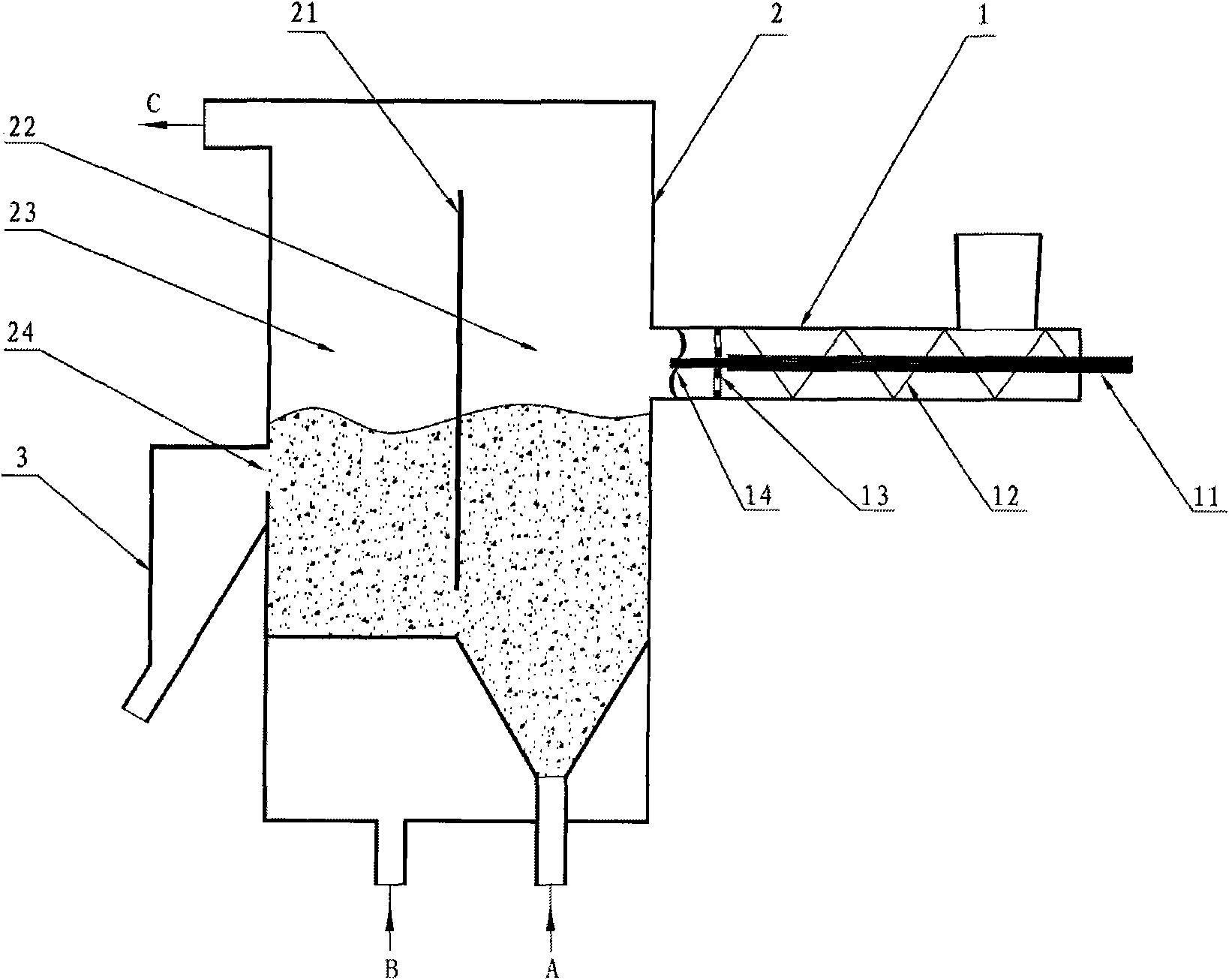

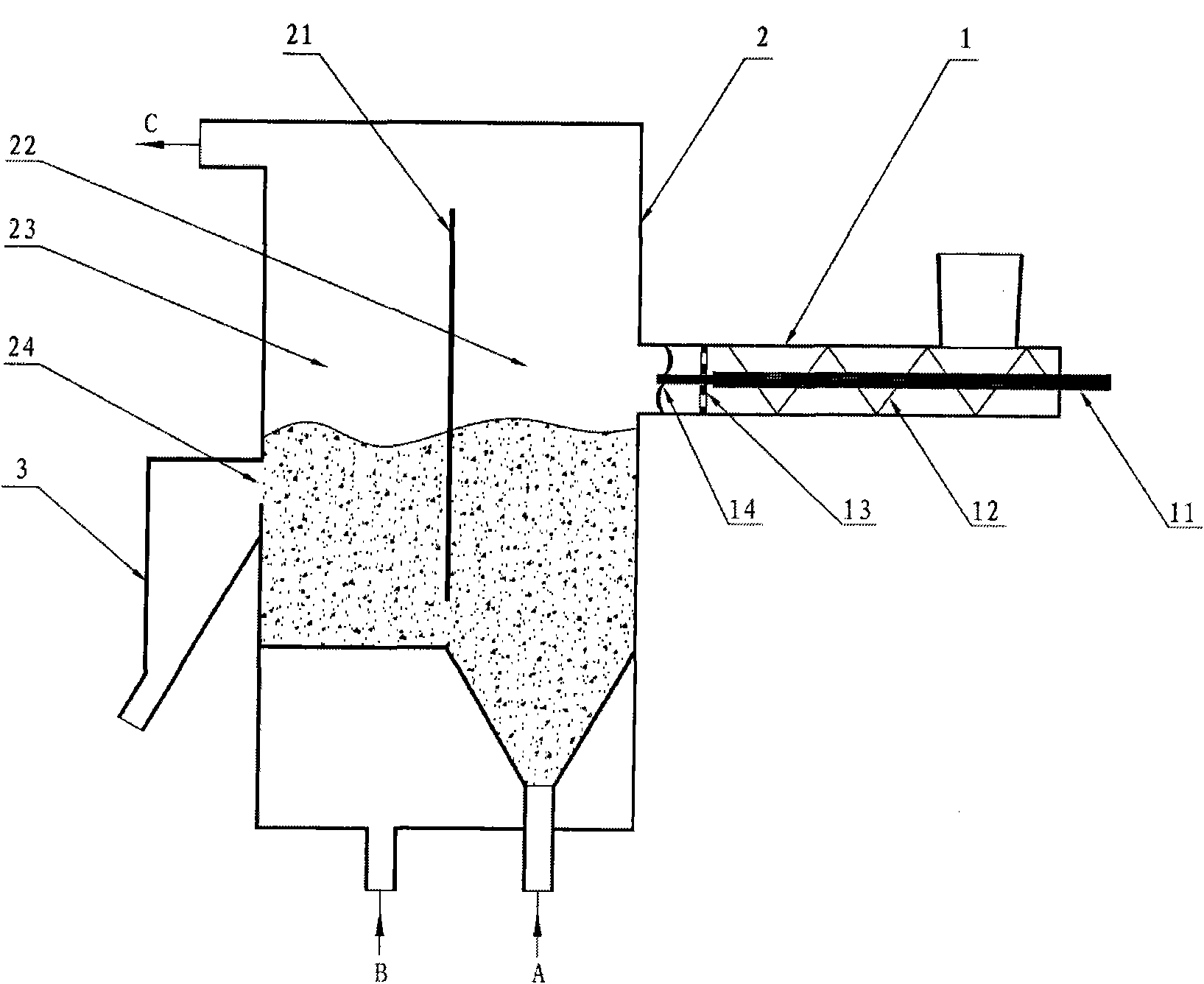

[0012] The sludge granulation and drying device of the present invention is composed of a screw extrusion granule forming machine 1, a spray fluidized bed 2 and a dried sludge granule silo 3, wherein the screw extrusion granule forming machine 1 is composed of a transmission shaft 11, Screw feeder 12, sludge extrusion forming orifice plate 13 and rotary blade 14, sludge extrusion forming orifice plate 13 is fixed in the downstream shell of screw feeder 12, transmission shaft 11 passes through sludge extrusion forming orifice plate 13 is connected with the rotary blade 14, and the spouted fluidized bed 2 is divided into two left and right areas that are connected up and down with the middle partition 21, corresponding to the spouted bed 22 and the fluidized bed 23 respectively, and the bottom of the spouted bed is the spouted air inlet A, the bottom of the fluidized bed is the fluidized air inlet B, the middle part of the spouted fluidized bed 2 is the overflow port 24, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com