Ultrasound-assisted tea oil extraction method

An auxiliary extraction and ultrasonic technology, which is applied in the direction of edible oil/fat, food science, application, etc., can solve the problem of not using ultrasonic auxiliary extraction of camellia oil, so as to promote the development and comprehensive development and utilization of resources, shorten the extraction time, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Now take the laboratory implementation as an example, and the non-limiting examples are described as follows:

[0023] The camellia seed is dried under vacuum at 40-60°C, then shelled and pulverized. Take 200g of pulverized raw material powder, add 600mL of n-hexane extractant, keep it in a closed state, add the material liquid into the ultrasonic extractor at the same time, extract at room temperature for 30min, then increase the temperature to 55°C, and keep the extraction for 45min. After the extraction, Suction filtration to remove dregs to obtain the suction filtration mixture, centrifuge at 2500r / min for 20min, and obtain the supernatant as the extract. Evaporate the extract under reduced pressure with a rotary evaporator, recover the solvent to obtain camellia oil, and then vacuum-dry the obtained camellia oil to obtain the final camellia oil product.

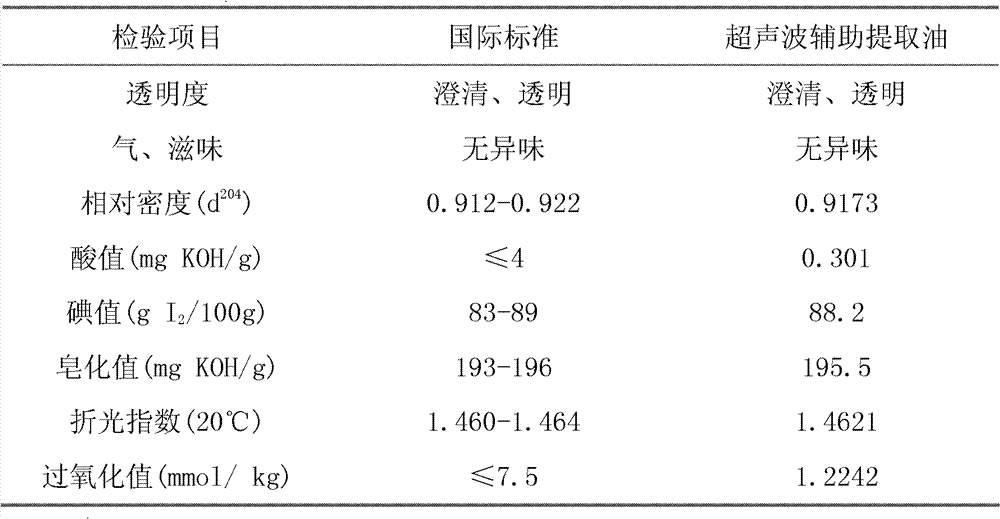

[0024] Comparison of physical and chemical indicators of tea seed oil obtained by ultrasonic-assisted extracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com