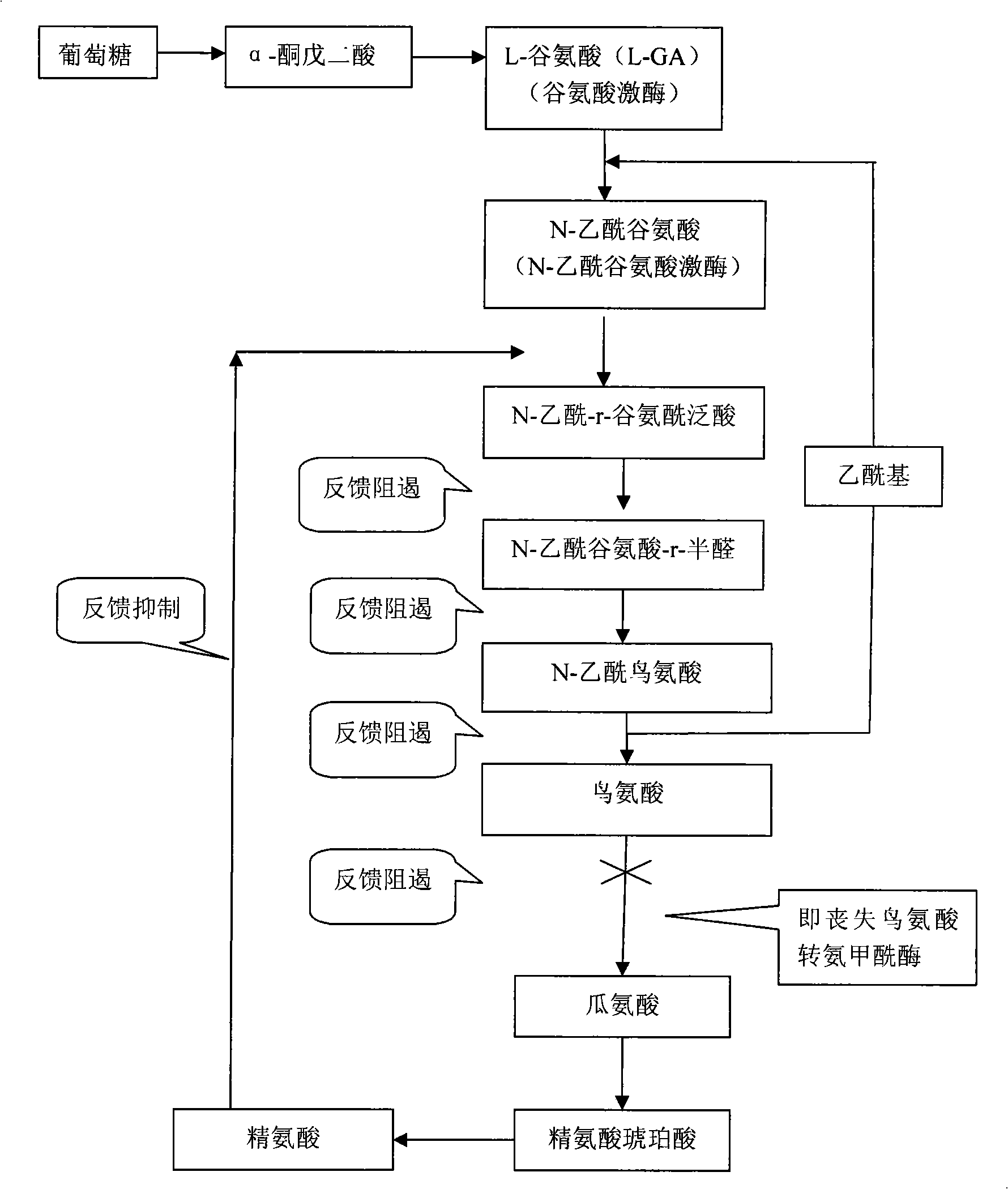

Method for producing L-ornithine by microorganism fermentation

A technology of microbial fermentation and ornithine, applied in the field of microbial fermentation technology, can solve the problems of difficulty in large-scale production, high cost, and limiting the wide application of L-Orn.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below by the examples, but the examples do not limit the protection scope of the present invention.

[0077] 1. Strain selection

[0078] (1) Strains

[0079] The starting strain is Corynebaetenom glutamicam preserved in this laboratory

[0080] (2) Culture medium and mutagenesis method

[0081] 1. The composition of the complete medium (A)

[0082] 1% beef extract; 1% peptone; 0.5% yeast extract; 0.5% NaCl; PH7.0 (PH6.4-8.0 test paper produced by Shanghai Reagent No. 4 Factory); add 2.0% agar powder when preparing solid medium.

[0083] 2. The composition of basic medium (B)

[0084] Glucose: 1%; (NH 4 ) 2 SO 4 : 0.3%; KH 2 PO 4 : 0.1%; K 2 HPO 4 ·3H 2 O: 0.2%; MgSO 4 ·7H 2 O: 0.05%; FeSO 4 ·7H 2 O: 0.002%; MgSO 4 0.002%, V B1 . HCl 200 μg / L, V H 50 μg / L, PH7.0~7.2 (adjusted with NaOH); agar powder 1.6%.

[0085] 3. Preparation of 1 / 30M phosphate buffer solution (PH7.0)

[0086] Liquid A: Na2 HPO 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com