Patents

Literature

146results about How to "Fast acid production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation process for fermented chilli sauce

ActiveCN102919814AGrowth inhibitionReduce accumulationFood preparationCALCIUM LACTOBIONATEToothpaste

The invention discloses preparation process for fermented chilli sauce. The preparation process includes the following steps: placing fresh chilli and ginger into a jar, mixing cultures of lactobacillus planetarium and fermentation lactobacillus, and conducting three times of culture cultivation to obtain fermentation broth; adding the fermentation broth and fermenting; taking the chilli and ginger out of the jar and pulping; stirring and seasoning; packaging the fermented chilli sauce with tins or toothpaste-tube-shaped jars for replacing the jars and vacuum-sealing; and sterilizing through heat to obtain finished products. The chilli sauce is produced through pure-culture fermentation, calcium lactate and calcium chloride are used as a hardener, and color protecting processing is conducted by using 0.1% erythorbic acid combined with 0.1% laurel kojic acid. Simultaneously, the chilli sauce is packaged by using the tins and toothpaste-tube-shaped cans and has the advantages of being short in fermenting time, low in nitrite content, stable in product quality and good in product appearance quality.

Owner:HUNAN HUAKANG FOOD

Lactobacillus leavening agent, preparation method thereof and special bacterial strain

InactiveCN101748082AIncrease productionHigh content of live bacteriaMilk preparationBacteriaAdditive ingredientBacterial strain

The invention discloses a lactobacillus leavening agent, a preparation method thereof and a special bacterial strain. The preservation serial number of lactobacillus is CCTCC M208151. An active constituent of the lactobacillus leavening agent is the lactobacillus. The invention also discloses a method for preparing the lactobacillus leavening agent, which comprises the following steps: firstly, leavening and culturing lactobacillus plantarum SC79 CCTCC M208151 in SC79 optimal culture medium; and secondly, collecting thallus in the step 1 and then adding a protective agent to the thallus to obtain the leavening agent. The lactobacillus leavening agent has small dosage, quick acid production speed through mixing the lactobacillus leavening agent and a harvestless exopolysacchatide yoghourt bacterial strain to prepare yoghourt, better relative viscosity, elasticity, denseness and adhesiveness than that of the conventional yogurt and small syneresis sensibility of formed sticky yogurt colloids, larger water holding capacity than that the conventional yogurt and hard whey separation.

Owner:JILIN ACAD OF AGRI SCI

Method for preparing microbial symbiotic fermented bread kvass beverage

Owner:HARBIN DE MUOLI MINERAL WATER

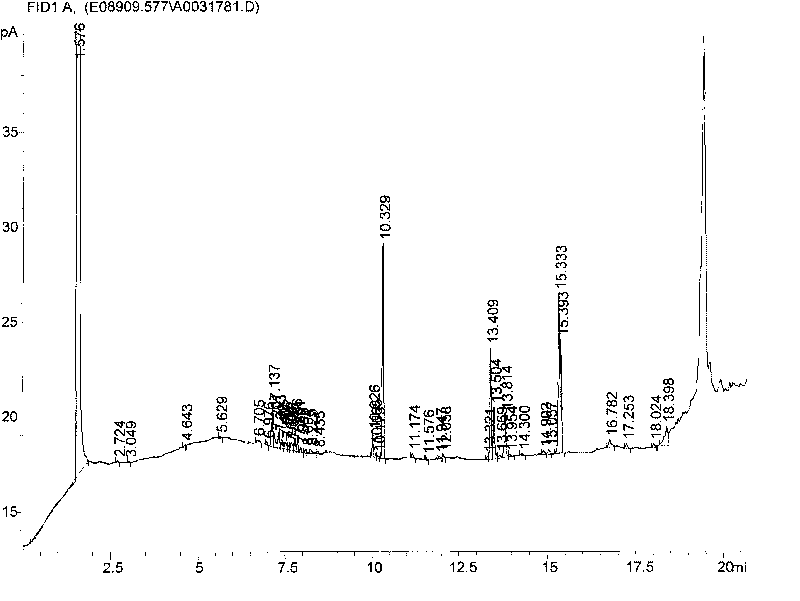

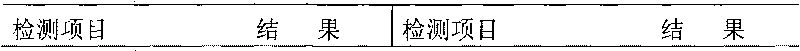

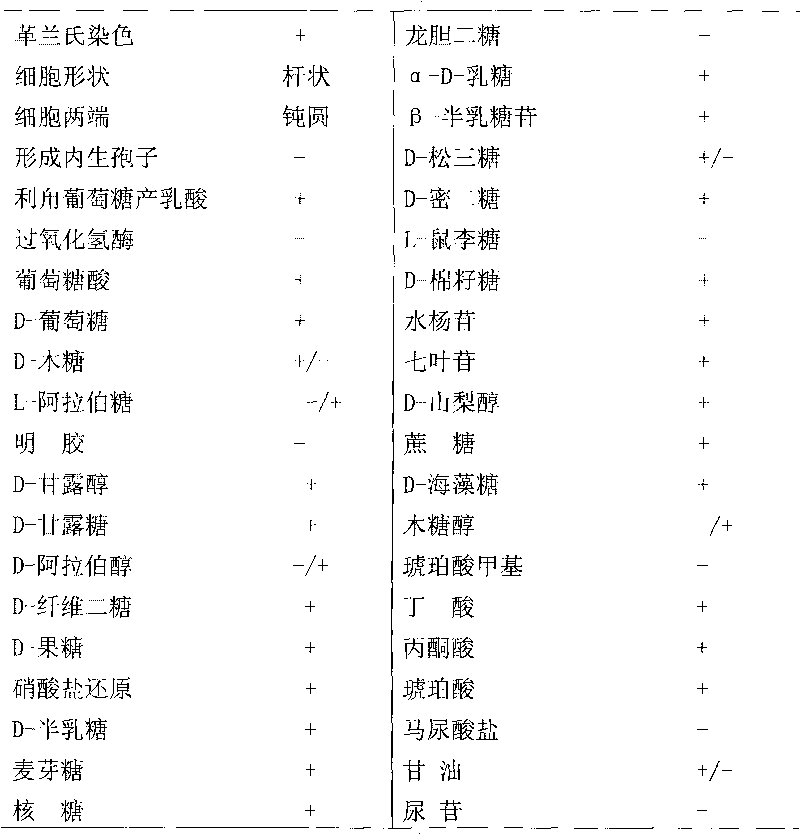

Greengage vinegar, preparation method thereof and application method thereof

InactiveCN101597583AShorten the production cycleLabor savingBacteriaMicroorganism based processesBrewingFood processing

The invention discloses a greengage vinegar, preparation method thereof and application method thereof, belonging to the technical field of brewed food processing. The invention discloses a greengage vinegar, preparation method thereof and application method thereof, belonging to the technical field of brewed food processing. The greengage vinegar can also be used for preparing greengage vinegar drinks. The method adopts a new strain and a deep liquid fermenting process and has the advantages of short process, high labor productivity, and the like. The greengage vinegar and the vinegar drink which are prepared according to the method are clear and transparent, have strong and harmonious fruit and vinegar aroma, appropriate sour and soft taste and keeps the clear characteristics of greengage vinegars. {} The method can be popularized in brewing enterprises.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

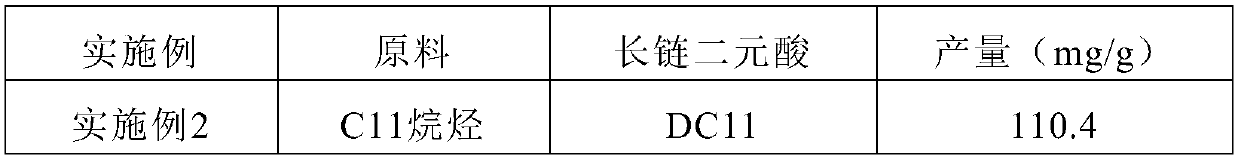

Method for increasing long-chain biatomic acid fermentation production rate

This invention relates to one method of improving fermentation efficiency of long chain diacid. In this method, normal alkane is the material, and animalcule fermentation method is adopted to produce correspondent diacid. Its major character is to add catastaltica, which includes halogeno-aliphatic acid, methyl fat acid and one or two kinds of its salt or ester, to reduce beta oxidation ability of bacterial strain. The concentration of the catastaltica is 0.01-5mmol / L. the added catastaltica can efficiently reduce beta oxidation ability of bacterial strain, lowers the alkane consumption, and improves greatly the fermentation efficiency, the acid-producing rapidity and is particularly suitable for long chain diacid.

Owner:CHINA PETROLEUM & CHEM CORP +1

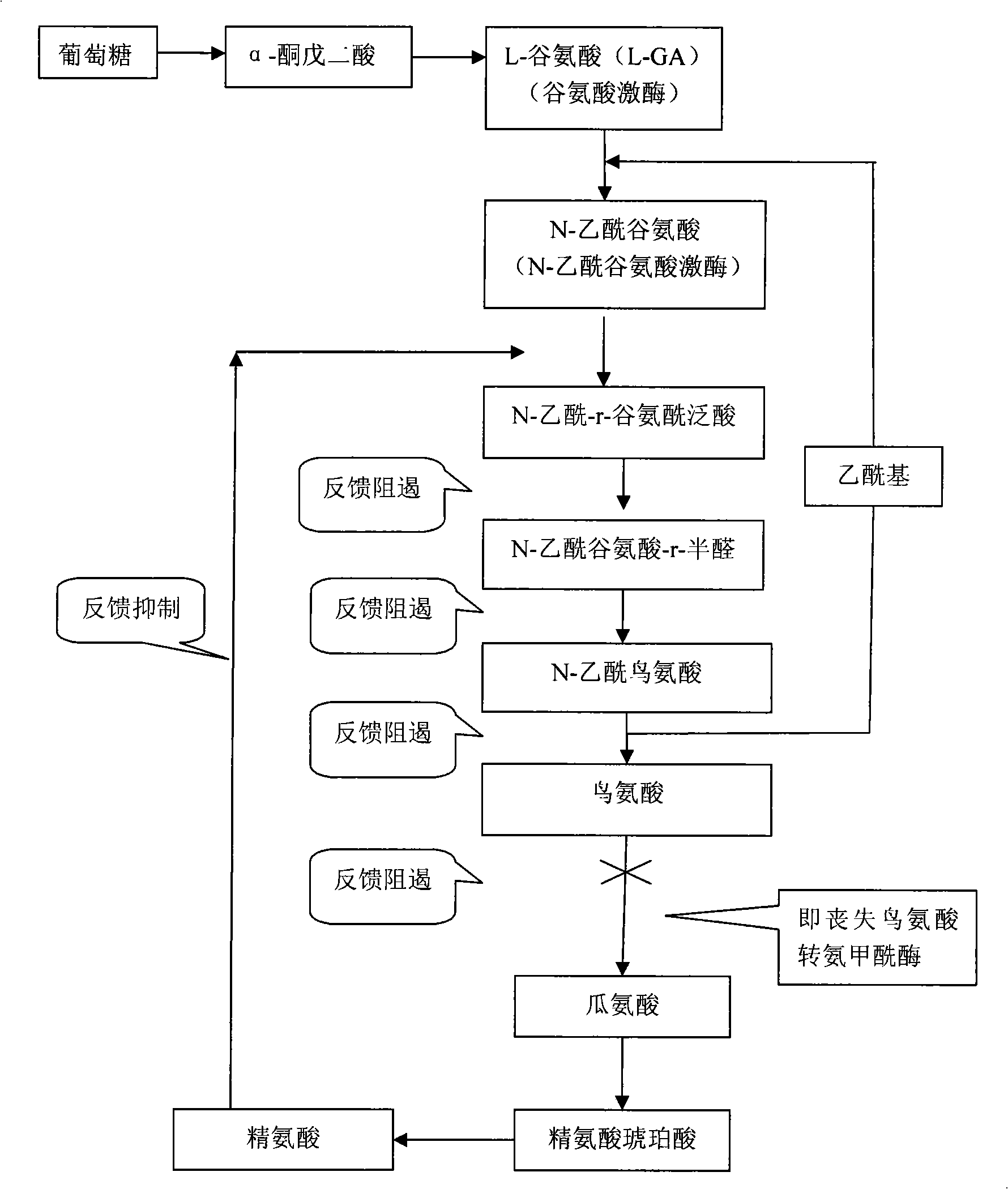

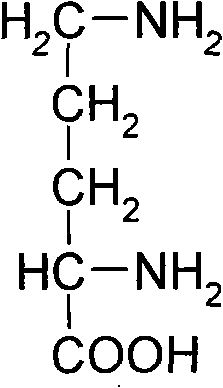

Method for producing L-ornithine by microorganism fermentation

InactiveCN101323866AFast acid productionImprove sugar conversion rateBacteriaMicroorganism based processesSolubilityChemical treatment

The invention provides a method for producing L-ornithine by microbial fermentation, namely, using Corynebacterium glutamate to obtain the strains of CS-189(cit<(-)>+SG<r>) by chemical treatment, and obtain the L-ornithine hydrochloride by fermentation, culture solution micro-filtration by a ceramic membrane, ion exchange resin and extraction by a hydrothermal crystallization method with decompression concentration. The strains used in the method are auxotrophy resistant to sulfaguanidine, which significantly enhances acid yield by fermentation. Meanwhile, aiming at the problem that the solubility of the L-ornithine hydrochloride in water is extremely difficult, the hydrothermal crystallization method is adopted to obtain better extraction rate under the condition that flammable and explosive alcohol is not used. The method simplifies processes and reduces extraction cost.

Owner:上海聚瑞生物技术有限公司

Fresh marigold flower lactic fermentation process

InactiveCN1903028APrevent outflowReduce pollutionOrganic chemistryDead plant preservationLactobacillusLactic acid fermentation

A process for fermenting the fresh flower of marigold by bacterium lactis includes such steps as drying in the air, screening, loading it in fermenting pool, uniformly spraying composite bacterium lactis, compacting, sealing, and anaerobic fermenting at medium temp for 8-12 days. Its advantages are high acid generating speed and wall-breaking effect, and unique taste.

Owner:辽宁省农业科学院食品与加工研究所

Fermentation medium for fermenting and producing glutamic acid from thermo-sensitive type strain and fermenting method for producing glutamic acid by using fermentation medium and application

The invention relates to a fermentation medium for fermenting and producing glutamic acid from a thermo-sensitive type strain. The components and the final concentration of the fermentation medium in the formula are as follows: 165-205g / L corn starch amylolysis, 15-30g / L maize slurry, 10-18g / L molasses, 0.5-1.5g / L glycine betaine, 5-10g / L bean pulp hydrolysate, 3-8g / L H3PO4, 1.25-1.75g / L MgSO4.7H2O, 0.064-0.084g / L MnSO4.7H2O, 0.055-0.085g / L FeSO4.7H2O, 3-6g / L KCl, 0.08-0.15g / L threonine, 0.8-1.2g / L succinic acid, and 0.1-0.3g / L defoamer, and the solvent is water, the pH value of the fermentation medium is 6.8-7.0 when the phosphoric acid is neutralized by alkali. Due to the appropriate carbon source, the nitrogen source, the carbon nitrogen ratio and the phosphorus content in the medium, the acid production rate is increased, the acid production of the thallus is promoted, the final acid production level is obviously improved by about 5.5% and the glutamic acid yield and the glucose acid conversion ratio are increased.

Owner:COFCO BIO CHEM ENERGY LONGJIANG CO LTD

Low-temperature resistant lactobacillus with ACE (angiotensin converting enzyme) inhibitory activity

ActiveCN102994420AHas inhibitory activityGood antibacterial effectBacteriaMicroorganism based processesBiotechnologyStaphyloccocus aureus

The invention relates to a lactobacillus and in particular relates to a low-temperature resistant lactobacillus with ACE (angiotensin converting enzyme) inhibitory activity. The low-temperature resistant lactobacillus with the ACE inhibitory activity is lactobacillus plantarum I1 which is preserved in the China general microbiological culture collection center of which the preservation address is No.3, No1. yard, Beichen west road, Chaoyang District of Beijing, the preservation data is September 18th, 2012, and the preservation number is CGMCC No.6575; the lactobacillus plantarum I1 has the ACE inhibitory rate being 66%, can tolerate 6% of NaCl and 100mg / kg of nitrite, and can fast generate acid; the growing temperature of the lactobacillus plantarum I1 is 4-40 DEG C, and is suitable for low-temperature fermentation; and the low-temperature resistant lactobacillus has obvious protease activity and lipase activity, can not generate mucus, has an obvious antibacterial effect on staphylococcus aureus and colon bacillus, and can be used as a meat product leavening agent strain under a low-temperature condition.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

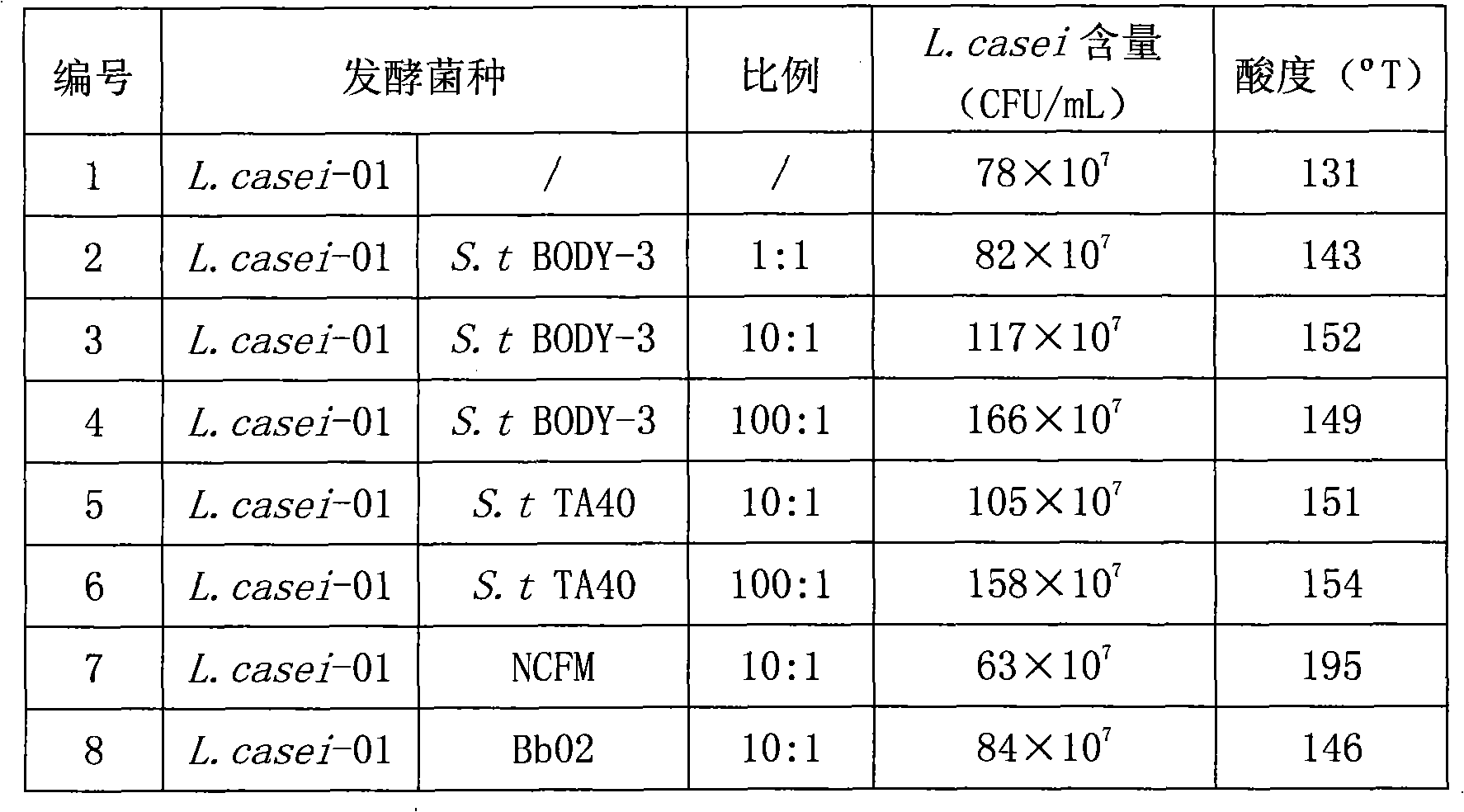

Active lactobacillus casei beverage and preparation method thereof

ActiveCN101911973AShorten fermentation timeBacteria content increasedMilk preparationMicroorganismSugar

The invention discloses an active lactobacillus casei beverage and a preparation method thereof and relates to an active probiotics beverage in the technical field of microorganism fermentation. The beverage comprises the following components in percentage by mass: 25 to 40 percent of fermented milk, 8 to 12 percent of white granulated sugar, 0.3 to 0.5 percent of stabilizing agent, 0.03 to 0.05 percent of food flavor and 50 to 70 percent of purified water. The preparation method comprises the following steps of: 1, preparing base materials; 2, fermenting the base materials; (3) preparing and disinfecting sugar liquor; and (4) preparing the beverage. Compared with the prior art, the method has the advantages of remarkably shortened product fermentation time, remarkably increased bacteria content of lactobacillus casei, lowered product cost and fermentation pollution risk, lowered equipment investment and suitability for producing the lactobacillus casei probiotics beverage under the conventional equipment condition by national dairy enterprises.

Owner:武汉光明乳品有限公司

Method for composite acetic acid bacterium culture and solid-state acetic acid fermentation

InactiveCN101875908AMild tasteIncrease productionBacteriaMicroorganism based processesMetaboliteFruit juice

The invention relates to the table vinegar production field, in particular to a method for composite acetic acid bacterium culture and solid-state acetic acid fermentation, which solves the problems that the acetic acid bacterium is simplex in strain, the acetic acid conversion rate is low, the traditional acetic acid bacterium culture method causes instability of table vinegar quality and the like in the prior art. The method comprises the following steps: utilizing Huniang 1.01, As1.41, bacterium gluconicum, acetobacter separated from a Shanxi mature vinegar grains and high-yield acetaldehyde dehydrogenase acetobacter to form the composite acetic acid bacteria, and then carrying out continuous culture in a composite culture medium comprising grape fruit juice, multi-strain nutrition-enhancing yeast, yeast extract, ethanol and distilled water to obtain a composite acetic acid bacteria culture solution; and finally carrying out solid-state acetic acid fermentation, wherein the inoculation process adopts operating techniques of mixing the grains at a pan bottom, drawing fire, burying in fire and rubbing the grains. The invention uses the advantages of multiple strains, raises the yield of gluconic acid in metabolite, produces a final product which is moderately sour and has unique flavor, improves the conversion rate of acetic acid, and shortens the fermentation period, thereby having profound significance in the progress of the table vinegar brewage technology.

Owner:山西三盟实业发展有限公司

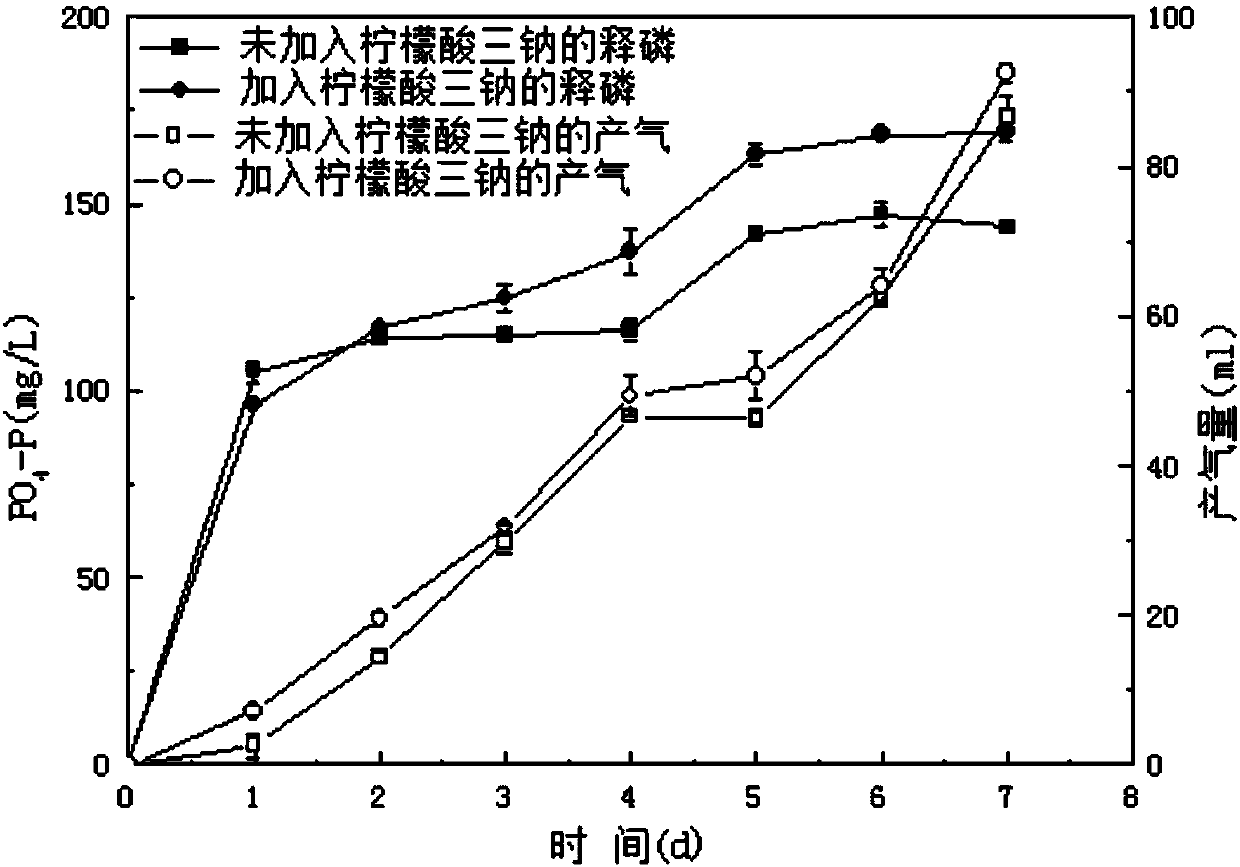

Method for promoting phosphorus release and gas production of phosphate-precipitate-containing sludge under room temperature condition

ActiveCN108046557AIncrease phosphorus release rateIncrease methane productionWater contaminantsWaste based fuelPhosphateSludge

The invention relates to a method for promoting the phosphorus release and the gas production of phosphate-precipitate-containing sludge under a room temperature condition. The method comprises: placing phosphate-precipitate-containing sludge in a reactor, carrying out static precipitation at a room temperature, and discharging the supernatant to obtain concentrated mixed sludge; adding trisodiumcitrate according to the total suspended solid content of the sludge, sealing the reactor, and carrying out anaerobic fermentation for more than 7 days under a room temperature condition, wherein thephosphorus release rate of the sludge can be increased, and the anaerobic fermentation of the sludge can be promoted so as to produce acid and methane. Compared to the method in the prior art, the method of the present invention has the following characteristics that the phosphorus release in the phosphate-precipitate-containing sludge can be promoted sp as to improve the recovery rate of the phosphorus resource at the late stage and promote the anaerobic fermentation of the sludge to produce acid and gas, and achieve the resource utilization of the residual sludge, and the operation is performed at the room temperature, such that the economic cost is low.

Owner:TONGJI UNIV

Method for solidifying natural rubber latex by using microbe culture solution

Microbe culture solution which contains a large number of viable bacteria is formed by fermenting microorganisms of which the main floras are acetic bacteria and yeasts; the microbe culture solution is mixed with a small amount of ethanol, acetic acid, sugar source, inorganic salt and the like; the mixture is added into a rubber latex; and latex particles are further solidified through the acetic acid and bacterial cellulose which are generated from nutrient substances in the rubber latex by the microorganisms, such as the acetic bacteria, yeasts and the like in the microbe culture solution. At the same time, the microorganisms decompose a large number of nutrient substances, such as a nitrogen source and the like, in the latex in a growing process, then the total solid content in solidified waste liquid is further reduced and pollution emission is reduced; and serum left in the solidified latex can serve as a culture medium of microorganism solidification liquid or a beneficial microbial ecological agent, and then the rubber latex is comprehensively used. The method has simple operation; by the method, the cost and the pollution are reduced and the rubber yield is improved; and the product produced by the method has better physical and chemical property than the product produced by acidic solidification.

Owner:蒋盛军 +2

Recombinant D-lactic acid produced lactobacillus plantarum strain and method for producing D-lactic acid by utilizing same

ActiveCN109504630AFast acid productionHigh optical purity of the productBacteriaMicroorganism based processesLactobacillus plantarumChemistry

The invention relates to a D-lactic acid produced strain and a method for producing D-lactic acid by using the same. When the D-lactic acid is produced by using the D-lactic acid produced strain Lp-DAprovided by the invention, the acid production speed and the optical purity of a product are obviously improved, namely, the D-lactic acid produced strain Lp-DA has obviously improved acid productionperformance for producing the D-lactic acid. Correspondingly, the production of the D-lactic acid can be improved greatly by using the D-lactic acid produced strain Lp-DA to produce the D-lactic acidthrough fermentation. Moreover, the D-lactic acid produced strain Lp-DA also has the advantages that the fermentation cost is low, the production cycle can be shortened, energy consumption required for temperature control in fermentation production is reduced, cooling water is saved, living contaminants are reduced and the method is environmentally-friendly.

Owner:JILIN COFCO BIOCHEM +2

Culture medium for detecting difficult cultivation type lactic acid bacteria in food and detection method thereof

ActiveCN105296591AFast acid productionShorten detection timeMicrobiological testing/measurementMicroorganism based processesSodium acetateDipotassium hydrogen phosphate

The invention relates to a culture medium for detecting difficult cultivation type lactic acid bacteria in food and a detection method thereof. The formula in every 1000 parts of the culture medium includes: by weight, 10-40 parts of carbohydrate, 5-15 parts of peptone, 2-6 parts of yeast extract powder, 5-15 parts of beef extract powder, 1-3 parts of dipotassium hydrogen phosphate, 1-3 parts of triammonium citrate, 2.5-7.5 parts of sodium acetate, 0.1-0.3 part of magnesium sulfate, 0.02-0.06 part of manganese sulfate, 0.5-1.5 parts of tween-80, 0.5-1.5 parts of soluble starch, 0.2-2 parts of acid production metabolism promoting factor (ferrous sulfate heptahydrate and / or nickel chloride hexahydrate), 100-500 parts of unpolluted sample filtrate, and the balance distilled water. The pH adjusts to 4-5.5. The culture medium can simulate a real growing environment of the microorganism, and the solid difficult cultivation type lactic acid bacteria can be cultured rapidly because of the addition of the metabolism promoting factor. Whether the putrefying lactic acid bacteria exists can be determined simply and rapidly by using the culture medium to perform cultivation and fermentation, so that the rapid detection of the difficult cultivation type lactic acid bacteria on food can be realized.

Owner:FOSHAN HAITIAN GAOMING FLAVORING & FOOD +1

Method for making waxberry vinegar

InactiveCN102242047AAlcohol conversion rate is highFast acid productionMicroorganism based processesVinegar preparationFiltrationSubmerged fermentation

The invention discloses a method for making waxberry vinegar, which comprises the following steps of: 1, sorting, namely selecting waxberry materials; 2, deseeding; 3, squeezing; 4, performing ultrahigh temperature (UHT) sterilization; 5, performing primary fermentation, namely adding active dry yeast Q23 into a fermentation tank filled with waxberry juice, performing alcoholic fermentation on the waxberry juice to obtain waxberry wine, and controlling the fermentation temperature to be between 23 and 28DEG C; 6, performing secondary fermentation to obtain waxberry raw vinegar; 7, clarifying; 8, filtering; 9, performing secondary UHT sterilization, namely pumping the waxberry vinegar subjected to fine filtration into a UHT sterilizer for sterilization; and 10, filling. The waxberry juice is subjected to two-stage liquid state submerged fermentation to form the waxberry vinegar, and the waxberry vinegar is dark amber and clarified, and has luster, natural inherent aroma of waxberries, full, smooth and mild mouthfeel, and high typicality.

Owner:浙江聚仙庄饮品有限公司

Method for increasing long-chain biatomic acid fermentation production rate

InactiveCN1259424CReduce consumptionReduced beta-oxidative capacityFermentationProduction rateDicarboxylic acid

The invention relates to a method for improving the fermentation yield of long-chain dibasic acids. The method of the present invention uses C 10 ~C 18 Normal alkanes are used as raw materials to produce corresponding dibasic acids by microbial fermentation. The main feature is that inhibitors are added during the fermentation process to weaken the β-oxidation ability of the strain. The inhibitors include C 5 ~C 18 One or more of halogenated fatty acids, methyl fatty acids and their salts or esters, the inhibitor concentration is 0.01-5 mmol / L. The inhibitor added in the method of the invention can effectively weaken the β-oxidation ability of the bacterial strain, reduce the consumption of alkane, greatly improve the fermentation yield, and produce acid quickly, and is especially suitable for preparing long-chain dibasic acid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for recycling sludge

InactiveCN101973683AFast acid productionEfficient removal rateSludge treatment by de-watering/drying/thickeningBiological sludge treatmentSludgeFilter press

The invention discloses a method for recycling sludge, comprising the following steps of: mixing the sludge with Ca(OH)2, placing the mixture into an fermentation reactor and stirring and performing anaerobic fermentation; discharging a certain volume of fermentation mixture from the reactor at regular time intervals, and adding fresh sludge in the same amount as the discharged mixture and a certain amount of Ca(OH)2; and adding a FeSO4 solution into the discharged mixture, stirred for a certain time, adding a polyacrylamide solution, stirring for a certain time, and then carrying out filter pressing for dewatering. The method remarkably improves the concentration and the fermentation liquor amount of short chain fatty acid generated by the sludge, decreases the volatile substances of the sludge, and meanwhile, can remove most phosphate in the fermentation liquor.

Owner:TONGJI UNIV

Lactobacillus fermentum LG1 and application thereof

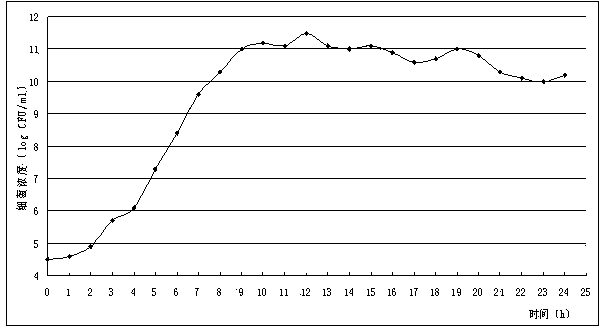

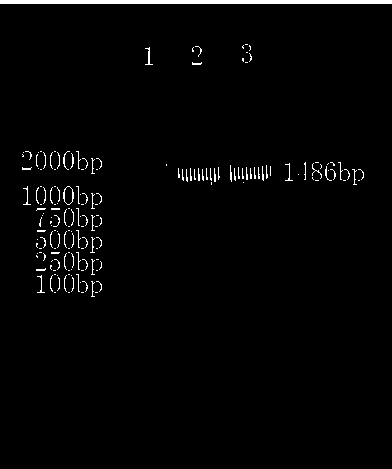

ActiveCN103352014AShorten the fermentation cycleFast acid productionBacteriaPre-baking dough treatmentBiotechnologyLactobacillus fermentum

The invention relates to lactobacillus fermentum LG1 and an application thereof, wherein the collection number of the strain lactobacillus fermentum LG1 is CGMCC No. 7121; the registration number of the 16SrDNA gene sequence of the lactobacillus fermentum LG1 in a GenBank database is Accession No. KC348395; the lactobacillus fermentum LG1 CGMCC No. 7121 is applied to production for traditional millet fermented dough. A fermentation process for the millet dough can be rapidly finished via 6-8 hours of culture by taking the lactobacillus fermentum LG1 provided by the invention as a fermentation agent, and the quantity of the lactobacillus fermentum LG1 in the dough can be increased to 7.0-8.5 logcfu / g from 4.5-5.0 logcfu / g during inoculation; during production for traditional millet fermented dough products, a natural fermentation process for the millet dough generally needs 48-96 hours, therefore, by using the lactobacillus fermentum LG1, the fermentation period is greatly reduced.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Method for improving fermentation yield of long-chain dicarboxylic acid

InactiveCN102808004AReduce unit consumptionImprove conversion rateMicroorganism based processesFermentationAlkaneBeta oxidation

The invention belongs to the technical field of chemical products, and relates to a method for improving the fermentation yield of long-chain dicarboxylic acid. According to the method, the long-chain dicarboxylic acid is produced by a microbiological fermentation method by taking C10 to C18 n-alkanes as raw materials; the method is characterized in that alpha oxidative decarboxylation inhibitor and beta-oxidation inhibitor are added in a fermentation production process to reduce the alpha-oxidative decarboxylation and beta-oxidation capacities of strains, wherein the alpha oxidative decarboxylation inhibitor is one or mixture of more of chlorpromazine hydrochloride, phenobarbital sodium, crylic acid and polyacrylic acid, and the concentration is 0.01 to 1mmol / L; and the beta-oxidation inhibitor is one or mixture of more of mercaptoacetic acid, sodium thioglycollate, ranolazine, ranolazine dihydrochloride and mildronate, and the concentration is 0.01 to 1 mmol / L. Compared with the prior art, the method has the advantages of high acid producing speed, weak alpha oxidative decarboxylation and beta-oxidation capacity, low unit consumption of alkane, and high fermentation alkane conversion rate, and is particularly suitable for preparing the long-chain dicarboxylic acid.

Owner:ZIBO GUANGTONG CHEM

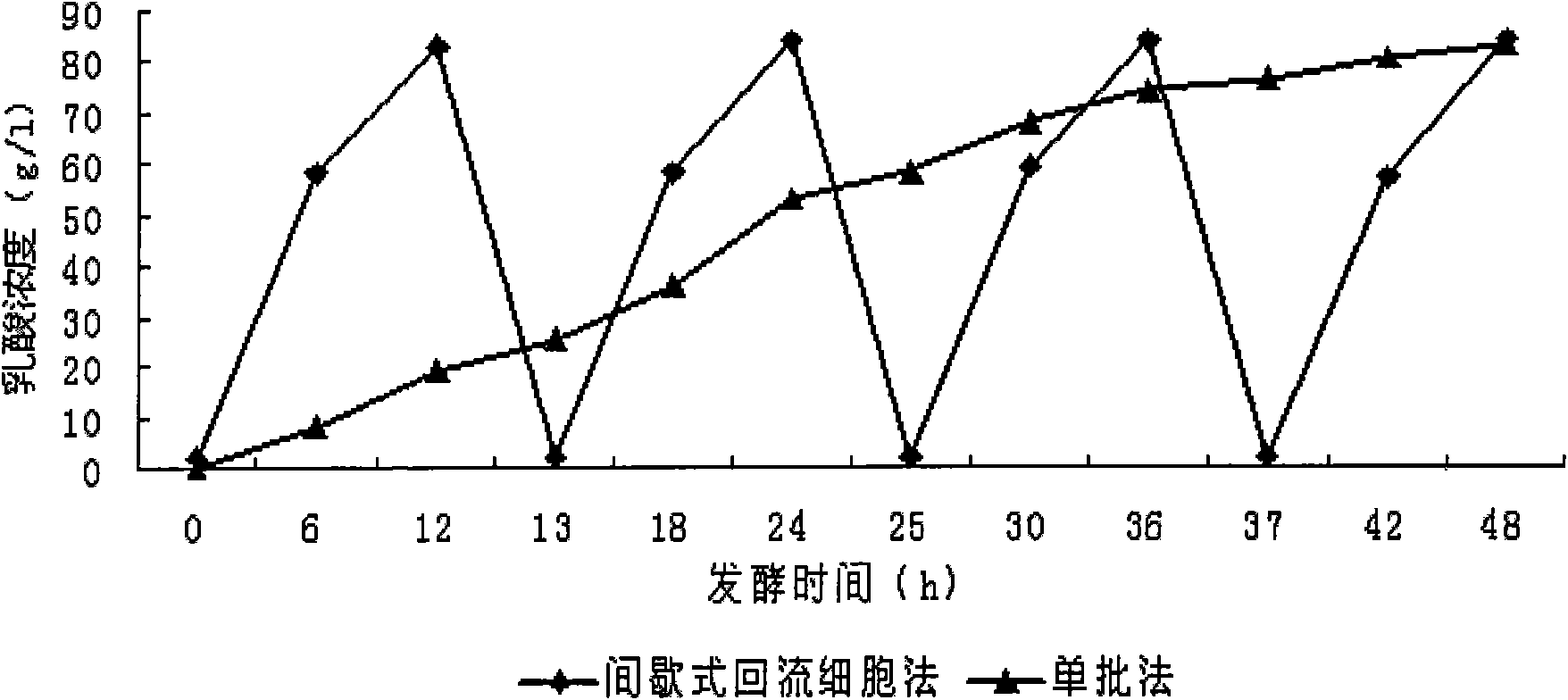

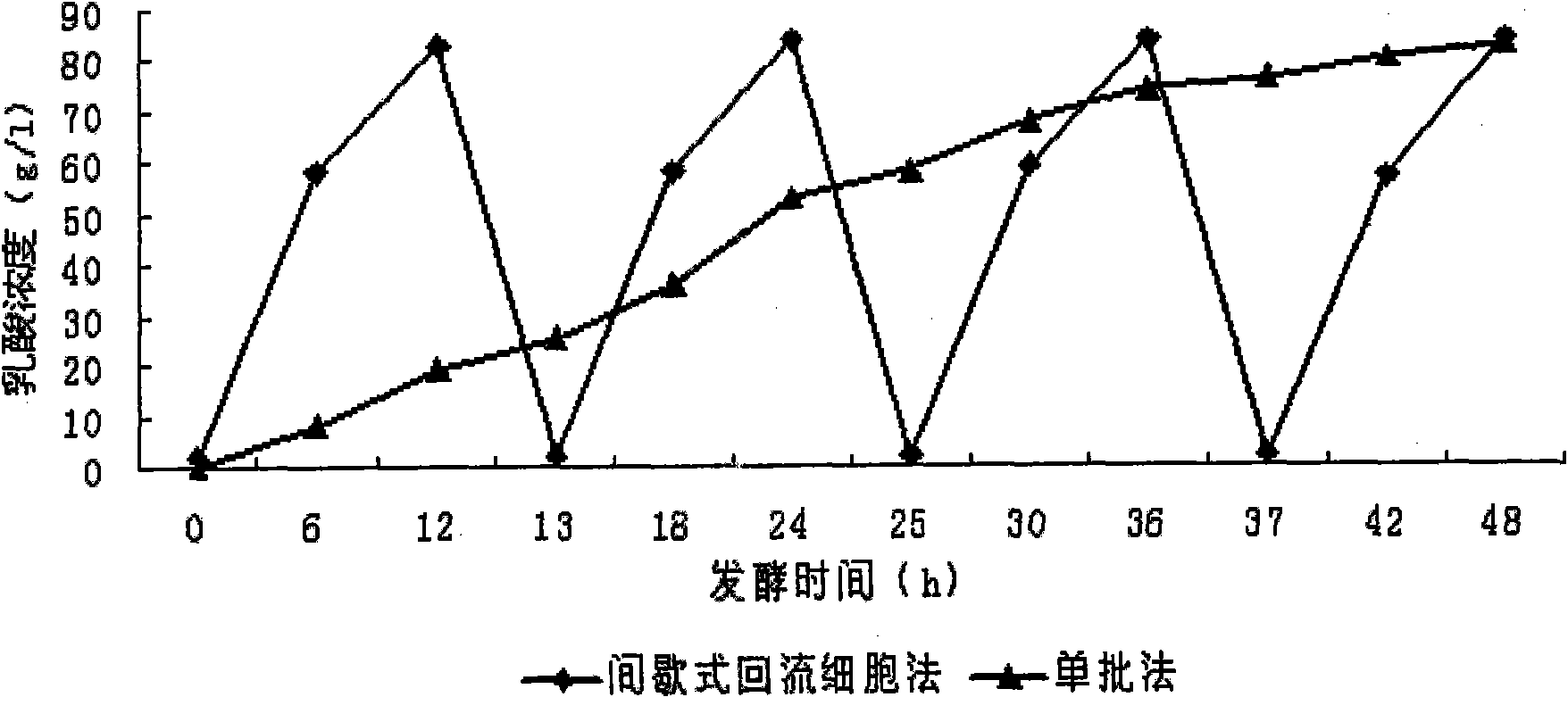

Method for producing organic acid at high production rate through fermentation of intermittent backflow cells

InactiveCN102051386ALarge biomassBreed fastMicroorganism based processesFermentationOrganic acidProduction rate

The invention provides a method for producing organic acid at a high production rate through fermentation of intermittent backflow cells, which comprises the following steps of: performing filtration sterilization on a fresh culture medium, introducing into a fermentation tank, and inoculating high-density seed liquor into the fermentation tank; controlling organic acid fermentation production conditions of the used strain, when fermentation is performed until a small amount of sugar residue is in fermentation liquor, discharging partial or all fermentation liquor to a filtering device for processing, simultaneously supplementing a fresh germ-free culture medium into the fermentation tank, returning intercepted strain cell concentrated solution to the fermentation tank to serve as a production strain for later use, wherein the filtered liquor is used for extracting organic acid; and only when the production rate of the organic acid is obviously reduced, not returning the strain cell concentrated solution intercepted by the filtering device is not to the fermentation tank any more, and supplementing new high-density seed liquor and a fresh germ-free fermentation culture medium into the fermentation tank so as to perform a new round of production of organic acid at the high production rate through fermentation of the intermittent backflow cells. Through the method, high biomass and high production rate are always kept in the organic acid fermentation production process, and the method has high industrial application value.

Owner:HUAZHONG UNIV OF SCI & TECH

A method for producing a probiotic agent of live Lactobacillus bulgaricus

InactiveCN103283974AEasy to operateQuality improvementBacteriaAnimal feeding stuffBiotechnologyLactobacillus

The present invention relates to a method for producing a probiotic agent of live Lactobacillus bulgaricus, belonging to the field of microbial technology and specially relates to a liquid anaerobic fermentation method for producing the probiotic agent of live Lactobacillus bulgaricus. The method comprises the steps of: employing the Lactobacillus bulgaricus as a fermentation strain which is inoculated on an optimized liquid fermentation medium, fermenting at a temperature of 37-42 DEG C for 12-14h, drawing off and determining the number of viable cells, adsorbing fermentation broth by using vegetable starch, drying, crushing, and packaging to prepare the probiotic agent of live Lactobacillus bulgaricus with stable viability. The method of the invention is advantageous in that: high density fermentation of the Lactobacillus bulgaricus can be completed by using an ordinary fermentation tank, with simple operation, stable effect and low energy consumption; and centrifuges, freeze-drying machines, etc. are not required, thus reducing production costs and improving production efficiency.

Owner:GUANGZHOU GLAM BIOTECH

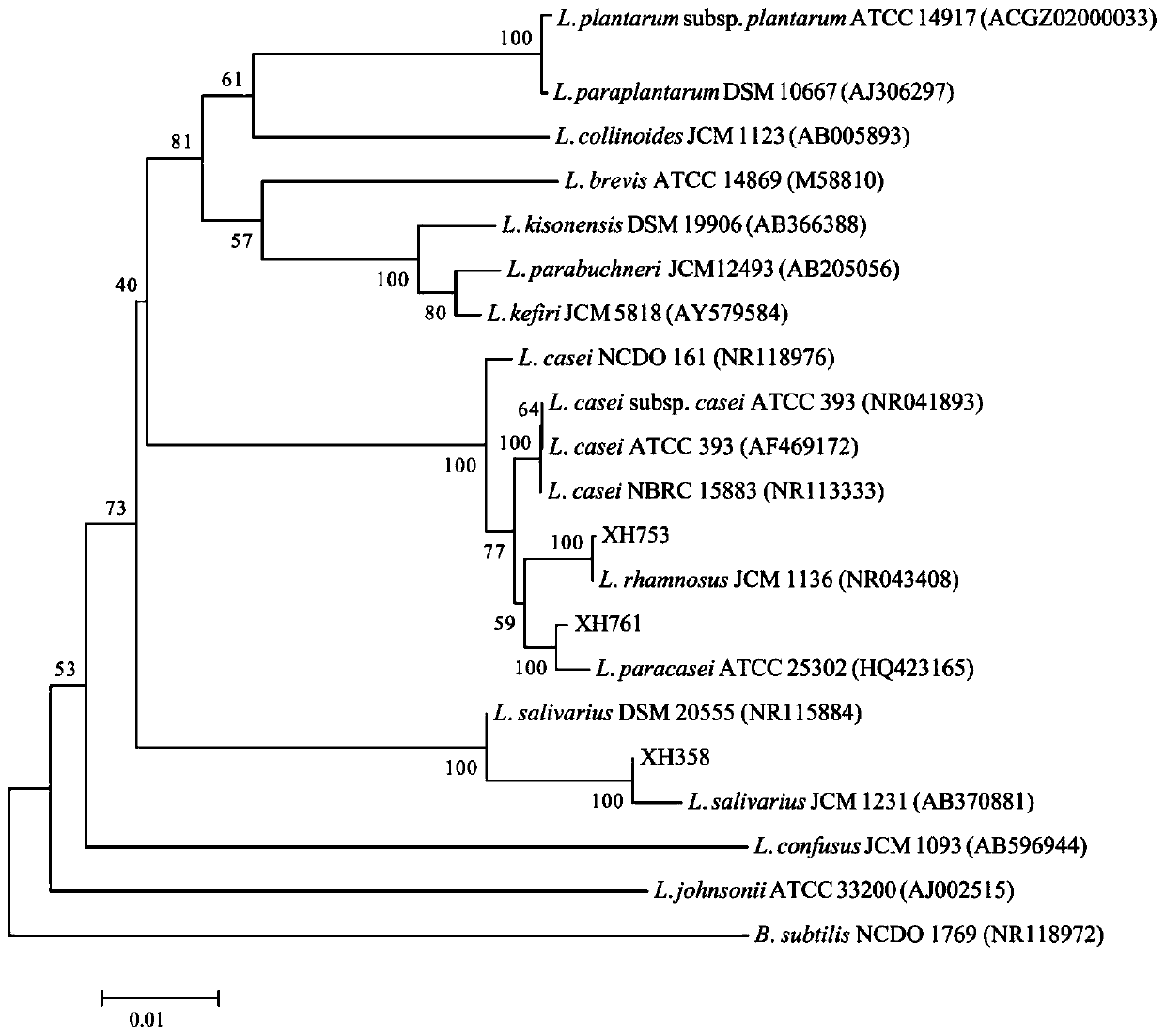

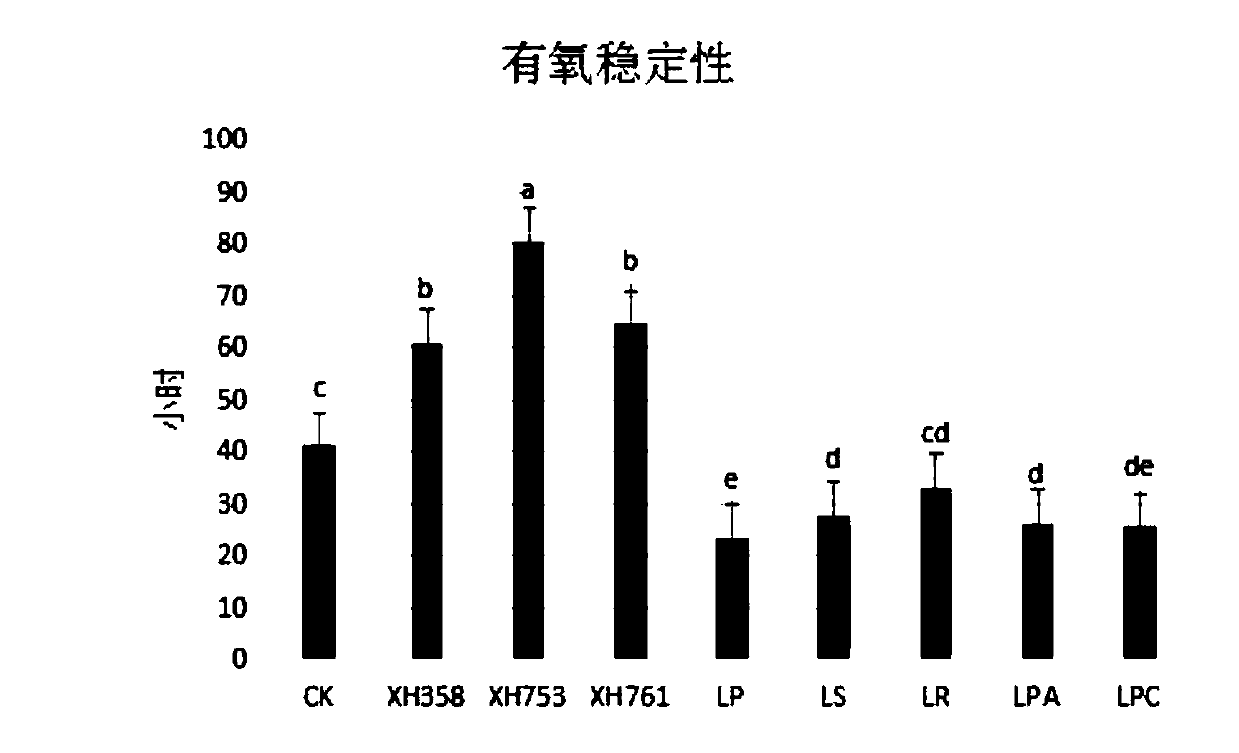

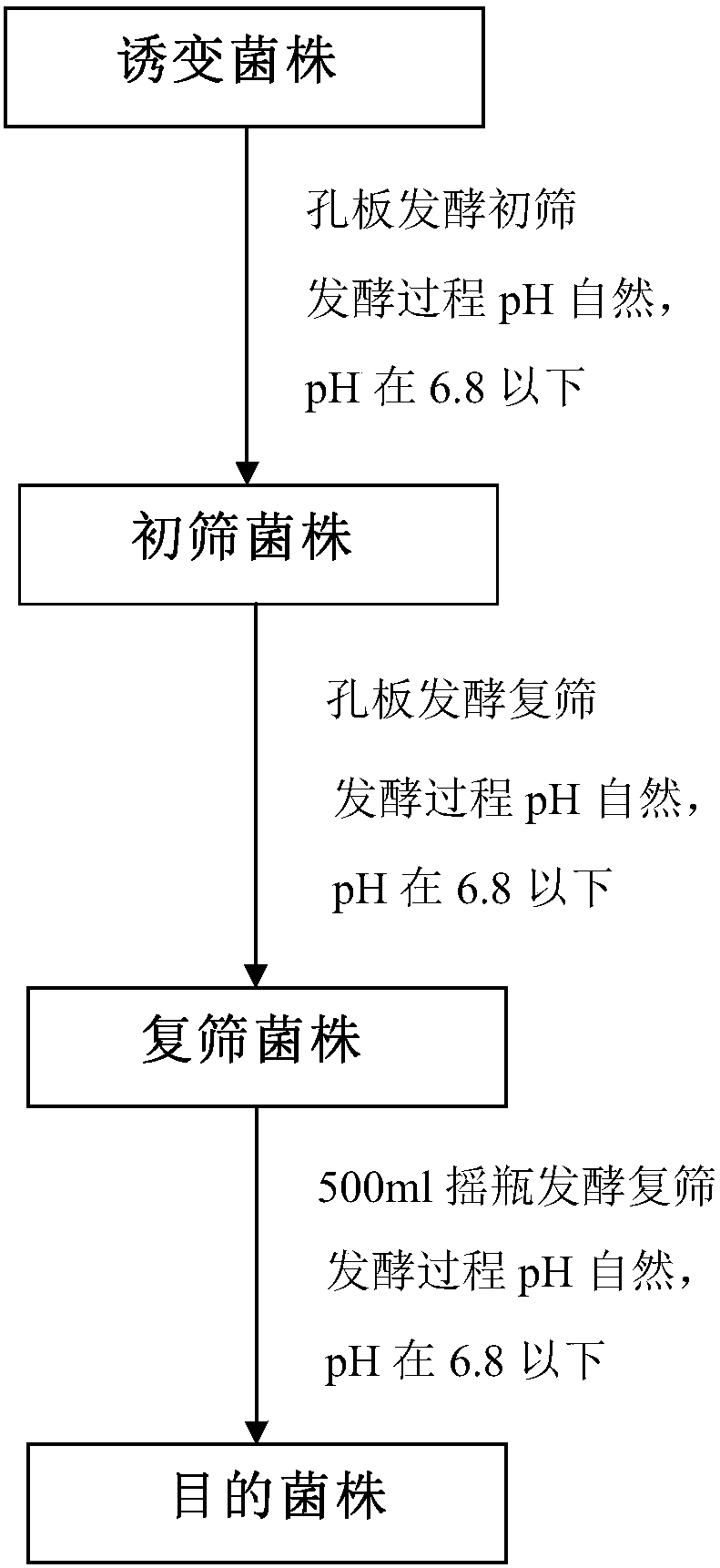

Lactobacillus paracasei 761, application of Lactobacillus paracasei 761, silage additive and silage

ActiveCN110643544AGood high temperature resistanceGood acid resistanceBacteriaMicroorganism based processesMicrobiologyLactobacillus paracasei

The invention discloses a Lactobacillus paracasei 761, application of the Lactobacillus paracasei 761, a silage additive and silage. The Lactobacillus paracasei 761 is deposited at China General Microbiological Culture Collection Center, and the deposit number is CGMCCNo.18234; the Lactobacillus paracasei 761 can improve the quality of the silage in high-temperature and high-humidity areas, and the silage treated by the Lactobacillus paracasei 761 has better aerobic stability, can reduce pH, aflatoxin B1 and dry matter loss and has good high-temperature resistance and acid resistance and goodadaptability to the environment, under culturing in high-temperature conditions, the growth and acid production of the Lactobacillus paracasei 761 has no significant lag phase, and can achieve rapid acid production to achieve the effect of lower pH .

Owner:SICHUAN AGRI UNIV

Candida tropicalis and application thereof, and production method for long chain diprotic acid

PendingCN110218661AReduce dosageSimple extraction processFungiMicroorganism based processesMicrobial agentCandida tropicalis

The invention discloses a candida tropicalis strain CAT H1614, a microbial agent comprising the same and an application thereof, and a method for producing long chain diprotic acid by fermentation anda preparation method of the long chain diprotic acid. The candida tropicalis strain CAT H1614 of the invention can maintain high vitality for a long time in an environment with a pH lower than 7.0, thereby being particularly suitable for production of the long chain diprotic acid by a biological method, acid production is rapid during fermentation, the yield is high, and a fermentation cycle canalso be reduced. The fermentation method and the preparation method of the long chain diprotic acid provided by the invention have significant cost advantages, can effectively alleviate pressure on resources and environment, and thus have very obvious industrialization value advantages.

Owner:CATHAY R&D CENT CO LTD +1

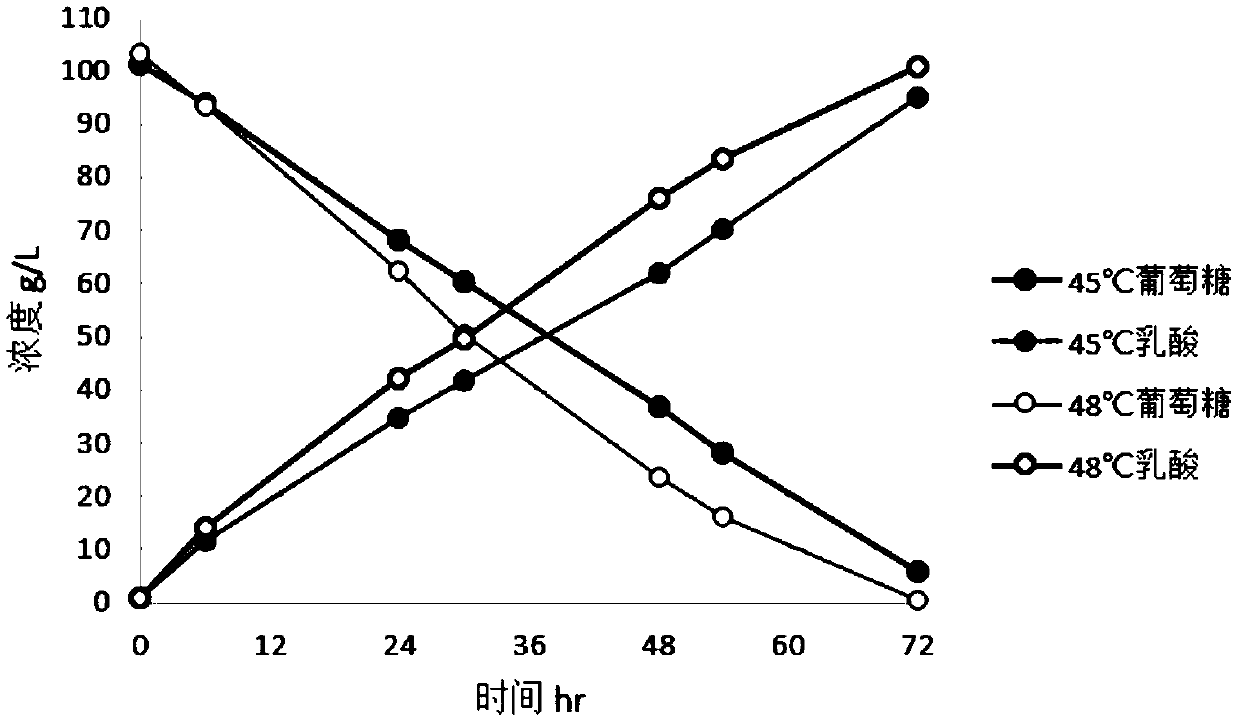

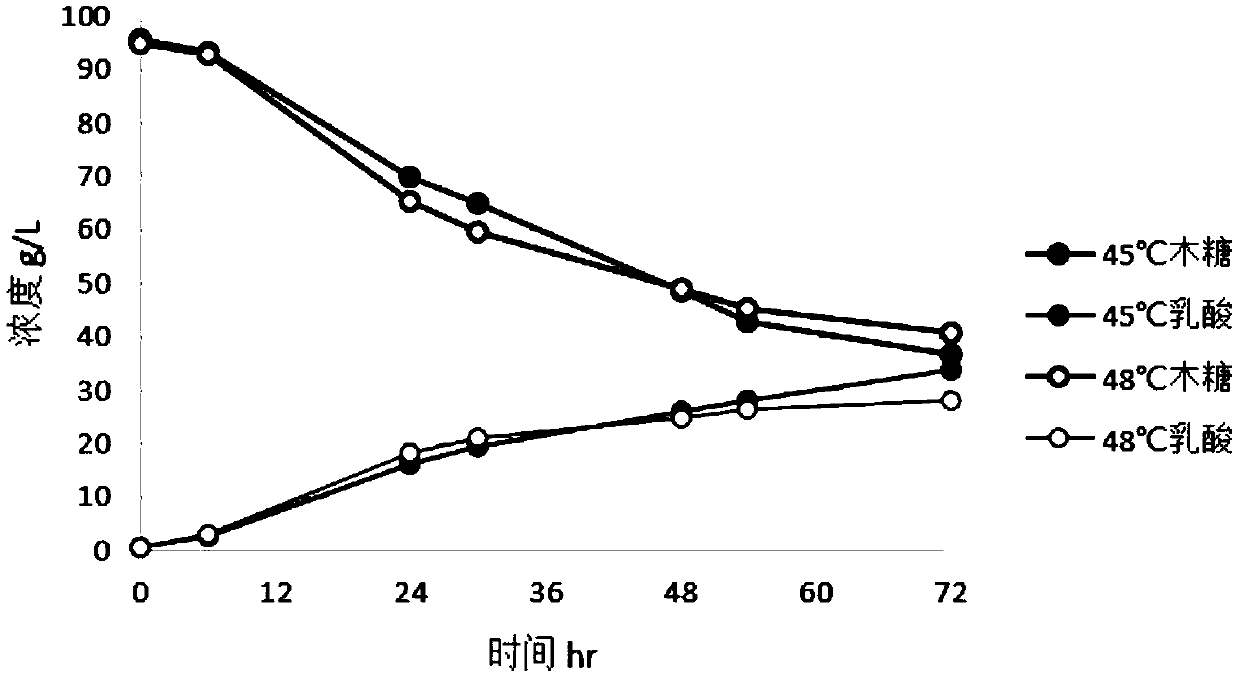

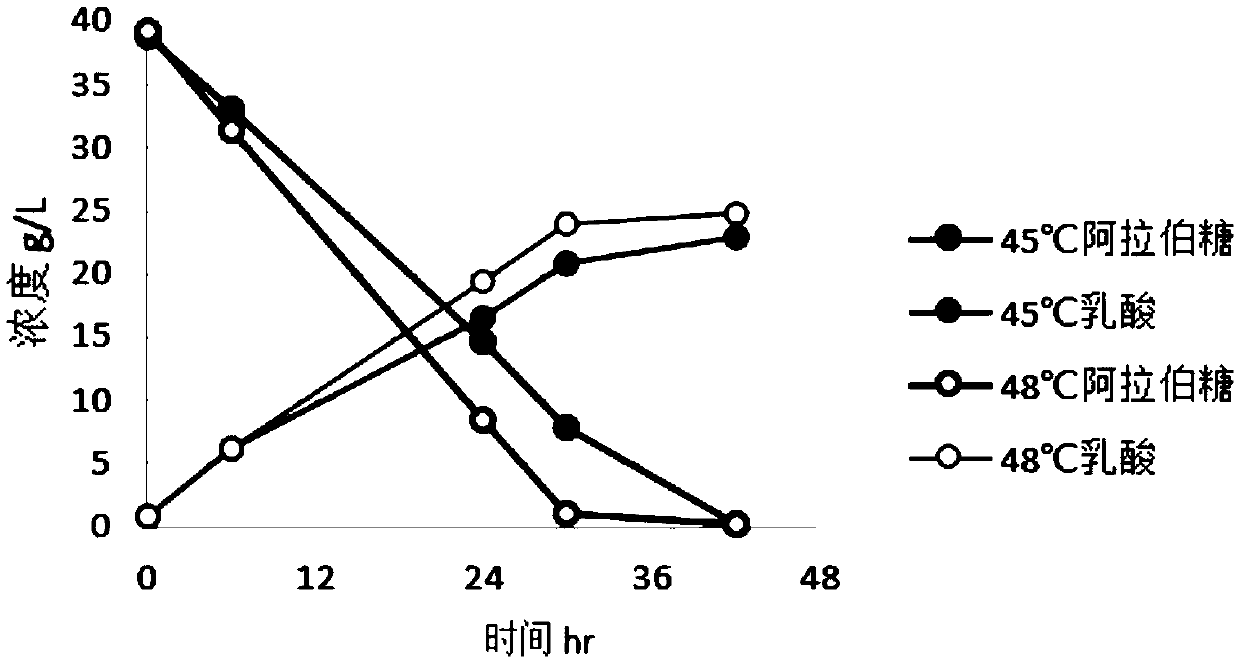

Pediococcus acidilactici strain high in stress resistance and capable of utilizing various carbon sources, and method for producing lactic acid through strain

ActiveCN109536409AEasy to produceReduce fermentation costsBacteriaMicroorganism based processesHigh concentrationCellulose

The invention relates to a lactic acid producing strain and a method for producing lactic acid through the lactic acid producing strain. When the lactic acid is produced through the lactic acid producing strain namely pediococcus acidilactici Pa-COT, the lactic acid production speed is significantly increased, namely that the lactic acid producing strain Pa-COT can significantly increase the lactic acid production property during lactic acid production. Accordingly, when the lactic acid is produced through fermentation of the lactic acid producing strain Pa-COT, the production of the lactic acid can be greatly improved. Besides, the lactic acid producing strain Pa-COT further has the advantages of being low in fermentation cost and environmental-friendly. In addition, the lactic acid producing strain Pa-COT disclosed by the invention further has the following advantages that the lactic acid can be produced through normal fermentation at the fermentation temperature of 45-50 DEG C, thelactic acid producing strain has very good adaptability to a lignocellulose system and can bear stayers generated in the high-concentration preprocessing process, and lactic acid fermentation can be performed by using lignocellulose as a raw material.

Owner:JILIN COFCO BIOCHEM +2

Pure natural lactobacillus millet enzyme

InactiveCN105495322AGuaranteed to be pure and naturalEnsure safetyFood ingredient as flavour affecting agentFood ingredient as mouthfeel improving agentBiotechnologyFood additive

The invention relates to pure natural lactobacillus millet enzyme. The pure natural lactobacillus millet enzyme is prepared from the following steps: preparing powder: smashing millet, and screening by a 100-mesh sieve; carrying out saccharification liquid preparation: weighing 200g of obtained millet powder, adding 1000mL of water, heating to 50 DEG C, adding glucoamylase for saccharification, heating to 85DEG C after saccharification is carried out, and maintaining for 10 minutes; blending and inoculating: weighing 1000g of obtained millet powder, adding 4000mL of water, adding saccharification liquid of which the water volume is 10-20%, and inoculating lactobacillus fermentium, lactobacillus reuteri, lactobacillus plantarum and bifidobacterium adolescentis at the ratio of 3:1:2:1; fermentation: sealing a fermentation container, carrying out fermentation for 90 days under the condition of 28-35 DEG C, and carrying out after-ripening fermentation for 30 days under the condition of 4-10 DEG C, thus obtaining the pure natural lactobacillus millet enzyme after fermentation ends. No food additive is added into the pure natural lactobacillus millet enzyme, and the pure nature and the safety of food can be guaranteed furthest.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

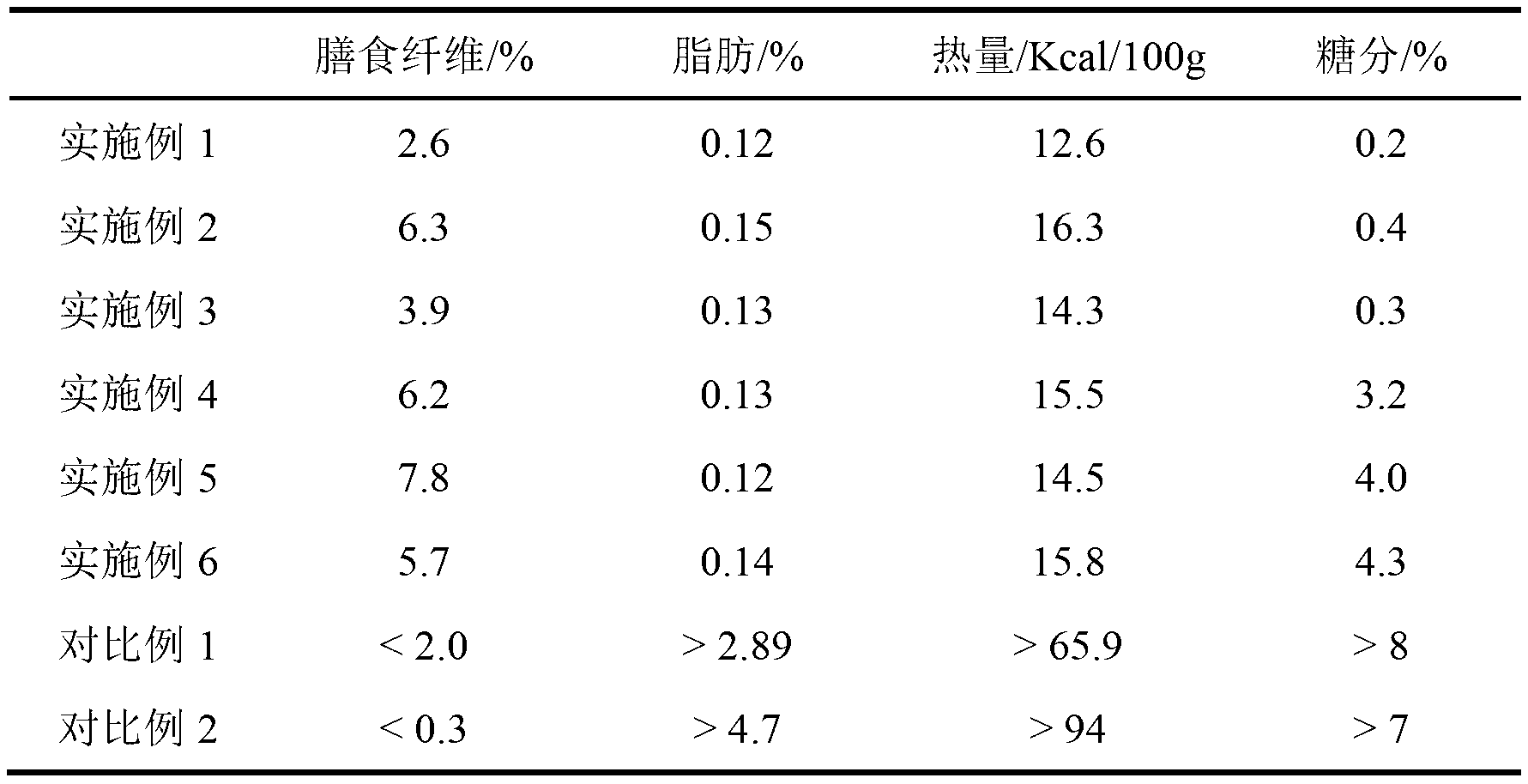

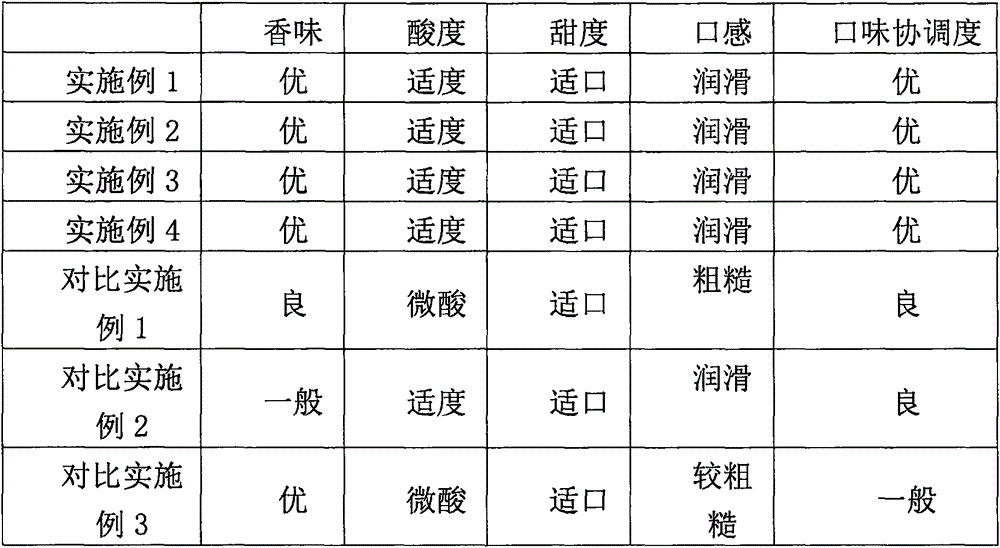

Inulin low-fat yogurt pudding and preparation method thereof

The invention discloses an inulin low-fat yogurt pudding and a preparation method thereof, and belongs to the technical field of food processing. The inulin low-fat yogurt pudding is prepared from the following components by weight percent: 30-40% of yogurt base, 2-10% of inulin, 0.05-0.5% of a thickener, 0.001-5% of a sweetening agent and the balance of water, wherein the inulin is a soluble dietary fiber, can selectively promote growth of colon probiotics, and has the functions of reducing blood sugar concentration, maintaining lipid metabolism balance, improving the bioavailability of mineral elements, enhancing the immunity of the organism, and the like. The inulin low-fat yogurt pudding disclosed by the invention contains the inulin dietary fiber, is low in fat content, and smooth in mouthfeel, has the functions of improving the intestinal microenvironment, controlling blood fat and blood sugar levels, reducing the energy, promoting absorption of a mineral substance and synthesis of vitamins, and is especially suitable for middle aged and elderly people with diseases such as constipation, obesity, hypertension, hyperlipidemia and diabetes mellitus.

Owner:HENAN UNIV OF SCI & TECH

Potato yoghourt and making method thereof

InactiveCN106465750APrevent browningNo precipitationMilk preparationOther dairy technologySweetnessSolanum tuberosum

Potato yoghourt and a making method thereof are disclosed. 40-60% of potato juice is creatively added into yoghourt, and lactobacillus bulgaricus and streptococcus thermophilus are used in cooperation for fermentation. On the basis of controlling the ratio of the materials and the making method, the potato yoghourt with rich nutrients, moderate sweetness and palatable sour taste is prepared.

Owner:SHENYANG AGRI UNIV

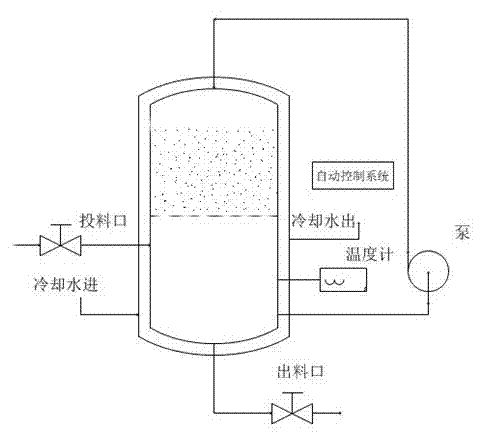

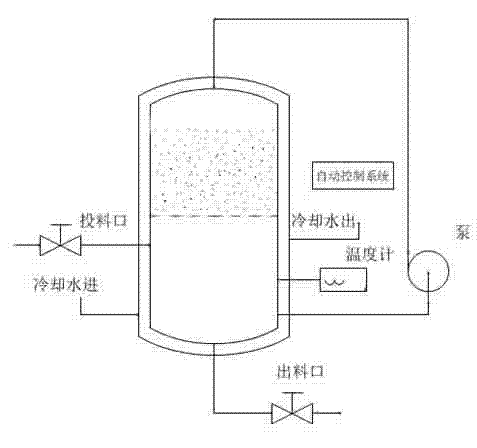

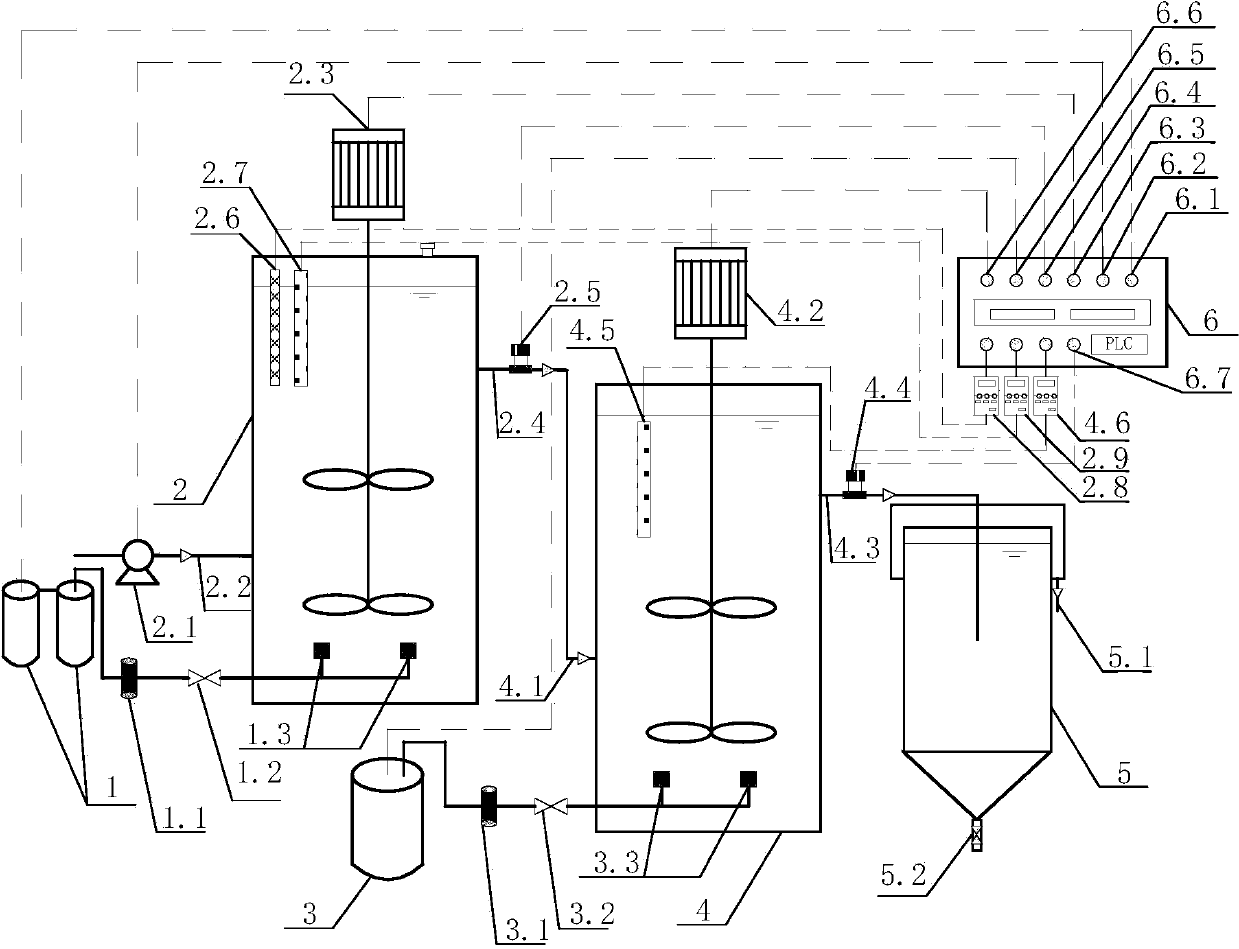

Device and method for acid production by anaerobic and low dissolved oxygen hydrolysis and fermentation of excess sludge

ActiveCN103626372ASimple and fast operationFast acid productionBiological sludge treatmentBiological water/sewage treatmentSludgeNitrogen

The invention discloses a device and a method for acid production by anaerobic and low dissolved oxygen hydrolysis and fermentation of excess sludge. The device comprises a nitrogen machine, an excess sludge hydrolysis and fermentation reactor, an air compressor, an excess sludge acid production reactor and a carbon source storage pool, wherein the excess sludge hydrolysis and fermentation reactor is a sealed pool, and is provided with a sludge feeding pipe, a stirrer and a fermentation liquor output pipe; the excess sludge acid production reactor is a sealed pool and is provided with a fermentation liquor input pipe, a stirrer and a carbon source output pipe; the carbon source storage pool is an open pool, and is provided with a water discharging pipe and a sludge discharging pipe. The method comprises the following steps that the excess sludge firstly is conveyed into the hydrolysis and fermentation reactor, cell walls are broken down and macromolecule organics are released, and the macromolecule organics are converted into micromolecule organics under the action of hydrolysis and ferment bacteria; then, micromolecule organics are conveyed into the acid production reactor, and under the action of acid-producing bacteria, the micromolecule organics are converted into short chain fatty acids (SCFAs); after that the short chain fatty acids are conveyed into the carbon source storage pool; all the steps are repeated, and finally, the SCFAs can be produced efficiently for a long time.

Owner:BEIJING UNIV OF TECH

Ginkgo sour milk, and its processing art

InactiveCN1718010AFast acid productionHigh nutritional valueMilk preparationNutritive valuesSoured milk

A ginkgo-type sour milk with high nutritive value is prepared proportionally from the immersed-in-water ginkgo pulp, fresh milk, purified water, yoghourt lactobacillus, thermophilic streptococcus and granular white sugar. Its preparing process is also disclosed.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com