Recombinant D-lactic acid produced lactobacillus plantarum strain and method for producing D-lactic acid by utilizing same

A technology for producing Lactobacillus plantarum and strains, which is applied in the field of genetic engineering and microbial fermentation, can solve problems such as limited strains, and achieve the effects of increasing the rate of acid production, saving cooling water, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

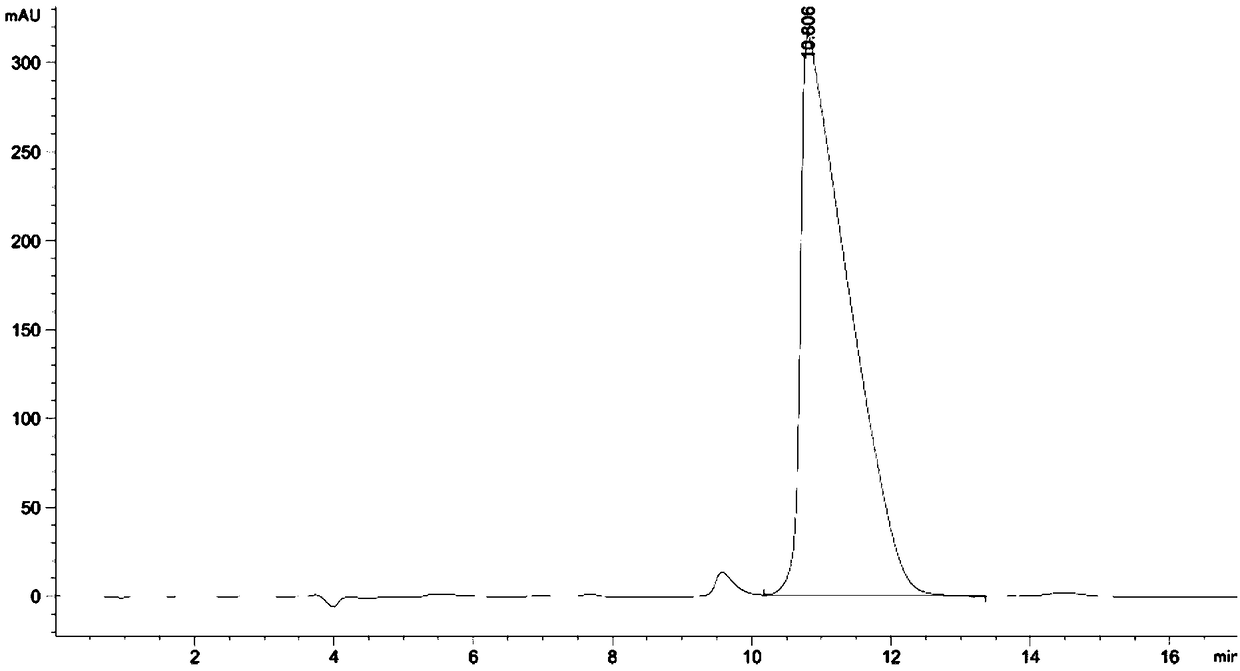

[0052] Example 1: strain isolation and identification

[0053] Isolation and screening of strains: mash 1g of Daqu sample and dissolve it in 10mL of sterile normal saline, mix well for 30min; take the above diluted solution 10-fold gradient dilution and spread it on a solution containing 1% (w / v) CaCO 3(neutralizing agent) MRS solid medium, cultured at 37°C for 24 hours, picked colonies with larger transparent circles to inoculate MRS medium, cultured at 150rpm at 37°C for 1 hour, took 5 μl of culture solution and spot on MRS+CaCO 3 On a solid plate, place the plate in an incubator at 45°C and incubate for 40 hours; select a single colony on the plate that grows faster and has a larger calcium-dissolving circle and transfer it to MRS medium again, culture at 37°C and 150rpm for 1 hour, and take 5 μl for culture Liquid point at MRS+CaCO 3 On a solid plate, place the plate in a 48°C incubator for culture. Among them, the candidate strains with obvious calcium-dissolving circle...

Embodiment 2

[0057] Embodiment 2: Recombinant plasmid construction

[0058] Gene knockout plasmid construction: amplify the Escherichia coli replicon p15Aori (sequence amplified from commercial vector pACYC), erythromycin resistance gene (sequence from commercial vector pMG36e), and 1000bp sequence upstream of the CDS of the gene to be knocked out (sequence amplified from Lp43 #genome), chloramphenicol resistance gene (sequence from commercial vector pNZ8148) and gene CDS downstream 1000bp sequence to be knocked out (sequence amplified from Lp43#genome), using DNA Assembly recombination kit (purchased from Transgen company) to assemble into Gene knockout plasmids. The gene knockout plasmid can replicate in Escherichia coli but cannot replicate in lactic acid bacteria, and has erythromycin and chloramphenicol resistance genes that can be used in Escherichia coli and plantarum lactobacillus. To knock out the ldh1 gene (Gene ID: 1061886), ldh2 gene (Gene ID: 1063343) and larA gene (Gene ID: ...

Embodiment 3

[0088] Example 3: Strain Homologous Recombination

[0089] Lactobacillus plantarum electrotransformation scheme: inoculate a single colony of Lactobacillus plantarum Lp43# obtained in Example 1 activated on the plate and culture overnight at 37°C in 4mL MRS medium, according to the initial OD 600 =0.2 was transferred to 100mL MRS medium containing 1% glycine, cultured on a shaker at 37°C until OD 600 =0.6; Bacterial liquid was ice-bathed for 20min, and the bacterial cells were collected by centrifugation at 4℃, 8000×g for 15min; 100mL 1mM MgCl 2 30% PEG1000 and 30% PEG1000 were used to wash the cells once respectively; resuspended cells were resuspended with 1 mL of 30% PEG1000 pre-cooled at 4°C, and each aliquot was filled with 100 μL of competent cells. Add 5 μg of the corresponding recombinant plasmid prepared in Example 2 to each competent cell, ice-bath for 10 minutes, use a 0.2cm electric cup, 1.5kV, 25F, 200Ω electric shock, quickly add 0.8mL MRS-SM medium (in MRS medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com