Device and method for acid production by anaerobic and low dissolved oxygen hydrolysis and fermentation of excess sludge

A technology of excess sludge and low dissolution, applied in water/sludge/sewage treatment, biological sludge treatment, chemical instruments and methods, etc., can solve the problems of low acid production efficiency, long time required for acid production, high operating costs, etc. problems, to achieve the effect of increasing acid production, high practical application value, and strengthening sludge hydrolysis and fermentation

Active Publication Date: 2014-03-12

BEIJING UNIV OF TECH

View PDF6 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there are ultrasonic, microwave, pyrolysis, enzymatic, surfactant methods, etc. to promote the acid production of excess sludge by anaerobic hydrolysis acidification. However, these technologies have low acid production efficiency, long time required for acid production, and high operating costs. problem, it is difficult to apply to the actual sewage treatment plant

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

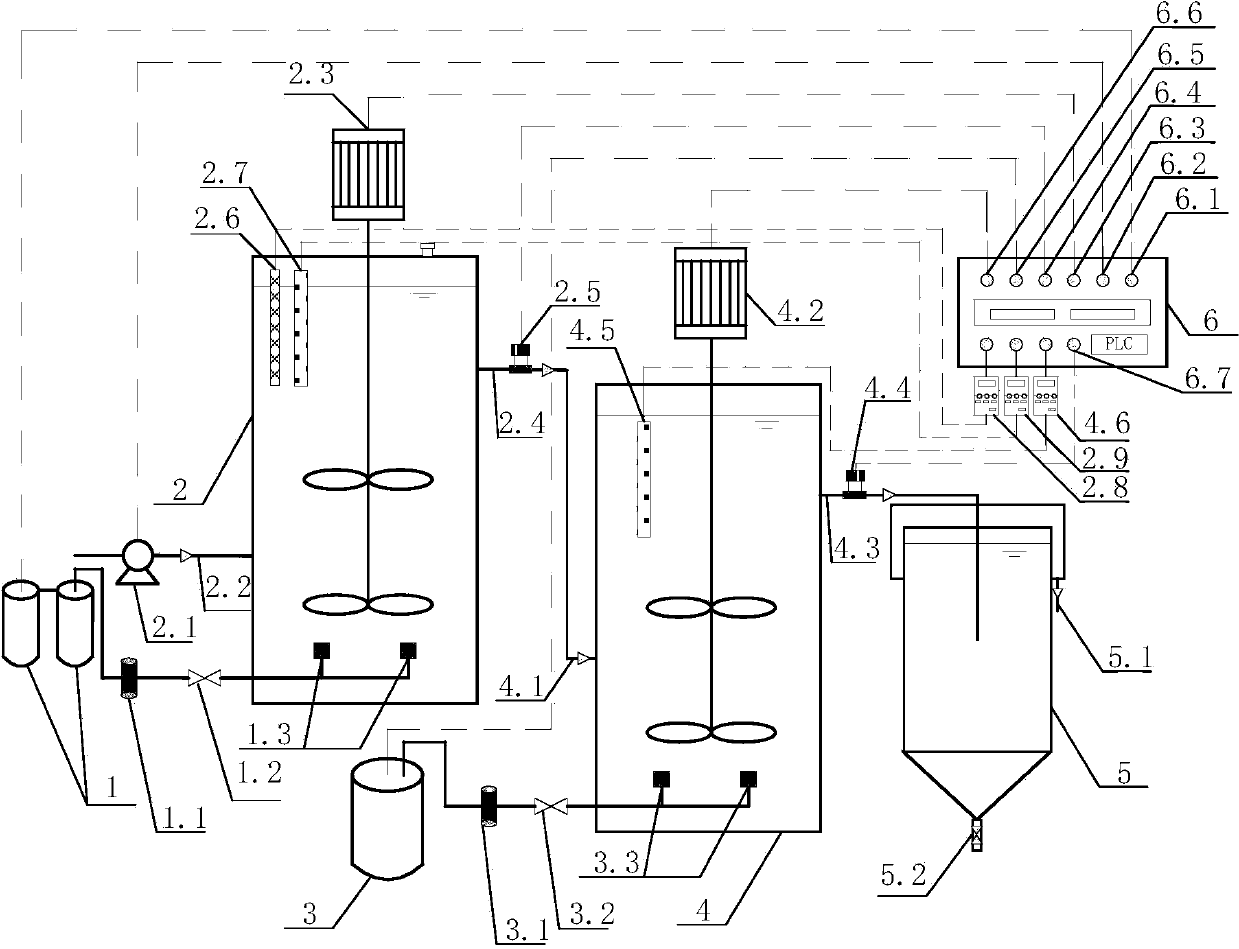

[0029] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a device and a method for acid production by anaerobic and low dissolved oxygen hydrolysis and fermentation of excess sludge. The device comprises a nitrogen machine, an excess sludge hydrolysis and fermentation reactor, an air compressor, an excess sludge acid production reactor and a carbon source storage pool, wherein the excess sludge hydrolysis and fermentation reactor is a sealed pool, and is provided with a sludge feeding pipe, a stirrer and a fermentation liquor output pipe; the excess sludge acid production reactor is a sealed pool and is provided with a fermentation liquor input pipe, a stirrer and a carbon source output pipe; the carbon source storage pool is an open pool, and is provided with a water discharging pipe and a sludge discharging pipe. The method comprises the following steps that the excess sludge firstly is conveyed into the hydrolysis and fermentation reactor, cell walls are broken down and macromolecule organics are released, and the macromolecule organics are converted into micromolecule organics under the action of hydrolysis and ferment bacteria; then, micromolecule organics are conveyed into the acid production reactor, and under the action of acid-producing bacteria, the micromolecule organics are converted into short chain fatty acids (SCFAs); after that the short chain fatty acids are conveyed into the carbon source storage pool; all the steps are repeated, and finally, the SCFAs can be produced efficiently for a long time.

Description

technical field [0001] The invention relates to an anaerobic + low dissolved oxygen residual sludge hydrolysis fermentation acid production device and method, and belongs to the technical field of sludge sewage treatment. Background technique [0002] Activated sludge method is currently an effective way to treat urban domestic sewage. However, due to insufficient biologically available carbon sources in sewage, the effect of biological nitrogen and phosphorus removal is not good, and the effluent is difficult to meet the first-class A discharge standard. In order to improve the efficiency of biological nitrogen and phosphorus removal, it is necessary to add carbon sources. One of the ways is to add chemically synthesized carbon sources. However, this method will undoubtedly increase the operating cost of the water plant. On the other hand, a large amount of excess sludge will be produced due to the continuous proliferation of sludge in the process of activated sludge treatm...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F11/04C02F3/00

Inventor 彭永臻袁悦王淑莹张为堂金宝丹王博

Owner BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com