Method for promoting phosphorus release and gas production of phosphate-precipitate-containing sludge under room temperature condition

A technology of phosphate precipitation and sludge, applied in biological sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Gas production inhibition and other problems, to achieve the effect of resource utilization, increase phosphorus release capacity, and increase methane production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

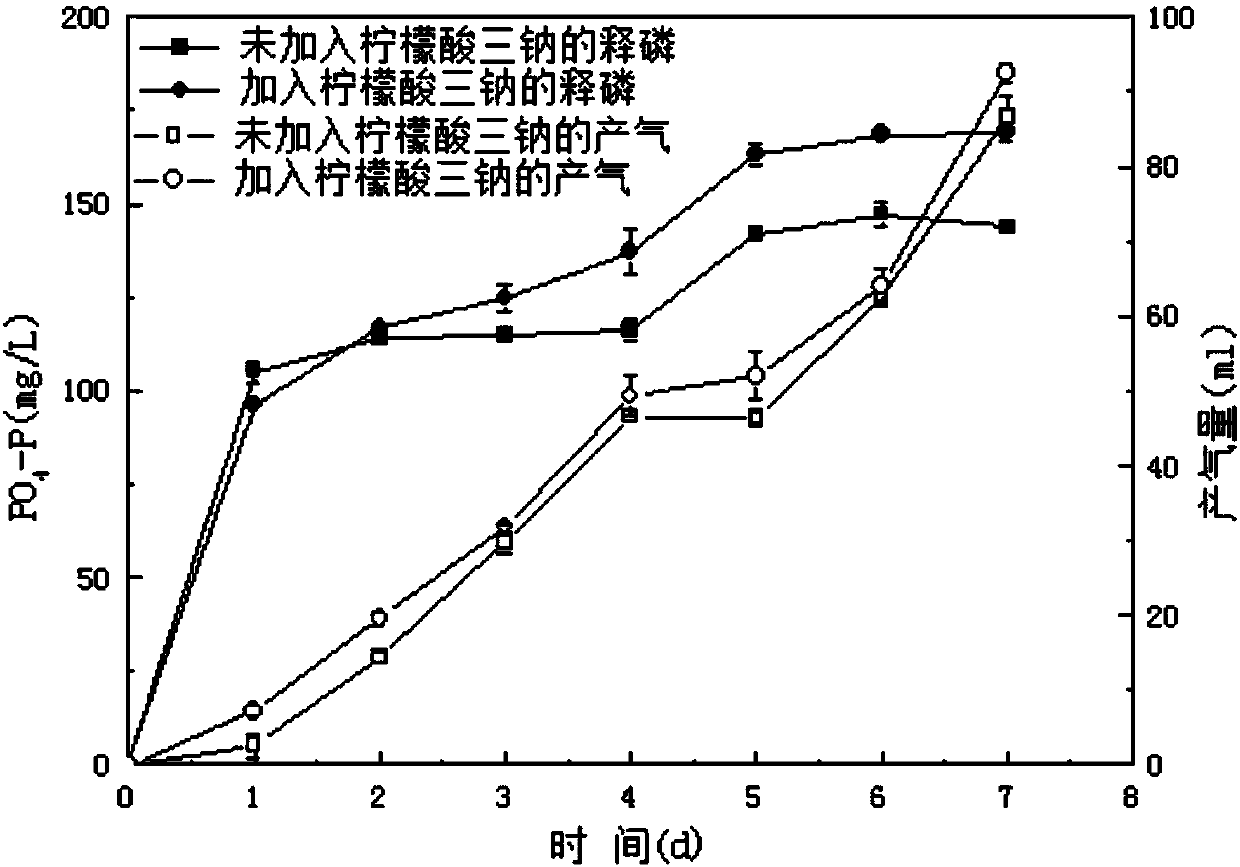

[0030] Take 500mL of concentrated pure biological sludge and sludge containing iron phosphate (total suspended solids concentration is 14.4g / L, volatile suspended solids concentration is 7.5g / L) into different reactors, add 0.882g Trisodium citrate solid (that is, adding 0.12g trisodium citrate / gTSS), driving oxygen to form an anaerobic environment, anaerobic fermentation in a closed reactor at 20-30°C for 7 days. At the same time, pure biological sludge without trisodium citrate and iron phosphate-containing sludge without trisodium citrate were used as controls.

[0031] Samples were taken every 24 hours. After each sampling, oxygen was driven away to form an anaerobic environment. The reactor was closed to measure orthophosphate, dissolved organic carbon (STOC), and volatile fatty acids (VFA) in the anaerobic fermentation supernatant of two kinds of sludge. ) concentration and methane production.

[0032] refer to figure 1 , when no trisodium citrate is added to the sludg...

Embodiment 2

[0036] Take 500mL of concentrated pure biological sludge and sludge containing iron phosphate (total suspended solids concentration is 14.4g / L, volatile suspended solids concentration is 7.5g / L) into different reactors, add 1.3235g Trisodium citrate solid (that is, adding 0.18g trisodium citrate / gTSS), driving oxygen to form an anaerobic environment, anaerobic fermentation in a closed reactor at 20-30°C for 7 days. At the same time, the pure biological sludge without trisodium citrate and the sludge containing iron phosphate without trisodium citrate were used as controls.

[0037] Samples were taken every 24 hours. After each sampling, oxygen was driven away to form an anaerobic environment. The reactor was closed to measure orthophosphate, dissolved organic carbon (STOC), and volatile fatty acids (VFA) in the anaerobic fermentation supernatant of two kinds of sludge. ) concentration and methane production.

[0038] When adding 0.37g trisodium citrate / gTSS and mixed sludge f...

Embodiment 3

[0042] Take 500mL of concentrated pure biological sludge and sludge containing aluminum phosphate (total suspended solids concentration is 14.4g / L, volatile suspended solids concentration is 7.5g / L) into different reactors, add 1.3235g Trisodium citrate solid (that is, adding 0.18g trisodium citrate / gTSS), driving oxygen to form an anaerobic environment, anaerobic fermentation in a closed reactor at 20-30°C for 7 days. At the same time, the anaerobic fermentation of pure biological sludge without trisodium citrate and aluminum phosphate sludge without trisodium citrate was used as a control.

[0043] Samples were taken every 24 hours. After each sampling, oxygen was driven away to form an anaerobic environment. The reactor was closed to measure orthophosphate, dissolved organic carbon (STOC), and volatile fatty acids (VFA) in the anaerobic fermentation supernatant of two kinds of sludge. )concentration.

[0044] After 7 days of anaerobic fermentation, when 0.18g trisodium cit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com