Processing system and method for recovering phosphorus from excess sludge obtained after municipal sewage treatment

A technology for excess sludge and urban sewage, applied in water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc., can solve the problems of sludge phosphorus waste, phosphorus secondary pollution, etc., and achieve clean phosphorus resources , Improve the phosphorus release rate and shorten the phosphorus release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

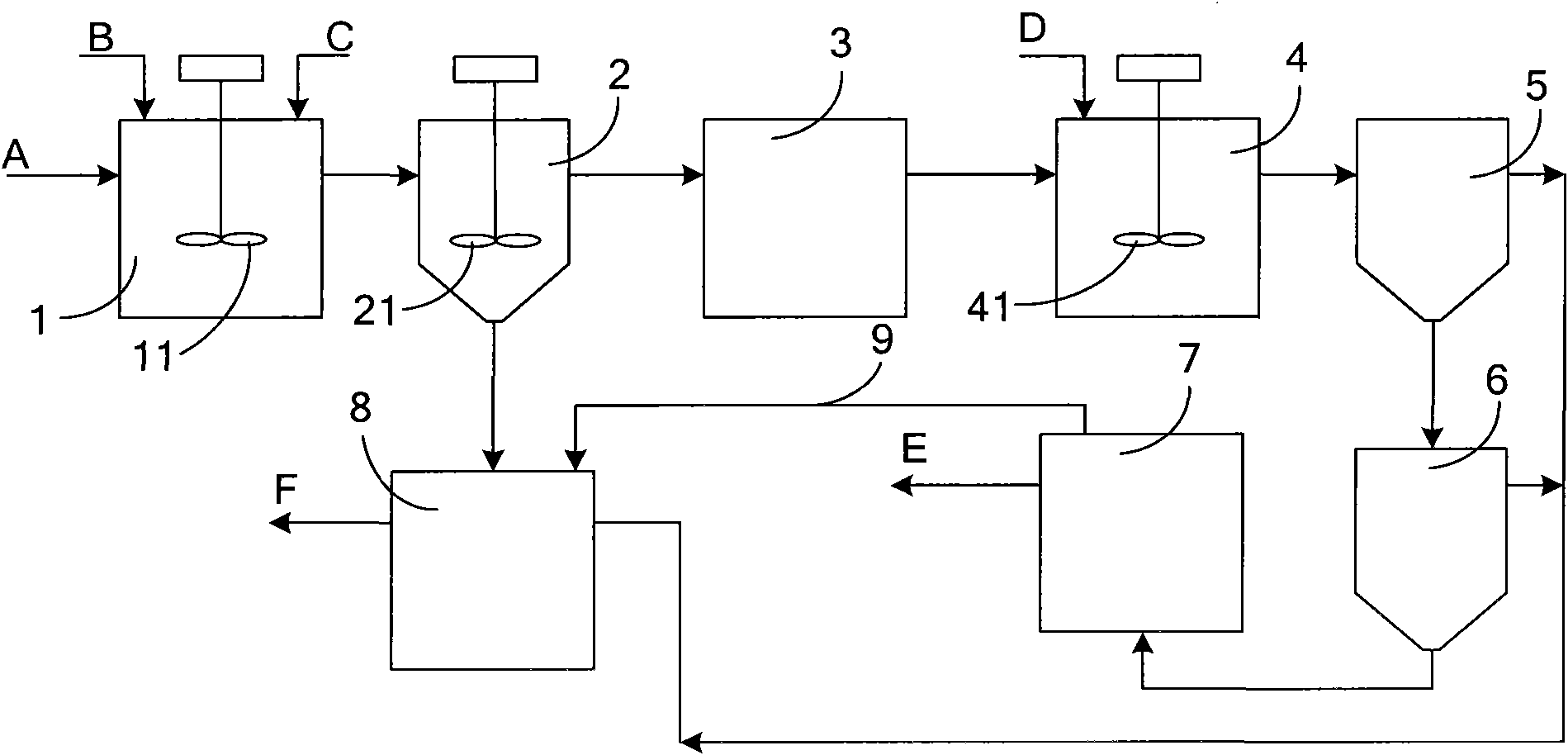

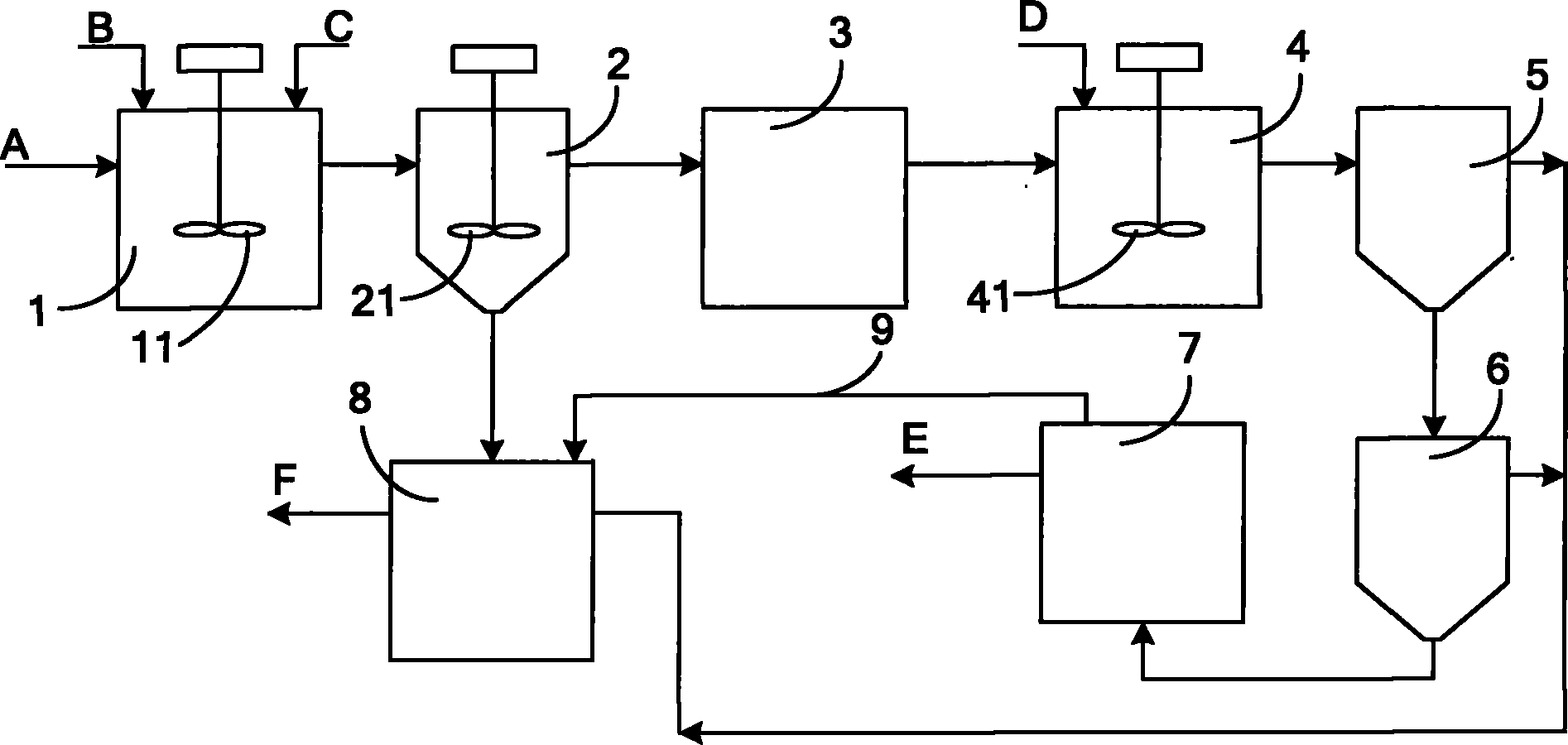

[0025] This embodiment provides a treatment system for recovering phosphorus from excess sludge after urban sewage treatment, for recovering phosphorus from excess sludge after sewage treatment, such as figure 1 As shown, the processing system includes:

[0026] Mixing tank 1, anaerobic phosphorus release tank 2, sand filter tank 3, chemical reaction tank 4, sedimentation tank 5, sludge thickening tank 6 and sludge dewatering machine 7;

[0027] Among them, the mixing tank 1 is provided with an inlet A for introducing the remaining sludge after urban sewage treatment, and the outlet of the mixing tank 1 is connected with the anaerobic phosphorus release tank 2, the sand filter tank 3, the chemical reaction tank 4 and the sedimentation tank 5 in sequence The mixing tank 1 is provided with a carbon source inlet B and an alkali solution inlet C, which is used to add a carbon source and an alkali solution into the mixing tank 1, and the mixing tank 1 is also provided with a stirri...

Embodiment 2

[0035] This embodiment provides a treatment for reclaiming phosphorus from the surplus sludge after urban sewage treatment, which is a method for treating surplus sludge using the treatment system given in the first embodiment above, the method comprising:

[0036] Stir and mix the remaining sludge after urban sewage treatment with the added carbon source and lye in the mixing tank;

[0037] The stirred and mixed sludge enters the anaerobic phosphorus release tank, and phosphorus is released under stirring, and the stirring speed gradient is controlled at ≤280S -1 , the residence time of the sludge in the anaerobic phosphorus release tank is 4 to 6 hours;

[0038] After the anaerobic phosphorus release tank releases phosphorus, the supernatant effluent enters the sand filter for filtration, and the suspended solids in the supernatant are filtered out;

[0039] The effluent filtered by the sand filter enters the chemical reaction tank and reacts with the phosphorus removal sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com