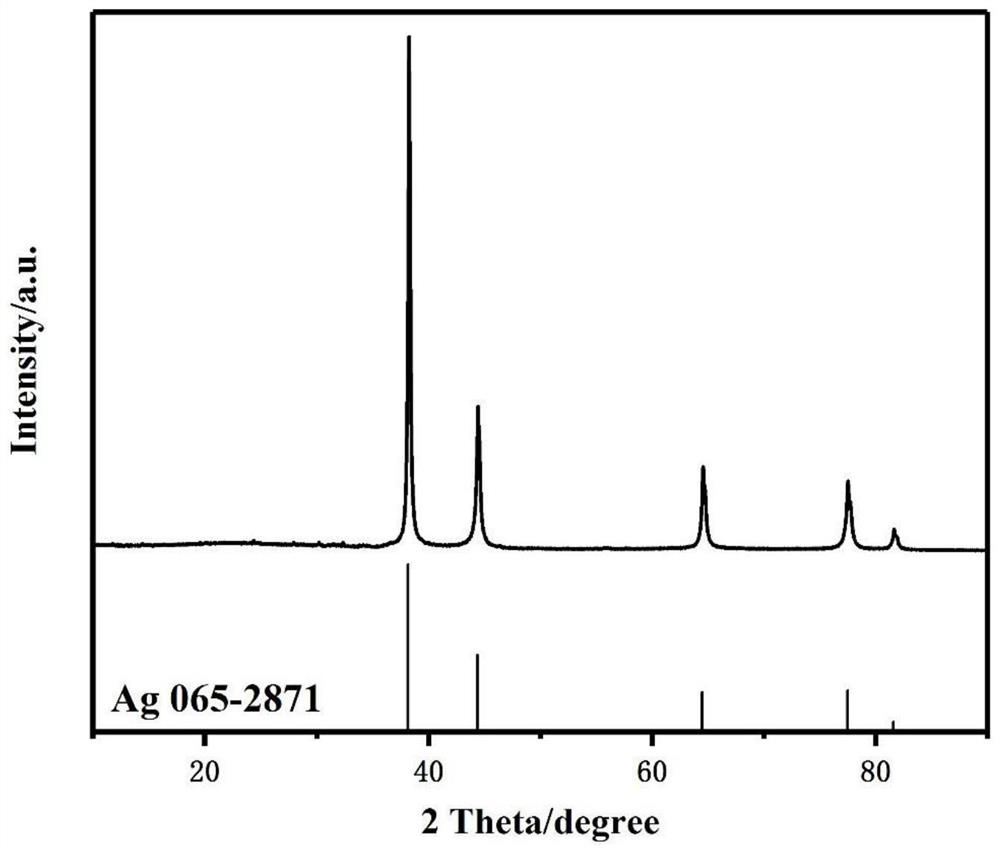

A silver-based catalyst for electrochemical reduction of carbon dioxide and preparation method thereof

A carbon dioxide and catalyst technology, which is applied in the field of silver-based catalyst for electrochemical reduction of carbon dioxide and its preparation, can solve the problem of high silver overpotential, and achieve the effects of improving conversion rate, reducing catalytic overpotential, and stable loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

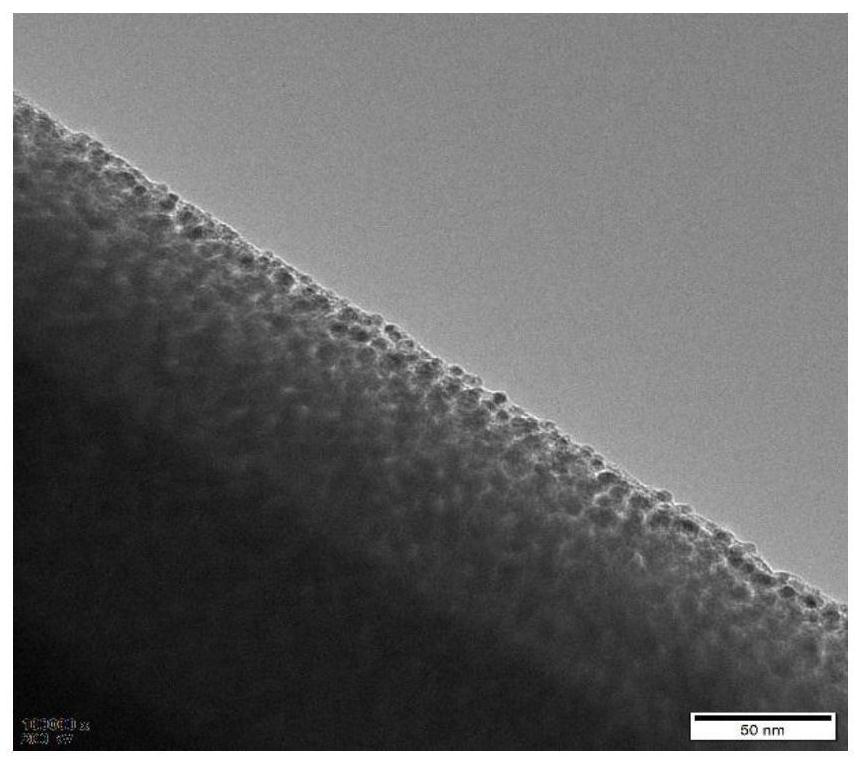

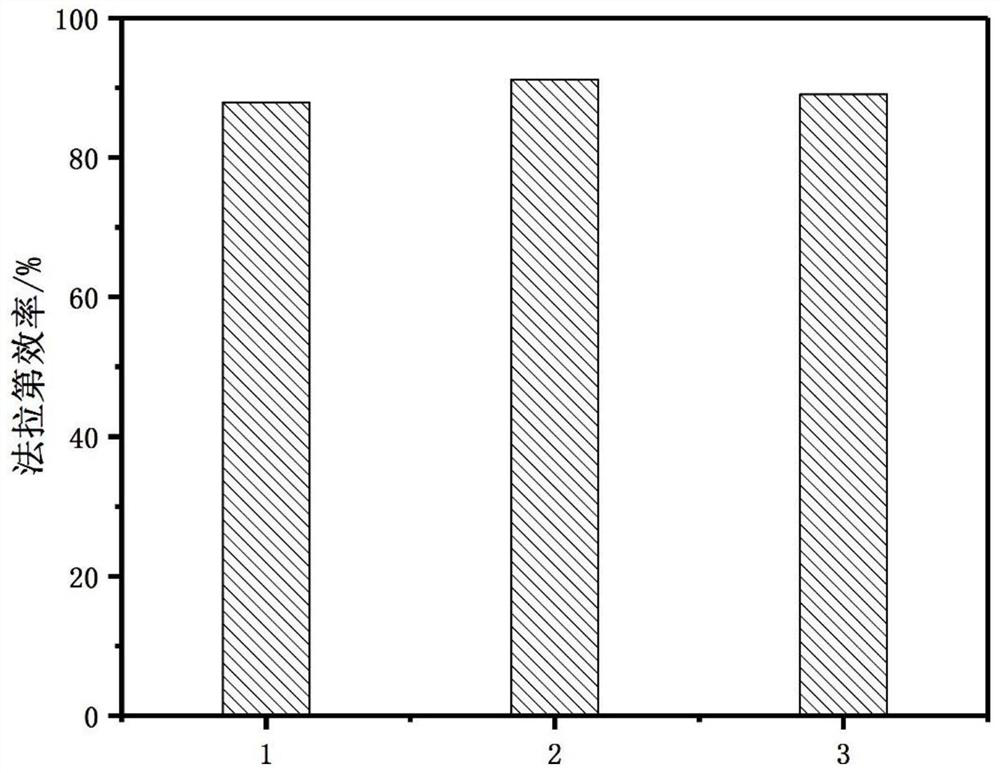

Embodiment 1

[0026] (1) Remember 1 cm × 2 cm of rectangular foamed silver sheet with foam, then the resulting foam sheet was tested for 15 min with acetone, ethanol and deionized water, dried in a 50 ° C oven and fell into a dryer. Preferences.

[0027] (2) 0.2 g / ml of polyacrylic acid (PAA) 500 μL and 500 μL of ammonia water (2M) was completely dissolved in 16.5 ml of deionized water, and two steps (1) processed foam sheets were added, and then stirred at room temperature. 10 min, 75 ml of isopropanol (IPA) was sufficiently dispersed in the solution, and then 7.5 ml of 5 mg / ml dopamine hydrochloride solution was added at 50 ° C for 3.5 h in the mixture, with water and IPA final volume. The ratio is 1: 3. The foam piece was taken out.

[0028] (3) Silver ammonia solution configuration: 4 mL of ammonia water (2M) was diluted with water to 50 mL to 10 g / ml of silver nitrate solution until brown disappeared.

[0029] (4) Preparation of foam silver sheets prepared by step (2) in step (3) pre...

Embodiment 2

[0031] (1) The rectangular foam piece of 1 cm × 2 cm with foam, then then treated with acetone, ethanol and deionized water, and dried in a 50 ° C oven and fell into the dryer.

[0032] (2) 0.2 g / ml of polyacrylic acid (PAA) 500 μL and 500 μL of ammonia water (2M) was completely dissolved in 16.5 ml of deionized water, and two steps (1) processed foam sheets were added, and then stirred at room temperature. 10 min, 75 ml of isopropanol (IPA) was sufficiently dispersed in the solution, and then 7.5 ml of 5 mg / ml dopamine hydrochloride solution was added at 50 ° C for 3.5 h in the mixture, with water and IPA final volume. The ratio is 1: 3.

[0033] (3) Silvermonia solution configuration: 4 mL of ammonia (2 m) was diluted to 50 mL to 100 mL of 10 g / ml of silver nitrate solution until brown disappeared.

[0034] (4) Putting the foam silver sheet prepared by step (2) into step (3) prepared for 2 h after preparing for 2 h, placed in silver nitrate, 0.2 g of 3,5-dicarboxylic acid ...

Embodiment 3

[0038] (1) The rectangular foam piece of 1 cm × 2 cm with foam, then then treated with acetone, ethanol and deionized water, and dried in a 50 ° C oven and fell into the dryer.

[0039] (2) Take 0.2 g / ml of polyacrylic acid (PAA) 500 μL and 500 μL of ammonia water (2M) in 16.5 ml of deionized water, add two treated foam, then stirred at room temperature for 10 min, add 75ml Isopropanol (IPA) is sufficiently dispersed in solution, followed by adding 7.5 mg / ml of dopamine hydrochloride solution at 50 ° C for 3.5 h in the mixture, wherein the final volume ratio of water and IPA is 1: 3.

[0040] (3) Silvermonia solution configuration: 4 mL of ammonia (2 m) was diluted to 50 mL to 100 mL of 10 g / ml of silver nitrate solution until brown disappeared.

[0041] (4) Putting the foam silver sheet prepared by step (2) in the step (3) prepared for 2 h, add 40 ml of silver nitrate, 0.2 g of 3,5-dicarboxylic acid pyridine containing 0.64 g of nitrateIn deionized water, ultrasonic mixing is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com