Preparation method and application of carbon material rich in topological defects obtained through high-temperature ammonia treatment

A carbon material and ammonia treatment technology, applied in the direction of carbon preparation/purification, separation methods, chemical instruments and methods, etc., can solve the problems of expensive catalyst, poor selectivity, poor stability, etc., and achieve high-efficiency carbon dioxide electroreduction catalytic activity, The preparation method is simple and easy, and the effect of high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

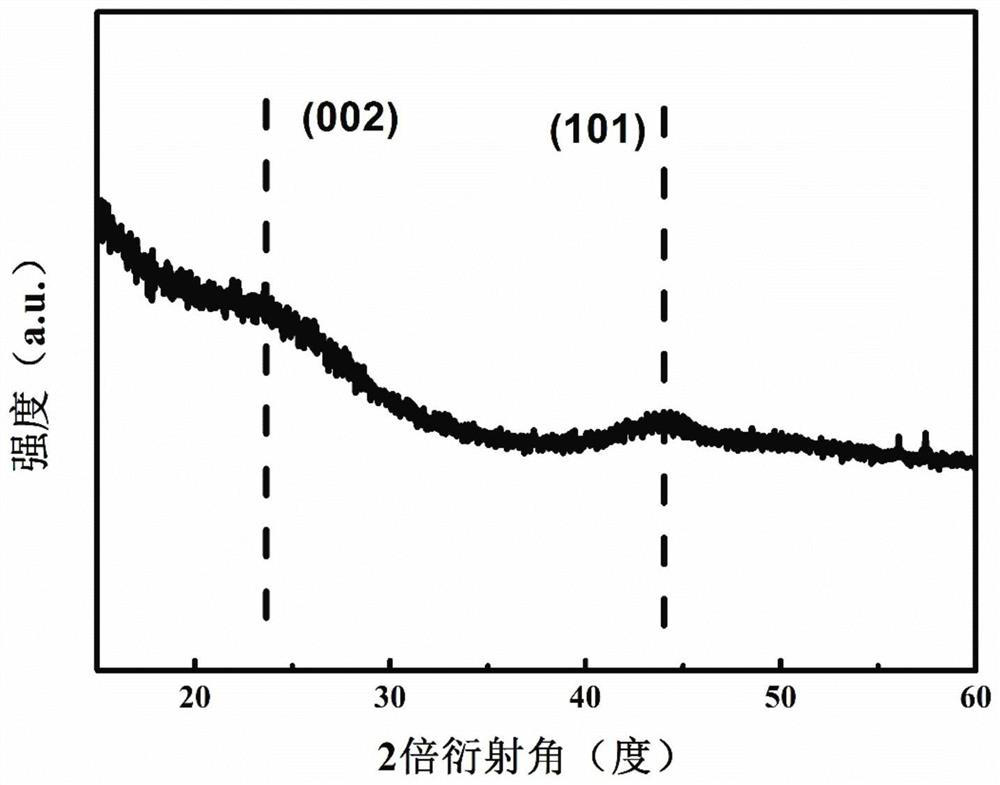

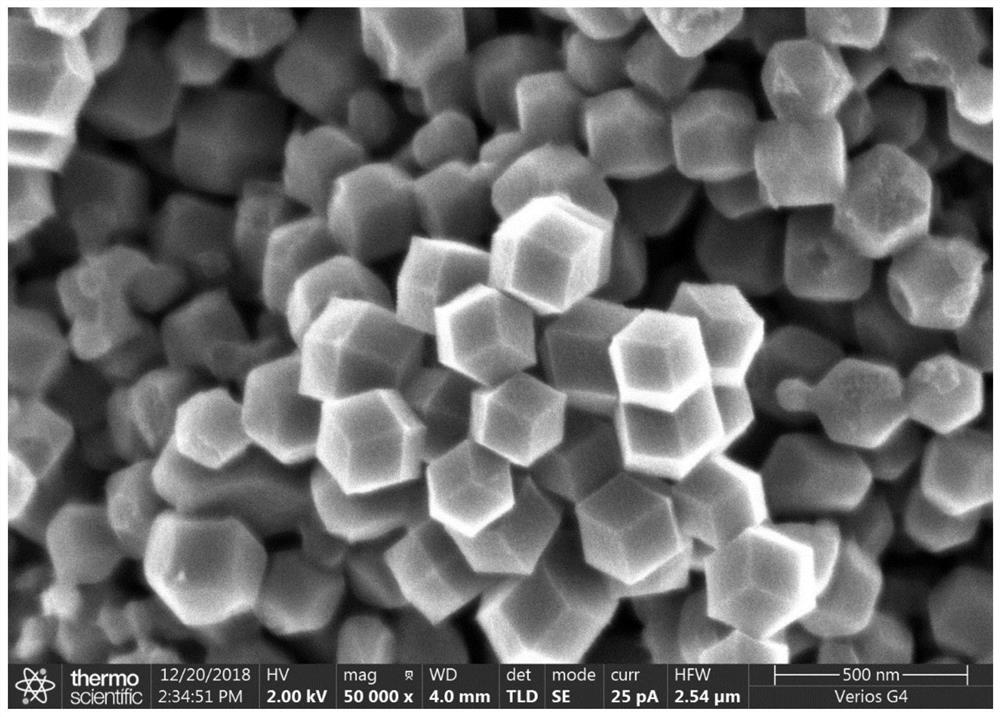

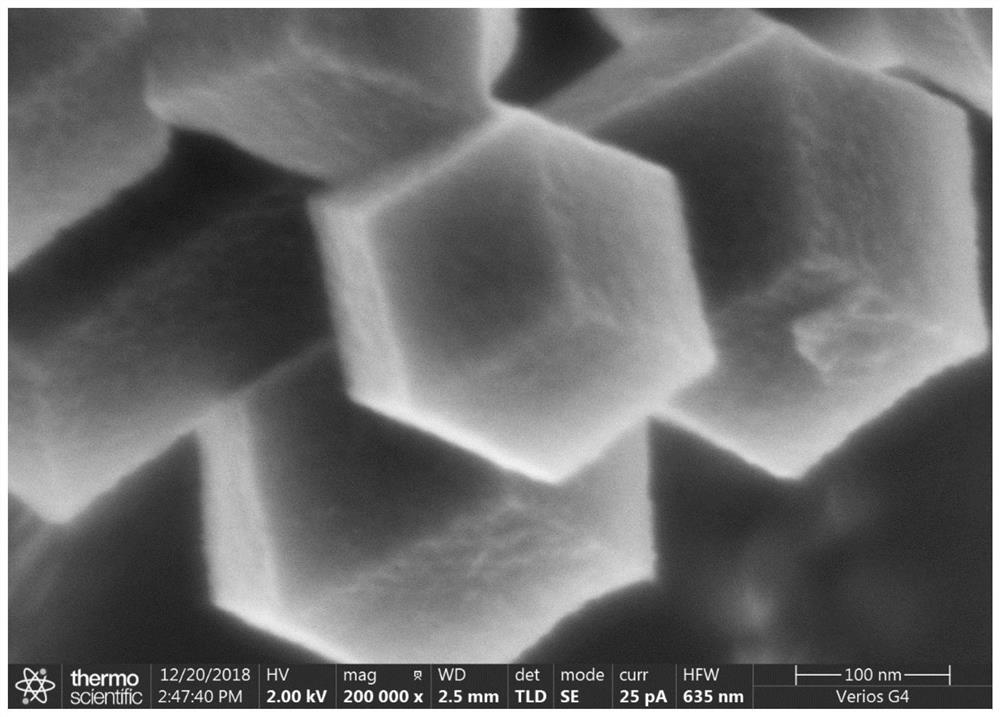

[0040] In this example, the carbon material rich in topological defects is prepared as follows:

[0041] (1) Preparation of ZIF-8 precursor

[0042] 4.05g zinc nitrate hexahydrate and 2.63g 2-methylimidazole were dissolved in 200ml of methanol respectively, the two solutions obtained were mixed and stirred for 5 minutes, then left to stand at room temperature for 24 hours, finally centrifuged and washed and separated, Dry in an oven at 60°C for 12 hours.

[0043] (2) Heat treatment in an inert gas atmosphere

[0044] The ZIF-8 precursor obtained in step (1) was put into a tube furnace, heated to 800°C at a rate of 5°C / min after argon flow for 2 hours, kept for 2 hours, and then cooled down to room temperature naturally.

[0045] (3) Acid etching cleaning

[0046] The product obtained in step (2) was washed with 36% hydrochloric acid and centrifuged three times, then washed with deionized water until neutral, and finally dried in an oven at 60° C. for 12 hours.

[0047] (4)...

Embodiment 2

[0070] In this embodiment, the preparation of the carbon dioxide electrochemical reduction catalyst is as follows:

[0071] (1) Preparation of ZIF-8 precursor

[0072] Same as step (1) in Example 1.

[0073] (2) Heat treatment in an inert gas atmosphere

[0074] Same as step (2) in Example 1.

[0075] (3) Acid etching cleaning

[0076] Same as step (3) in Example 1.

[0077] (4) Ammonia heat treatment

[0078] The product obtained in step (3) was put into a tube furnace, raised to 900°C at a rate of 10°C / min in 100% ammonia gas, kept for 1 hour, and then cooled naturally to room temperature.

Embodiment 3

[0080] In this embodiment, the preparation of the carbon dioxide electrochemical reduction catalyst is as follows:

[0081] (1) Preparation of ZIF-8 precursor

[0082] Same as step (1) in Example 1.

[0083] (2) Heat treatment in an inert gas atmosphere

[0084] Same as step (2) in Example 1.

[0085] (3) Acid etching cleaning

[0086] Same as step (3) in Example 1.

[0087] (4) Ammonia heat treatment

[0088] The product obtained in step (3) was put into a tube furnace, raised to 800°C at a rate of 10°C / min in 100% ammonia gas, kept for 1 hour, and then cooled naturally to room temperature.

[0089] According to the XPS of the carbon material obtained in the above-mentioned comparative examples and examples 1-3, the nitrogen content therein is as follows:

[0090]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com