Application of BN to electrochemical ammonia production

An electrochemical and ammonia technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve problems such as negative impact on the environment, and achieve the effects of energy saving, easy operation, and simple treatment plan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, the carbon paper working electrode deposited with BN nanosheets is prepared by the following steps:

[0026] (1) Stripping of BN nanosheets: Add 1.5 mg of commercially available block BN to 2.0 mL of a mixture of distilled water and ethanol with a volume ratio of 1:1 and crush it with an ultrasonic crusher for 2.0 hours to obtain a mixed solution A. Contains exfoliated BN nanosheets;

[0027] (2) Configuration of the catalyst solution: take 0.98 mL of the mixed solution A in step (1) in a centrifuge tube, add 0.02 mL of 5 wt % naphthol solution, and sonicate for 0.5 hours to obtain the mixed solution B;

[0028] (3) Draw the mixed solution B and drop it on the surface of carbon paper to obtain the working electrode.

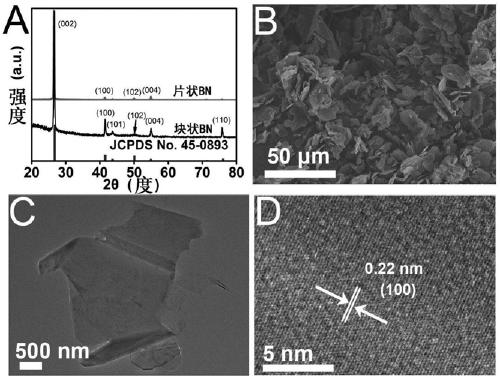

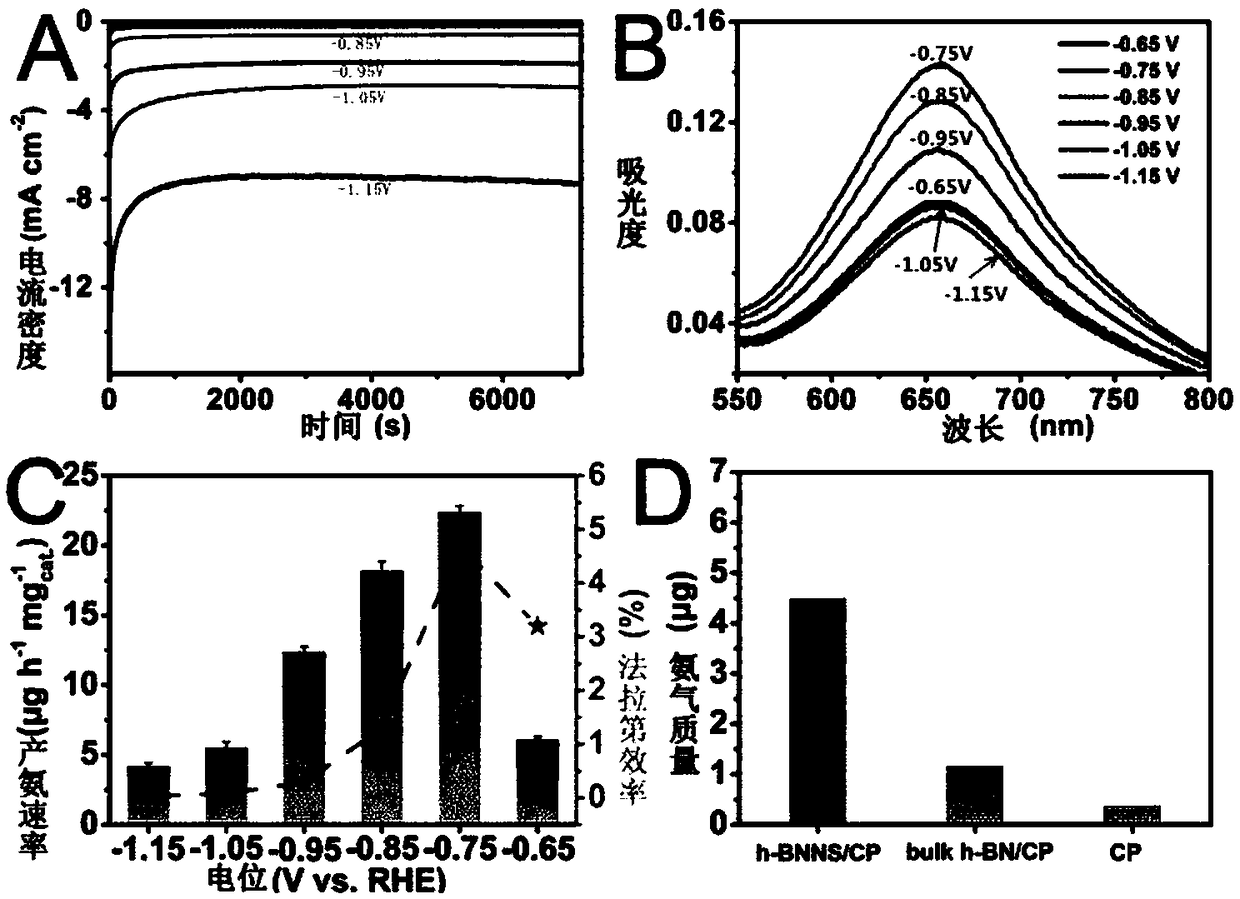

[0029] From figure 1 It can be seen in A that the diffraction peaks of unexfoliated bulk BN at 26.7°, 41.5°, 43.7°, 50.0°, 54.9° and 76.1° can be attributed to the (002), (100 ), (101), (102), (004) and (110) phases (JCPDS No. 45-089...

Embodiment 2

[0033] As described in Example 1, the difference is that the amount of block BN in step (1) is 1.0 mg.

Embodiment 3

[0035] As described in Example 1, the difference is that the crushing time of the ultrasonic crusher in step (1) is 1.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com