Ethylene oxychlorination catalyst as well as preparation method and application thereof

An ethylene oxychlorination catalyst and a catalyst technology, which are applied in the directions of catalyst activation/preparation, physical/chemical process catalyst, catalyst carrier, etc., can solve the problems of poor catalytic activity, uneven dispersion of active components, etc. Good for transport and high ethylene selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

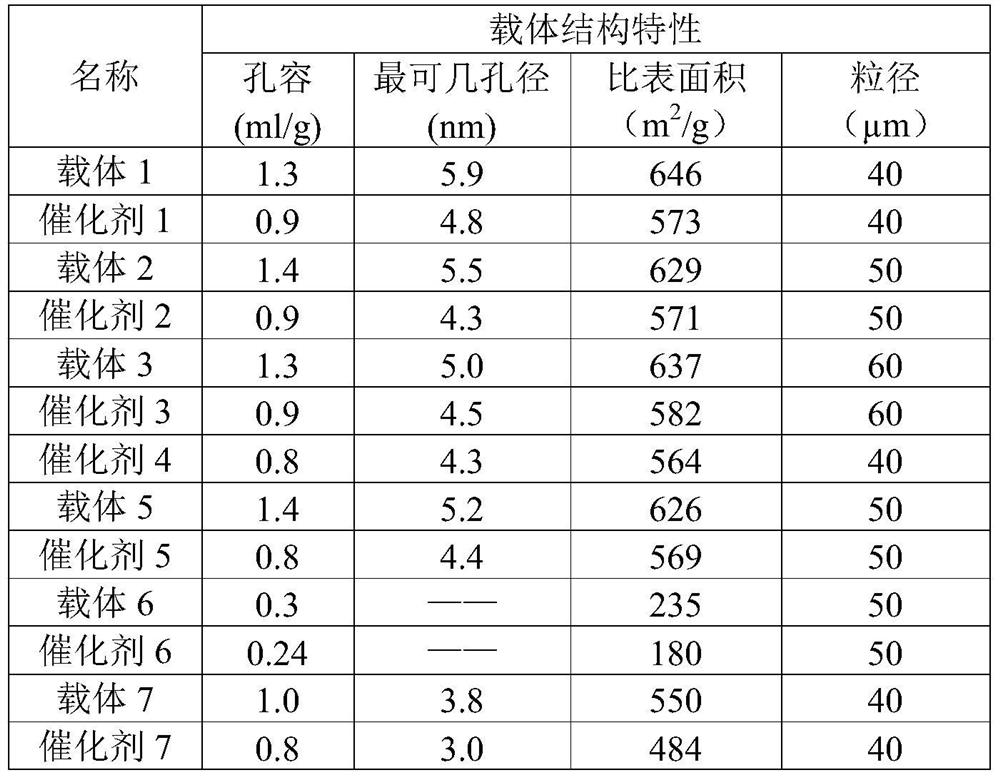

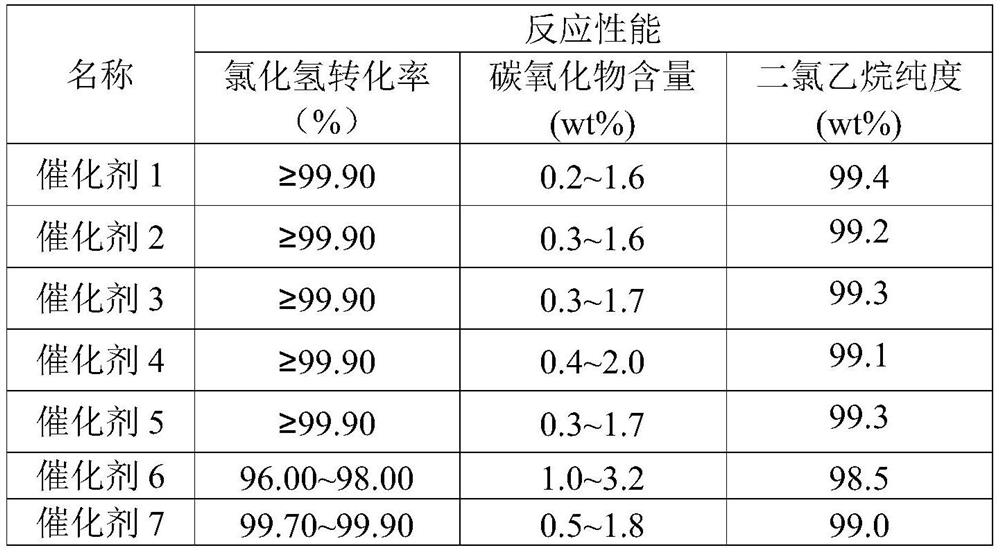

Examples

Embodiment 1

[0082] Add 7g of aluminum isopropoxide into a solution containing 90ml of water and 1.5g of nitric acid, stir at 60°C until completely dissolved to obtain solution A. Add 2g of template agent P123 into a solution of 12g of 37% hydrochloric acid and 70ml of water, mix and stir at 50°C until P123 is completely dissolved to obtain solution B. Mix solution A and solution B, slowly add 0.03 g of polyethylene glycol laurate while stirring, then adjust the pH value to 6.0-8.0 with NaOH, and age at room temperature for 24 hours. The obtained product was repeatedly washed with a mixed solution of water and ethanol with a volume ratio of 1:1 until the conductivity of the clear liquid after washing was lower than 30 μS / cm. Then spray-dry at 100° C. to obtain raw mesoporous alumina powder. The mesoporous alumina raw powder was calcined at 600° C. for 2 hours to remove the template agent to obtain a spherical mesoporous alumina carrier 1 .

[0083] Dissolve a certain amount of copper chl...

Embodiment 2

[0086]Add 10g of aluminum isopropoxide into a solution containing 100ml of water and 3g of nitric acid, stir at 80°C until completely dissolved to obtain solution A. Add 2g of template agent P123 into a solution of 20g of 37% hydrochloric acid and 70ml of water, mix and stir at 35°C until P123 is completely dissolved to obtain solution B. Mix solution A and solution B, slowly add 0.07g polyethylene glycol laurate while stirring, then adjust the pH value to 6.0-8.0 with NaOH, and age at room temperature for 30h. The obtained product was repeatedly washed with a mixed solution of water and ethanol at a volume ratio of 1:0.5 until the conductivity of the clear liquid after washing was lower than 30 μS / cm. Then spray-dry at 100° C. to obtain raw mesoporous alumina powder. The mesoporous alumina raw powder was calcined at 500° C. for 4 hours to remove the template agent to obtain spherical mesoporous alumina carrier 2 .

[0087] Dissolve a certain amount of copper chloride, potas...

Embodiment 3

[0090] Add 12g of aluminum isopropoxide into a solution containing 105ml of water and 3g of nitric acid, stir at 60°C until completely dissolved to obtain solution A. Add 2g of template agent P123 into a solution of 15g of 37% hydrochloric acid and 70ml of water, mix and stir at 50°C until P123 is completely dissolved to obtain solution B. Mix solution A and solution B, slowly add 0.03 g of polyethylene glycol laurate while stirring, then adjust the pH value to 6.0-8.0 with NaOH, and age at room temperature for 36 hours. The obtained product was repeatedly washed with a mixed solution of water and ethanol with a volume ratio of 1:2 until the conductivity of the supernatant after washing was lower than 30 μS / cm. Then spray-dry at 110° C. to obtain raw mesoporous alumina powder. The mesoporous alumina raw powder was calcined at 400° C. for 5 hours to remove the template agent to obtain a spherical mesoporous alumina carrier 3 .

[0091] Dissolve a certain amount of copper chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com