Method for preparing algae material fuel by catalytic liquefying method

A technology for catalytic liquefaction and seaweed, which is applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of cumbersome separation process of reaction products, difficulty in direct use of fuel, and low calorific value of bio-oil, and achieve economic and social benefits. Obviously, to avoid equipment corrosion, the effect of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

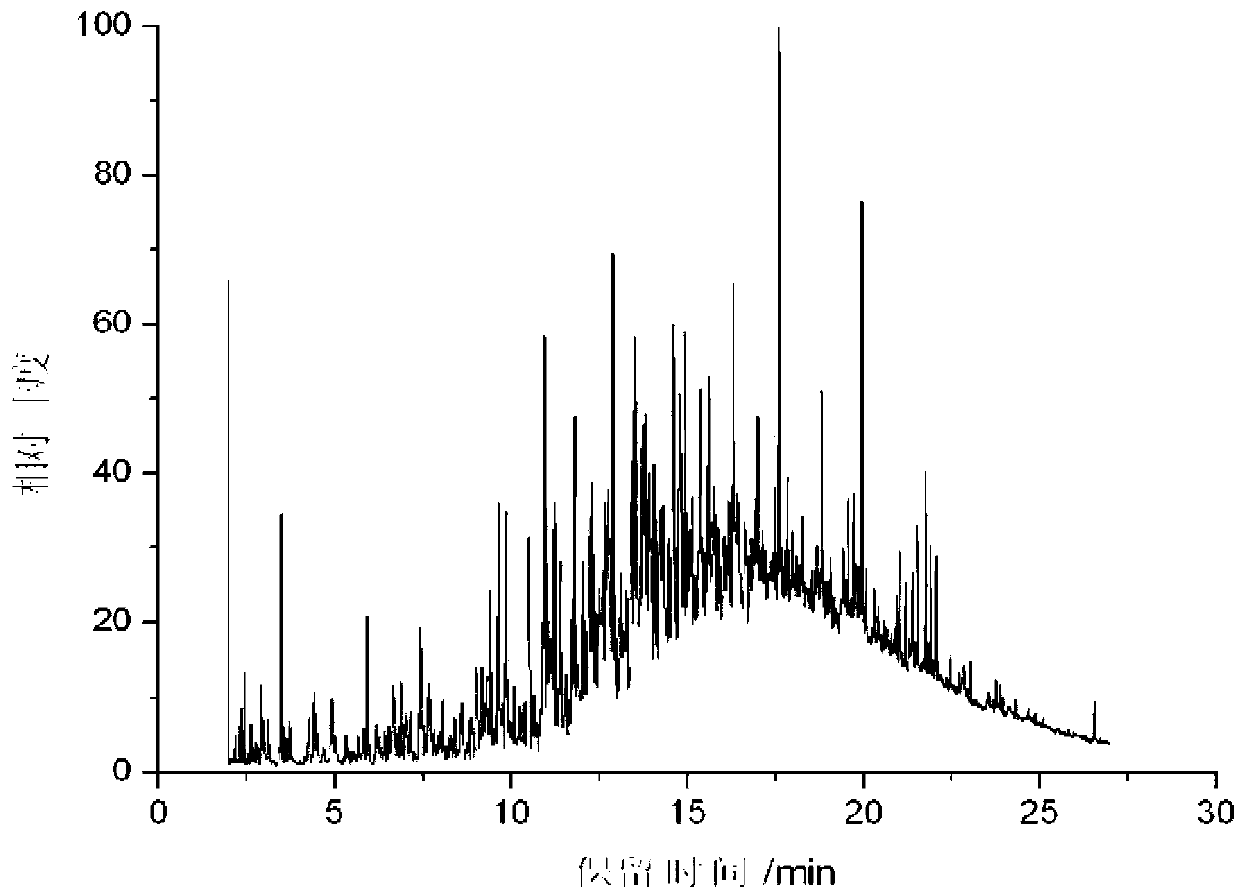

[0015] In this embodiment, the large seaweed Enteromorpha is washed and removed first, and 28 g of dried and pulverized Enteromorpha is taken, 5.6 g of water is added, 1.4 g of Fe / HZSM-5 catalyst is added, and after mixing evenly, put into a steel airtight reaction kettle, and then Raise the temperature to 350°C at a heating rate of 60°C / min, keep it for 15 minutes, and then end the reaction, cool it naturally in the air, then distill the solid-liquid product at atmospheric pressure, collect the fraction between 60-500°C, and separate the water in the fraction Obtain liquid fuel oil with a yield of 18.39%, a calorific value of 44.69MJ / kg, an H / C molar ratio of 1.82, and an oxygen content of 3.12%; figure 1 For the GC-MS total ion current chromatogram of the obtained liquid fuel oil, by mass spectrum peak analysis, the main component hydrocarbons of the obtained liquid fuel oil include toluene, ethylbenzene, trimethylbenzene, propylbenzene, 1-vinyl- 2-Methylbenzene, Dodecane, T...

Embodiment 2

[0017] In this embodiment, the large seaweed Enteromorpha is washed and removed first, and 28 g of dried and pulverized Enteromorpha is taken, 4.2 g of water is added, 0.84 g of Fe / HZSM-5 catalyst is added, and after mixing evenly, it is put into a steel airtight reaction kettle, and then Raise the temperature to 400°C at a heating rate of 60°C / min, keep it for 20min, then end the reaction, cool naturally in the air, then distill the solid-liquid product at atmospheric pressure, collect the fraction between 60-500°C, and separate the water in the fraction The liquid fuel oil was obtained with a yield of 17.81%, a calorific value of 42.89MJ / kg, a H / C molar ratio of 1.64, and an oxygen content of 4.06%.

Embodiment 3

[0019] In this embodiment, the large-scale seaweed Enteromorpha is washed and removed first, and 28 g of dried and pulverized Enteromorpha is taken, 8.4 g of water is added, 1.68 g of Fe / HZSM-5 catalyst is added, and after mixing evenly, it is put into a steel airtight reaction kettle, and then Raise the temperature to 450°C at a heating rate of 60°C / min, keep it for 20min, then end the reaction, cool naturally in the air, then distill the solid-liquid product at atmospheric pressure, collect the fraction between 60-500°C, and separate the water in the fraction The liquid fuel oil was obtained with a yield of 19.27%, a calorific value of 43.25MJ / kg, a H / C molar ratio of 1.71, and an oxygen content of 4.10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com