Catalyst for oxidative removal of CO in hydrogen-rich gas and preparation and application thereof

A catalyst, hydrogen-rich technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Easy to operate, easy to implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

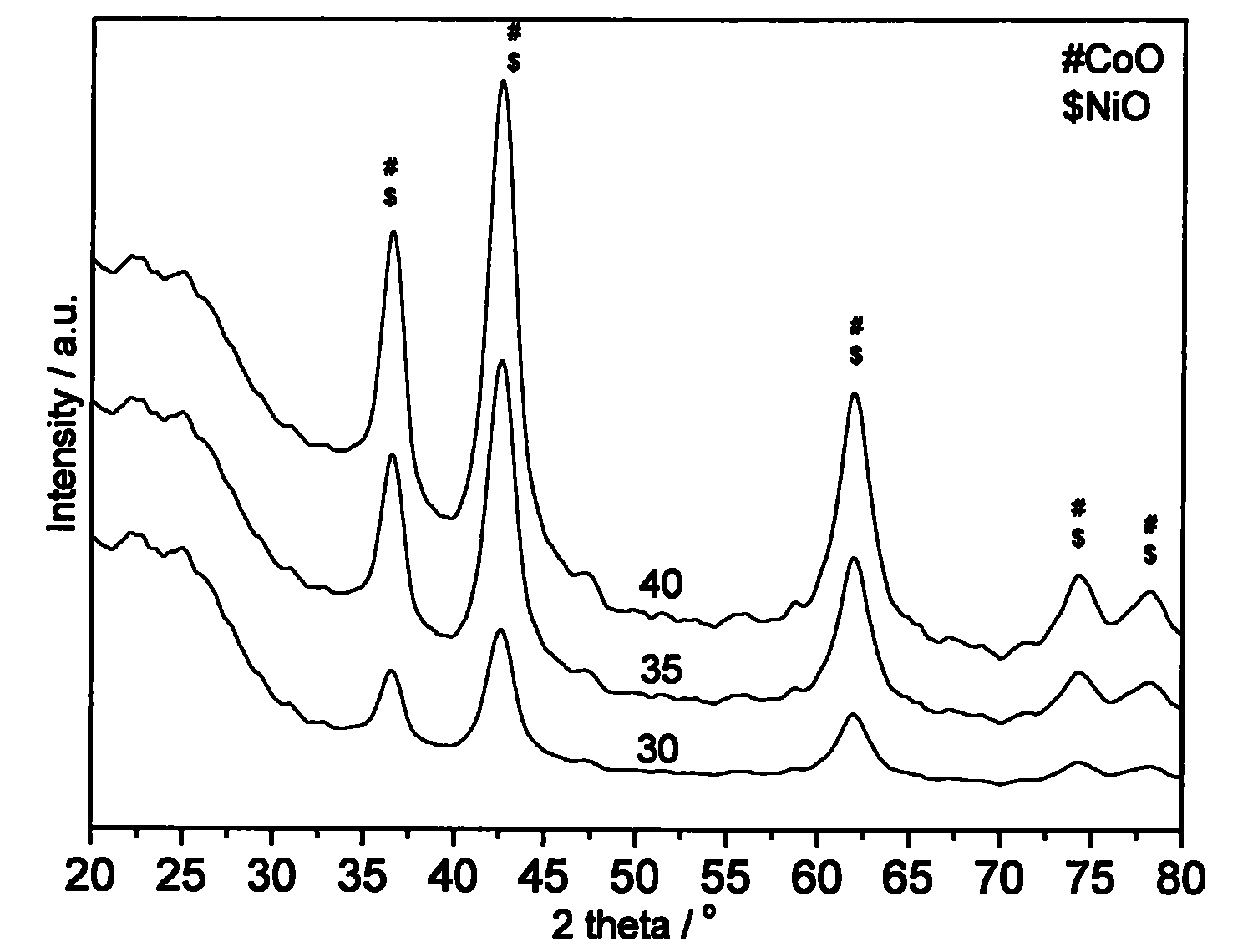

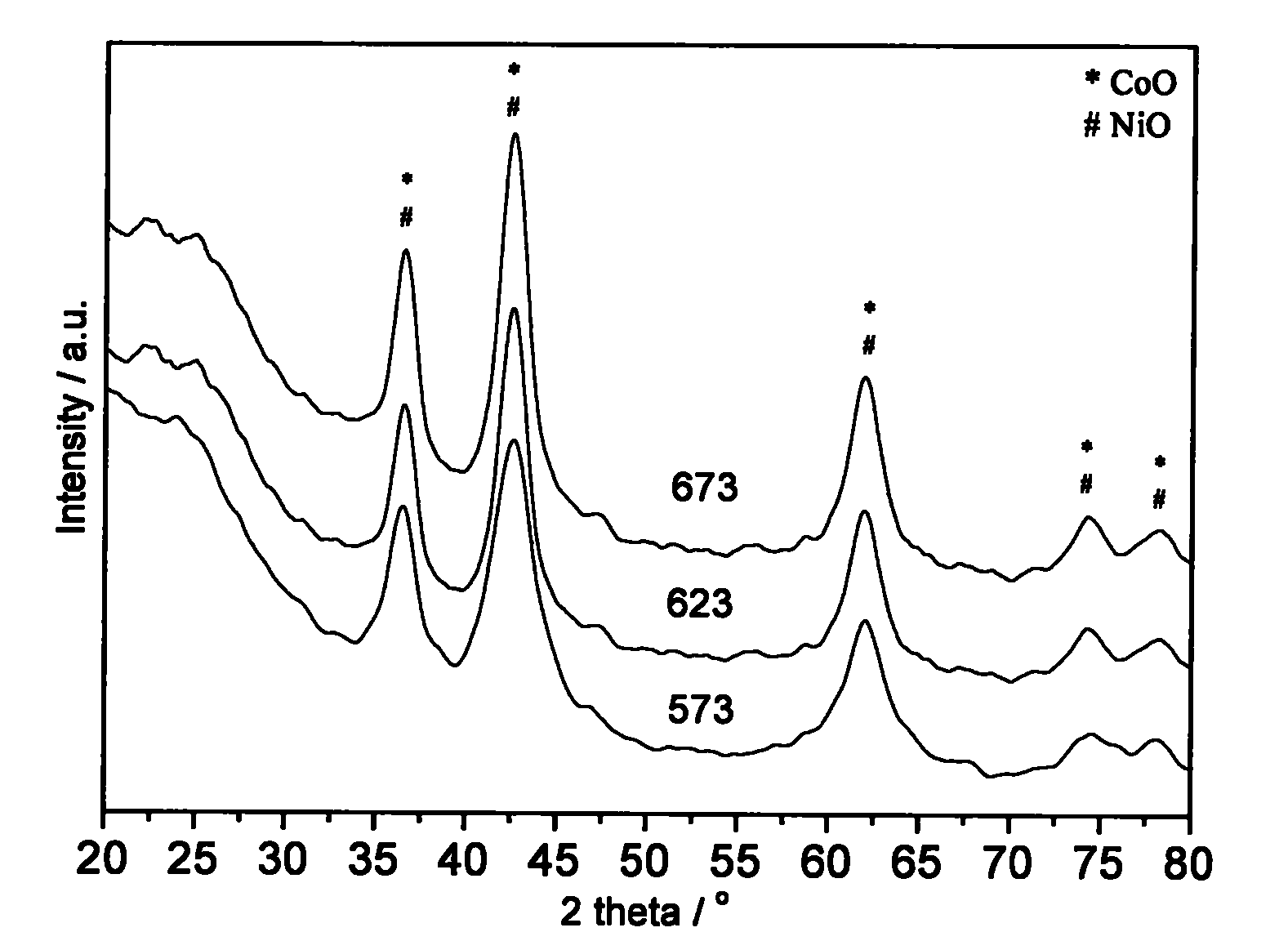

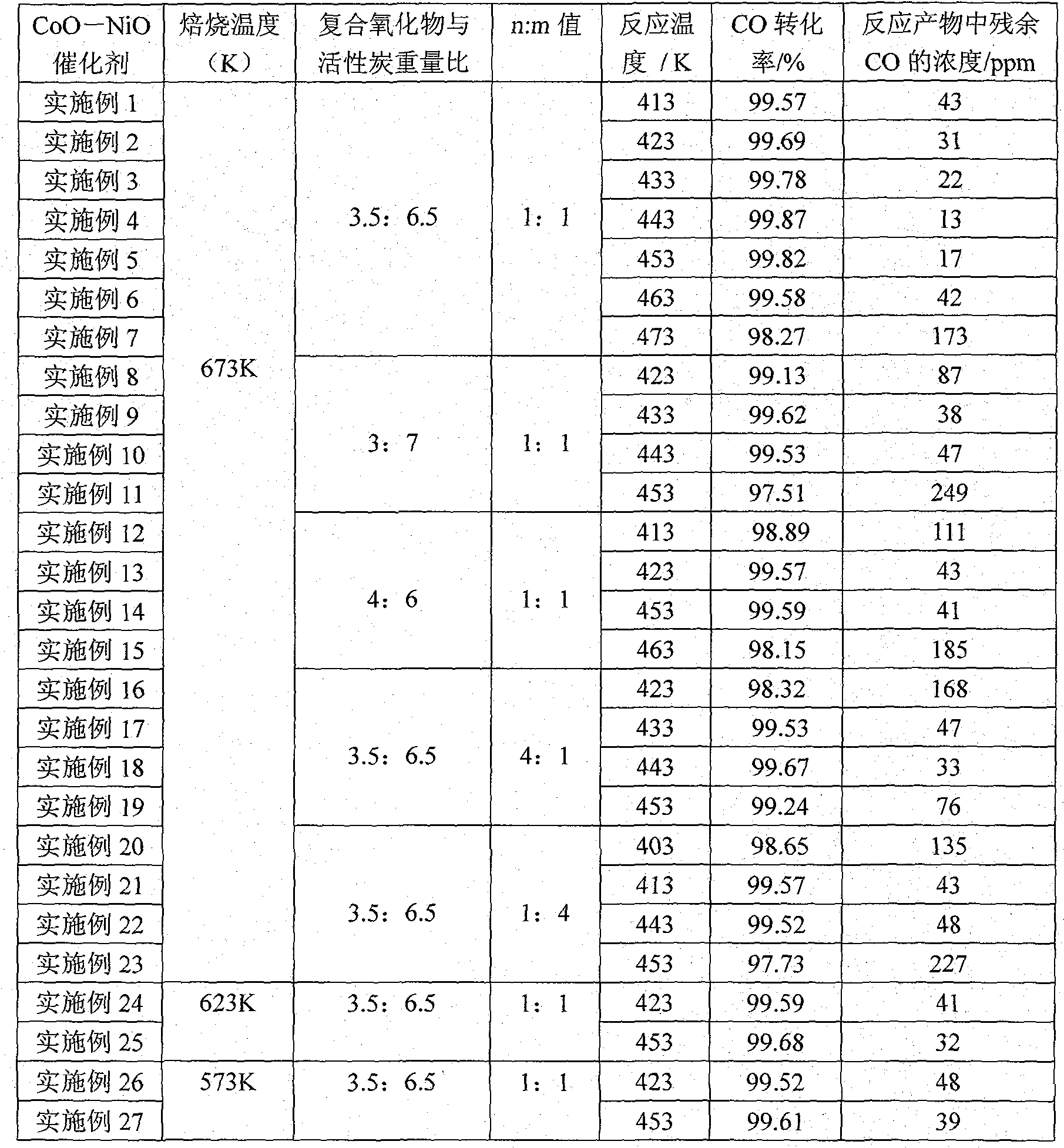

Embodiment 1

[0032] The atomic ratio of Co and Ni is 1: 1 and takes by weighing cobalt nitrate and nickel nitrate respectively and fully dissolving them in distilled water, and getting activated carbon particles with a particle size in the range of 20-80 meshes (the weight of activated carbon and the compound formed by the atomic ratio The ratio of oxide theoretical weight is 6.5: 3.5) impregnated in the obtained solution, evaporated to dryness at 353K under the condition of constant stirring to obtain the raw material, and the obtained raw material was dried at a constant temperature at 373K for 24h (the purpose of constant temperature drying at 373K is to remove the crystal water in the raw material, where the drying time is 10-24h and the purpose of the invention can be realized) to obtain the dry material; then the obtained dry material is heated up to 673K at a rate of temperature increase of 5K / min in an inert environment at room temperature, and then Calcined at constant temperatur...

Embodiment 2

[0037] The constant temperature in the CO oxidation removal process was changed to 423K, and other conditions were the same as in Example 1.

Embodiment 3

[0039] The catalyst was obtained by calcining at 673K for 4 hours, and the CO oxidation removal reaction temperature was 433K, and the rest of the conditions were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com