Patents

Literature

73results about How to "Reduce CO2 concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

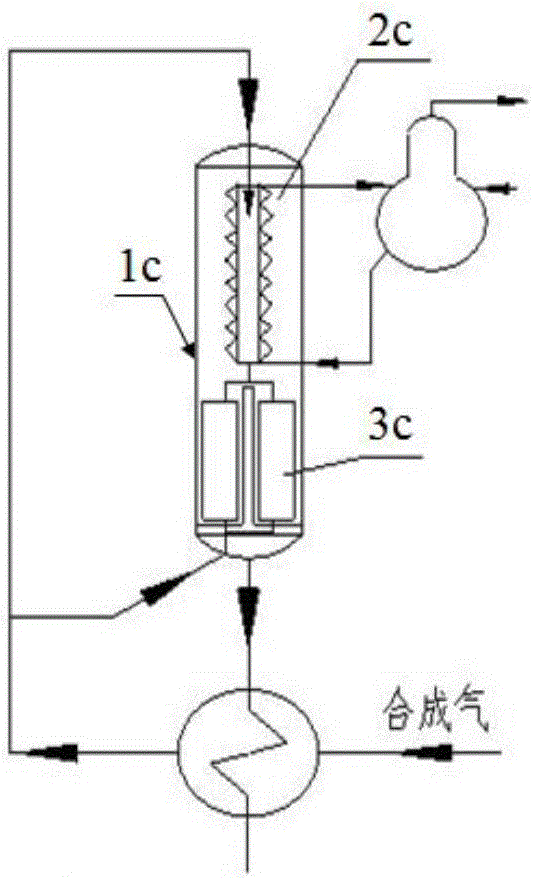

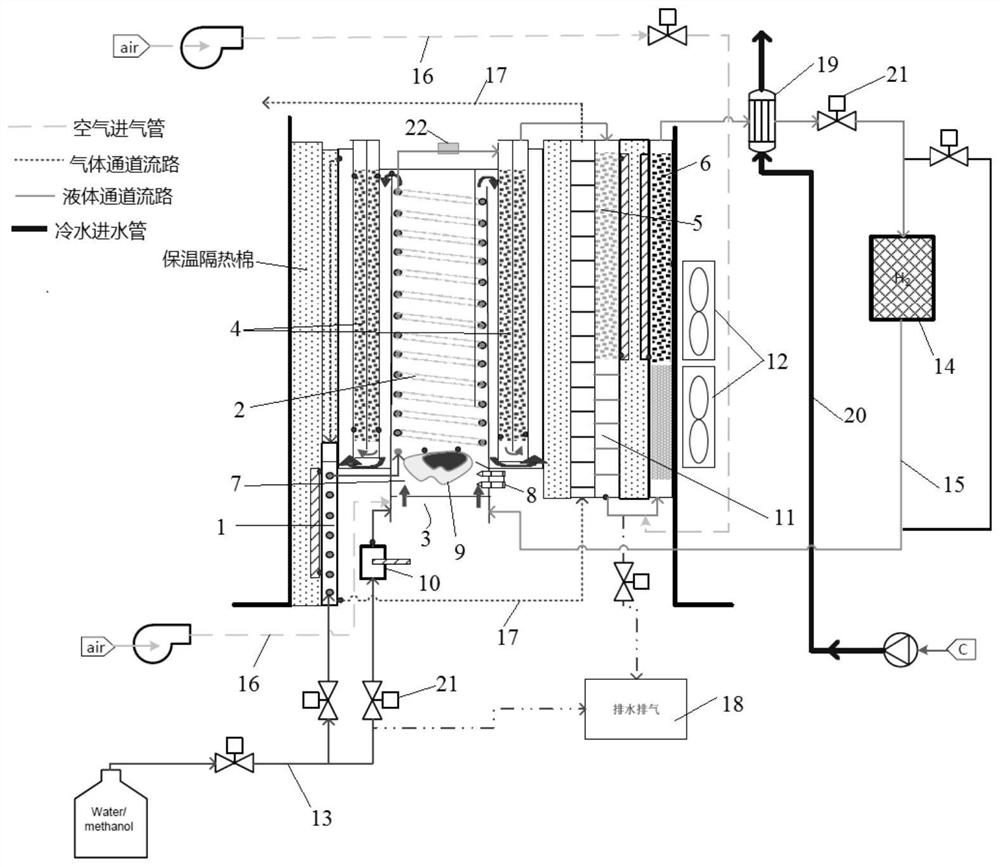

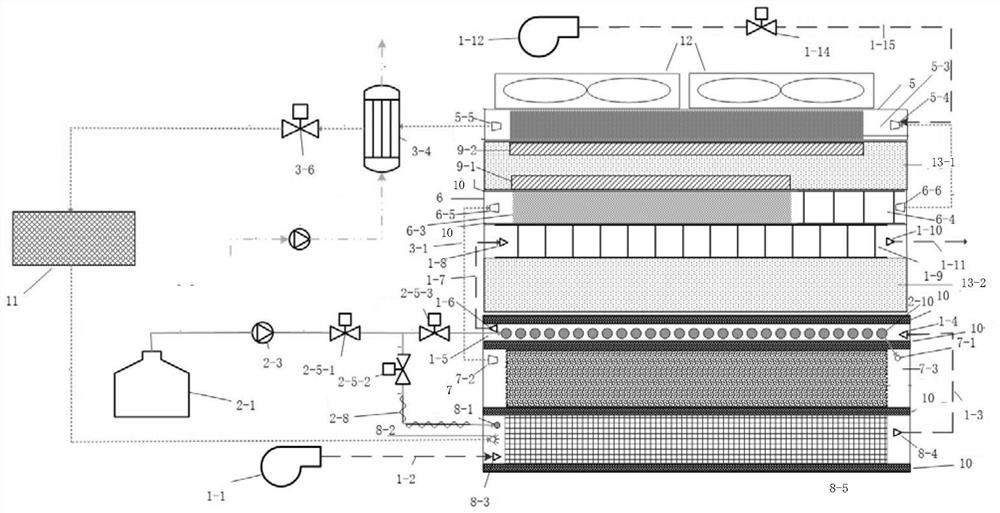

Enclosed methanol-water steam reforming fuel cell hydrogen source system and hydrogen production method

ActiveCN105655612AReduce CO2 concentrationGuaranteed uptimeHydrogenFuel cell auxillariesElectrochemical responseSteam reforming

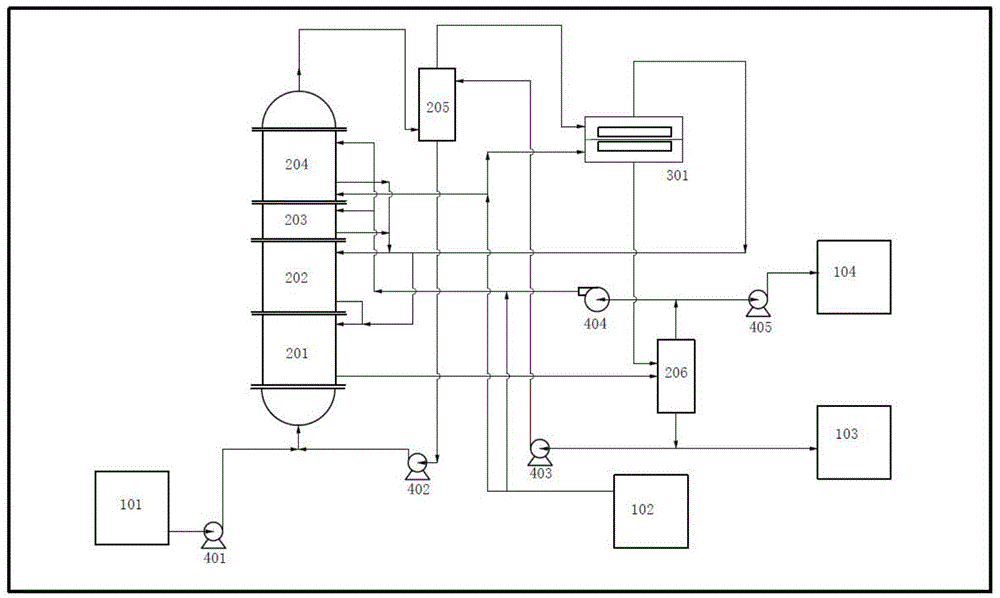

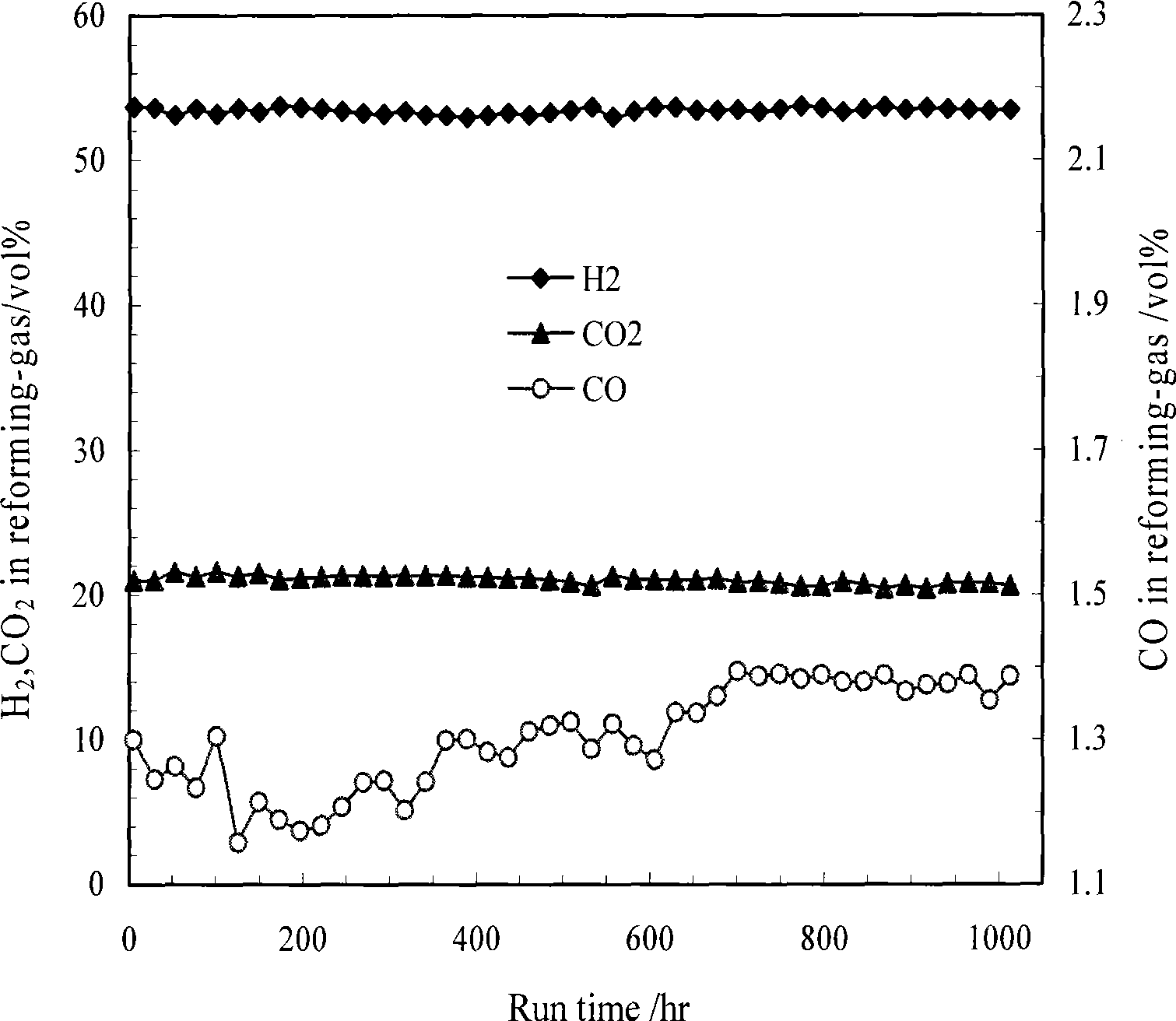

The invention discloses an enclosed methanol-water steam reforming fuel cell hydrogen source system, which comprises a methanol supplying device, a liquid oxygen device, a carbon dioxide storage device, a water storage device, and a methanol hydrogen producing device; wherein the methanol hydrogen producing device comprises an evaporation device, a reforming device, a combustion device, a carbon monoxide selective oxidation reactor, and other auxiliary systems; and the combustion device, reforming device, evaporation device, and carbon monoxide selective oxidation reactor are integrated into a module. According to the hydrogen production method, methanol and water are gasified by the evaporation device and then react in the reforming device to obtain reformed gas; then the reformed gas is processed by the monoxide selective oxidation reactor, the concentration of carbon monoxide in reformed gas is further reduced, and finally the reformed gas is introduced into the fuel cell system to carry out electrochemical reactions. The provided system has the advantages that the system operates in an enclosed space, the operability and safety of the system are both improved; the heat exchange and reactions are well matched, and the whole reforming hydrogen production system is high efficient and compact.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

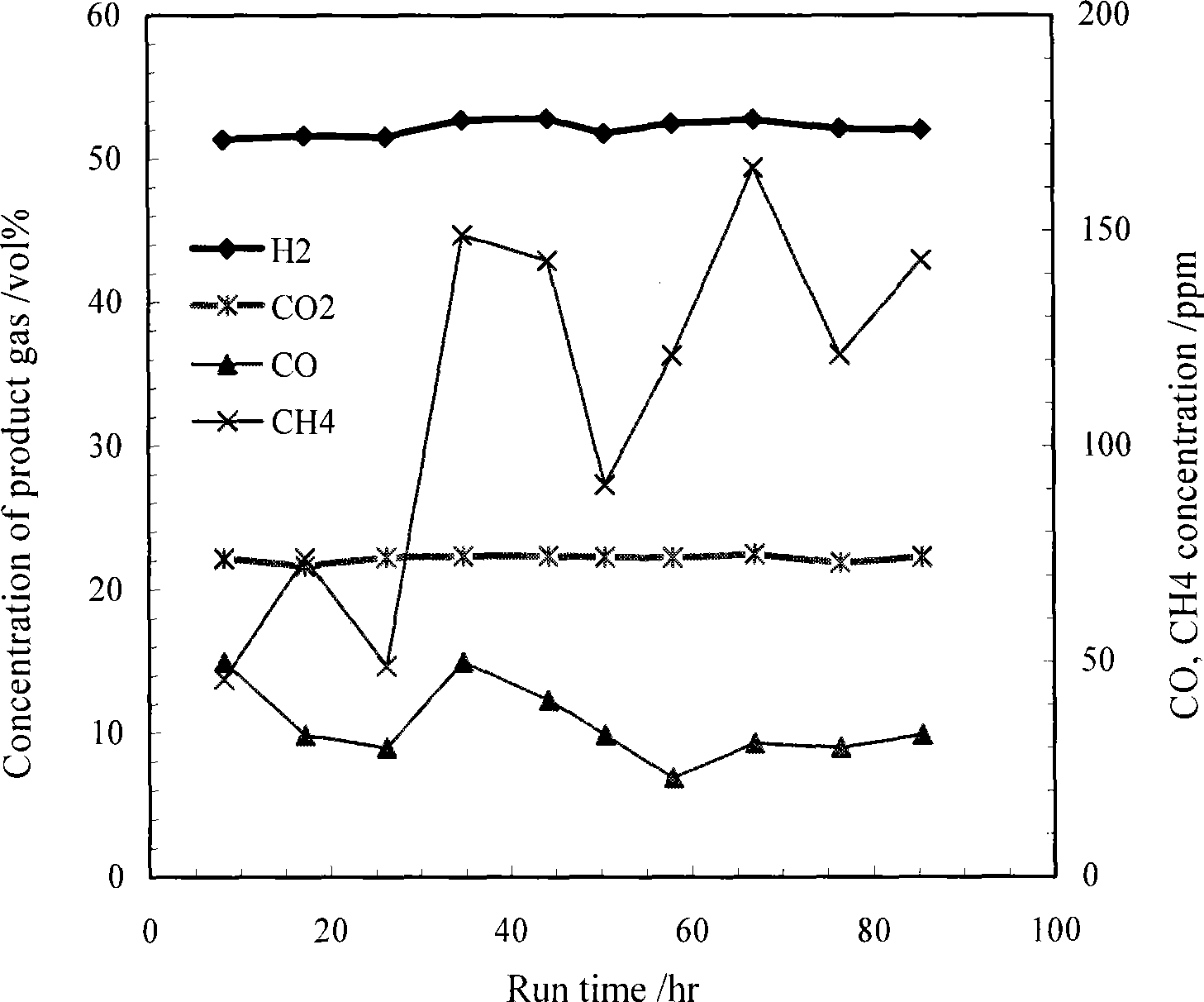

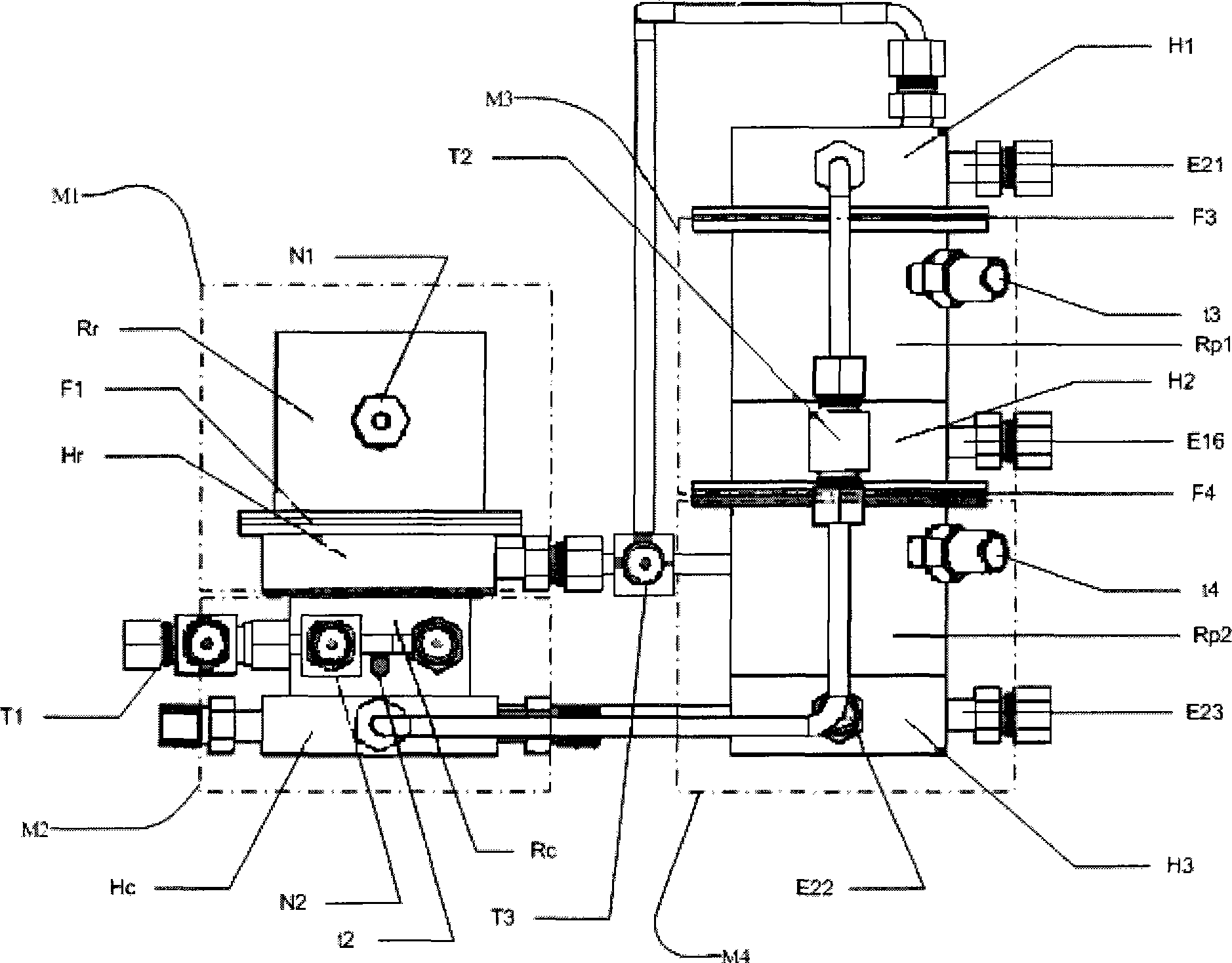

Miniaturized methanol self-heating reforming hydrogen making integrated apparatus and hydrogen production method

The invention relates to a miniaturized hydrogen production integrated device through methanol autothermal reforming and a hydrogen production method. The hydrogen source technology is characterized by integrating main reaction units such as the methanol autothermal reforming and CO selective oxidation (PROX), and only using two stages of the CO selective oxidation without the prior CO water-gas conversion unit; and the hydrogen source integrated system comprises a group of methanol autothermal reforming / heat exchange modules, a group of catalytic combustion / vapourization modules, and two groups of CO selective oxidation / heat exchange modules, wherein the four groups of modules all adopt a welding integration method of an integral catalytic reactor and a microchannel heat exchanger. The device and the method can obtain 1 kW class reformed gas (dry gas) of which CO concentration is less than 30 ppm and H2 concentration is more than 53 percent. The invention is particularly suitable for fuel cell hydrogen source systems in the range of between 100W and 100kW.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

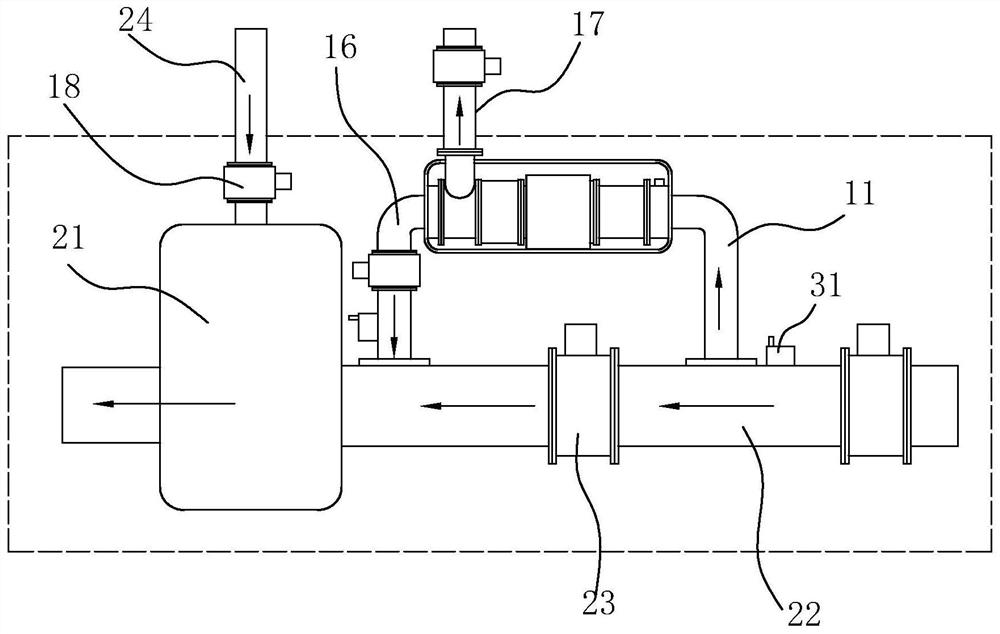

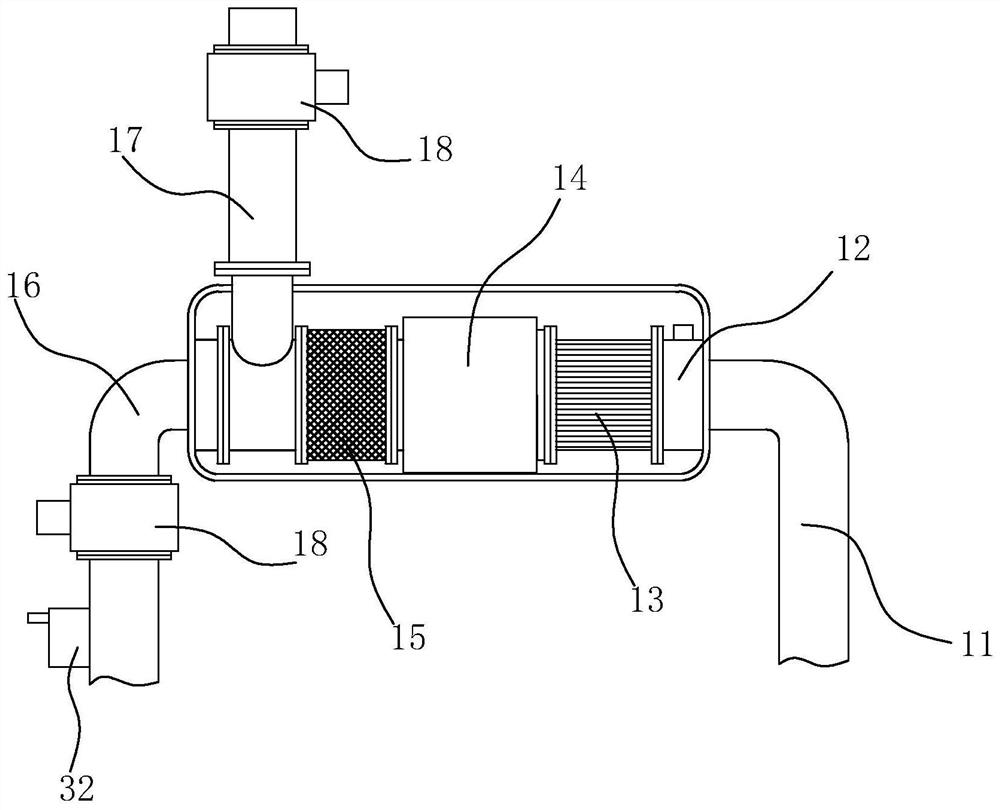

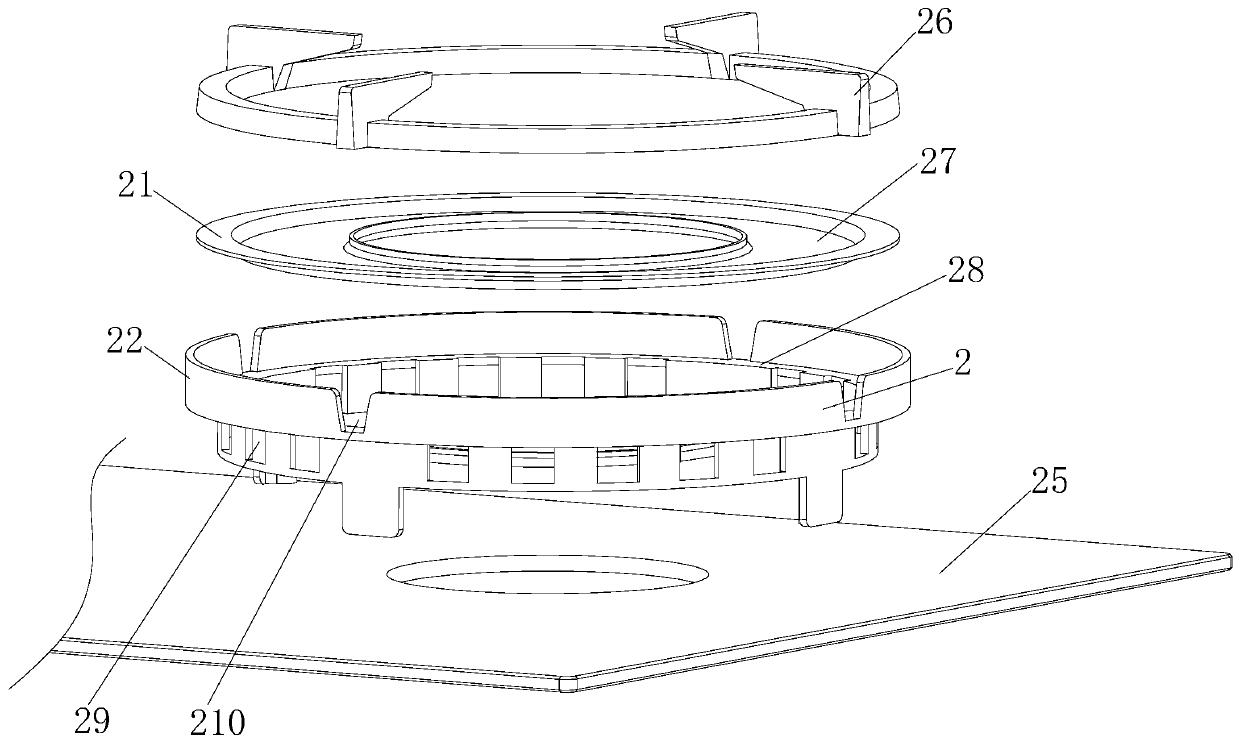

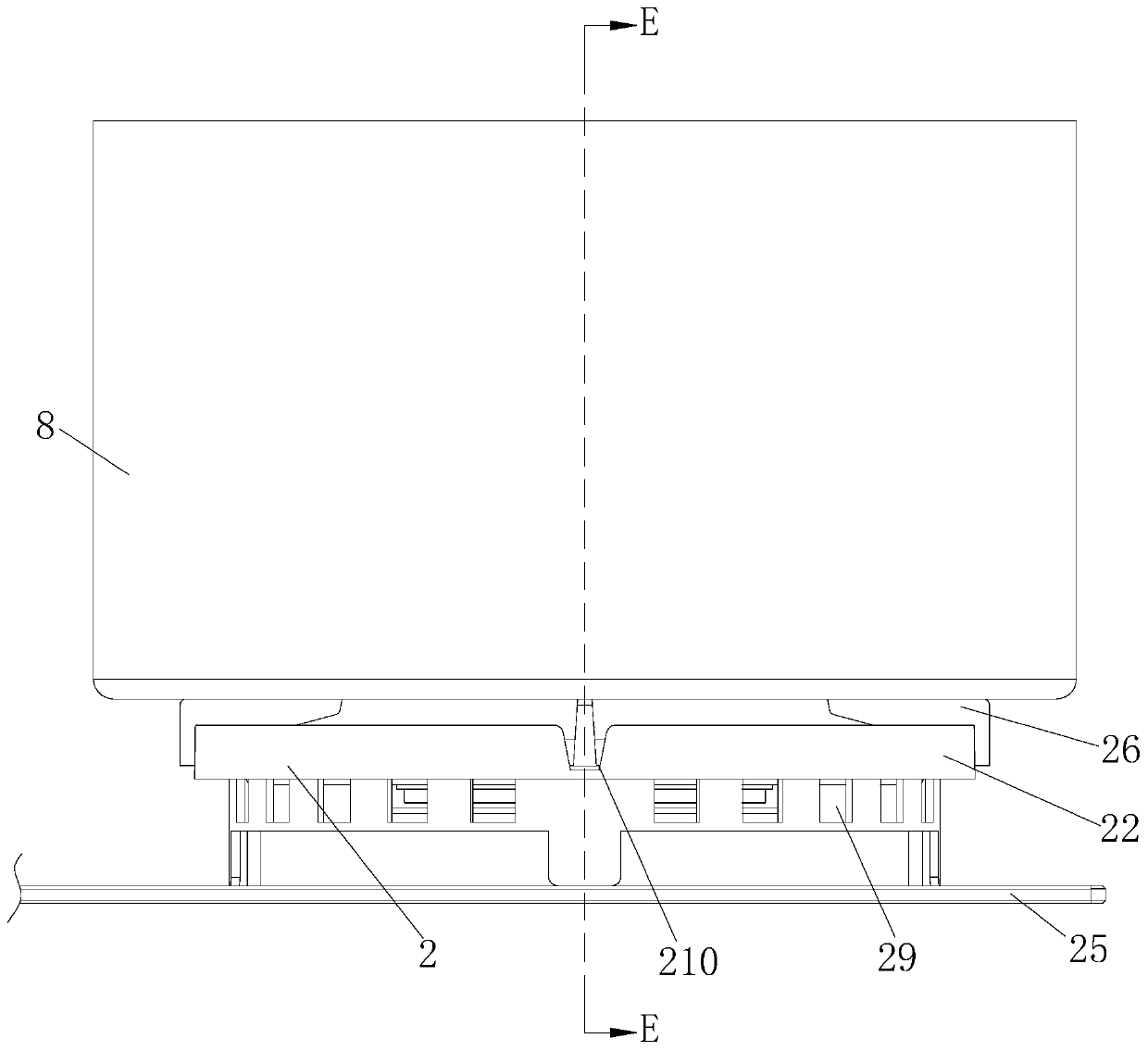

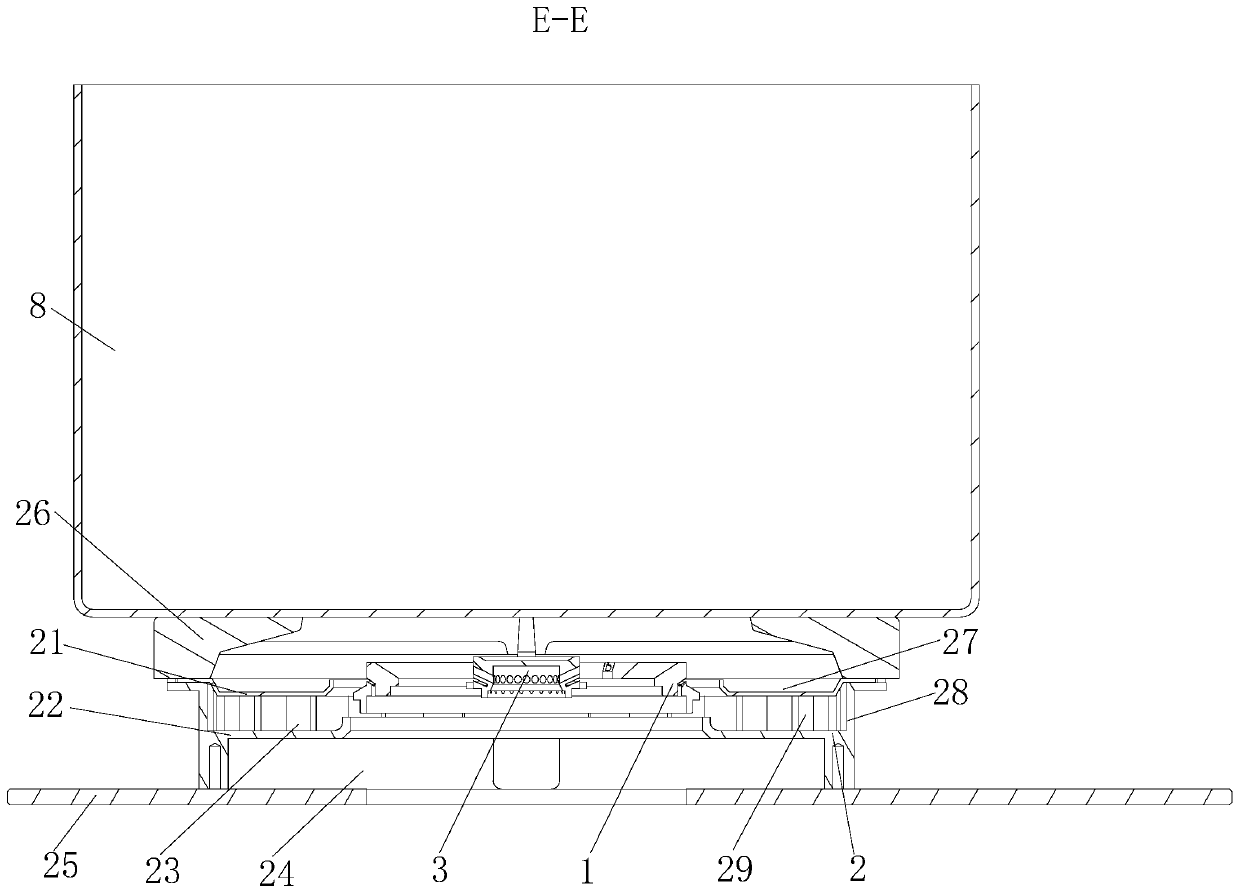

Energy-saving purification device based on internal circulation, air conditioning system and control method of air conditioning system

PendingCN111735114AReduce CO2 concentrationReduce energy consumptionDucting arrangementsMechanical apparatusFresh airProcess engineering

The invention discloses an energy-saving purification device based on internal circulation, an air conditioning system and a control method of the air conditioning system. The energy-saving purification device comprises a filtering and adsorbing unit which is used for adsorbing CO2; an air heating unit which is used for heating air entering the filtering and adsorbing unit so as to release CO2 inthe filtering and adsorbing unit; an air pressurizing unit which is communicated to the filtering and adsorbing unit and is used for increasing the static pressure of the air entering the filtering and adsorbing unit; and a switching unit, wherein the rear end of the air outlet end of the filtering and adsorbing unit is connected to the switching unit, and the switching unit is connected to a purification air outlet pipe and an exhaust pipe. According to the energy-saving purification device, the CO2 concentration of indoor air can be effectively reduced, the fresh air volume can be reduced, and the energy consumption of an air conditioning system can be reduced, so that the designed cold / heat load of the air conditioning system can be reduced, and as the fresh air volume required by a building is reduced, the cold demand of the air conditioning system can be reduced, and the manufacturing cost of the whole air conditioner is reduced.

Owner:森垚能源科技(上海)有限公司

Method for preparing hydrogen from cellulose

The invention relates to a method for preparing hydrogen from cellulose. In the method, a reaction is performed under the hydrothermal conditions of a lower temperature of between 180 and 320 DEG C and lower pressure of between 1 and 20MPa, wherein the process mainly comprises cellulose hydrolysis and hydrothermal reforming of a hydrolysis product; the cellulose hydrolysis is catalyzed by H+ produced through reversible ionization of extra water soluble Bronsted acid, water soluble Lewis acid, solid acid or water; a metal catalyst consists of an active ingredient and a carrier; the active ingredient of the metal catalyst is one or more of Pt, Pd, Ni, Co, Ir, Ru and Rh and accounts for 2 to 10 weight percent of the total amount of the catalyst; and the catalyst is prepared by a chemical reducing method or an immersion method. The method has the advantages of simple equipment, single reactor, no need of special equipment, relatively mild reaction conditions and high product hydrogen yield (20.3mmol / g cellulose) and selectivity and is easy to operate.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

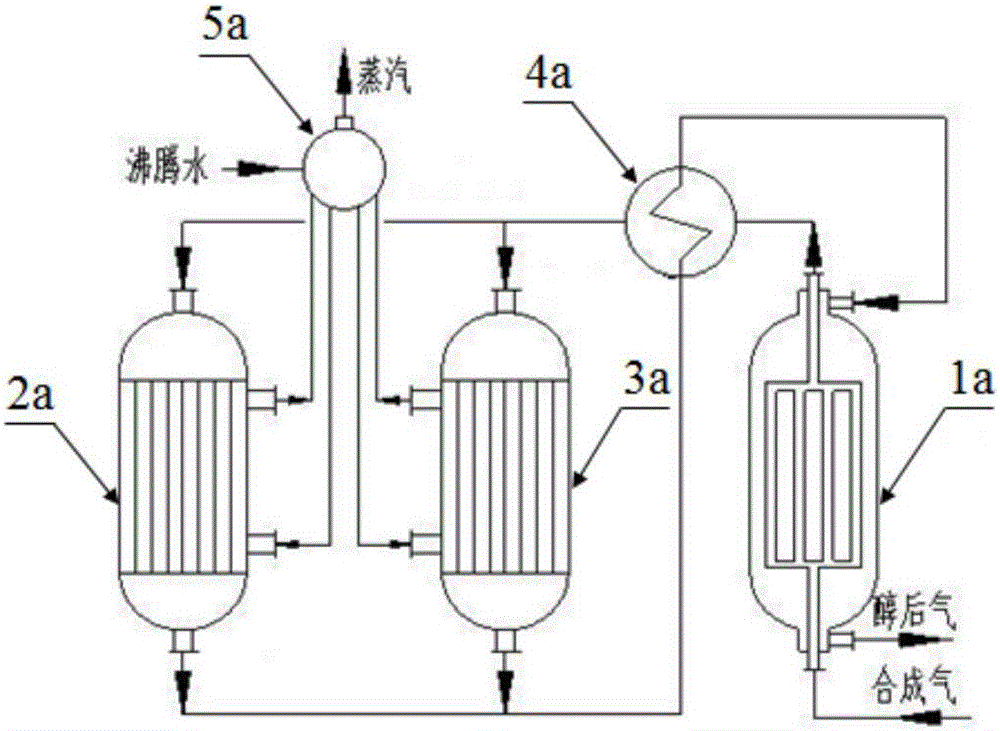

Energy-saving inter-section high low temperature gradient alcohol-division two-stage alcohol generation method and energy-saving inter-section high low temperature gradient alcohol-division two-stage alcohol generation device

ActiveCN105753646AReduce CO concentrationGuaranteed conversion rateOrganic compound preparationHydroxy compound preparationSyngasAlcohol

The invention discloses an inter-section high low temperature gradient alcohol-division two-stage alcohol generation method which comprises the following steps: respectively reheating fresh synthesis gas and recycle gas, mixing the fresh synthesis gas with the recycle gas, introducing the mixed gas into a first reactor, and enabling part of carbon oxides to react to obtain methyl alcohol; cooling a mixture containing synthesis gas and methyl alcohol steam output from the first reactor, guiding the mixture to flow to a first methyl alcohol separator, separating out methyl alcohol, pressurizing the separated gas, preheating, then introducing into a second reactor, and enabling part of carbon oxides to react to obtain methyl alcohol; cooling a mixture containing synthesis gas and methyl alcohol steam output from the second reactor, guiding the mixture to flow to a second methyl alcohol separator, separating out methyl alcohol, preheating the separated gas which separately serves as the recycle gas and fresh synthesis gas, mixing the recycle gas and the fresh synthesis gas, and feeding the mixture into the first reactor so as to perform next round of circulating preparation of methyl alcohol. The invention further discloses an inter-section high low temperature gradient alcohol-division two-stage alcohol generation device. The method is relatively high in single-pass alcohol net value and relatively small in circulation ratio, achieves a ton-alcohol steam yield as high as 1.2-1.3 ton, and is high in energy heat recovery amount.

Owner:NANJING GOODCHINA CHEM TECH

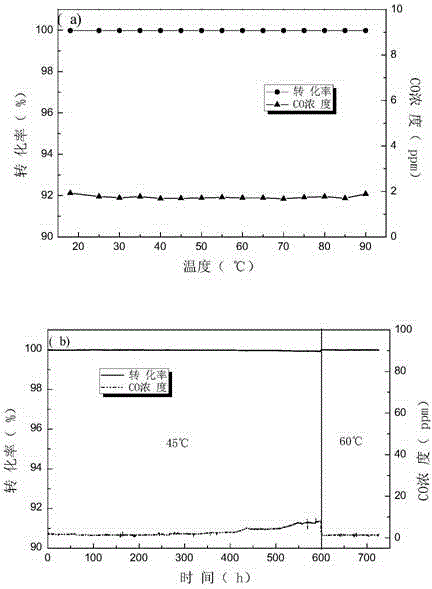

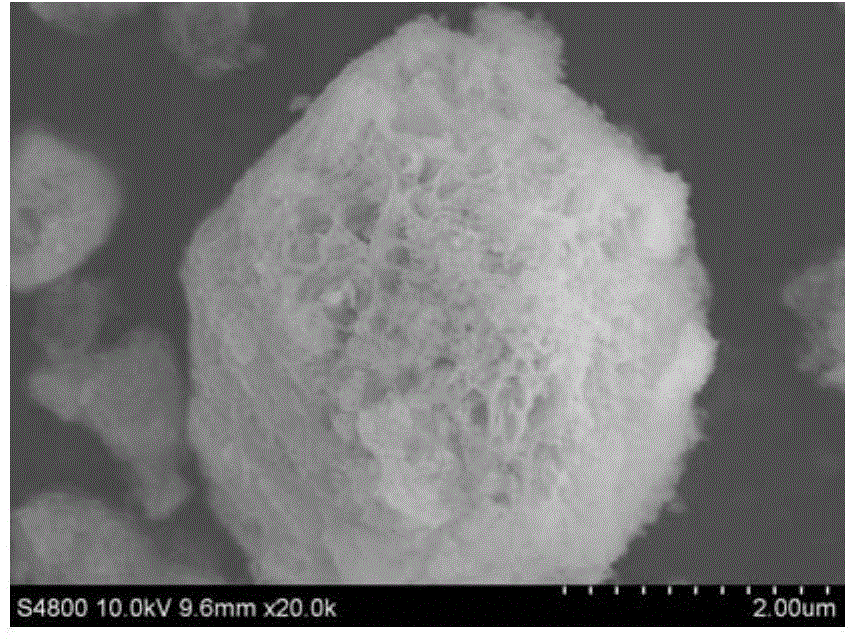

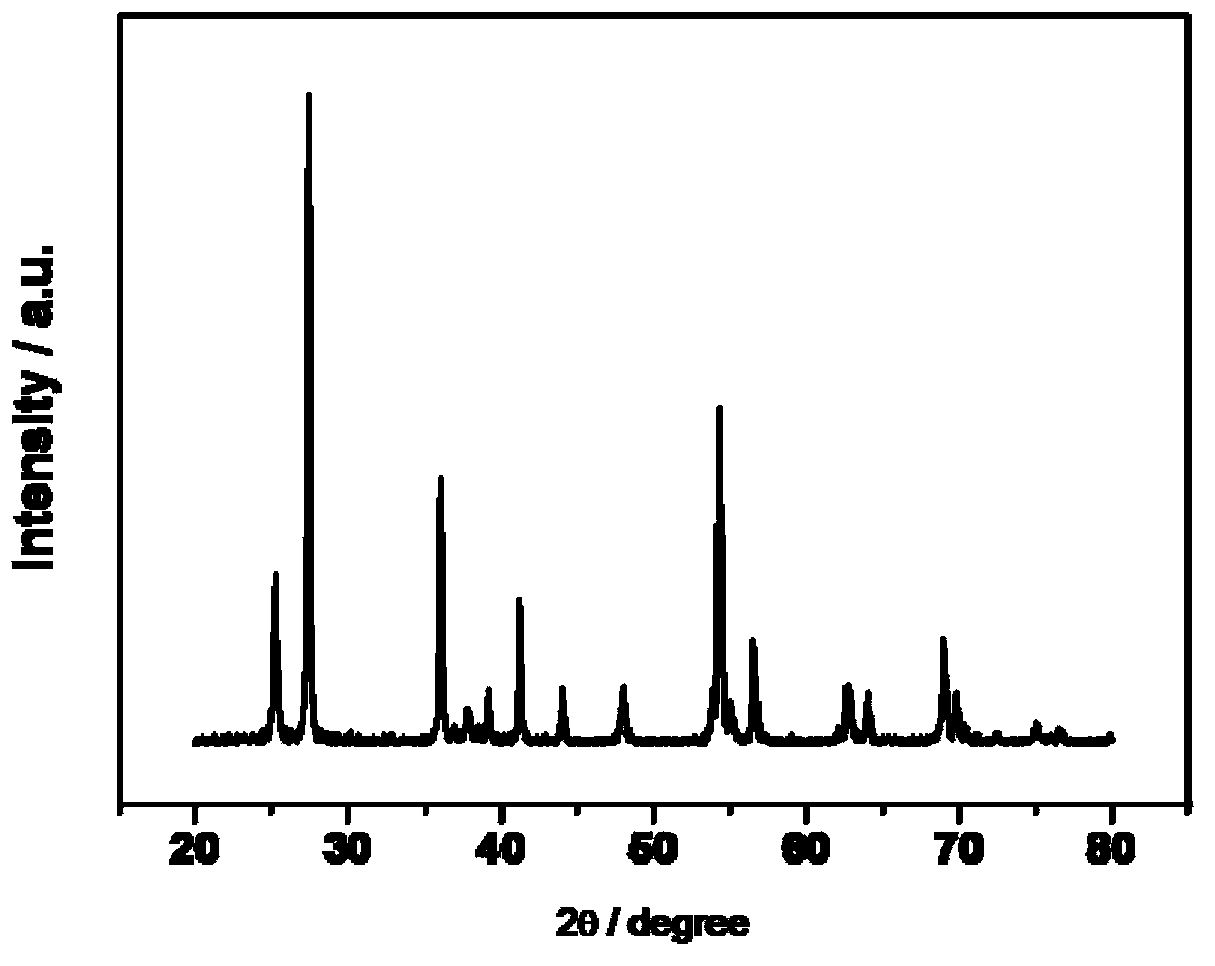

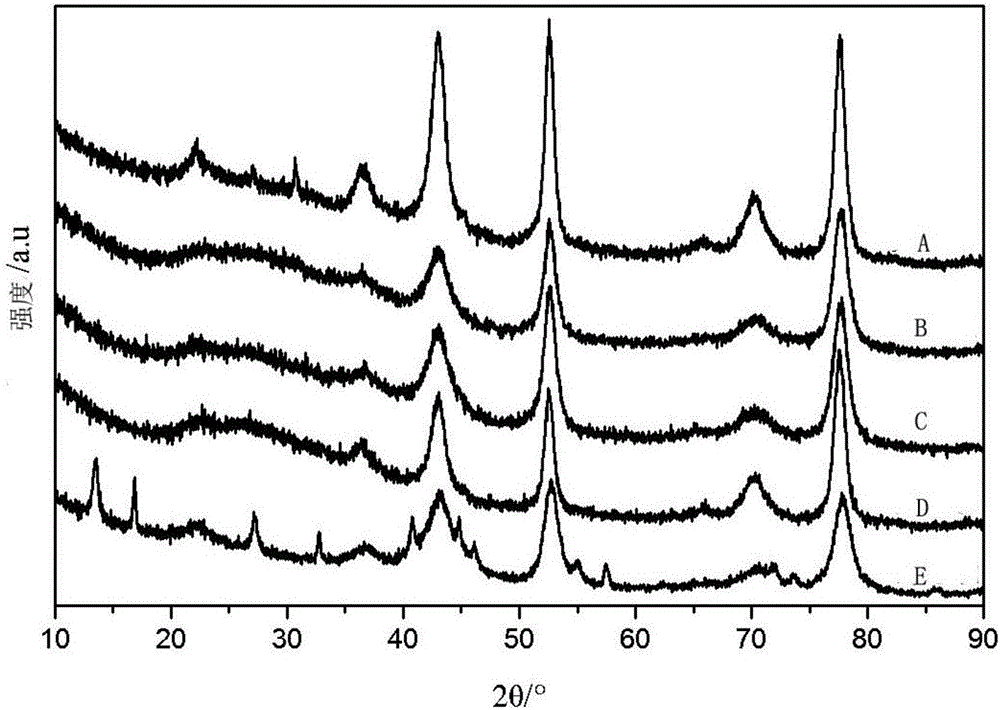

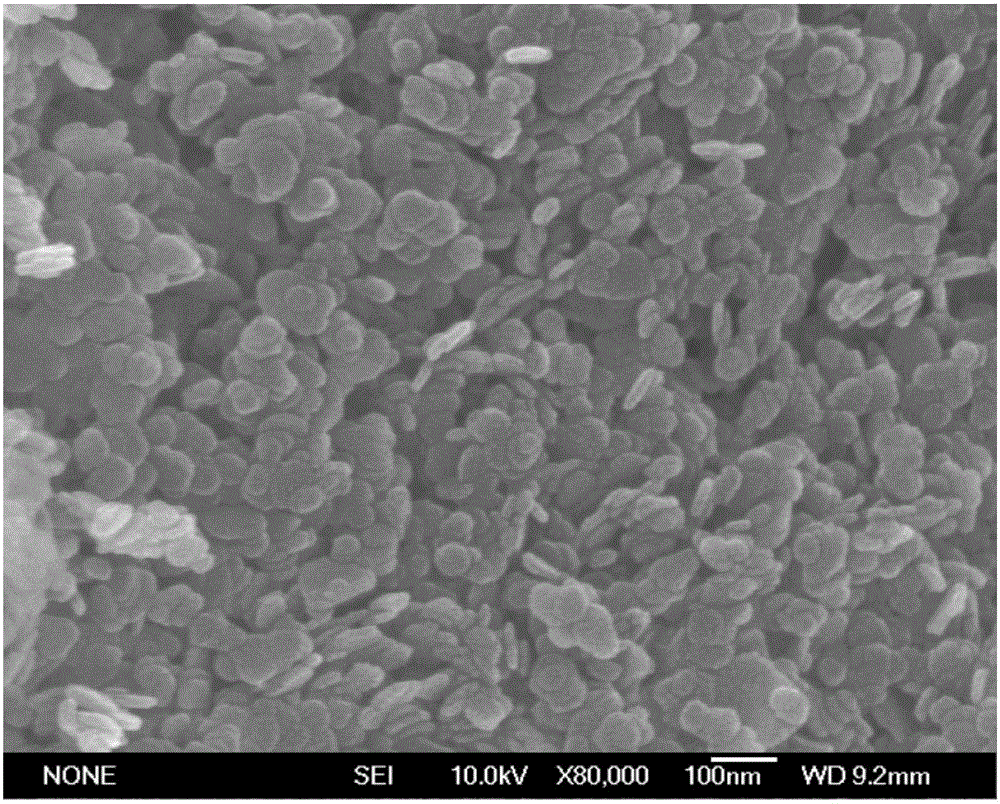

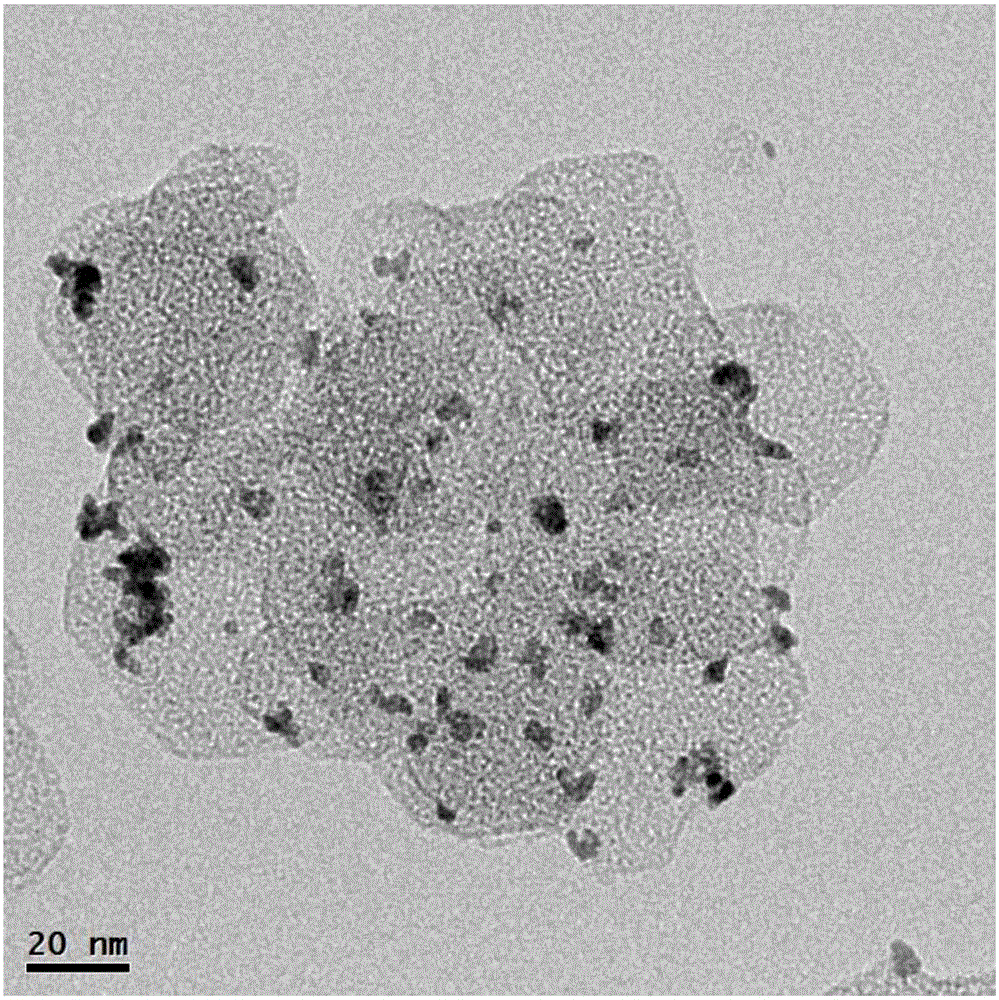

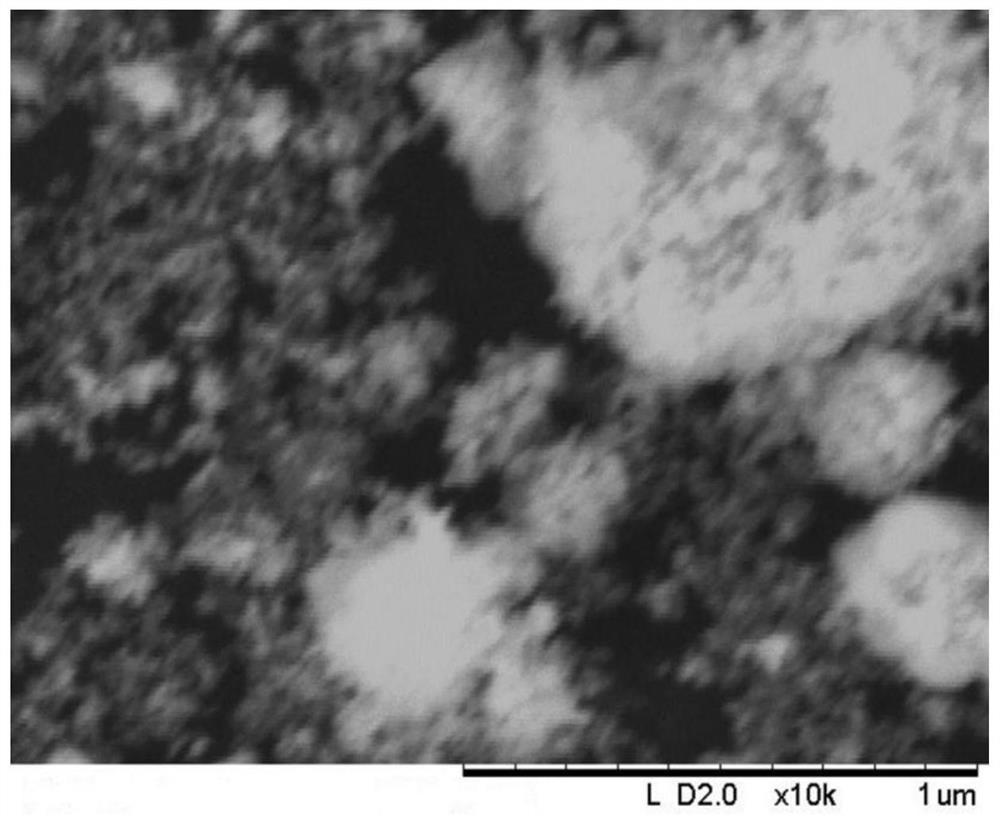

Gold catalyst used for low-temperature catalytic oxidation of carbon monoxide and preparation method thereof

InactiveCN104857957ASingle ingredientSimple preparation processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCerium nitrateCatalytic oxidation

The invention relates to a gold catalyst used for low-temperature catalytic oxidation of carbon monoxide and a preparation method thereof, belonging to the technical field of environmental protection. The gold catalyst is composed of a carrier and active ingredients, wherein the carrier is flower-ball-shaped cerium oxide, and the active ingredients are gold nanoparticles which are attached on the petals gaps of the carrier. The method comprises the following steps: firstly using lactosucrose or / and cerium nitrate and transition metal salt as raw materials so as to prepare a ball-shaped cerium oxide carrier; and using chloroauric acid, ball-shaped cerium oxide and the like as the raw materials so as to prepare the gold catalyst used for the low-temperature catalytic oxidation of carbon monoxide. The method in the invention uses the carrier with a single component, and has simple process of preparation process and good reproducibility; meanwhile, the prepared gold catalyst has high low-temperature activity and good stability, can be widely used in the fields of respirators, CO2 lasers, CO sensors, underground tunnels, submarines, spacecrafts, etc., and is a highly-effective catalyst for the catalytic oxidation of CO in a closed space.

Owner:中国人民解放军防化学院

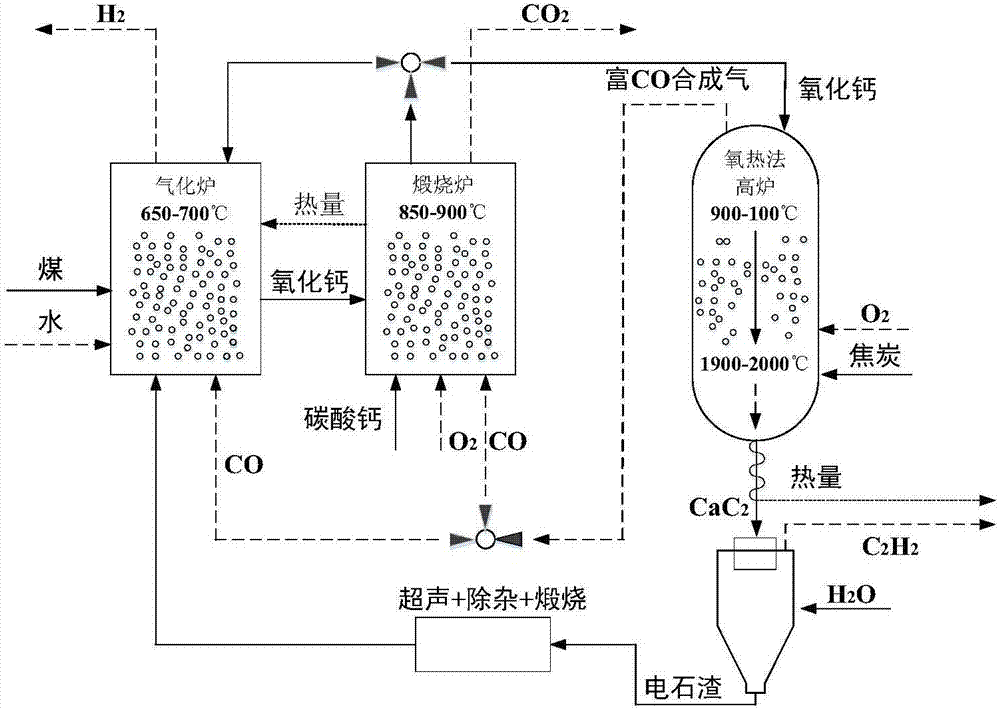

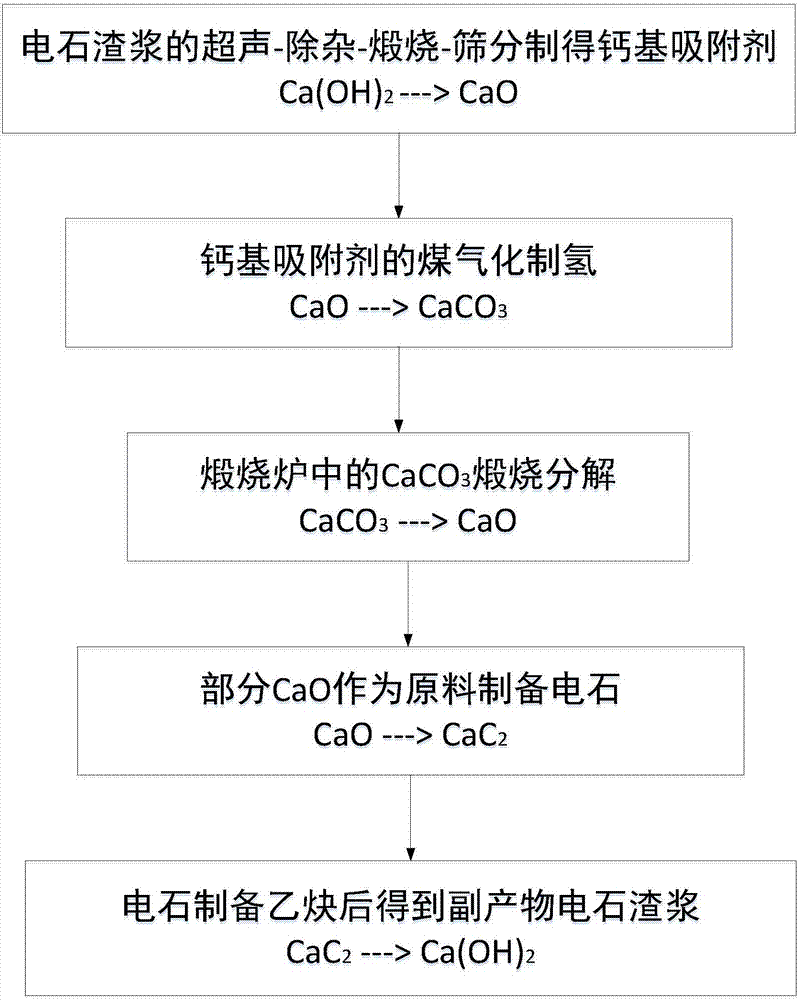

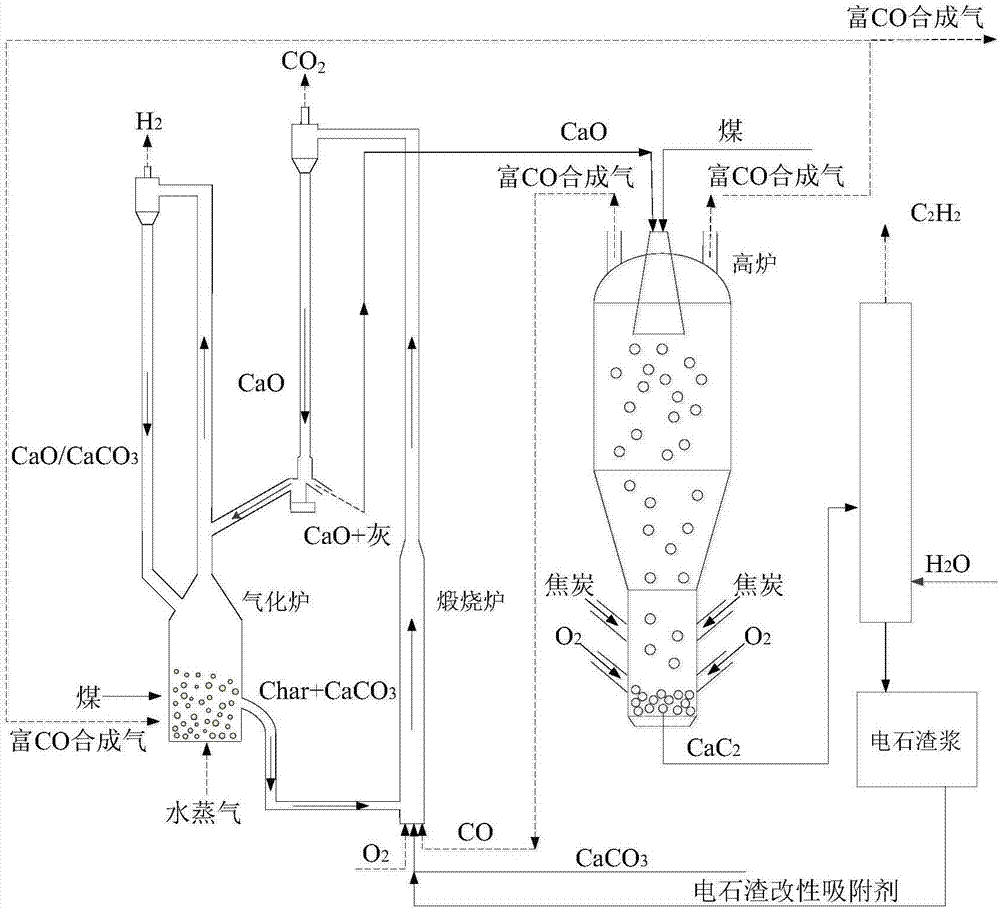

Method for multi-production of simultaneous H2-CO-C2H2 and capturing of CO2 through circulating of calcium carrier

ActiveCN107057772APolygenerationAddressing Industrial EmissionsGenerators with carbide submersionCombustible gas productionHigh concentrationSludge

The invention discloses a method for simultaneous multi-production of H2-CO-C2H2 and capturing of CO2 through circulating of a calcium carrier. According to the method, after industrially produced acetylene sludge slurry is subjected to ultrasonic treatment-edulcoration-calcination processes, acetylene sludge slurry is used as a calcium-base absorbent to be subjected to coal gasification to prepare high-concentration hydrogen, a solid mixture after the coal gasification mainly contains CaCO3 and unconverted coke, after the mixture is is calcinated in an O2 atmosphere in a calcining furnace, CO2 gas is captured, a part of generated CaO is used for producing hydrogen through coal gasification, the other part of generated CaO is used as a calcium carbide raw material for refining CaC2, and meanwhile, CO-rich synthesis gas is obtained and is respectively (1) used as a coal gasification raw material so as to increase hydrogen yield, (2) used for burning so as to supply heat to a system and (3) stored after being subjected to edulcoration and the like; and generated calcium carbide further reacts with water so as to obtain C2H2 gas and the acetylene sludge slurry, and the processes are repeatedly carried out. By virtue of waste utilization and recirculation of the calcium carrier, the simultaneous multi-production of high-purity H2-CO-C2H2 gas and the capturing of CO2 gas.

Owner:SOUTHEAST UNIV

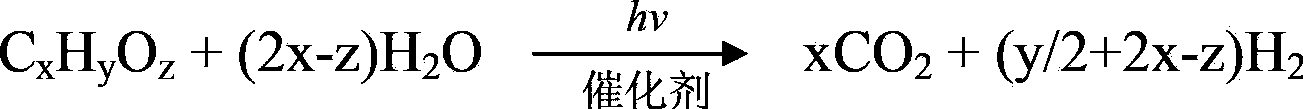

Method for preparing hydrogen CO with concentration by reforming methyl alcohol and biomass derivative in photocatalysis manner

InactiveCN103832971AMeet the requirements of hydrogen sourceFulfil requirementsHydrogenEnergy inputFuel cellsAlcohol

The invention provides a method for improving the catalyst activity of a hydrogen generated by reforming methyl alcohol and a biomass derivative in a photocatalysis manner and lowering the concentration of CO in the hydrogen to a minimum extent. According to the method, the activity of the generated hydrogen is greatly improved by regulating and changing the type and the matching of multicomponent cocatalysts which contain metals and metallic oxides and are carried on TiO2; and meanwhile, the generation of the CO is inhibited, wherein compared with the TiO2 which is not carried with the cocatalysts, the activity of the generated hydrogen of the TiO2 carried with the cocatalysts is improved by more than 20 to 90 times; and particularly, the concentration of the CO in the obtained hydrogen can be decreased below 5ppm. The technology provided by the invention can be applied to the preparation of a hydrogen energy source with an ultralow CO concentration by utilizing solar energy and a biomass at a normal temperature and a normal pressure and under an anaerobic condition so as to meet the requirements of fuel cells and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

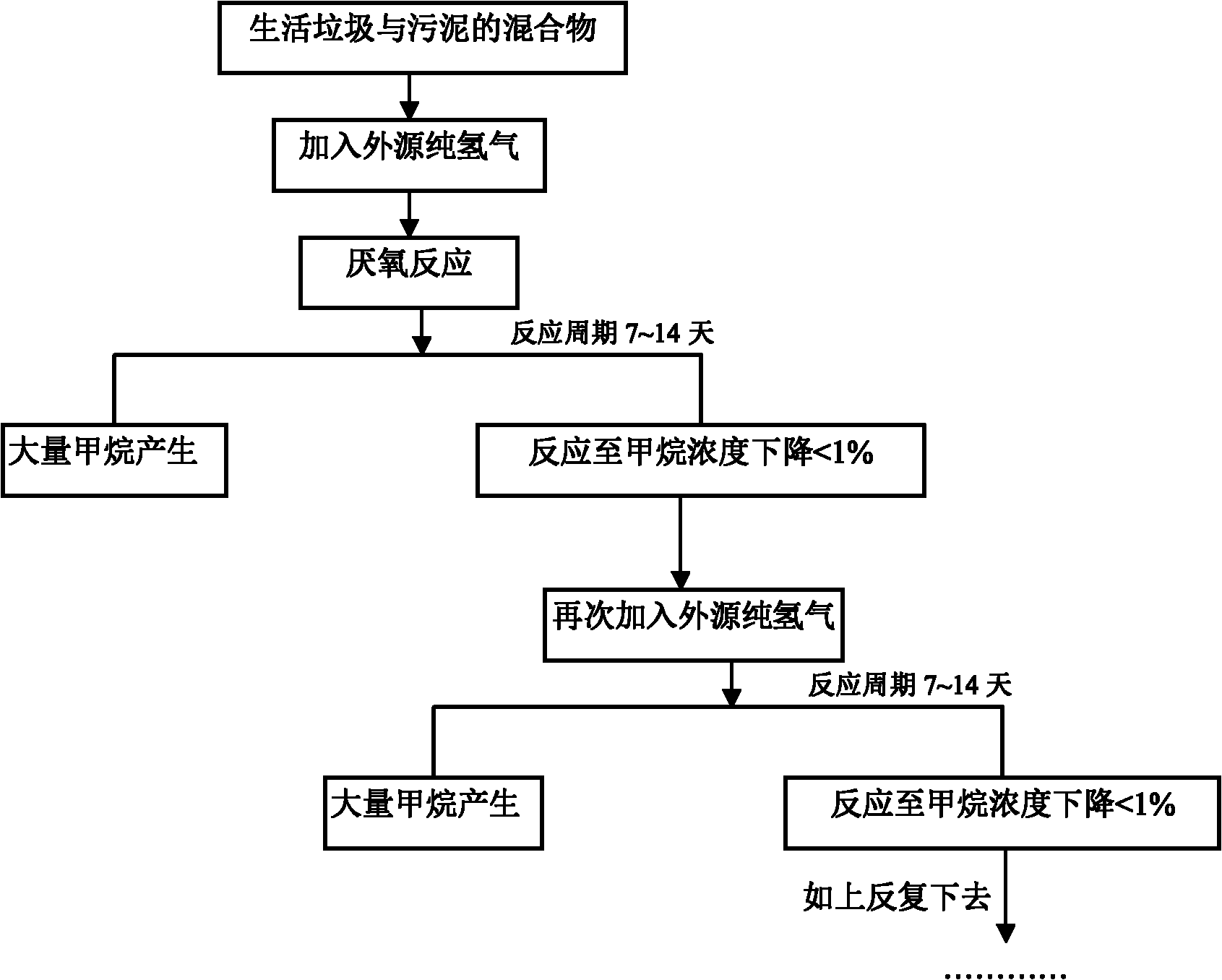

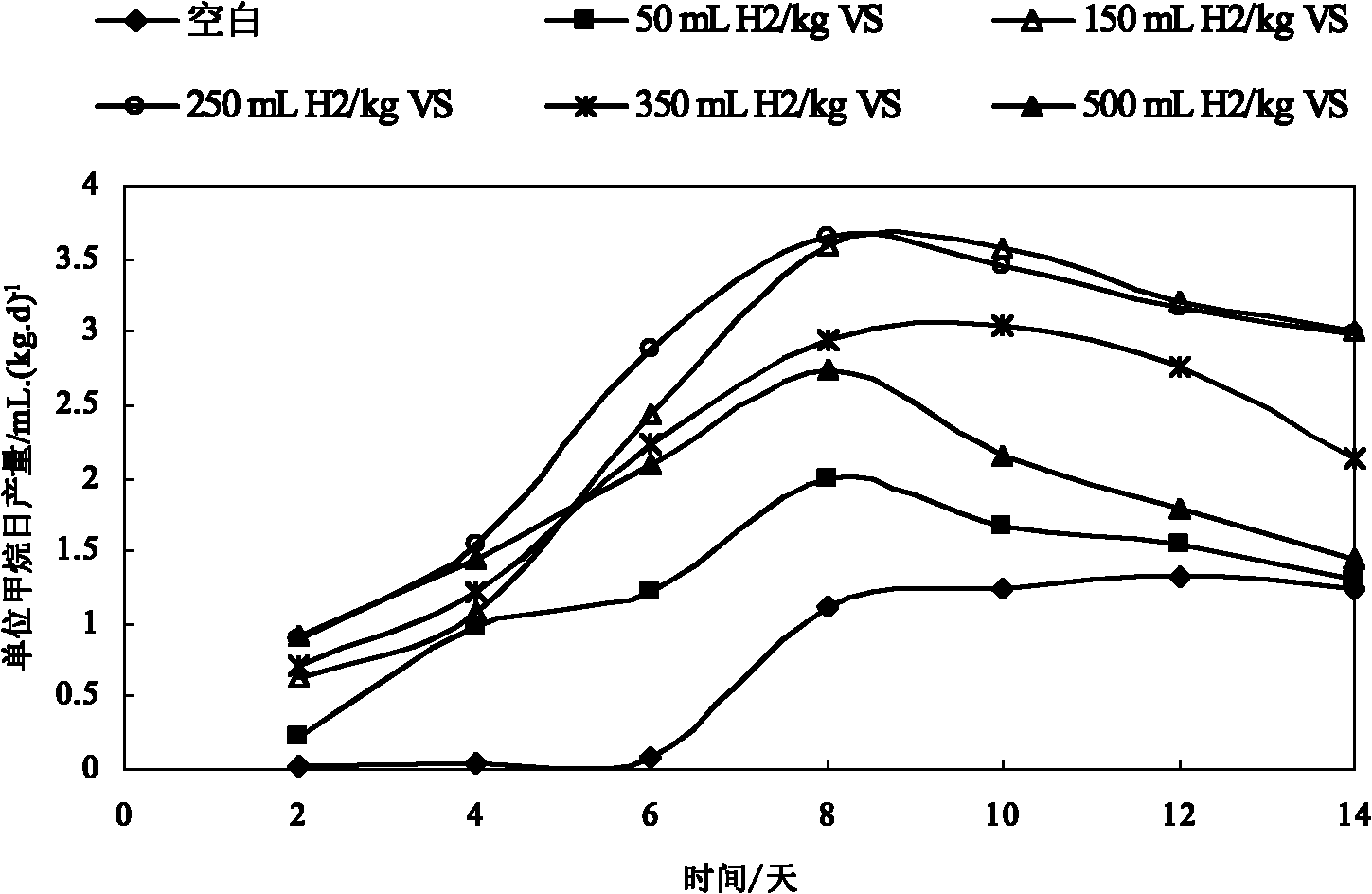

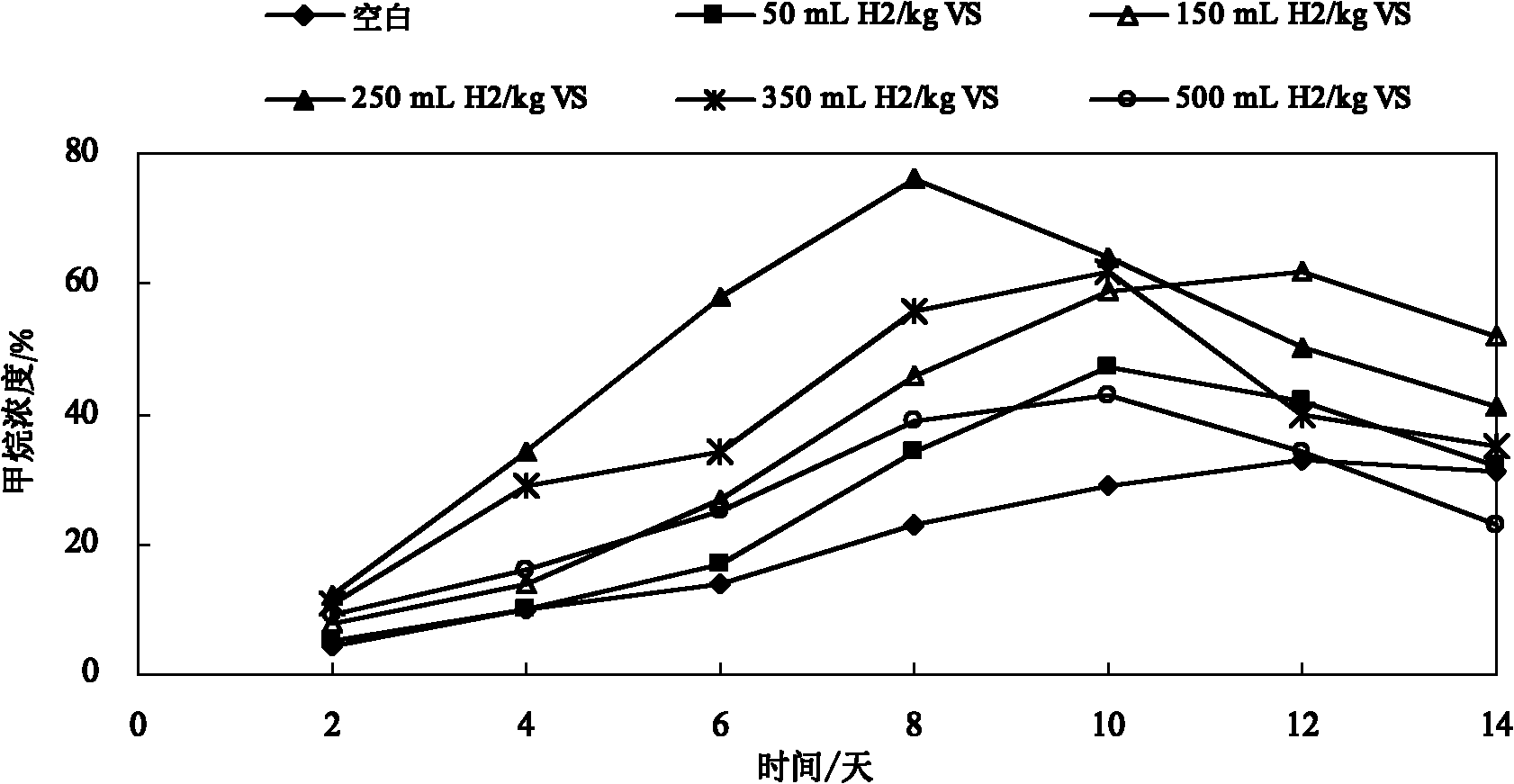

Method for promoting rapid preparation of methane from organic waste by utilizing exogenous hydrogen

InactiveCN102181486AReduce CO2 concentrationRaise the pHWaste based fuelFermentationWater contentGreenhouse gas

The invention relates to a method for promoting the rapid preparation of methane from organic waste by utilizing exogenous hydrogen. The method comprises the following steps of: mixing sludge and domestic garbage in a weight ratio of 1:(2-4), wherein the content of volatile substances (VS) in the mixture is 20 to 65 percent, and the water content is 18 to 68 percent; and performing anaerobic fermentation reaction on the mixture for a period of 7 to 14 days at the temperature of between 35 and 37 DEG C and at the pH value of between 6.5 and 7.5, and introducing exogenous pure hydrogen under the pressure of between 1.1 and 5.5MPa from the bottom of the mixture in the second day of each period, wherein the maximum daily output of the methane can reach 3.65L / kg.d when the introducing amount is 50 to 150mL H2 / kg VS, and is 2.81 times the yield of the methane when the hydrogen is not added. The concentration of the methane can be improved from 33.2 percent to 75.5 percent. The cost is low, the method is easy to operate, the problem of environmental pollution of municipal refuse and greenhouse gas is solved, and the clean energy is also provided, so that the method has good social benefit and economic benefit. The method can be widely applied to the rapid preparation of the methane from the organic waste in middle and small-sized landfill sites.

Owner:TONGJI UNIV

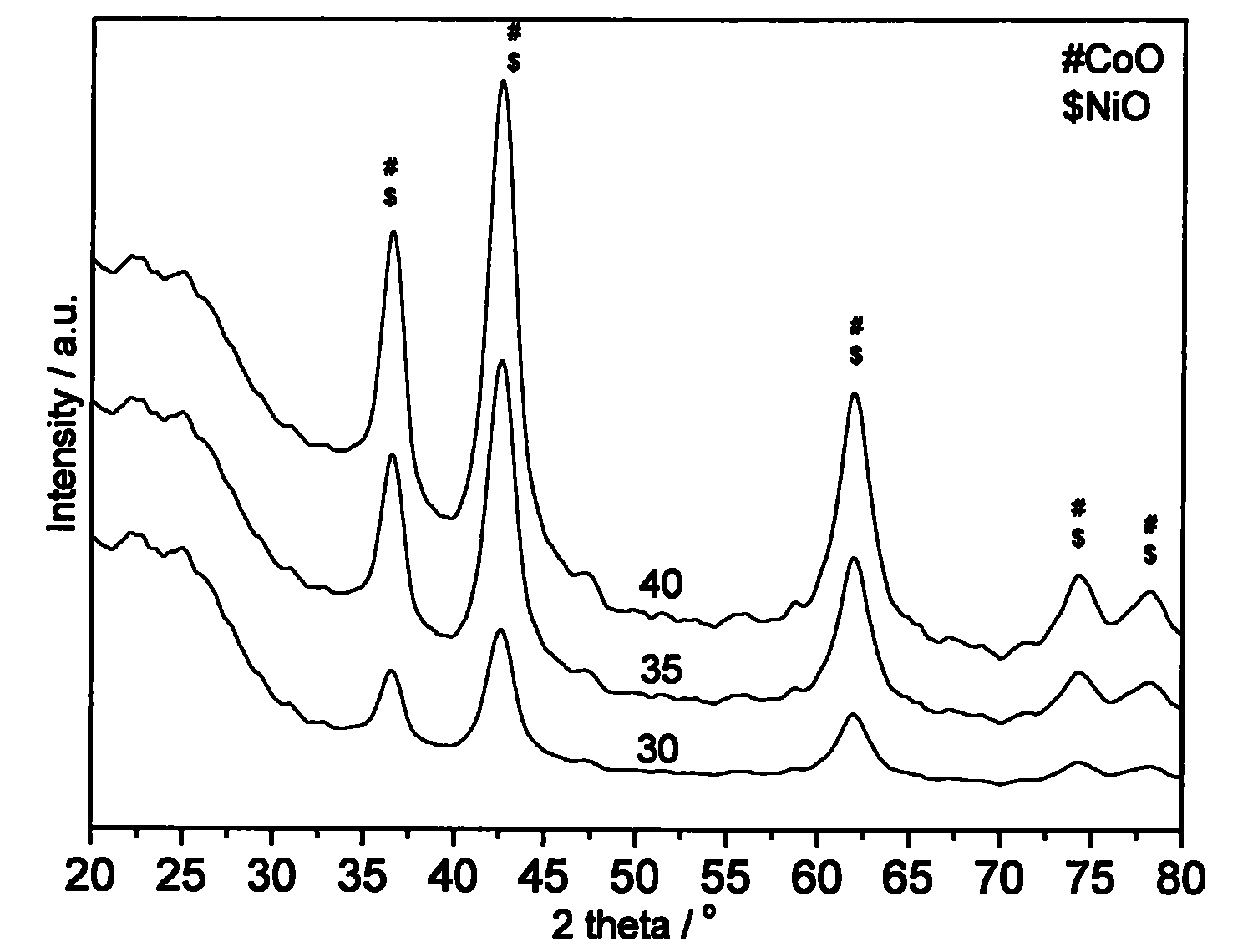

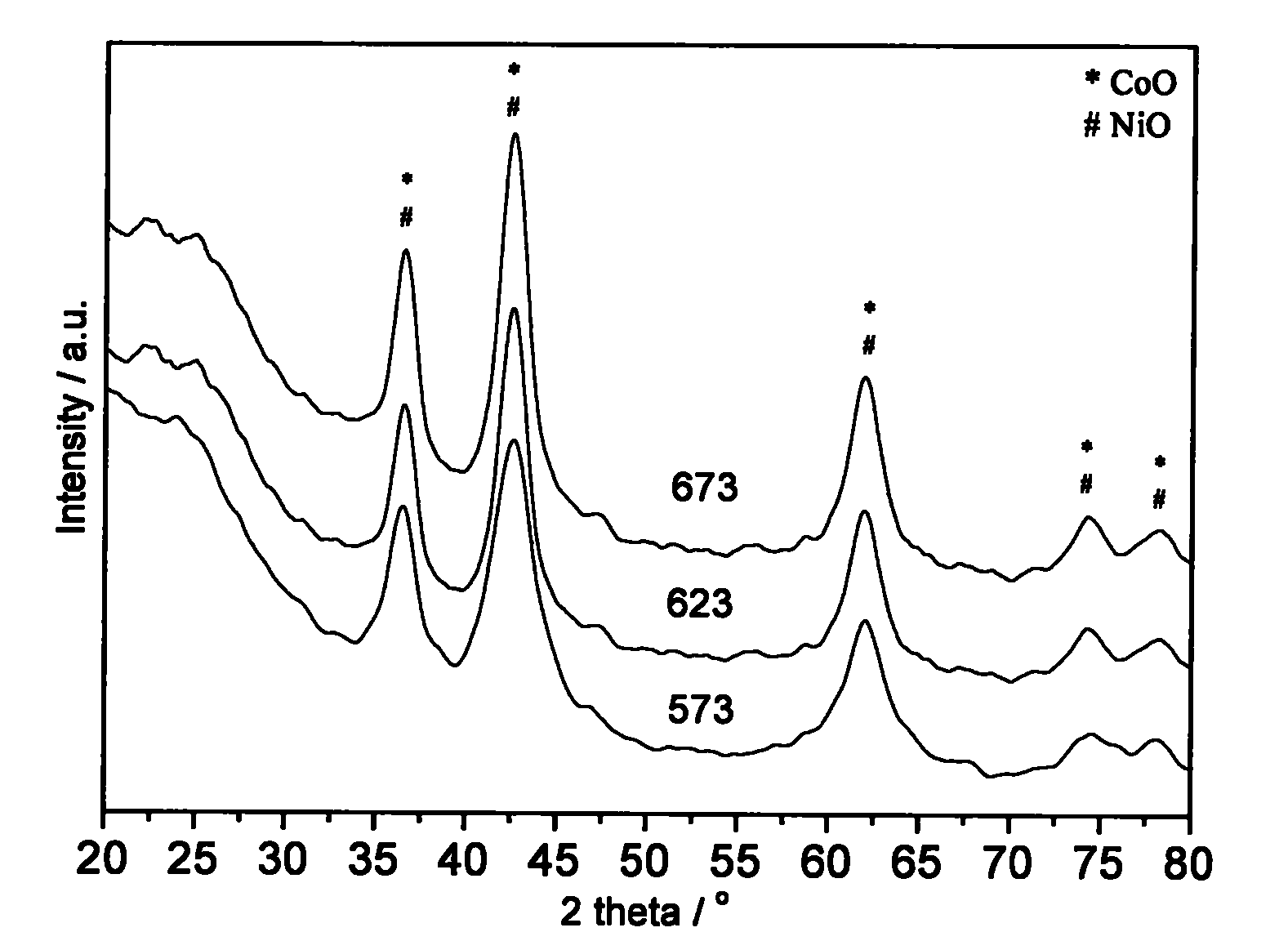

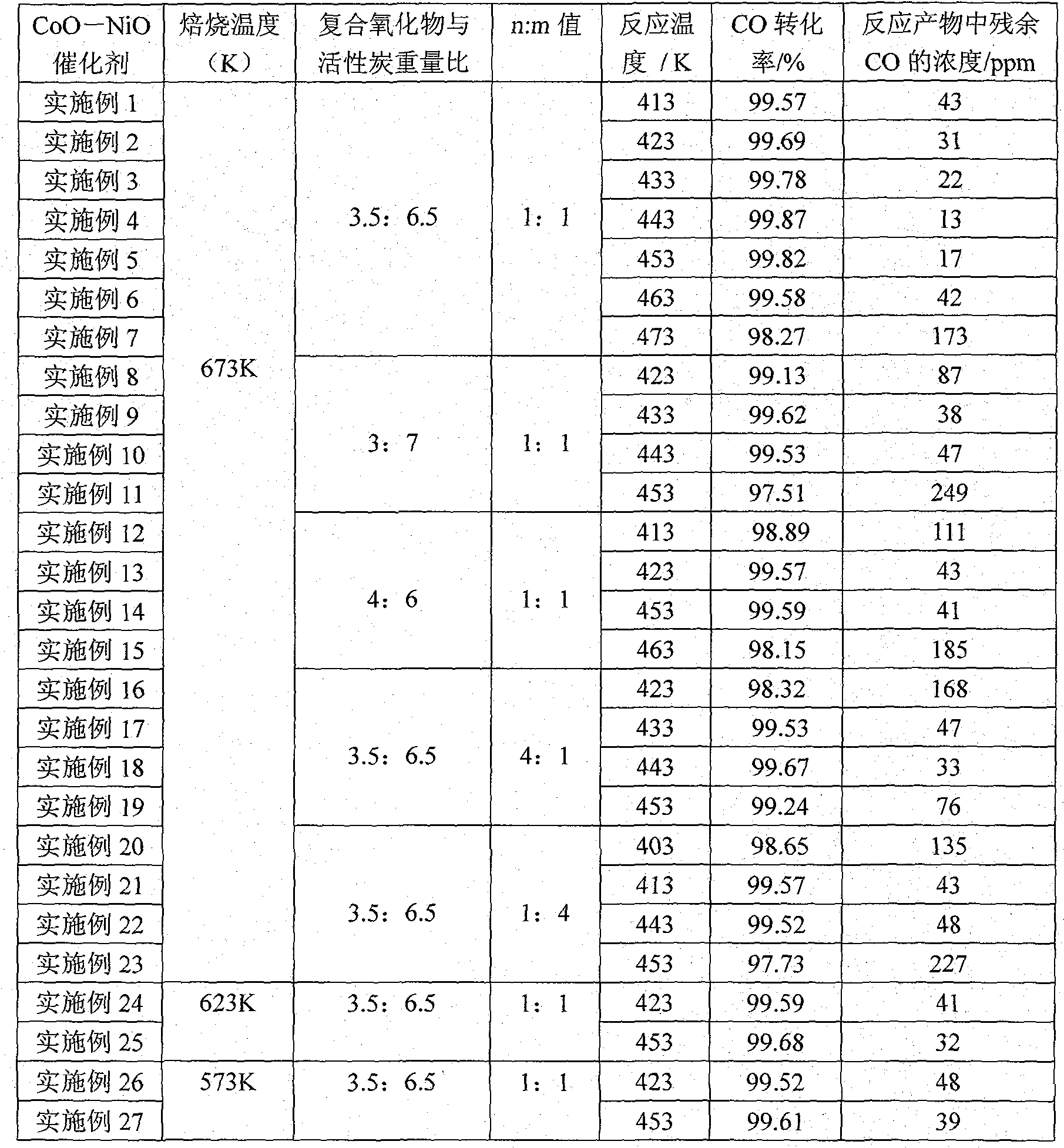

Catalyst for oxidative removal of CO in hydrogen-rich gas and preparation and application thereof

InactiveCN101934229ALow costGood catalytic activity and selectivityHydrogen separation using solid contactMetal/metal-oxides/metal-hydroxide catalystsActivated carbonComposite oxide

The invention discloses a catalyst for oxidative removal of CO in hydrogen-rich gas. In the catalyst, active carbon is taken as a carrier, and an nCoO-mNiO composite oxide formed by non-noble metals such as cobalt and nickel is taken as an active ingredient so that the cost of the catalyst is greatly reduced, and the catalyst has high CO catalytic oxidative activity and selectivity in a low and wide reaction temperature range and can keep more than 99.5 percent of CO conversion rate at a high reaction air speed, effectively reduce the CO concentration in the hydrogen-rich gas to be below 50ppm and meet the standard of a hydrogen fuel for a fuel cell. The invention also discloses a preparation method for the catalyst, which comprises the following steps of: loading a cobalt salt and a nickel salt on the active carbon by a wet immersion method, and then preparing the nCoO-mNiO composite oxide containing low-valence cobalt by high-temperature roasting. The method has the advantages of simple process, mild and easily controlled conditions and good repeatability. The invention discloses application of the catalyst at the same time, which has simple and convenient operation and easy implementation and is very suitable for industrialized popularization.

Owner:CHONGQING TECH & BUSINESS UNIV

Carbon monoxide conversion catalyst carrier, catalyst based on carrier, and preparation method thereof

ActiveCN105032497AImproves hydration resistanceHigh mechanical strengthHydrogenCatalyst carriersAluminum IonHigh absorption

The invention provides a catalyst carrier with conversion and adsorption purification performances. Modified bauxite added into the raw materials of the catalyst carrier has fluxing and pore-forming functions. Through modification, most of iron oxide in bauxite is removed, such that the modified bauxite contains a large amount of high-activity aluminosilicate compound. As a fluxing agent, during catalyst preparation, the aluminosilicate compound assists in significantly improving the migration rates of magnesium and aluminum ions during a roasting process, such that MgAl2O4 generation under low temperature is promoted. Therefore, the catalyst carrier provided by the invention has relatively high hydration resistance and mechanical strength. Also, with the modification treatment, modified bauxite is adopted as a macroporous hard template for preparing the catalyst. With a roasting treatment, macro-pores are formed in the catalyst carrier structure, such that the catalyst carrier has relatively high absorption purification capacity upon macromolecular particles such as oil and dust.

Owner:FUJIAN PROVINCE SINOGASHOLDER EQUIP INSTALLATION CO LTD

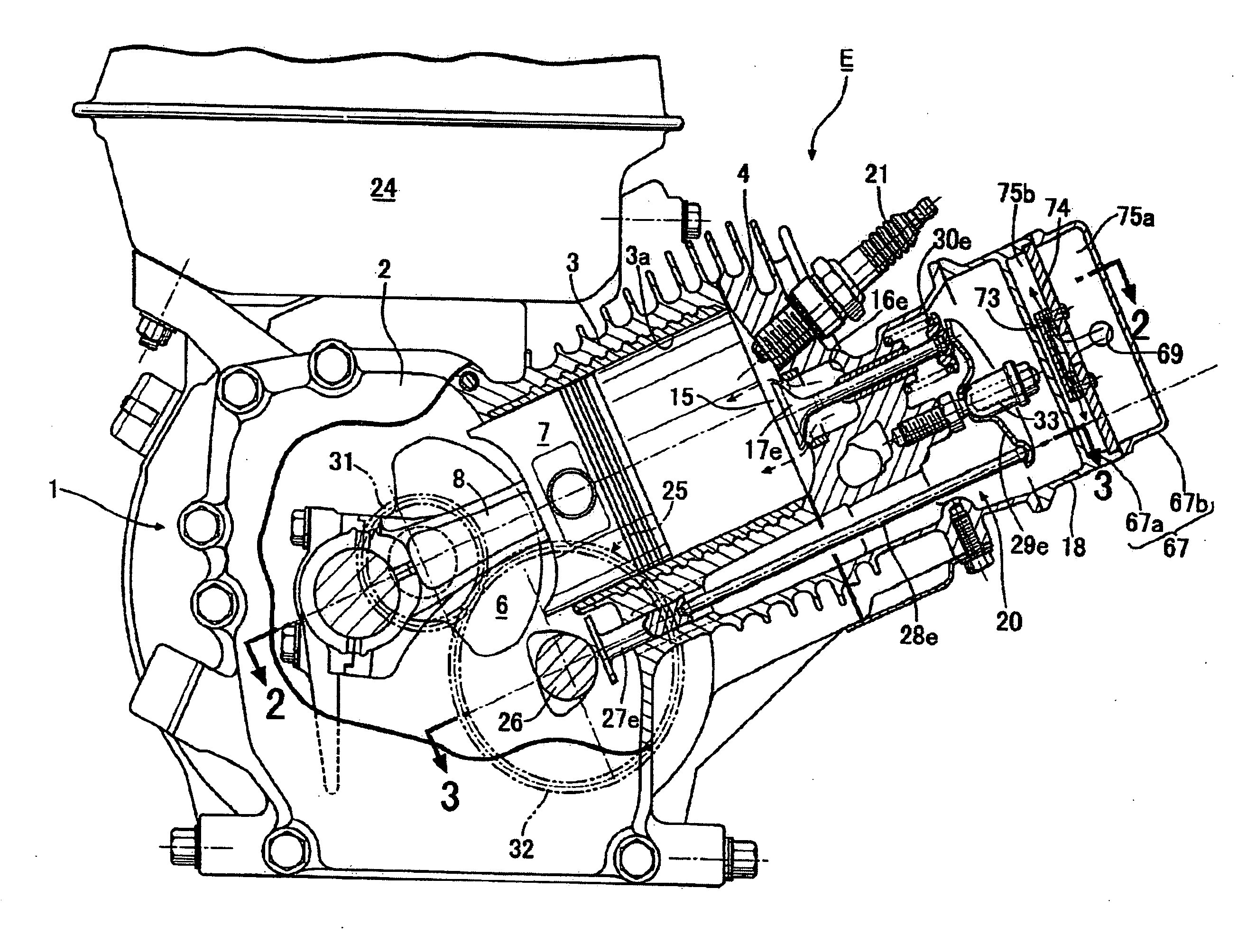

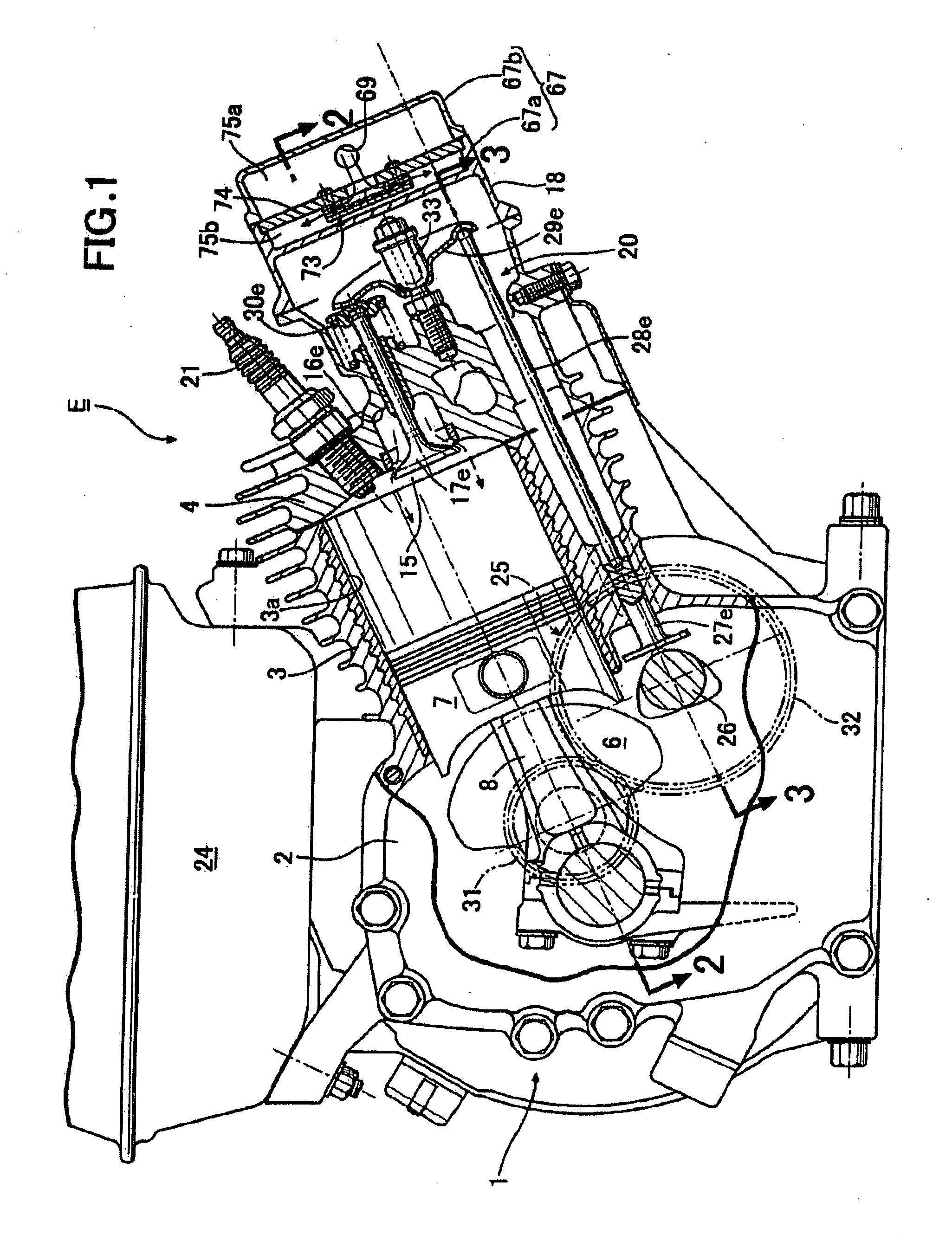

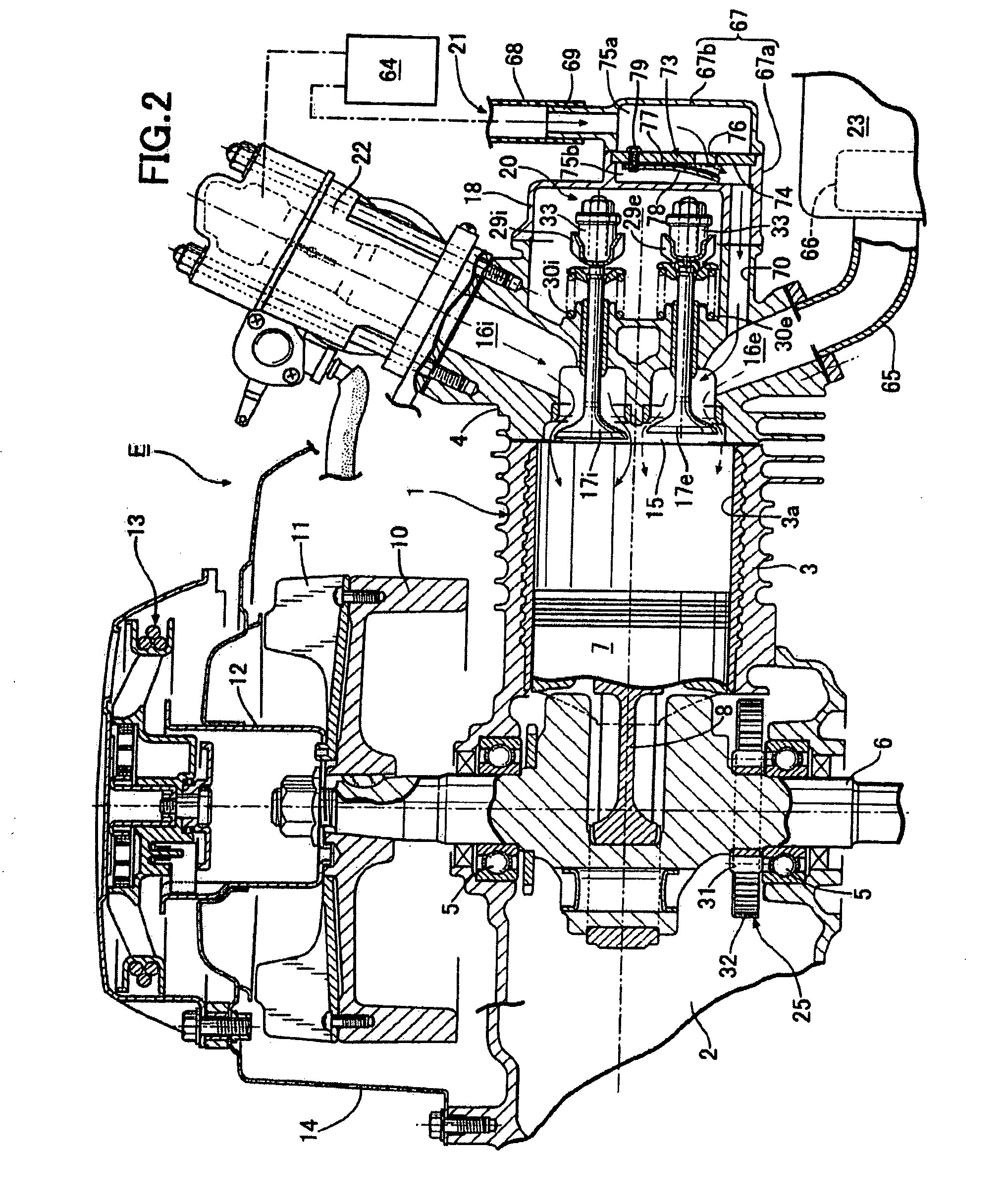

Exhaust emission control system for internal combustion engine

InactiveUS20090282819A1Reduce CO2 concentrationReduce the concentration of nitrogen oxidesValve arrangementsInternal combustion piston enginesSystem structureInternal combustion engine cooling

In an exhaust emission control system for an internal combustion engine, an exhaust gas recirculation device that operates so as to partially open an exhaust valve to introduce exhaust gas into a cylinder in an intake stroke is provided; a secondary air passage capable of supplying secondary air to an exhaust passage is connected to the exhaust passage; and a one-way valve opened by negative pressure applied from the cylinder to the exhaust passage following an operation of the exhaust gas recirculation device in the intake stroke is provided in the secondary air passage. Accordingly, it is possible to provide an exhaust emission control system for an internal combustion engine that allows secondary air to be supplied into an exhaust passage to reduce HC and CO concentrations and also a NOx concentration in an exhaust gas without using an air pump regardless of an exhaust system structure of the internal combustion engine.

Owner:HONDA MOTOR CO LTD

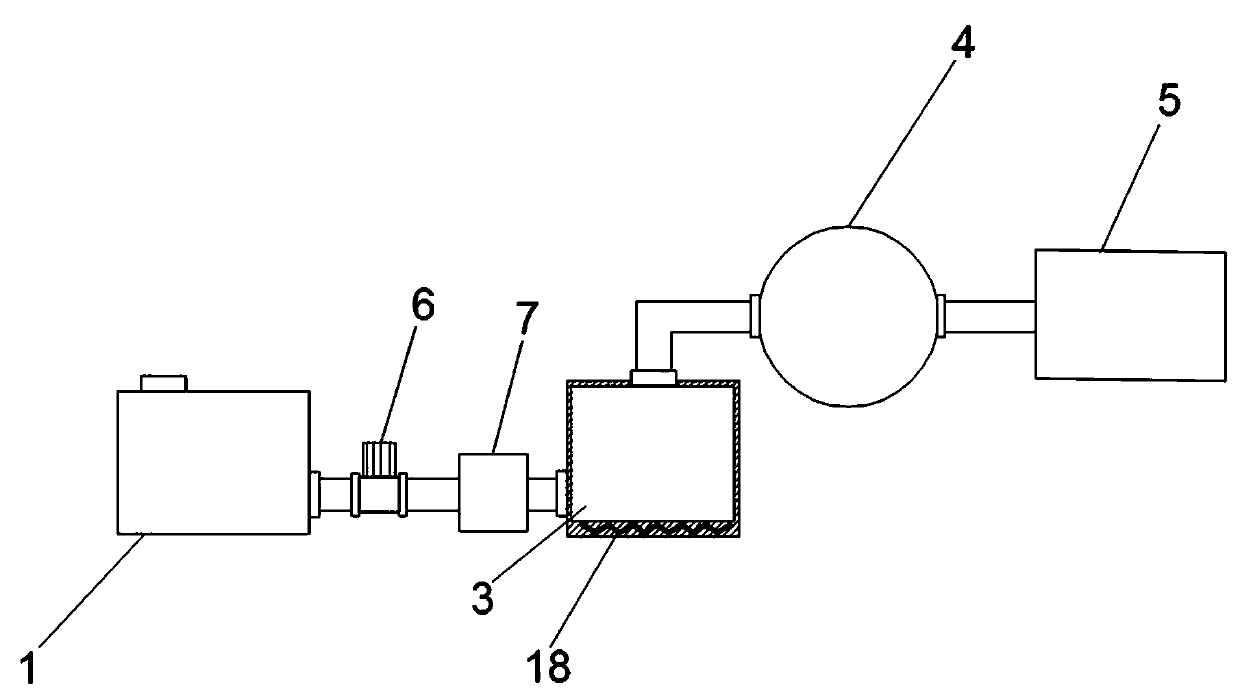

Fuel cell power generation system for hydrogen production by methanol reforming of trace CO

PendingCN110233276AHigh activityEnhanced strong interactionHydrogenFuel cell heat exchangeHydrogen productionControl system

The invention discloses a fuel cell power generation system for hydrogen production by methanol reforming of trace CO. The fuel cell power generation system comprises a control system, and a liquid storage bin, a liquid outlet pump, a vaporizer, a reactor, a condenser and a low-temperature proton exchange membrane fuel cell which are sequentially connected through pipelines. The fuel cell power generation system also comprises a plate heat exchanger; a catalyst for hydrogen production by methanol reforming is arranged in the reactor; the catalyst for hydrogen production by methanol reforming contains an active component containing NiO and Cr2O3, a carrier containing ZrO2 and Al2O and an auxiliary agent. The fuel cell power generation method for hydrogen production by methanol reforming oftrace CO and the low-temperature proton exchange membrane fuel cell are cooperatively used to avoid the step of hydrogen purification and the device module thereof, to be capable of using the mature low-temperature proton exchange membrane fuel cell system for power generation, and the device system is low in cost and reliable in performance, and can be applied to the fields of automobiles, shipsand base station power sources in a large scale.

Owner:中科氢焱零碳人居科技(苏州)有限公司

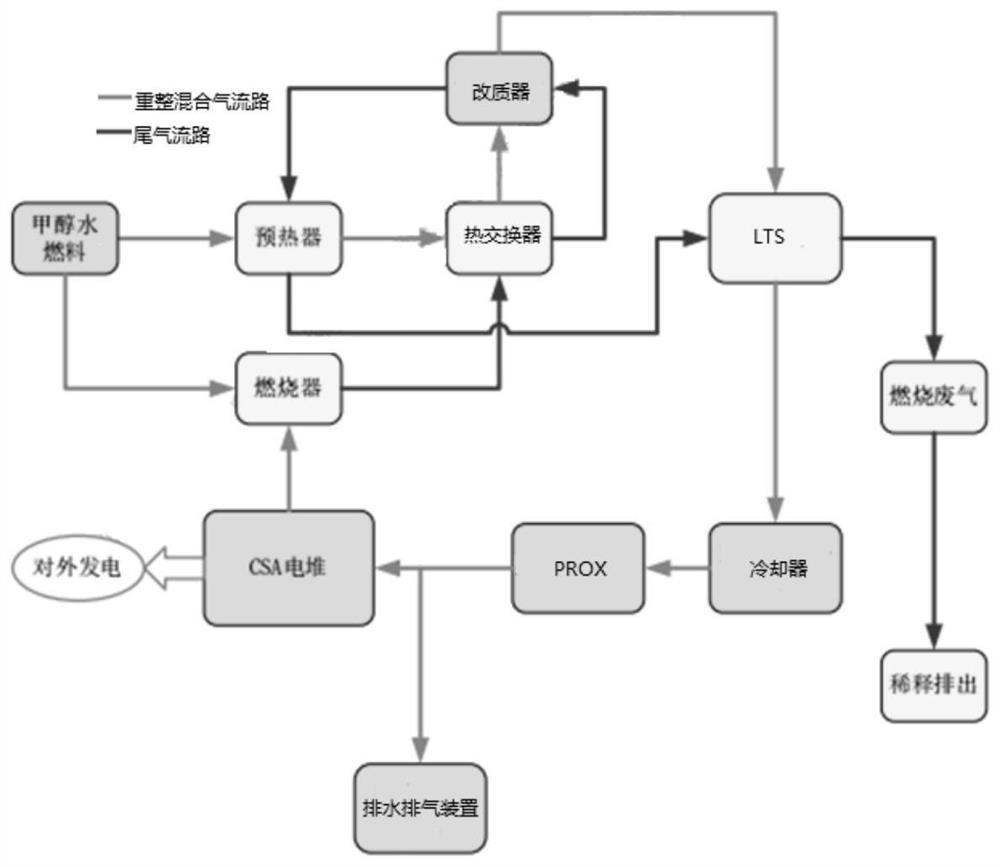

Methanol-water fuel reforming hydrogen production system

PendingCN111747378AReduce CO concentrationImprove the purification effectHydrogen separation using solid contactHydrogen/synthetic gas productionPtru catalystCatalytic oxidation

The invention discloses a methanol-water fuel reforming hydrogen production system. The system comprises a methanol-water fuel feeding pipe, an evaporator, a modifier, a CO oxidation removal device and a hydrogen-rich mixed gas conveying pipe which are connected in sequence. The CO oxidation removal device comprises an LTS catalytic oxidizer and a PROX catalytic oxidizer, a copper-zinc-based catalyst is arranged in the LTS catalytic oxidizer, and a ruthenium-based catalyst is arranged in the PROX catalytic oxidizer. The hydrogen-rich mixed gas is subjected to staged oxidation treatment throughthe LTS catalytic oxidizer and the PROX catalytic oxidizer, so that the CO concentration in the gas is gradually reduced to guarantee that CO is completely removed. According to the system, the conversion rate of methanol can reach 100%, CO in the reformed mixed gas can be completely removed, the starting time of the system is short, the reforming hydrogen production condition can be rapidly achieved, energy consumption is low, the hydrogen production speed is high, the hydrogen production cost is low, the energy conversion efficiency is high, environmental protection and energy conservationare achieved, and the power generation efficiency is high after the system is in butt joint with a fuel cell stack.

Owner:摩氢科技有限公司

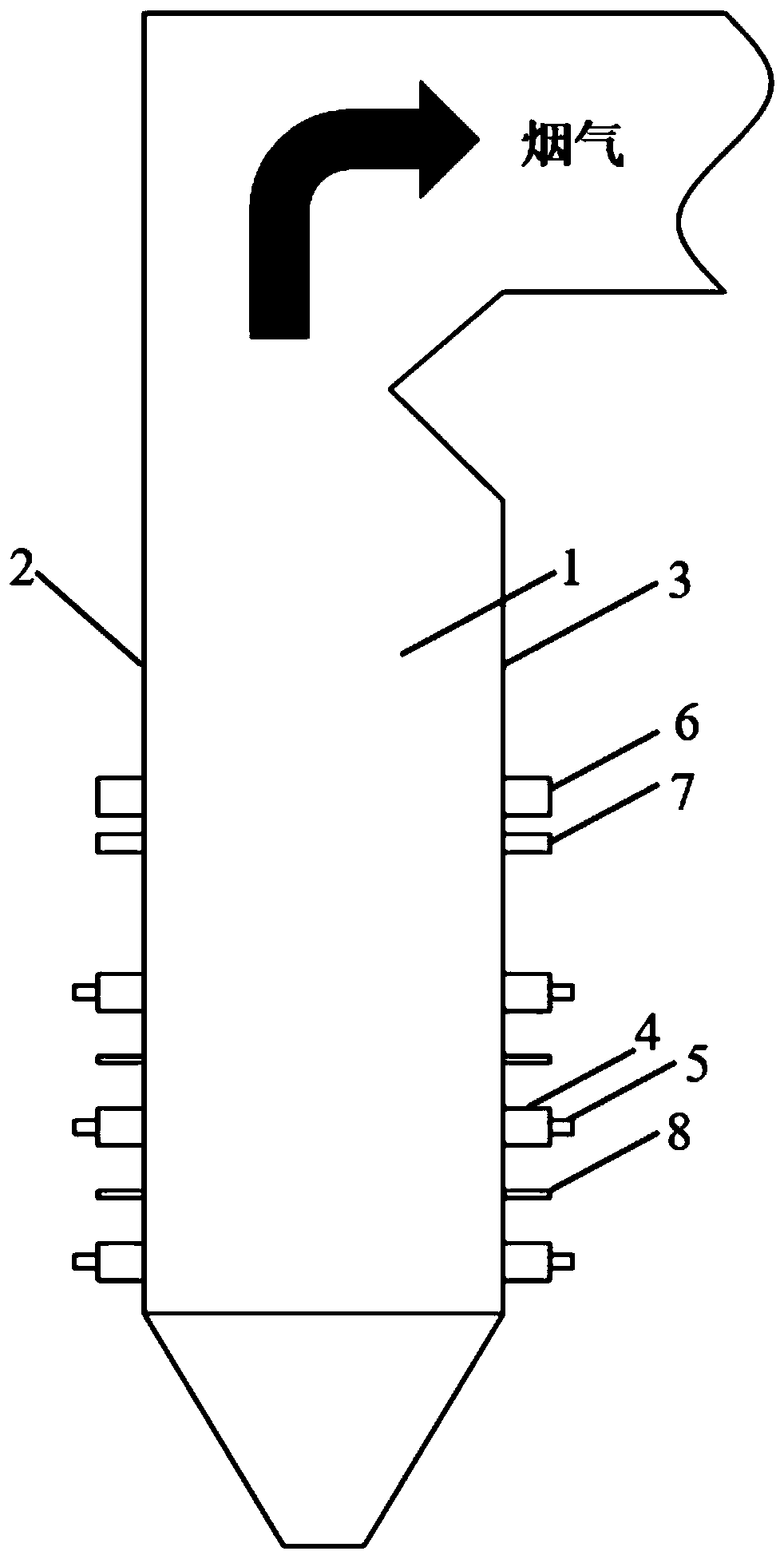

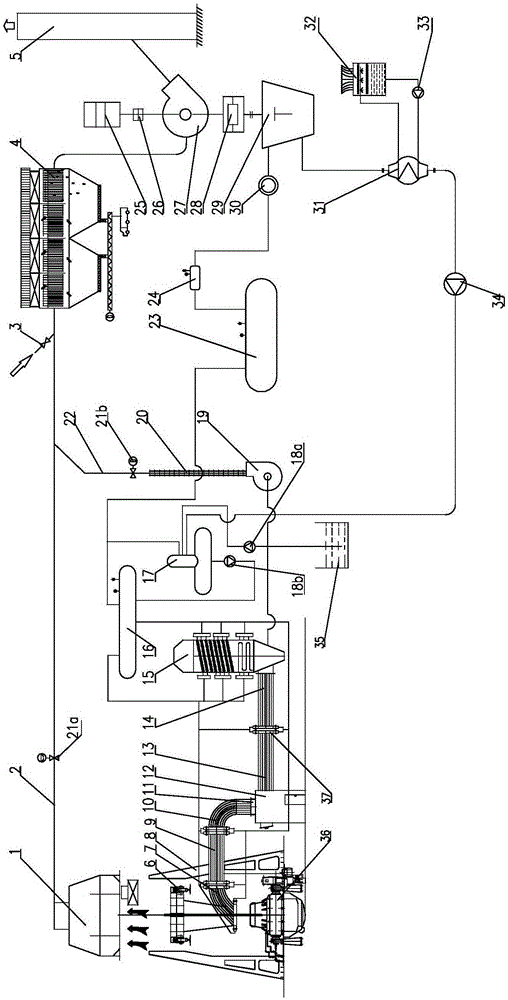

Smoke medium and high temperature waste heat positive energy recycling and dust removing system of AOD furnace

ActiveCN103759545AShorten the lengthLower height requirementIncreasing energy efficiencyWaste heat treatmentThermodynamicsRespirator

The invention relates to a smoke medium and high temperature waste heat positive energy recycling and dust removing system of an AOD furnace. During normal melting, primary smoke of the AOD furnace is mainly gathered through a vaporization smoke flue suction port cover, and secondary smoke generated during oxygen blowing, charging and tapping is gathered through a variable-flow roof smoke cover. An electric multi-blade butterfly valve is used for controlling the air quantity, a primary smoke exhausting system and a secondary smoke exhausting system are arranged in a combined mode, and the high dust and high temperature of the primary smoke are diluted and lowered by utilizing the characteristics that the secondary smoke is low in dust concentration, low in temperature and high in air quantity. Hot smoke passes through a system formed by an evaporation smoke flue and a finned-tube waste heat boiler, heat energy is absorbed through radiation convection, a large amount of saturated steam is generated to drive a turbine, the turbine directly drives a main dust removing fan, and therefore energy losses are avoided. By means of the smoke medium and high temperature waste heat positive energy recycling and dust removing system of the AOD furnace, waste heat positive energy of smoke of the AOD furnace can be recycled to the maximum, meanwhile, environment-friendly emission of smelting smoke can be realized, and the requirements for energy conservation, emission reduction and recycling economy are met.

Owner:无锡三达环保科技有限公司

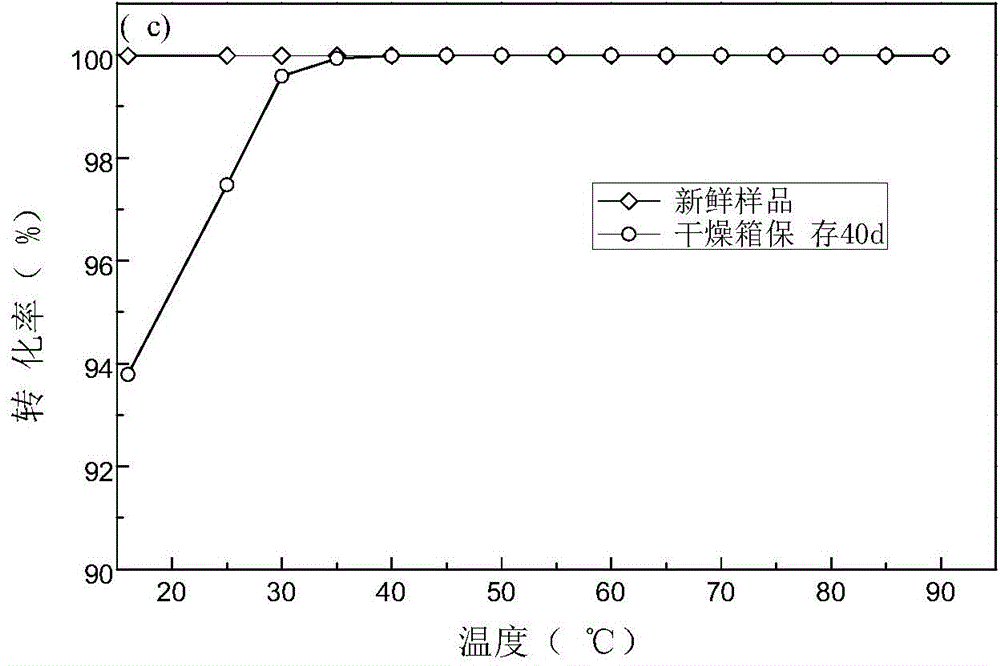

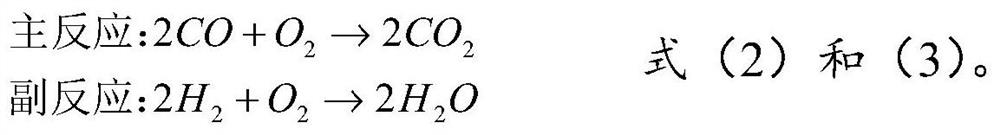

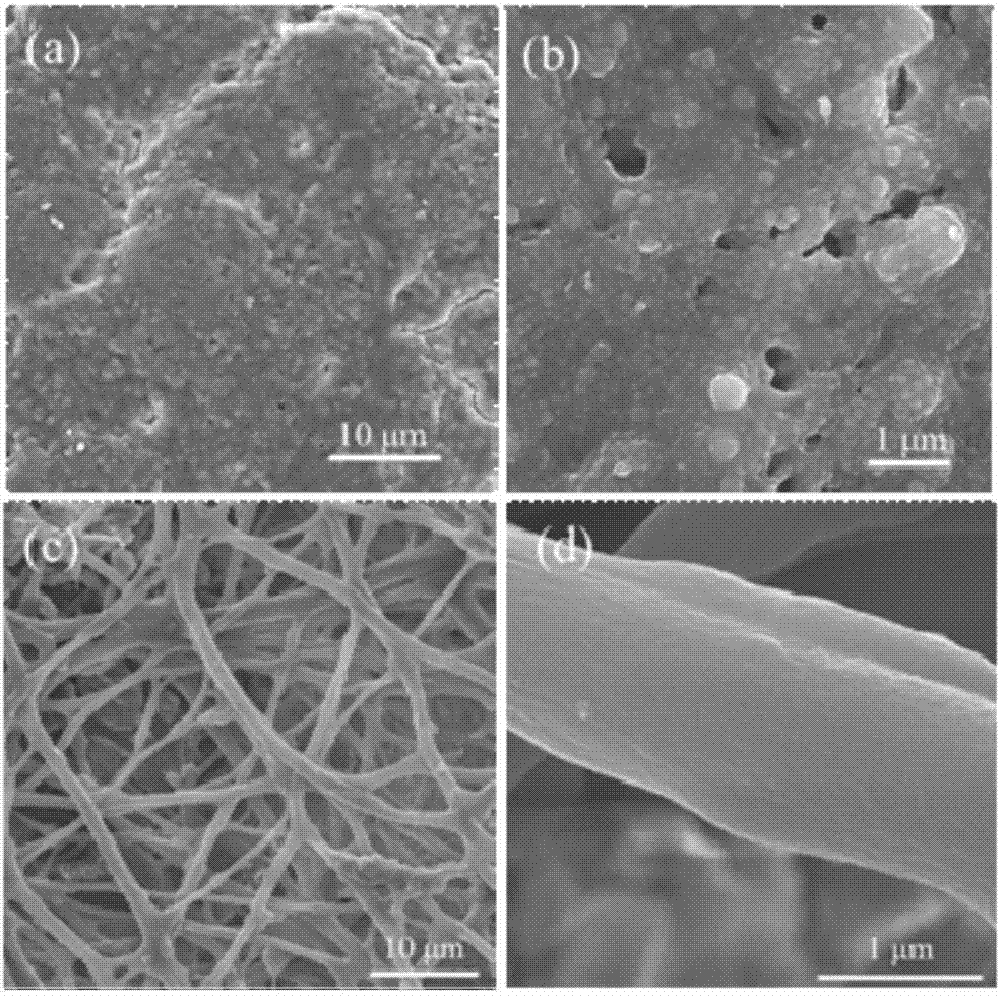

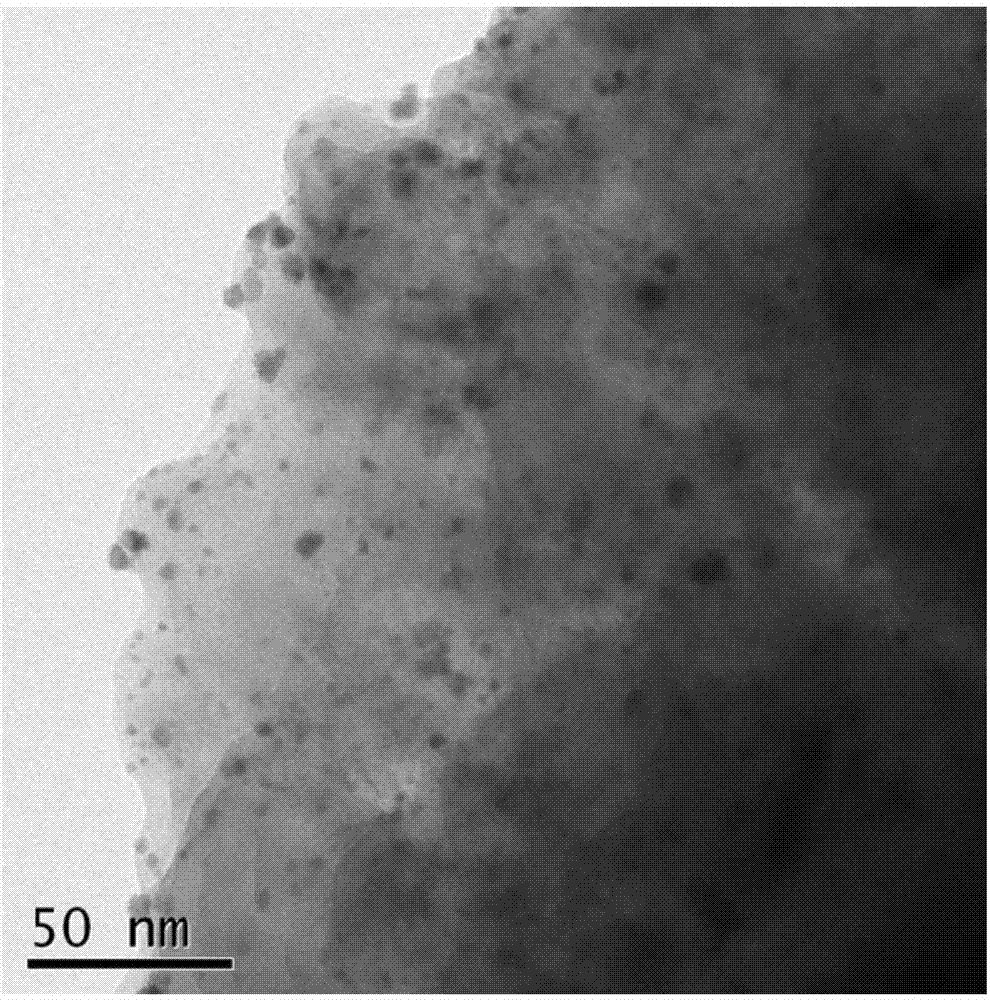

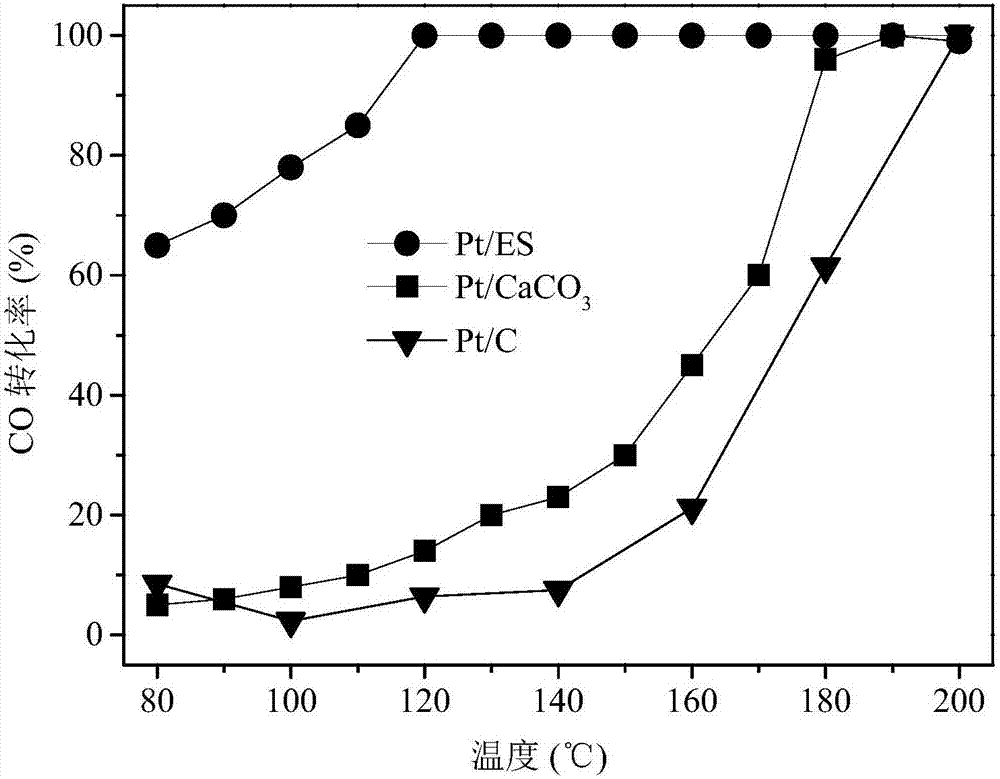

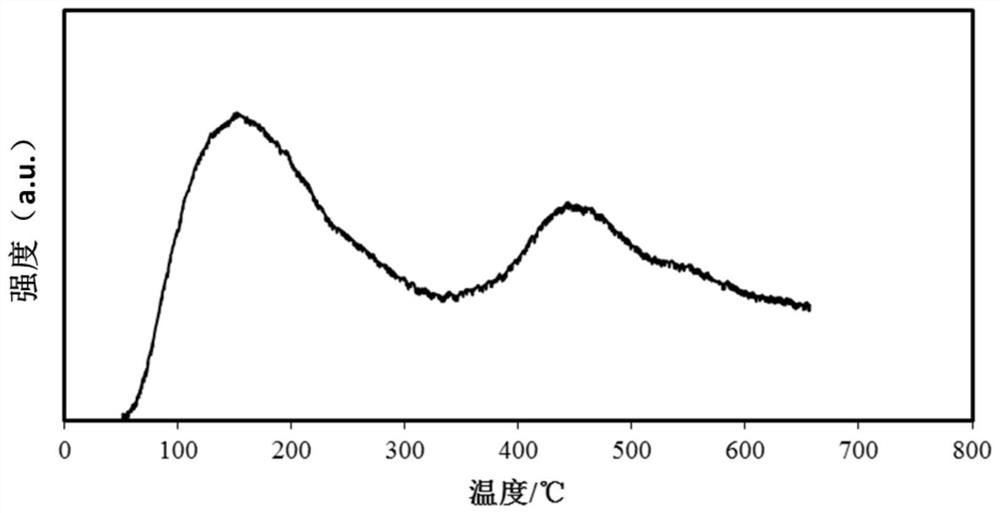

Catalyst for selective oxidation of CO and preparation method and application of catalyst

ActiveCN107456985AReduce CO2 concentrationSimple stepsHydrogen separation using solid contactHydrogen/synthetic gas productionIridiumAlloy

The application discloses a catalyst for selective oxidation of CO and a preparation method and application of the catalyst. The catalyst for selective oxidation of CO uses egg shells as a carrier to carry noble metal nanoparticles; noble metals in the noble metal nanoparticles are selected from at least one of platinum, palladium, ruthenium, rhodium, iridium, gold and silver; or the noble metals are selected from at least one of alloys of at least two of platinum, palladium, ruthenium, rhodium, iridium, gold and silver. The catalyst preferably and selectively oxidizes CO in a hydrogen-rich flow, and CO concentration in the hydrogen-rich flow can be decreased to 10 ppm and below within a wide temperature window; the catalyst is particularly applicable to hydrogen production systems using water-gas shift process and hydrogen supply systems of proton exchange membrane fuel cells.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

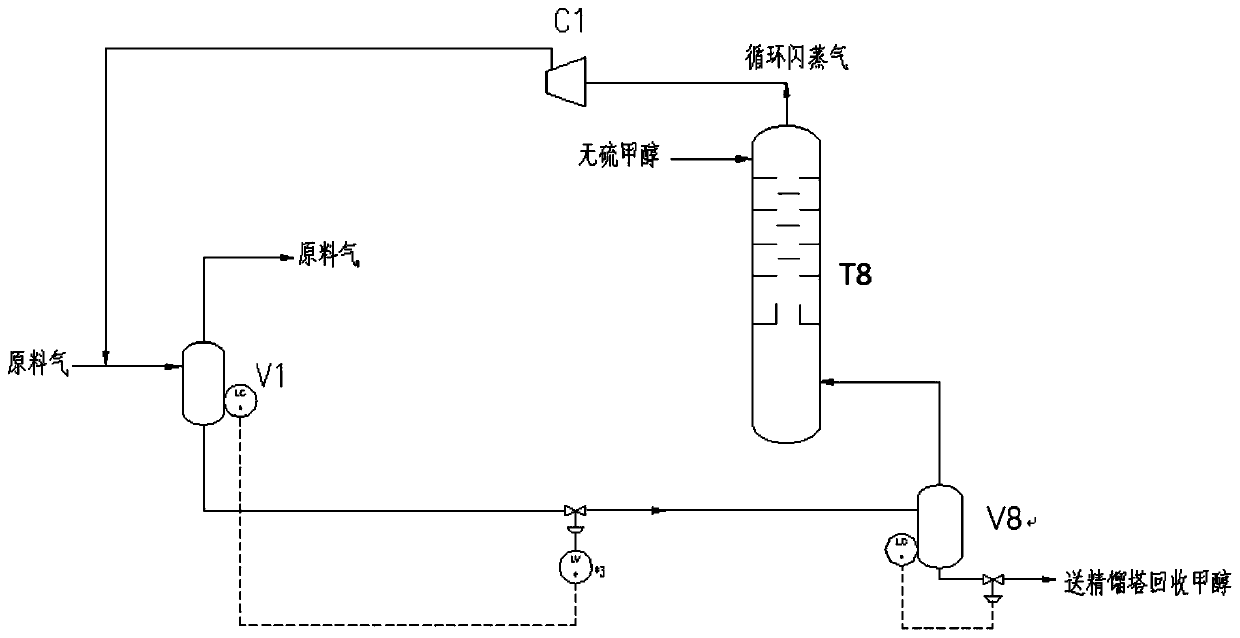

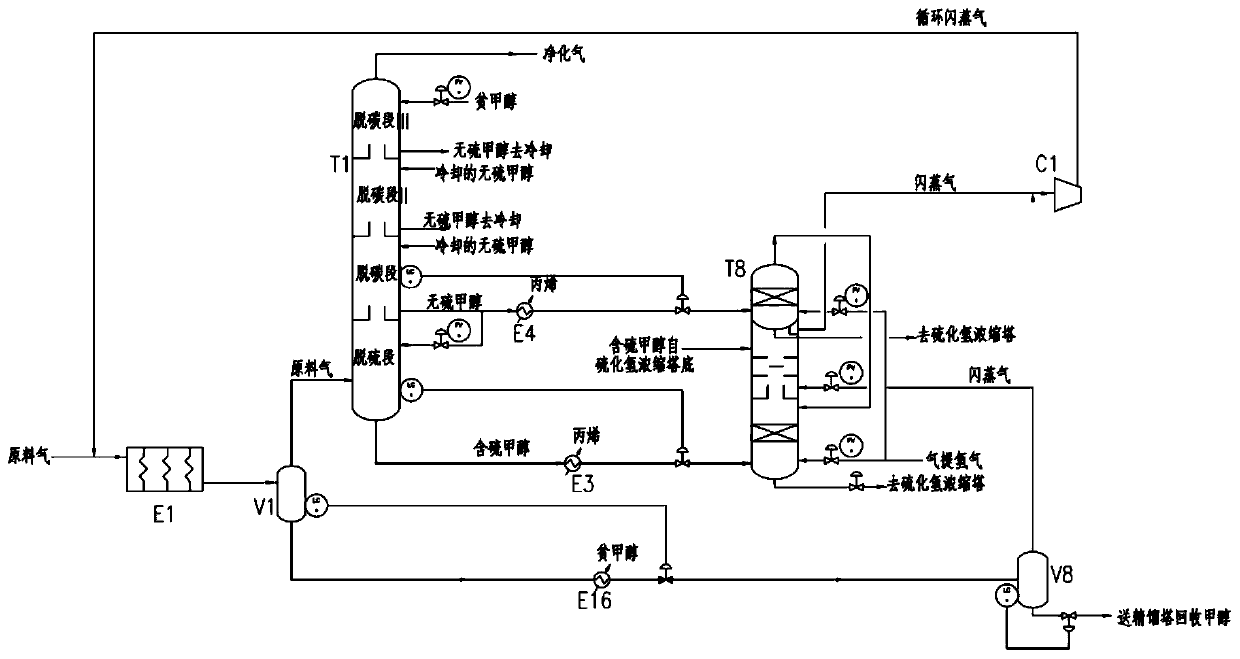

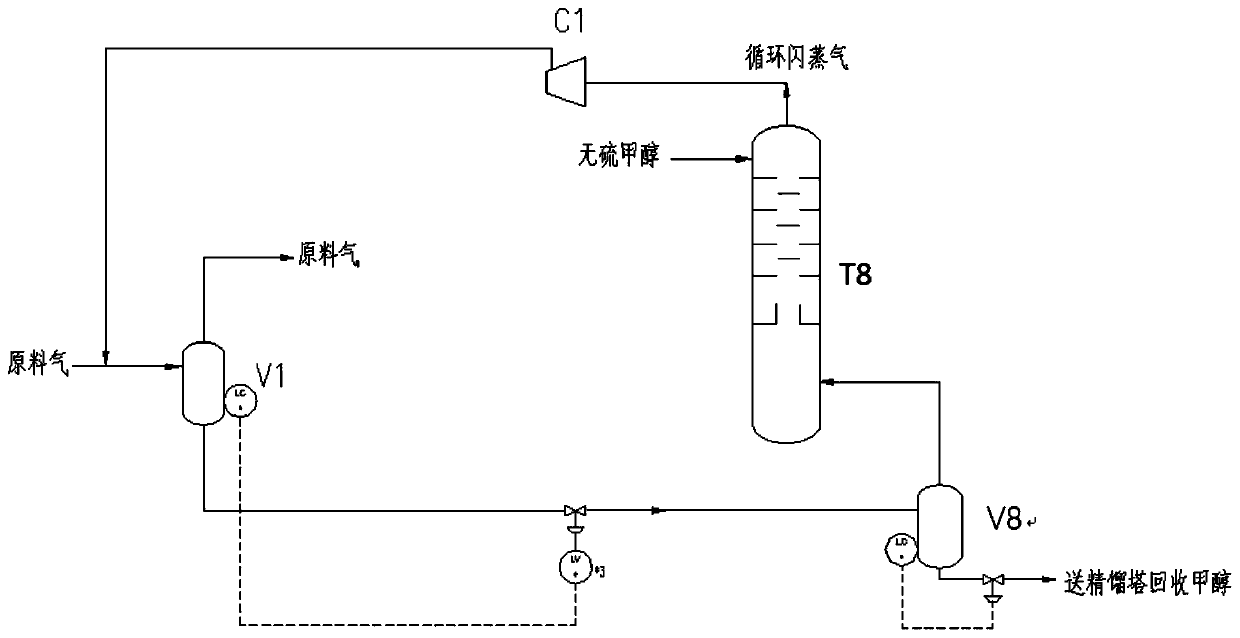

Process for reducing concentration of CO in low-temperature methanol wash tail gas

InactiveCN109999617AReduce CO concentrationHigh recovery rateDispersed particle separationExhaust gasChemistry

The invention relates to a process for reducing concentration of CO in low-temperature methanol wash tail gas. The process comprises main steps as follows: 1) flash evaporation is performed on a methanol water solution of low-temperature methanol wash, 2) flash evaporation gas is sent to a medium-pressure flash column and is washed by sulfur-free methanol to remove acidic components in the flash evaporation gas, 3)the flash evaporation gas is sent to a circulating gas compressor for recovery of effective gas. With a new technological process, energy in a system is ingeniously cycled and operated, useful substances are circularly utilized, CO and H2 in a raw gas condensation liquid and rich methanol are recovered in a flash evaporation pressurization manner, the CO recovery rate of the system can be increased by 0.2% or above, and the concentration of CO in the tail gas is reduced to 0.01 mol% or below.

Owner:CHINA TIANCHEN ENG

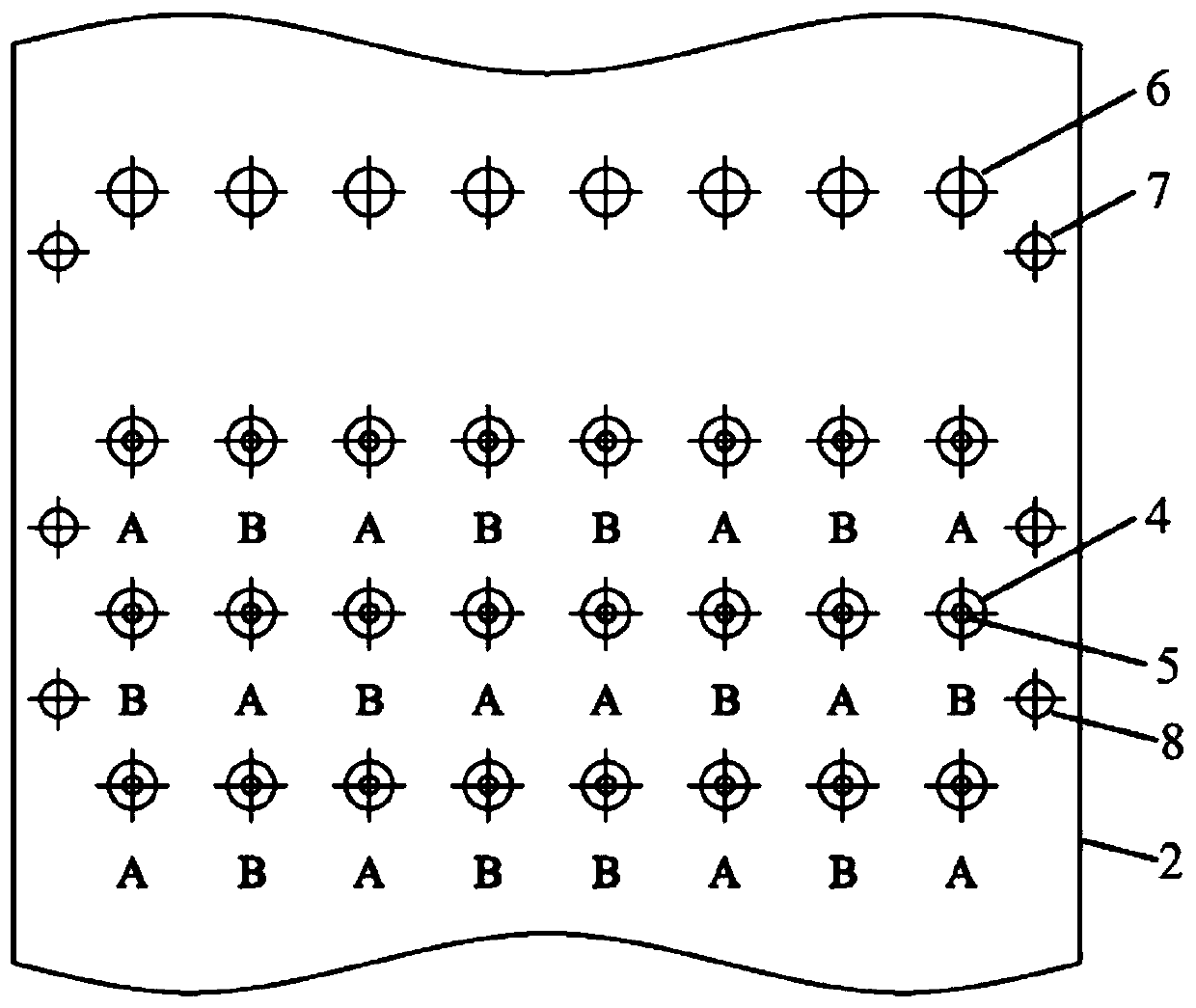

Wall-type combustion boiler mixed coal blending combustion optimization method

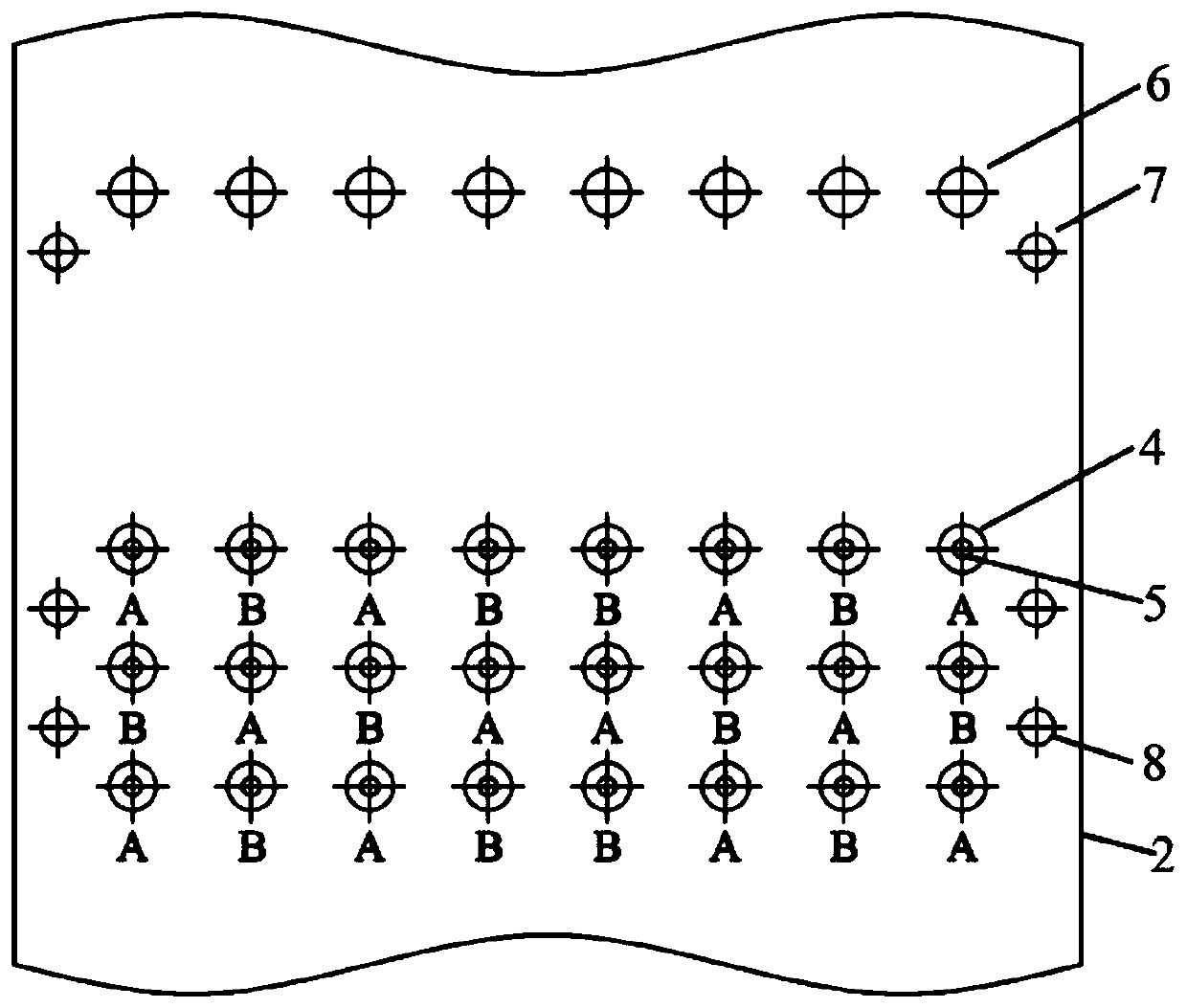

ActiveCN110319435ARaise on fireImprove combustion stabilityPulverulent fuel combustion burnersLump/pulverulent fuel preparationCombustorEngineering

The invention discloses a wall-type combustion boiler mixed coal blending combustion optimization method, and relates to the field of wall-type boiler pulverized coal combustion. The method comprisesthe following steps that combustion pulverized coal is divided into coal A and coal B; and a wall-type combustion boiler comprises combustors, primary air pipes, a burning-out air nozzle, a side burning-out air nozzle, wall-adhering air nozzles, a boiler front wall and a boiler rear wall, the combustors are arranged on the boiler front wall and the boiler rear wall, the combustors correspond to the primary air pipes in a one-to-one mode, and the first air pipes for conveying the coal A and the coal B are staggered and are connected with combustors arranged on the front wall and the rear wall of the boiler. The combustors are arranged in a layered mode in the height direction of a furnace, and the wall-adhering air nozzles are arranged between the adjacent combustor layers and close to theleft and right side walls. Through the implementation of the method, ignition and stable combustion of low-volatile coal can be enhanced, NOx generation can be reduced, and slagging and high-temperature corrosion of water-cooled furnace walls of the left and right side walls can be effectively prevented.

Owner:华能沁北发电有限责任公司 +1

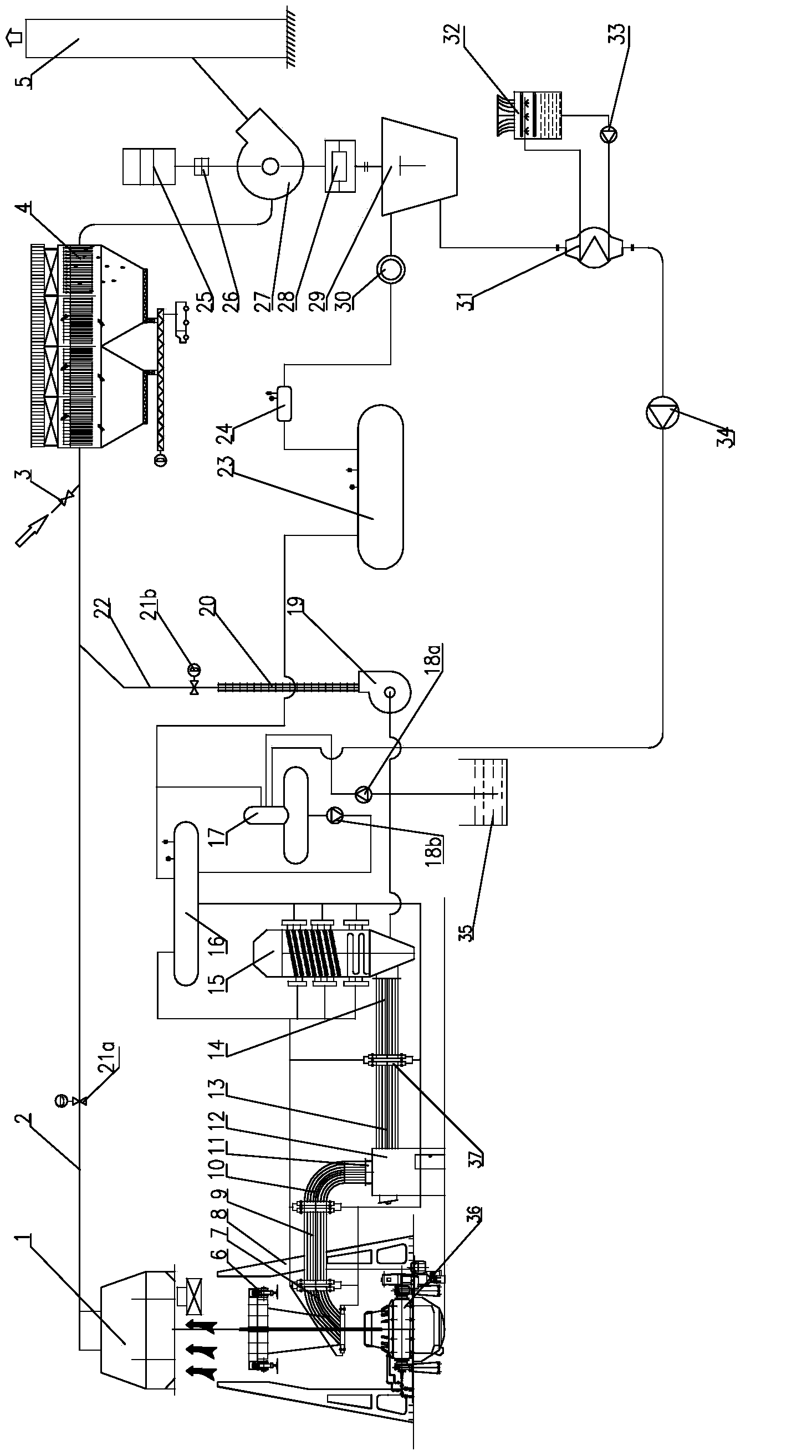

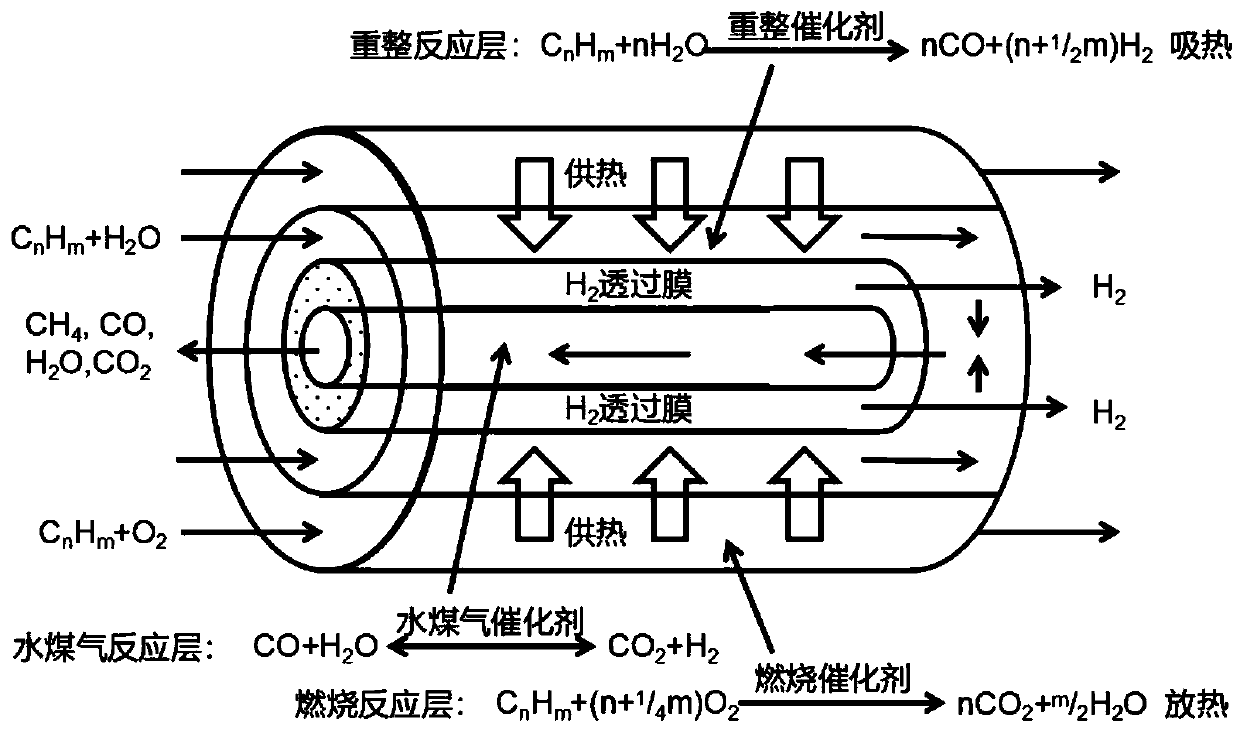

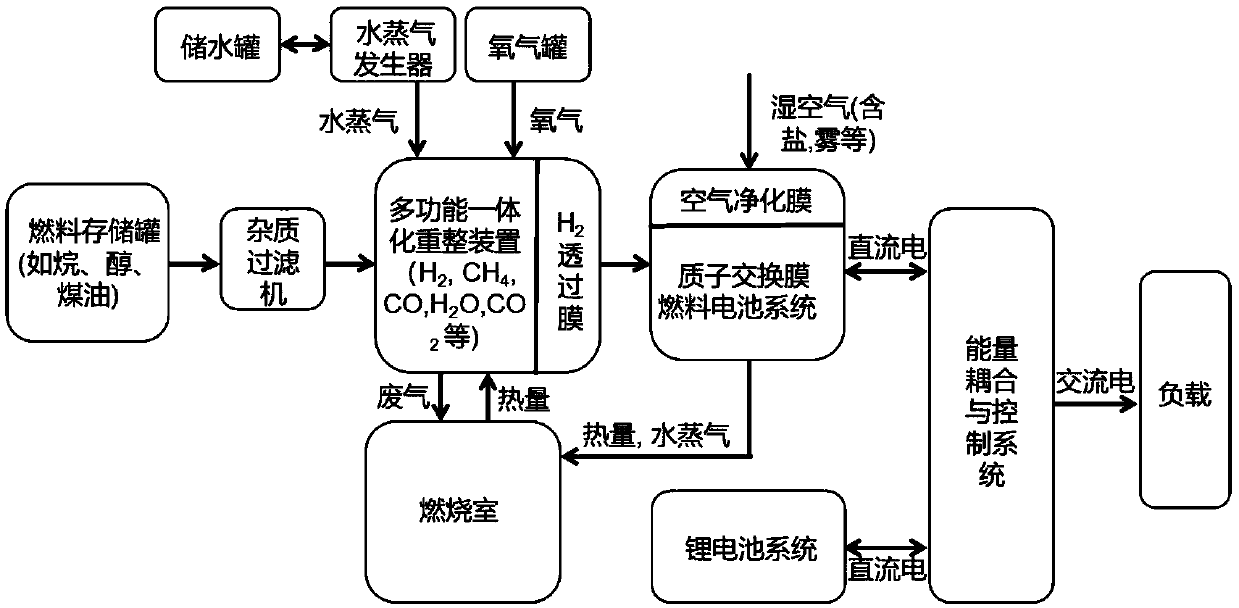

Pure hydrogen catalytic device with integrated multi-sleeve structure for various hydrocarbon fuels, and PEMFC power generation system

The invention discloses a pure hydrogen catalytic device with an integrated multi-sleeve structure for various hydrocarbon fuels, and a PEMFC power generation system. The pure hydrogen catalytic device is of a cylindrical structure, the interior of the pure hydrogen catalytic device is of a three-layer structure, the outermost layer is a combustion reaction chamber, the intermediate layer is a reforming catalytic reaction chamber, the innermost layer is a water gas reaction chamber, and a partition wall is arranged between every two adjacent layers; the combustion reaction chamber is used forsupporting a combustion catalyst, the reforming catalytic reaction chamber is used for supporting a reforming catalyst, the water gas reaction chamber is used for supporting a water gas reaction catalyst, and a hydrogen permeation membrane is arranged in the water gas reaction chamber; and the reforming catalytic reaction chamber communicates with the water gas reaction chamber, a product generated by the reforming catalytic reaction chamber enters the water gas reaction chamber to continuously react, and generated hydrogen is purified through the hydrogen permeation membrane and collected. The invention promotes the improvement and solution of hydrogen preparation, storage and transportation and logistics supply difficulties and the like in the PEMFC technology.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

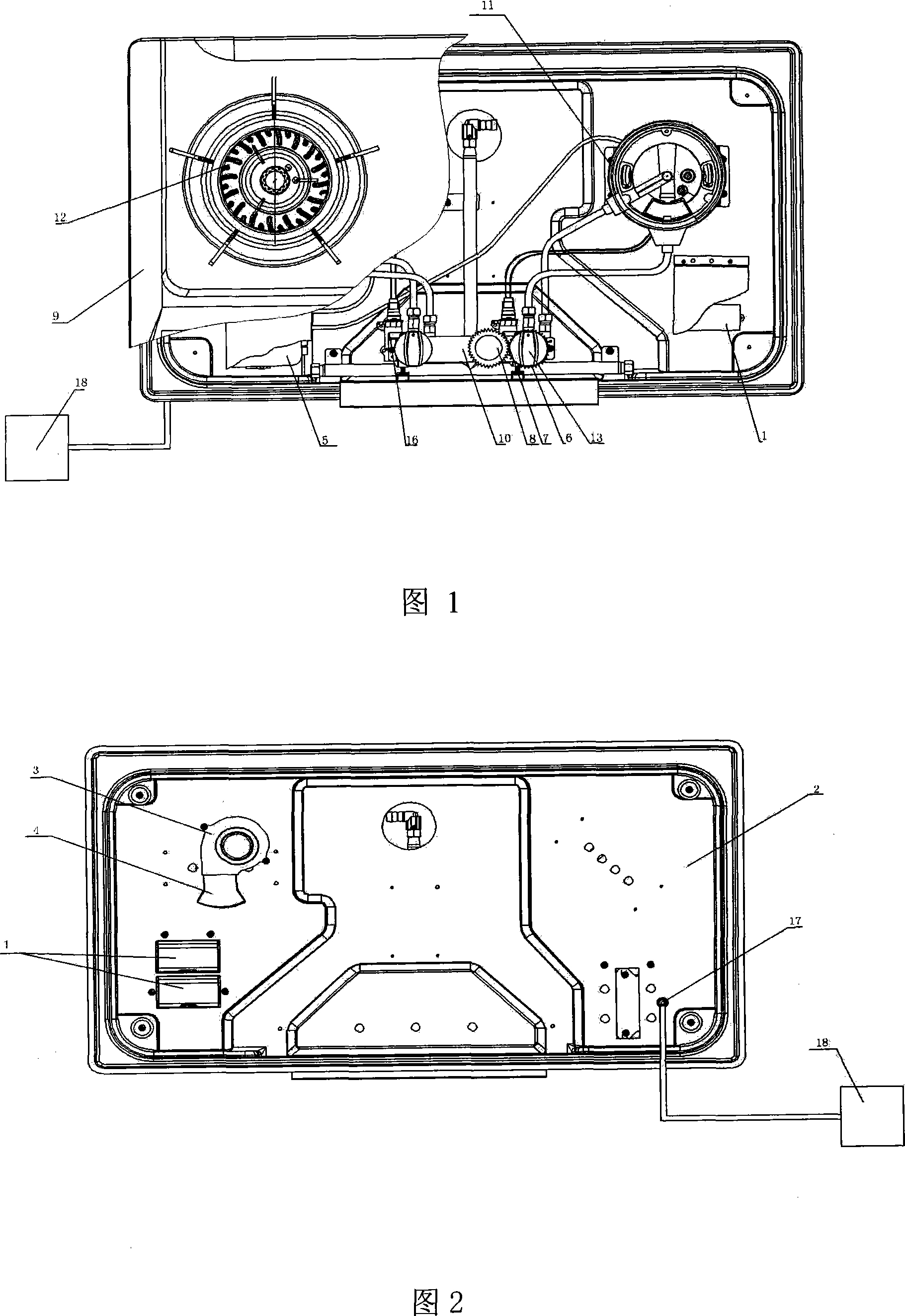

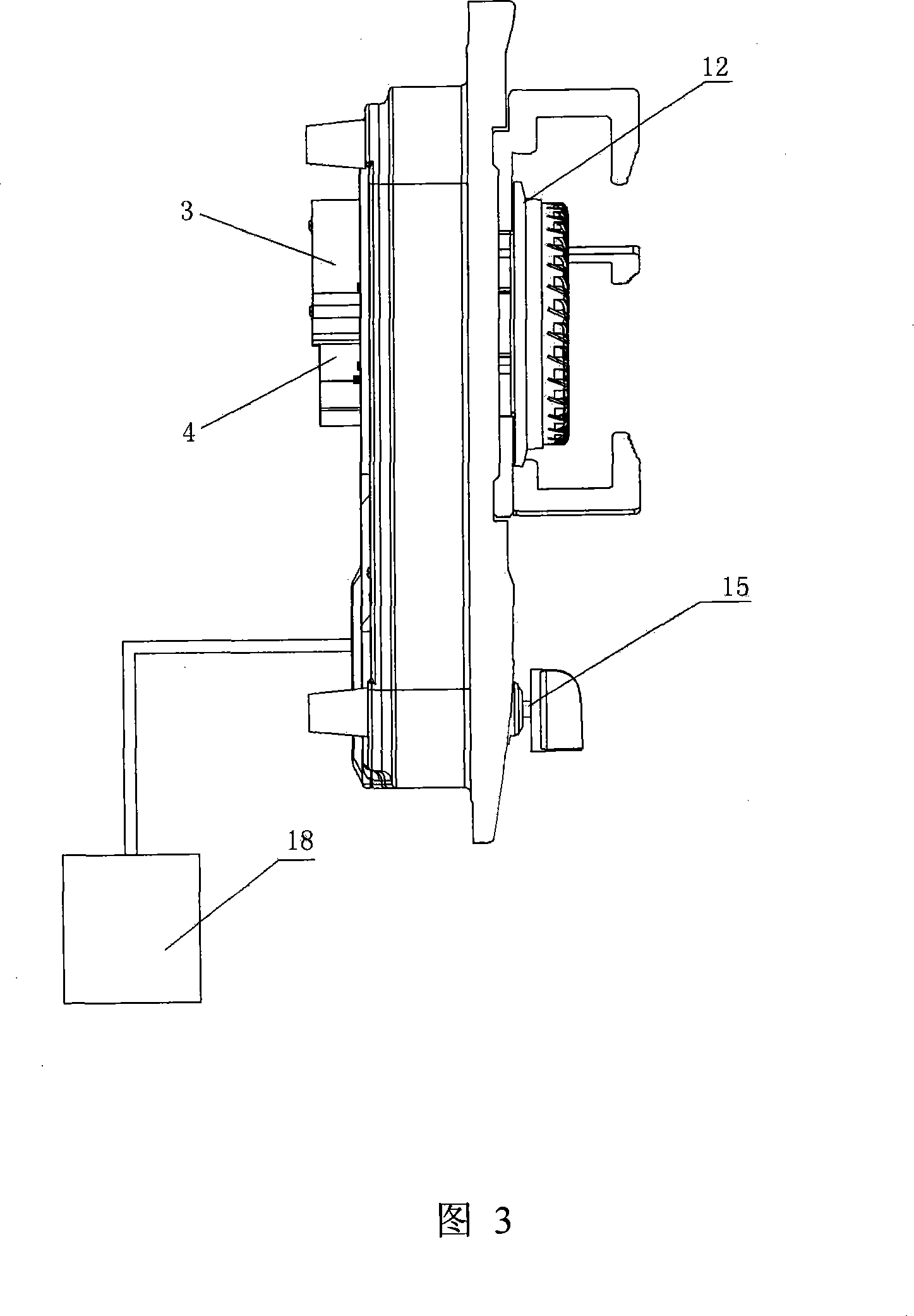

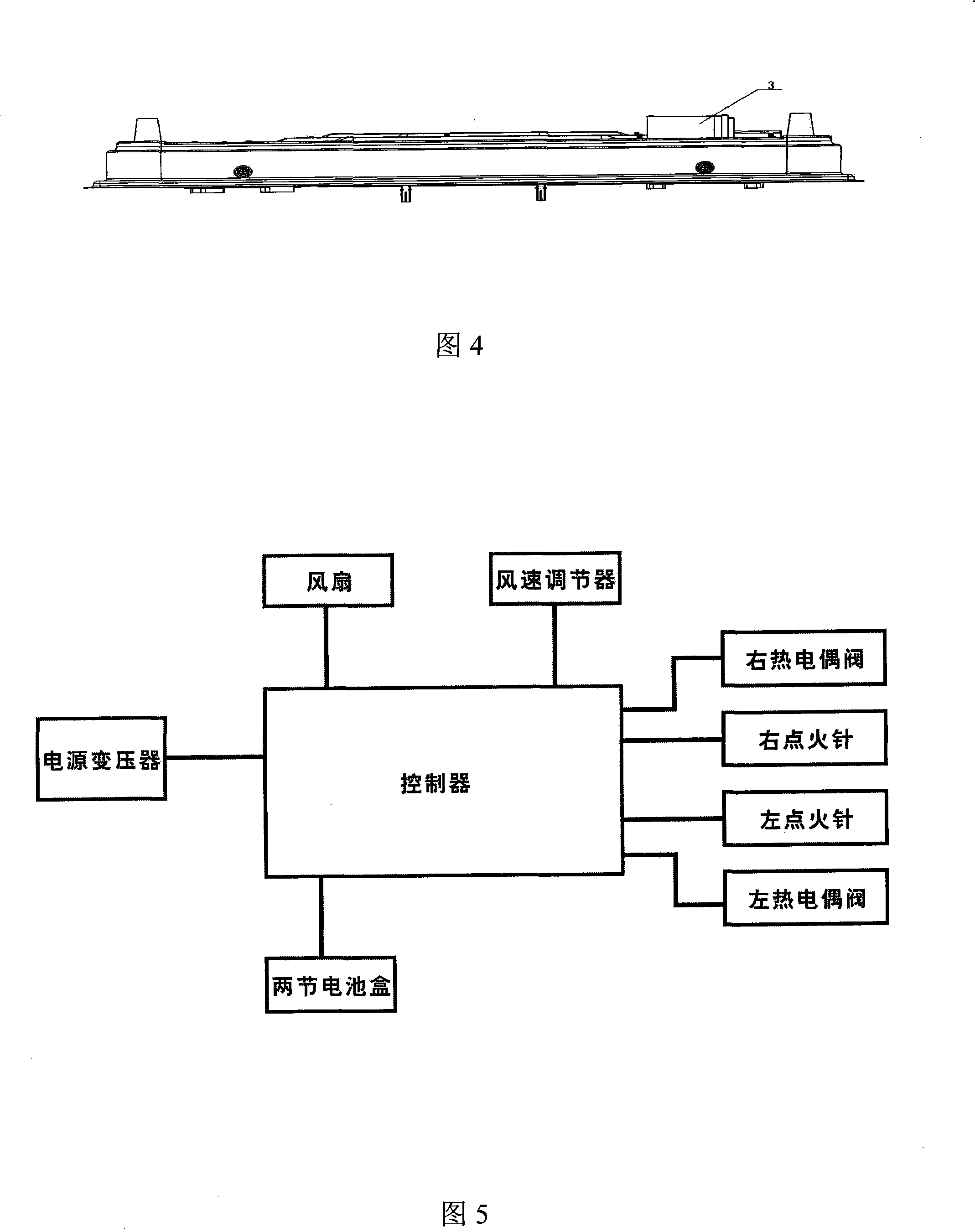

Blasting type household fuel gas kitchen range

InactiveCN101225969AIncrease heat flowImprove thermal efficiencyDomestic stoves or rangesLighting and heating apparatusCombustorTransformer

The invention provides a forced draft domestic gas cooker, which is characterized in that: a blast apparatus is arranged for supplementing gas when combusting; a controller is connected with an exteriorization transformer; the blast apparatus comprises a blower and a blowing channel communicated with the blower; the other end of the blowing channel is communicated to the nozzle of the valve body; the blast apparatus is arranged on a bottom shell of the gas cooker; and only burner of the side uses the blast apparatus; the controller is arranged on the bottom shell of the gas cooker; the controller switches on the blower through a belt gear potentiometer; the belt gear potentiometer is meshed with the linkage gears sleeve-jointed with the valve body rotating shaft; rotary ignition knob is used for regulating the inletting wind speed of the blower and the close and open state of the blower. The forced draft domestic gas cooker has the advantages of fully supplementing the primary required gas when combusting, thus improving the flow rate obviously; making the flame more blue, and the CO concentration lower, and the thermal efficiency higher, and resolving the problem of tempering quality.

Owner:马靖

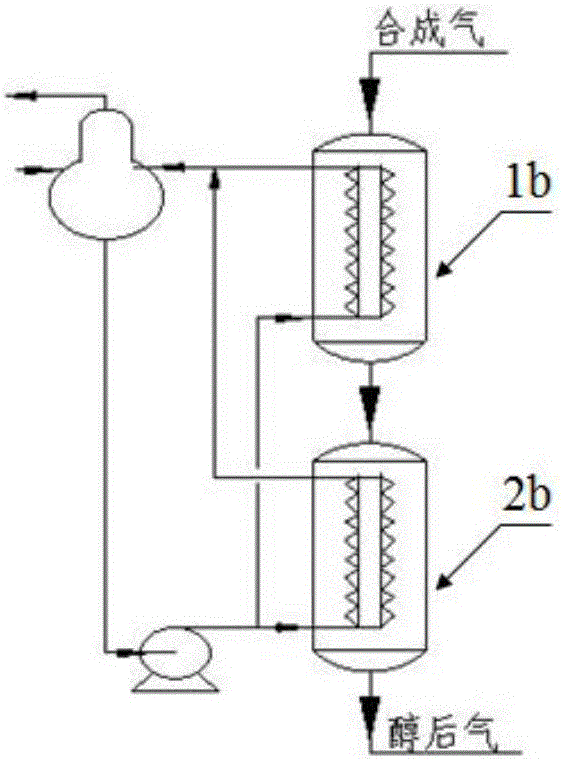

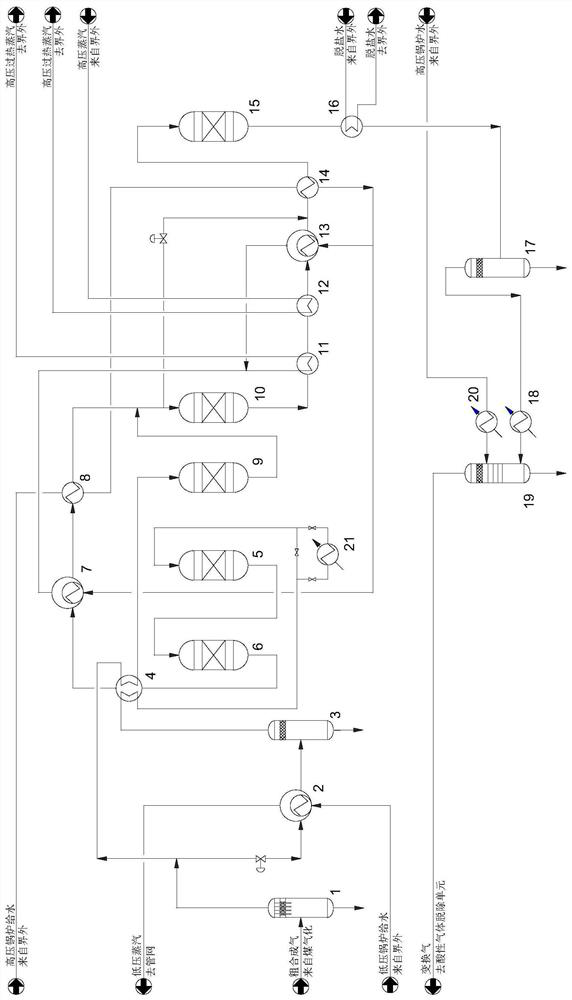

Low-water-gas-ratio CO conversion device and low-water-gas-ratio CO conversion method

InactiveCN112708478AReduce CO2 concentrationReduces the likelihood of methanation reactionsChemical industryCombustible gas catalytic treatmentSyngasThermodynamics

The invention belongs to the technical field of CO conversion processes of coal chemical industry devices, and relates to a low-water-gas-ratio CO conversion device and a low-water-gas-ratio CO conversion method. Aiming at high-CO crude synthesis gas from a coal gasification device, crude gas is reasonably divided into two streams by adopting a flow splitting mode, and the water-gas ratio of one stream is reduced, so that the reaction depth of a 1# shift converter and the hot spot temperature of a bed layer are controlled, and the overtemperature phenomenon of a reactor is avoided. After the other stream is mixed with the gas from the 1# shift converter, the CO concentration is greatly reduced, and the possibility of methanation reaction of a 2# shift converter is greatly reduced. The technological process has the advantages of being high in upstream device operation fluctuation resistance, good in system energy integration effect, remarkable in energy conservation and consumption reduction and the like.

Owner:SINOPEC NANJING ENG & CONSTR +1

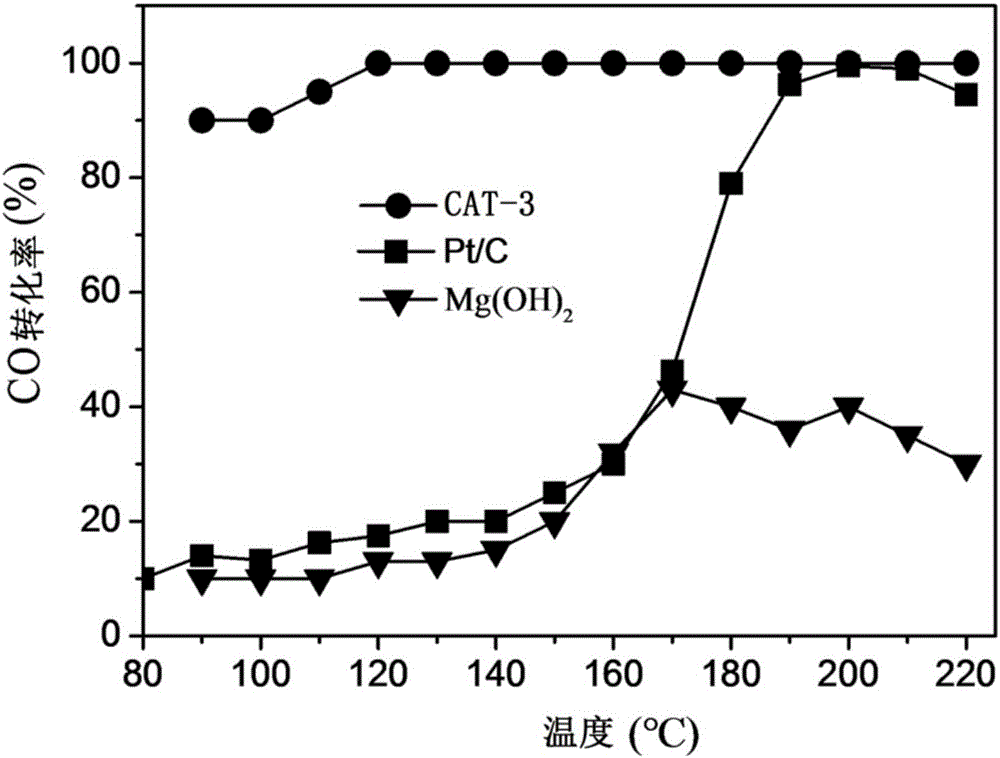

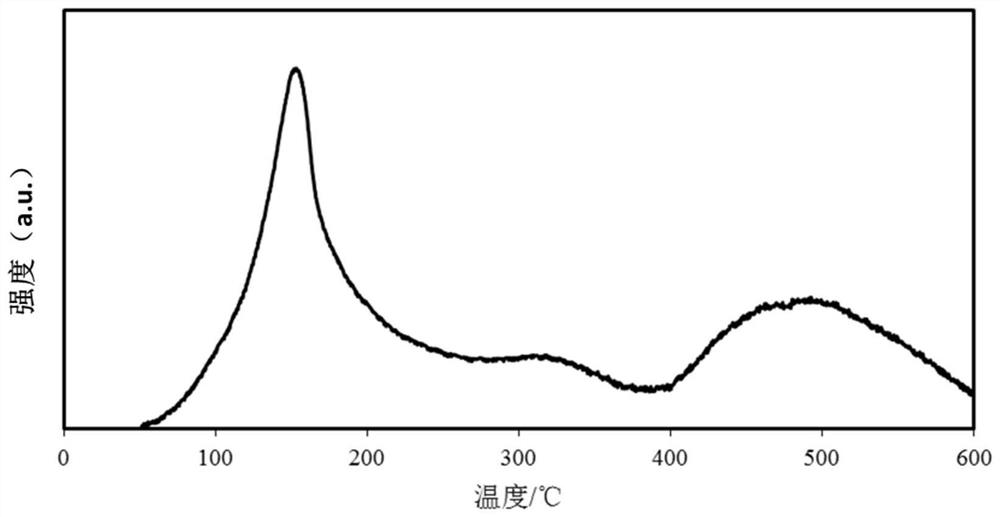

Catalyst for selective oxidation of CO, and preparation method and application of catalyst

ActiveCN106799227AReduce CO concentrationSimple stepsHydrogen separation using solid contactHeterogenous catalyst chemical elementsIridiumAlloy

The invention discloses a catalyst for selective oxidation of CO, and a preparation method and application of the catalyst. The catalyst for selective oxidation of CO contains a hybrid material; the hybrid material is prepared from crystals and precious metal quantum dots positioned on crystal edges, wherein the crystals are selected from at least one of metal hydroxide crystals in group IIA, alkaline earth metal oxide crystals in group IIA, metal hydroxide crystals in group IIIA and alkaline earth metal oxide crystals in group IIIA; precious metals in the precious metal quantum dots are selected from at least one of platinum, palladium, ruthenium, rhodium, iridium, gold and silver, or are selected from at least one of alloys formed by at least two of the platinum, the palladium, the ruthenium, the rhodium, the iridium, the gold and the silver. The catalyst can preferentially oxidize the CO in a selective way in hydrogen-rich airflow, and can reduce the concentration of the CO in the hydrogen-rich airflow to 10ppm or below in a wide temperature window, thus being very suitable for a water-gas conversion process hydrogen production system and a hydrogen supply system of a proton exchange membrane fuel cell.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

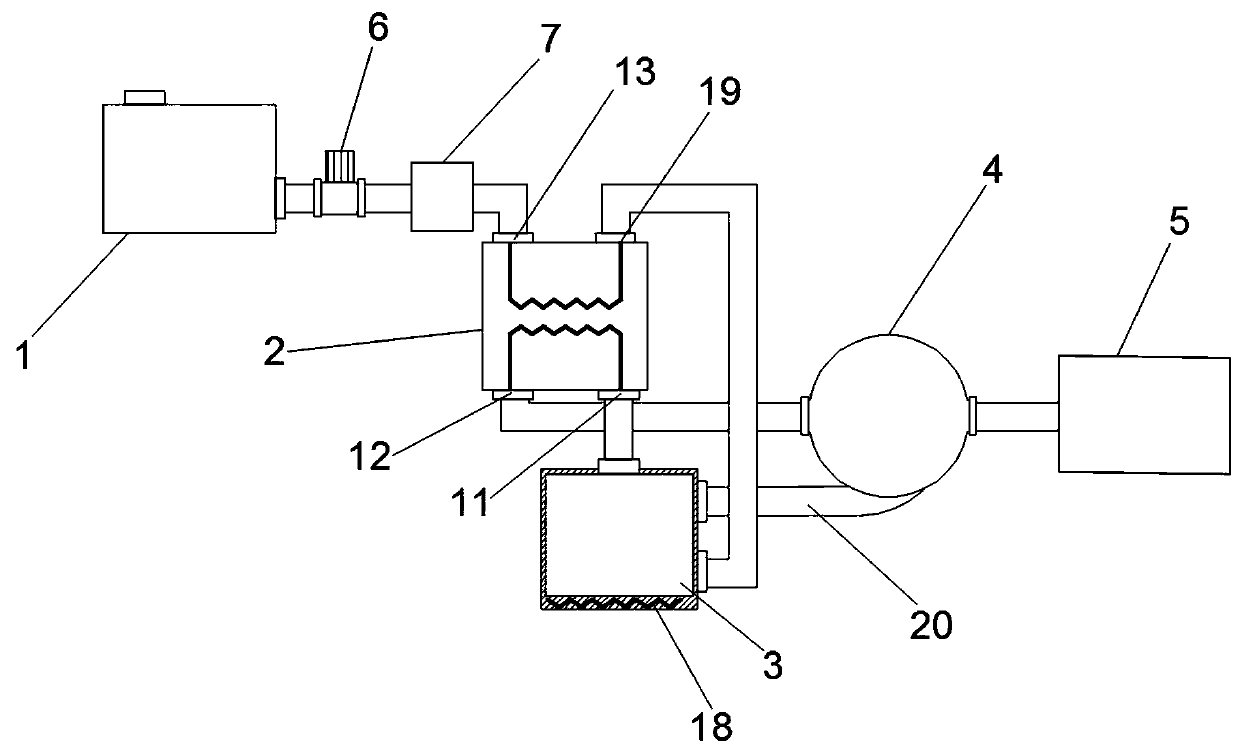

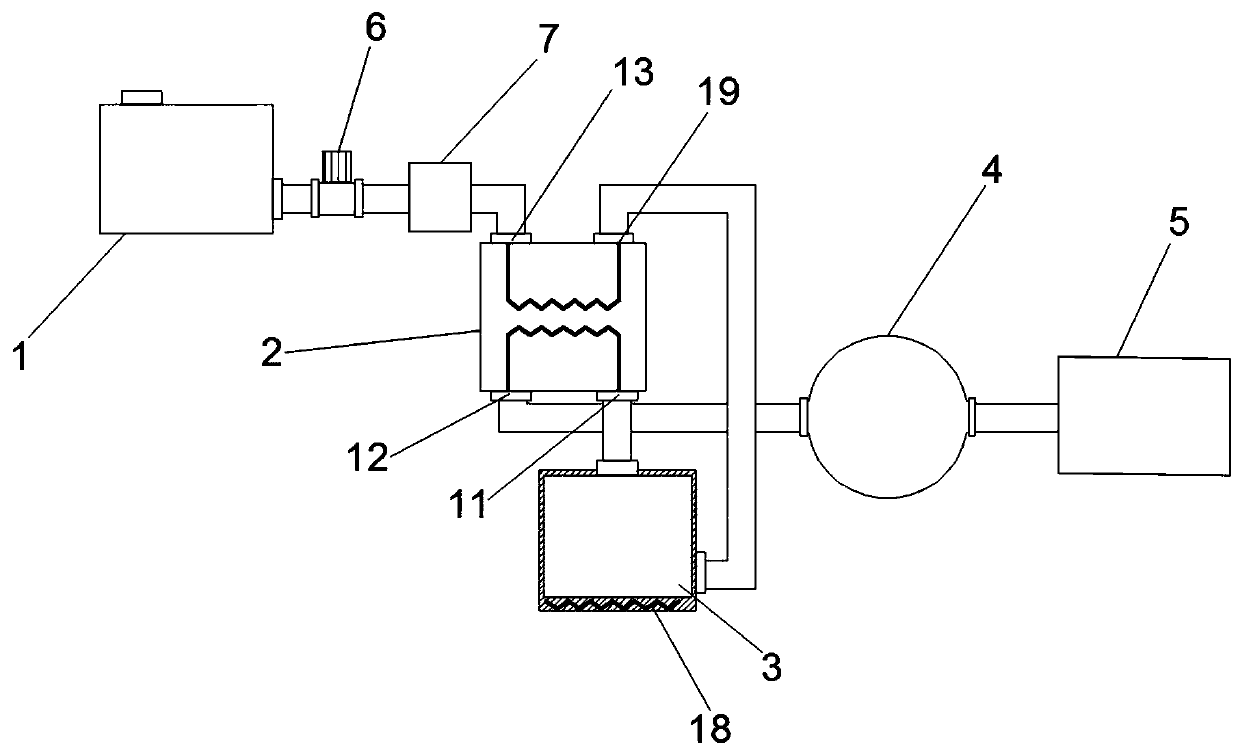

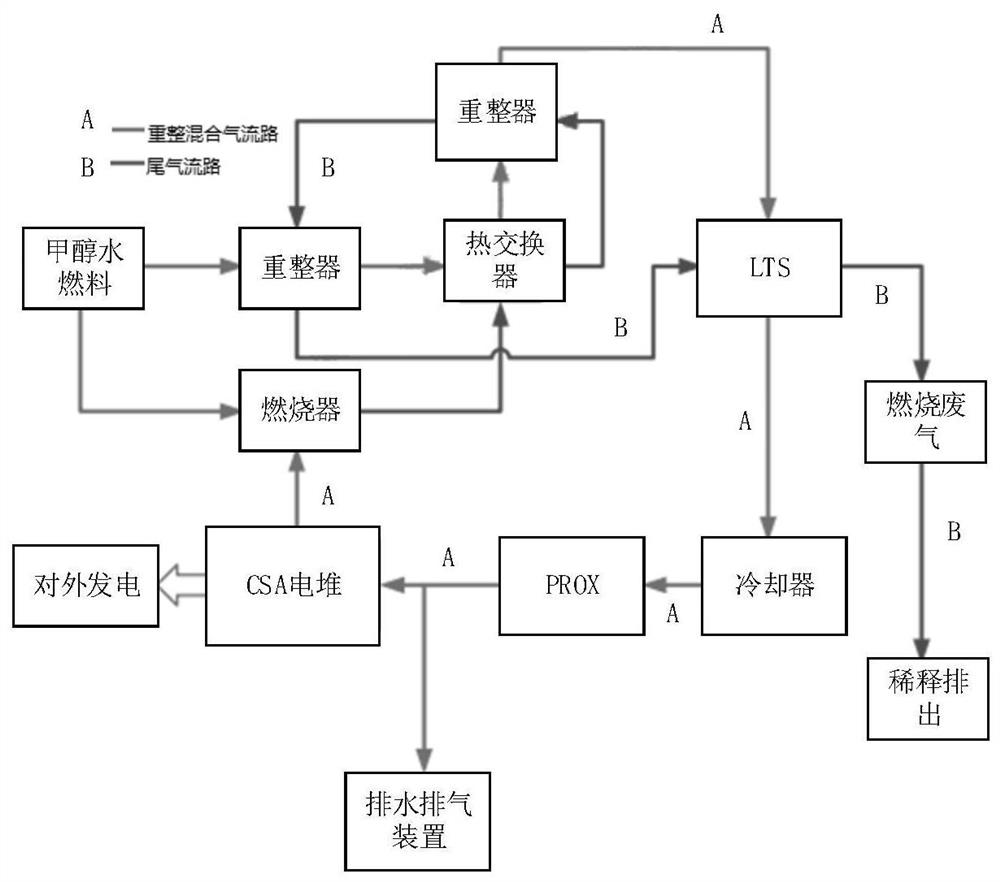

Methanol water fuel reforming hydrogen production system

PendingCN112811390AReduce CO2 concentrationImprove the purification effectHydrogenHydrogen/synthetic gas productionMethanol waterFuel cells

The invention provides a methanol water fuel reforming hydrogen production system. The methanol water fuel reforming hydrogen production system comprises a catalytic burner, a reformer, a water vapor converter, a selective oxidizer, a fuel storage tank and a fuel cell which are connected in sequence. The hydrogen-rich mixed gas is subjected to staged oxidation treatment through the water vapor converter and the selective oxidizer, the CO concentration in the gas is gradually reduced, and it is guaranteed that CO is completely removed. The system disclosed by the invention is short in starting time, low in energy consumption, high in hydrogen production speed, low in hydrogen production cost, high in energy conversion efficiency, environment-friendly, energy-saving and relatively high in power generation efficiency after being butted with a fuel cell stack, and the reforming hydrogen production condition can be quickly met.

Owner:摩氢科技有限公司

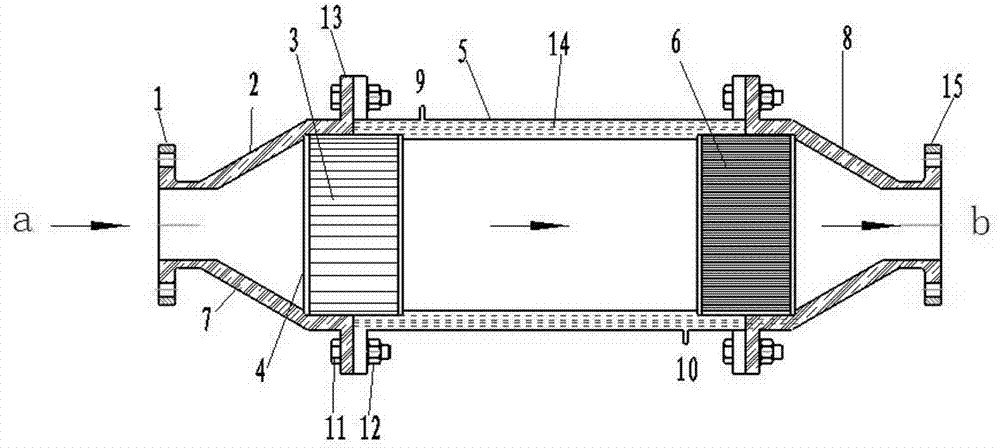

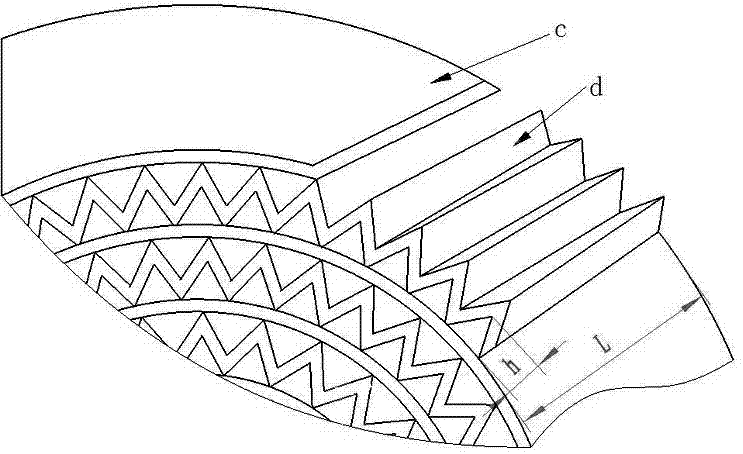

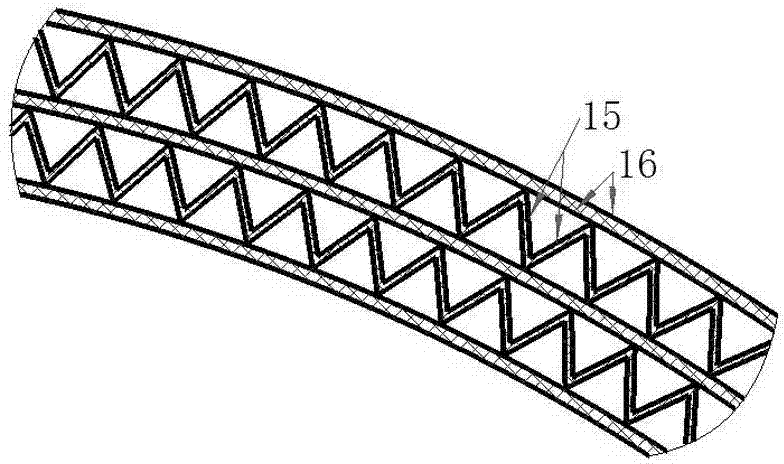

Exhaust corrugated fire retardance purifier of mining diesel engine

ActiveCN104265425AGuaranteed catalytic effectGuaranteed safe operationExhaust apparatusSilencing apparatusFlame arresterThermal insulation

The invention belongs to the technical field of mining diesel engine exhaust systems, and particularly relates to an exhaust corrugated fire retardance purifier of a mining diesel engine, in order to solve the problem of severe tail gas pollution caused by the structure of an existing mining explosion-proof diesel engine exhaust system and the problem of large exhaust resistance caused by an existing flat flame arrester. A pipe flange and a front housing are connected into a whole, the front housing and a middle housing are connected through a flange, the middle housing and a rear housing are connected through a flange, a corrugated catalyst purification layer is arranged between the front housing and the middle housing, a corrugated flame retardance layer is arranged between the middle housing and the rear housing, metal gaskets are arranged in the front and in the back of the corrugated flame retardance layer and the corrugated flame retardance layer, thermal insulation material aluminum silicate wool is arranged in the front housing and the middle housing, the middle housing is internally filled with cooling water, alumina coatings are arranged on two sides of a ventilation passage of the corrugated purification layer, and platinum, palladium and rhodium catalysts are attached to the two sides of the ventilation passage. By the purifier, content of carbon cigarette pellet, NOx and CO in tail gas is lowered effectively, and sparks in exhaust can be blocked from being discharged from the device by the corrugated fire retardance layer.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Dual-layer energy gathering hood of gas cooker combustor

PendingCN110006079AEasy to moveReduce CO concentrationDomestic stoves or rangesStoves/ranges topsCombustorEngineering

The invention relates to a dual-layer energy gathering hood of a gas cooker combustor, and belongs to the field of gas cookers. The dual-layer energy gathering hood comprises a second energy gatheringhood and is characterized by further comprising a first energy gathering hood, the first energy gathering hood is placed on the second energy gathering hood, an outer ring fire secondary air supplementing channel for supplementing secondary air to the outer ring fire is formed between the first energy gathering hood and the second energy gathering hood, an inner ring fire secondary air supplementing channel for supplementing secondary air to the inner ring fire is formed between the second energy gathering hood and a cooker panel, through the outer ring fire secondary air supplementing channel, the secondary air is supplemented to the outer ring fire, the secondary air is supplemented to the inner ring fire through the inner ring fire secondary air supplementing channel, gas is sufficiently combusted, and CO concentration standard exceeding in the smoke can be avoided.

Owner:HANGZHOU DE&E ELECTRICAL CO LTD

AOD furnace smoke and dust high and medium temperature waste heat positive energy recovery and dust removal system

ActiveCN103759545BShorten the lengthLower height requirementIncreasing energy efficiencyWaste heat treatmentButterfly valveSmoke hood

Owner:WUXI SANDA ENVIRONMENTAL PROTECTION TECH CO LTD

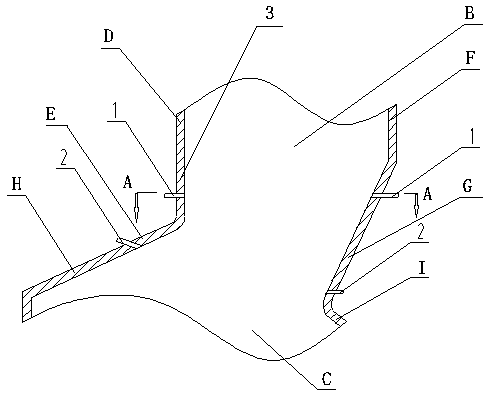

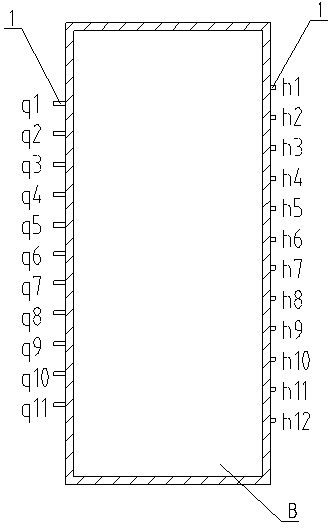

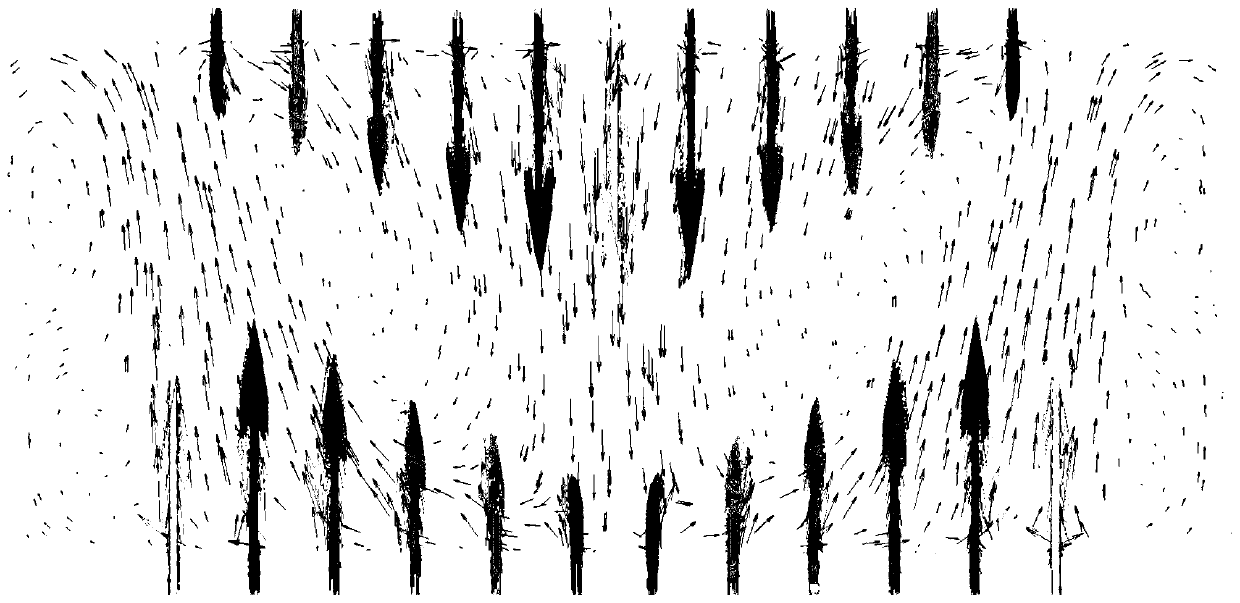

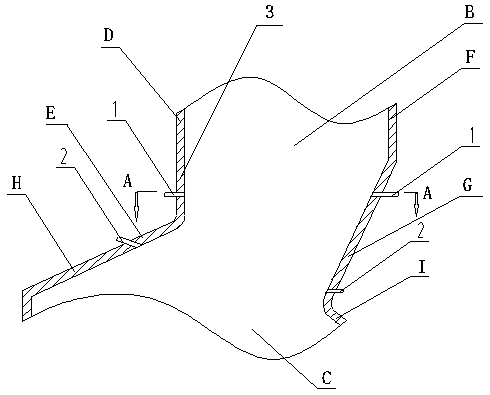

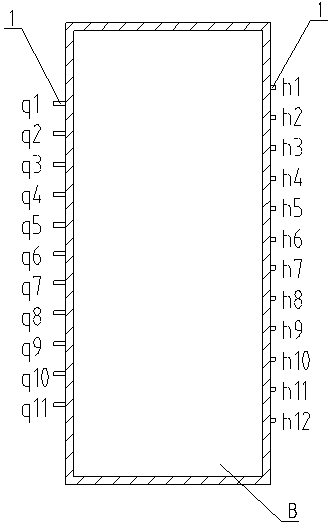

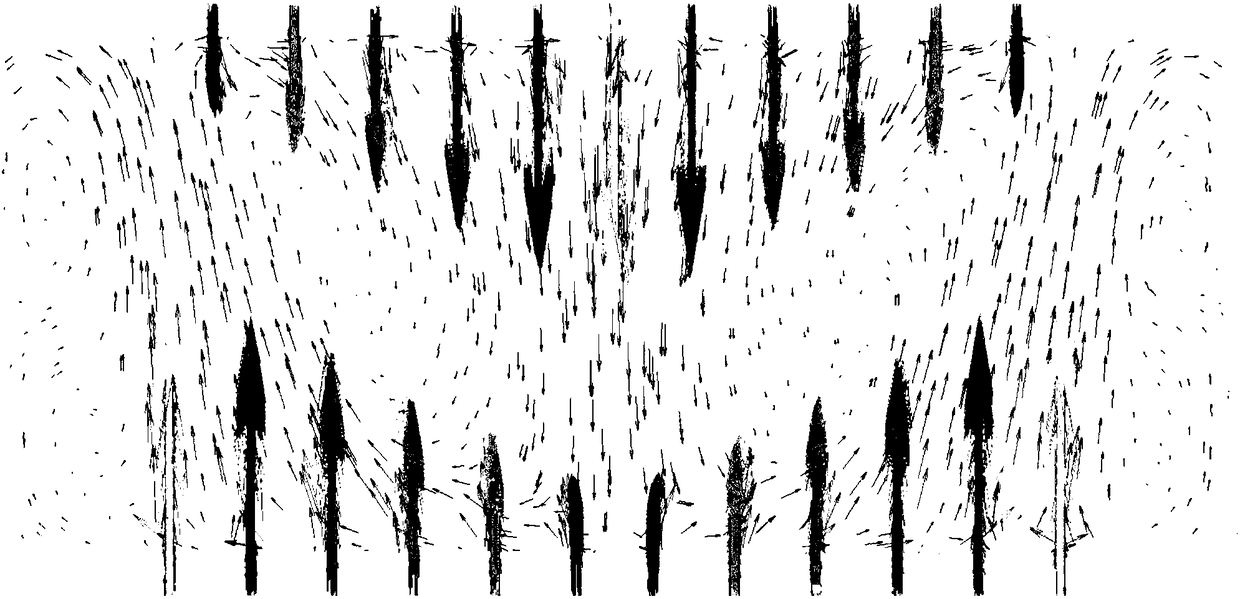

A double-layer vortex secondary air system for a garbage incinerator

InactiveCN108317520BAgitated obviouslyExtended stayIncinerator apparatusNon-combustible gases/liquids supplyCombustion chamberPower station

A double-layer vortex secondary air system of a garbage incinerator comprises upper layer vortex secondary air nozzles, lower layer secondary air nozzles and a garbage incinerator body, wherein the upper portion of the garbage incinerator body is provided with an upper furnace B, and the lower portion of the garbage incinerator body is provided with a lower combustion chamber C. One of the upper layer vortex secondary air nozzles is arranged at the junction of the upper section D of the front wall and the middle section E of the front wall of the garbage incinerator body, and the other one ofthe upper layer vortex secondary air nozzles is arranged at the junction of the upper section F of the rear wall and the middle section G of the rear wall of the garbage incinerator body. One of the lower layer secondary air nozzles is arranged at the junction of the middle section E of the front wall and the lower section H of the front wall of the garbage incinerator body, and the other one of the lower layer secondary air nozzles is arranged at the junction of the middle section G of the rear wall and the lower section I of the rear wall of the garbage incinerator body. According to the double-layer vortex secondary air system of the garbage incinerator, the horizontal vortex combustion technology is adopted for upper layer vortex secondary air, flue gas is in a spirally-rising state, the concentration of co is significantly reduced, and the combustion is more sufficient; the upper layer vortex secondary air constitutes a symmetric double-vortex region, and the combustion efficiencyis improved; and the double-layer vortex secondary air system of the garbage incinerator is used in the technical field of garbage incineration equipment of a large-scale power plant.

Owner:NORTHERN HEAVY IND GRP CO LTD

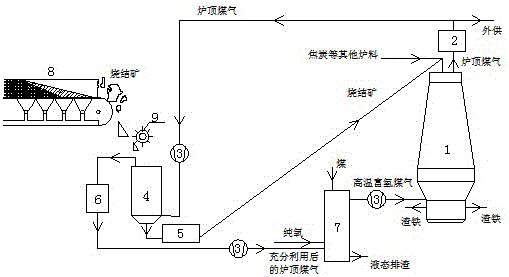

Iron smelting process achieving effective and cyclic utilization of stock gas of blast furnace

InactiveCN106636508AImprove cooling efficiencyLarge volume utilizationBlast furnace detailsIncreasing energy efficiencySmelting processCrusher

Provided is an iron smelting process achieving effective and cyclic utilization of stock gas of a blast furnace. The reduction potential of the stock gas of the blast furnace is fully utilized for performing prereduction on sintering ore, with high temperature, of the tail of a sintering machine so as to eliminate reduction degradation of the sintering ore in the blast furnace and improve the metallurgical performance of furnace charges put into the furnace. A sintering circular cooler is replaced with a vertical sintering ore prereduciton and cooling furnace, waste heat of the sintering ore is effectively recycled, and the sintering energy consumption is reduced. Coal gas circulates from the blast furnace to a dust remover, a pressure device, the vertical sintering ore prereduciton and cooling furnace, a waste heat recovery device, the presure device, a gas making converter, the pressure device and the blast furnace. According to the sintering ore reduction and cooling process, the finished sintering ore at the machine tail passes through a hot crusher, the vertical sintering ore prereduciton and cooling furnace and a sintering ore whole-grain screening device and is conveyed to top charging equipment of the blast furnace.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Double-layer vortex secondary air system of garbage incinerator

InactiveCN108317520AAgitated obviouslyExtended stayIncinerator apparatusNon-combustible gases/liquids supplyCombustion chamberPower station

A double-layer vortex secondary air system of a garbage incinerator comprises upper layer vortex secondary air nozzles, lower layer secondary air nozzles and a garbage incinerator body, wherein the upper portion of the garbage incinerator body is provided with an upper furnace B, and the lower portion of the garbage incinerator body is provided with a lower combustion chamber C. One of the upper layer vortex secondary air nozzles is arranged at the junction of the upper section D of the front wall and the middle section E of the front wall of the garbage incinerator body, and the other one ofthe upper layer vortex secondary air nozzles is arranged at the junction of the upper section F of the rear wall and the middle section G of the rear wall of the garbage incinerator body. One of the lower layer secondary air nozzles is arranged at the junction of the middle section E of the front wall and the lower section H of the front wall of the garbage incinerator body, and the other one of the lower layer secondary air nozzles is arranged at the junction of the middle section G of the rear wall and the lower section I of the rear wall of the garbage incinerator body. According to the double-layer vortex secondary air system of the garbage incinerator, the horizontal vortex combustion technology is adopted for upper layer vortex secondary air, flue gas is in a spirally-rising state, the concentration of co is significantly reduced, and the combustion is more sufficient; the upper layer vortex secondary air constitutes a symmetric double-vortex region, and the combustion efficiencyis improved; and the double-layer vortex secondary air system of the garbage incinerator is used in the technical field of garbage incineration equipment of a large-scale power plant.

Owner:NORTHERN HEAVY IND GRP CO LTD

Catalyst for deep removal of CO, and preparation method thereof

ActiveCN114082420AEasy to prepareMild reaction conditionsHydrogen separation using solid contactCatalyst activation/preparationPtru catalystPhysical chemistry

The invention discloses a preparation method of a catalyst for deep removal of CO. The preparation method comprises the following steps: (1) taking zirconium nitrate pentahydrate or a mixture of zirconium nitrate pentahydrate and metal oxide as a raw material, then adding urea for hydrothermal reaction, and washing, drying and calcining the obtained reaction product to obtain a ZrO2-based carrier; and (2) performing a hydrothermal reaction on nickel nitrate hexahydrate, the ZrO2-based carrier prepared in the step (1) and urea which serve as raw materials, and washing, drying and calcining an obtained reaction product to obtain the catalyst for deep removal of CO. According to the prepared catalyst, NiO is loaded on the ZrO2-based carrier, and the catalyst is small in particle size, has excellent adsorption performance on hydrogen and CO, can reduce the concentration of CO in hydrogen-rich gas to 0.05 ppm or below, can be used for deep purification of raw material gas of a proton membrane exchange battery, meets the national standard requirement and is wide in application prospect.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com