Low-water-gas-ratio CO conversion device and low-water-gas-ratio CO conversion method

A technology for conversion device and water-gas ratio, applied in the direction of climate sustainability, catalytic treatment of combustible gas, sustainable manufacturing/processing, etc., can solve the problems of affecting the service life of the catalyst, difficult to control the depth of the reaction, large steam consumption, etc. , to achieve the effect of reducing subsequent system equipment and pipeline loads, flexible and convenient air volume adjustment, and avoiding over-temperature phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

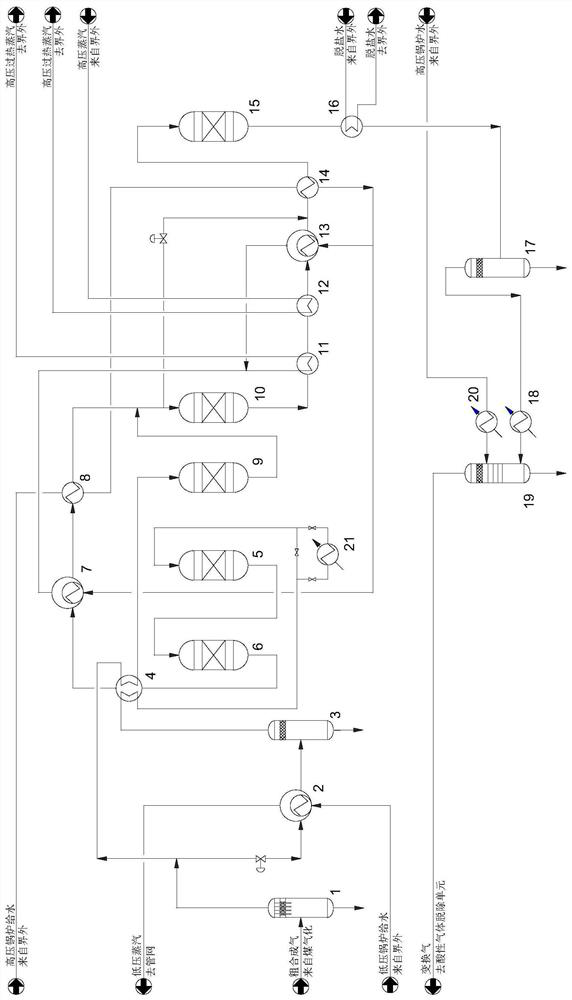

Embodiment 1

[0039] The 484880kg / h crude synthesis gas (206℃, 3.84MPa, water-gas ratio: 0.91) from the upstream coal gasification unit enters the 1# gas-liquid separator for gas-liquid separation, and is divided into two streams. The first stream is on the pipeline A flow regulating valve is set to control the flow distribution ratio of the first stream and the second stream to be 6:4. After the first stream (flow rate is 290928kg / h) passes through the steam generator, the by-product is 92503kg / h hLow-pressure saturated steam (165°C, 0.5MPa), after the water-gas ratio of the crude synthesis gas is reduced to 0.24, it enters the 2# gas-liquid separator for gas-liquid separation, and the top gas phase is heated to 200°C by the feed gas heater, After passing through the 1# detoxification tank, it enters the 1# shift furnace for carbon monoxide shift reaction. The inlet temperature of the 1# shift furnace is 200°C, and the outlet temperature of the shift gas at the outlet of the 1# shift furnac...

Embodiment 2

[0041] The 484880kg / h crude synthesis gas (206℃, 3.84MPa, water-gas ratio: 0.91) from the upstream coal gasification unit enters the 1# gas-liquid separator for gas-liquid separation, and is divided into two streams. The first stream is on the pipeline A flow regulating valve is provided to control the flow distribution ratio of the first stream and the second stream to be 5:5. After the first stream (flow rate is 242440kg / h) passes through the steam generator, the by-product is 82146kg / h hLow-pressure saturated steam (165°C, 0.5MPa), after the water-gas ratio of the crude synthesis gas is reduced to 0.2, it enters the 2# gas-liquid separator for gas-liquid separation, and the top gas phase is heated to 225°C by the feed gas heater, After passing through the 1# detoxification tank, it enters the 1# shift furnace for carbon monoxide shift reaction. The inlet temperature of the 1# shift furnace is 225°C, and the outlet temperature of the shift gas at the outlet of the 1# shift fu...

Embodiment 3

[0043] The 484880kg / h crude synthesis gas (206℃, 3.84MPa, water-gas ratio: 0.91) from the upstream coal gasification unit enters the 1# gas-liquid separator for gas-liquid separation, and is divided into two streams. The first stream is on the pipeline A flow regulating valve is provided to control the flow distribution ratio of the first stream and the second stream to be 4:6. After the first stream (flow rate is 193952kg / h) passes through the steam generator, the by-product is 55218kg / h hLow-pressure saturated steam (165°C, 0.5MPa), after the water-gas ratio of the crude synthesis gas is reduced to 0.3, it enters the 2# gas-liquid separator for gas-liquid separation, and the top gas phase is heated to 260°C by the feed gas heater, After passing through the 1# detoxification tank, it enters the 1# shift furnace for carbon monoxide shift reaction. The inlet temperature of the 1# shift furnace is 260°C, and the outlet temperature of the shift gas at the outlet of the 1# shift fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com