Method for promoting rapid preparation of methane from organic waste by utilizing exogenous hydrogen

A technology for organic waste and methane production, applied in waste fuel, fermentation, etc., can solve the problems of unbalanced distribution, unsuitable scale, complicated operation, etc., shorten anaerobic digestion cycle, increase methane bacteria activity, and reduce CO2 concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

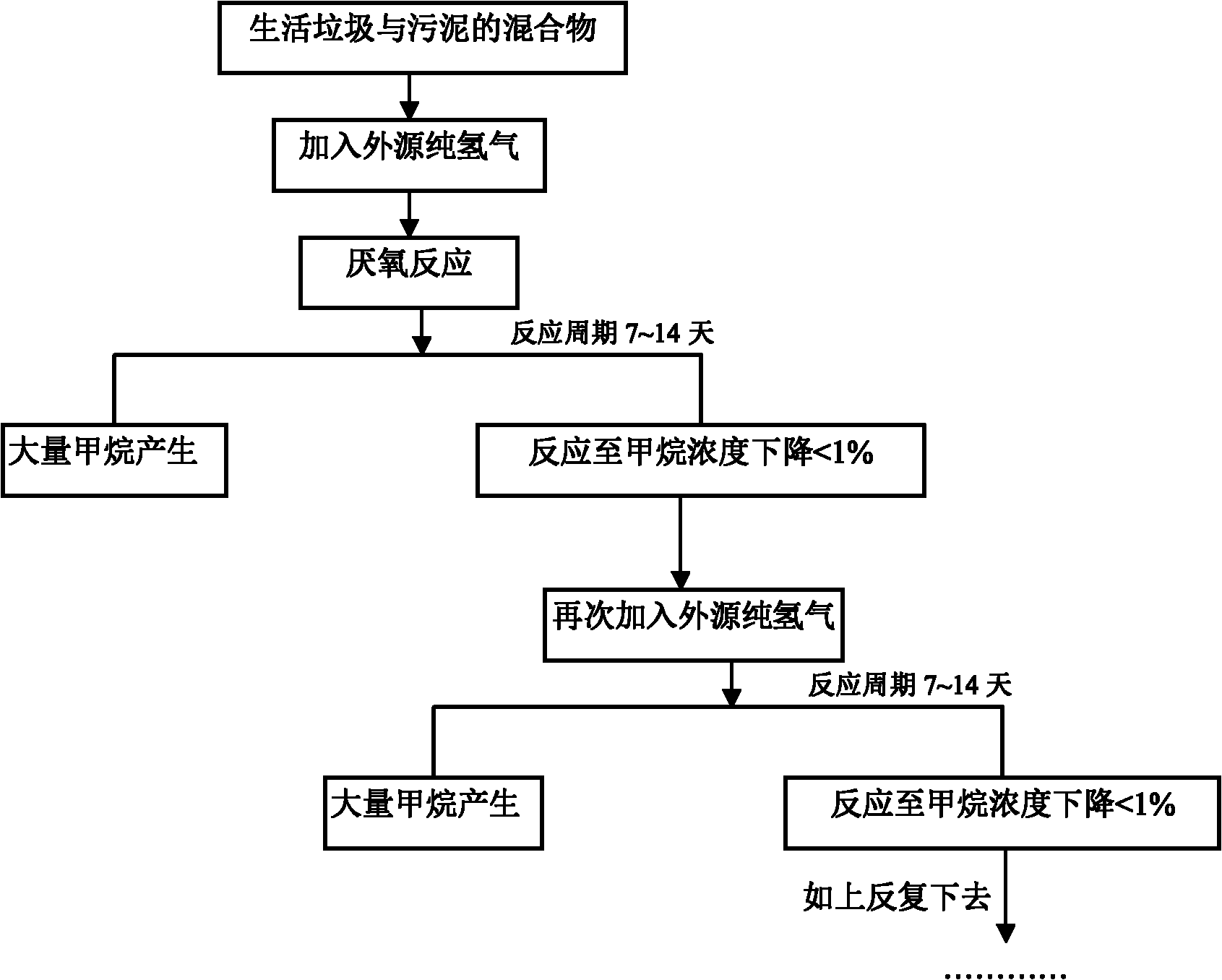

Method used

Image

Examples

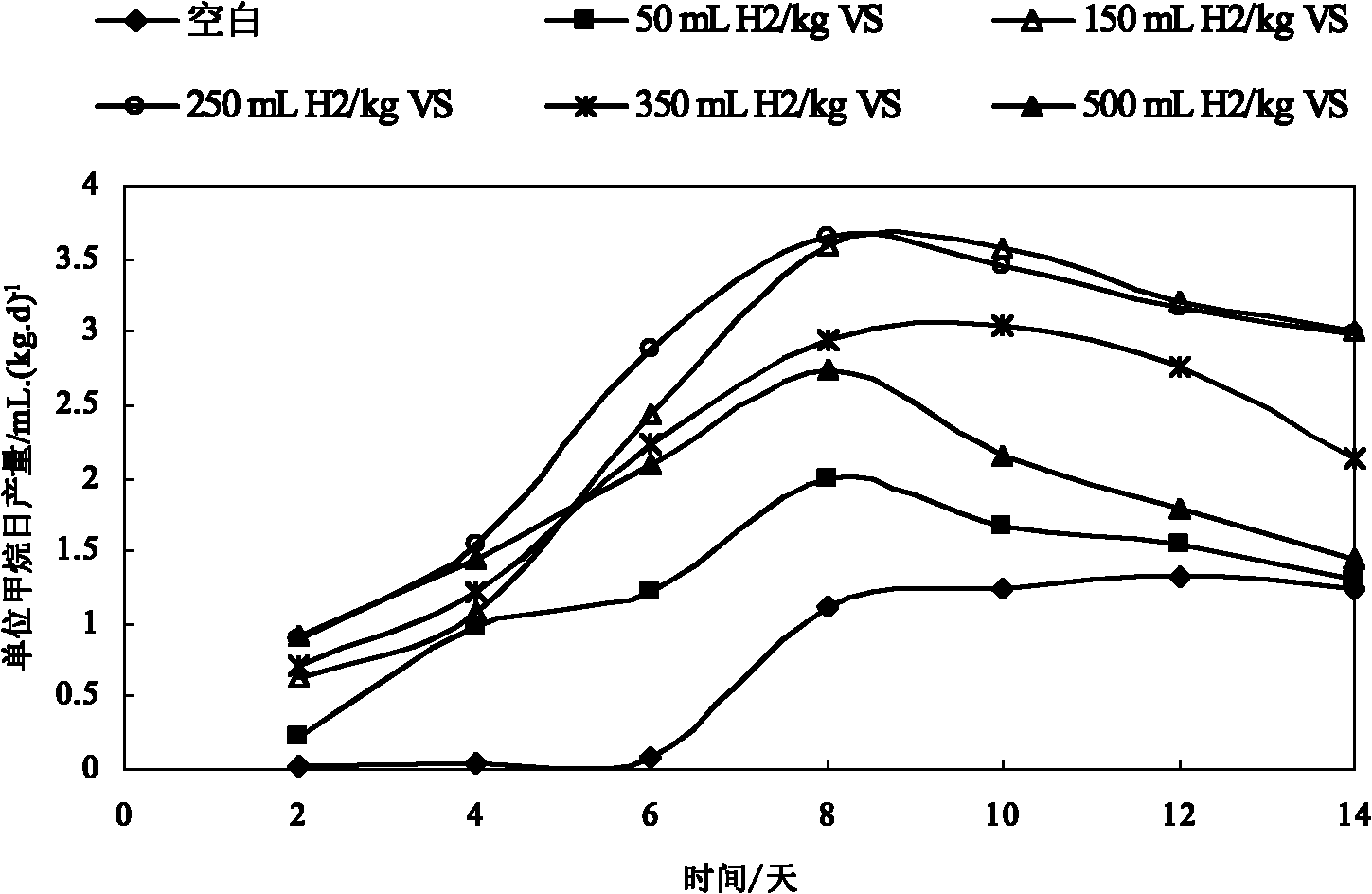

Embodiment 1

[0022] After simply crushing domestic waste with a moisture content of 50-60%, 12 domestic waste samples were weighed, each 0.070 kg. At the same time, sludge with a moisture content of 60-80% was prepared, and 12 parts were also weighed, each 0.030 g. Take 1 part each of domestic garbage and sludge and mix them thoroughly and put them into 200mL plastic test bottles. In this experiment, a total of 12 mixed test samples were placed in 12 test bottles, divided into 6 groups, and each group had two parallel samples. The VS content of the mixed experimental sample is about 20%, and the water content is about 65%. Introduce nitrogen to make the test bottle free of other impurity gases, seal it and place it in a constant temperature room at 37°C to simulate the anaerobic fermentation state. Add 0, 1, 3, 5, 7, 10 mL of pure H from the lower end of the test bottle under a pressure of 3.3 MPa. 2 (0mL is a blank group for comparison; since the VS content of the sample is about 20%, ...

Embodiment 2

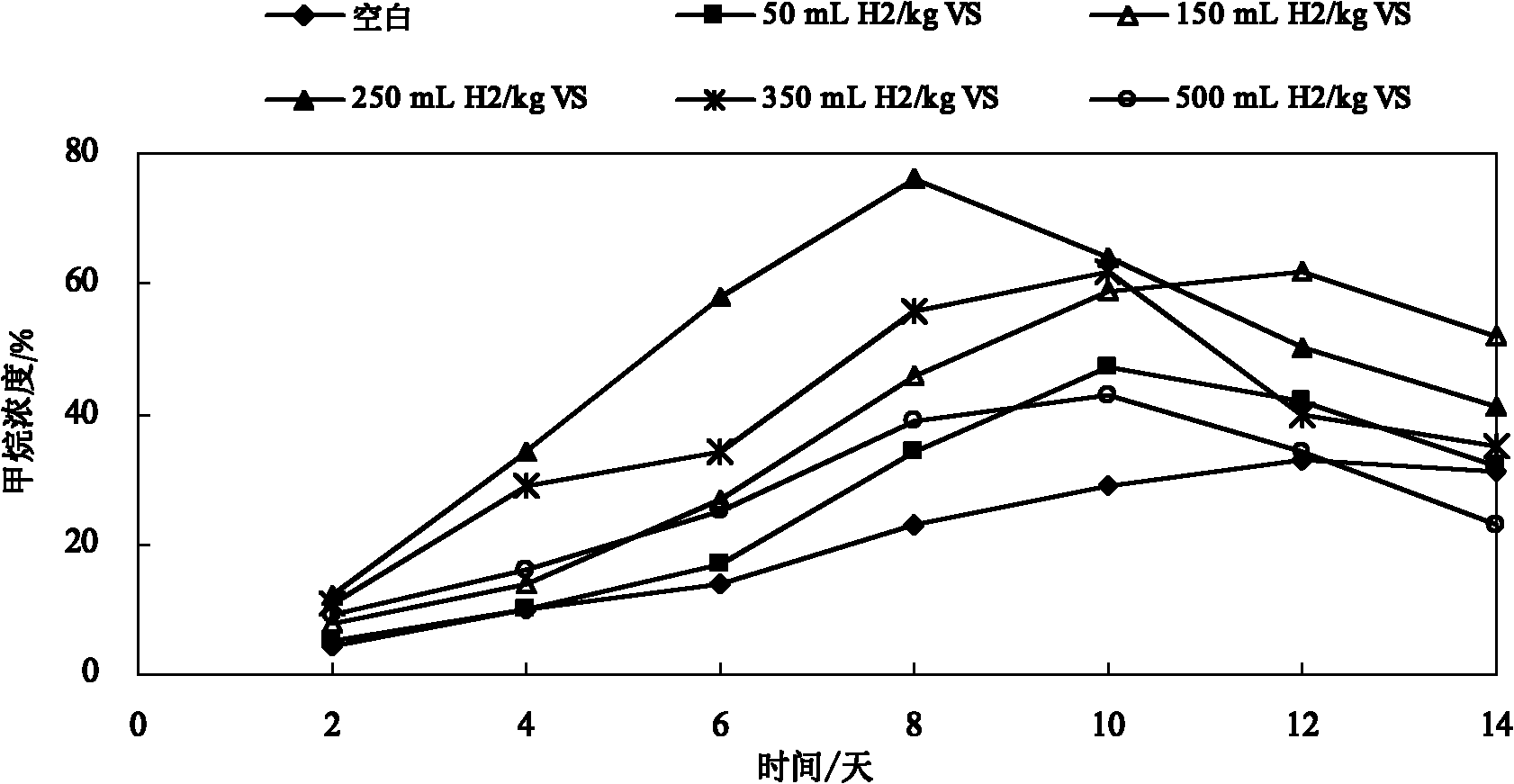

[0024] Please refer to the attached Figure 4 .

[0025] If acid accumulation occurs in the anaerobic decomposition process of garbage, that is, the pH drops, the rate of methane production will be greatly reduced, and the process of garbage decomposition will also slow down. Choose hydrogen addition amount to be 0, 3mL and 5mL respectively, all the other are identical with embodiment 1, in one cycle of reaction (7-14 days) sample solid sample, mix and measure pH with solid sample: water=1: 3, the result sees Figure 4 . Depend on Figure 4 It can be seen from the pH of the system that the pH of the blank group has dropped below 6.4, and such a downward trend will greatly inhibit the activity of methanogens and hinder the decomposition of garbage and the production of methane. After adding hydrogen, the pH of the anaerobic fermentation process is stabilized at 6.5-7.8, which effectively prevents the accumulation of volatile fatty acids and is conducive to the survival of me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com