Miniaturized methanol self-heating reforming hydrogen making integrated apparatus and hydrogen production method

An autothermal reforming, integrated device technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve problems such as low reaction rate, and achieve the effect of easy disassembly and installation, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

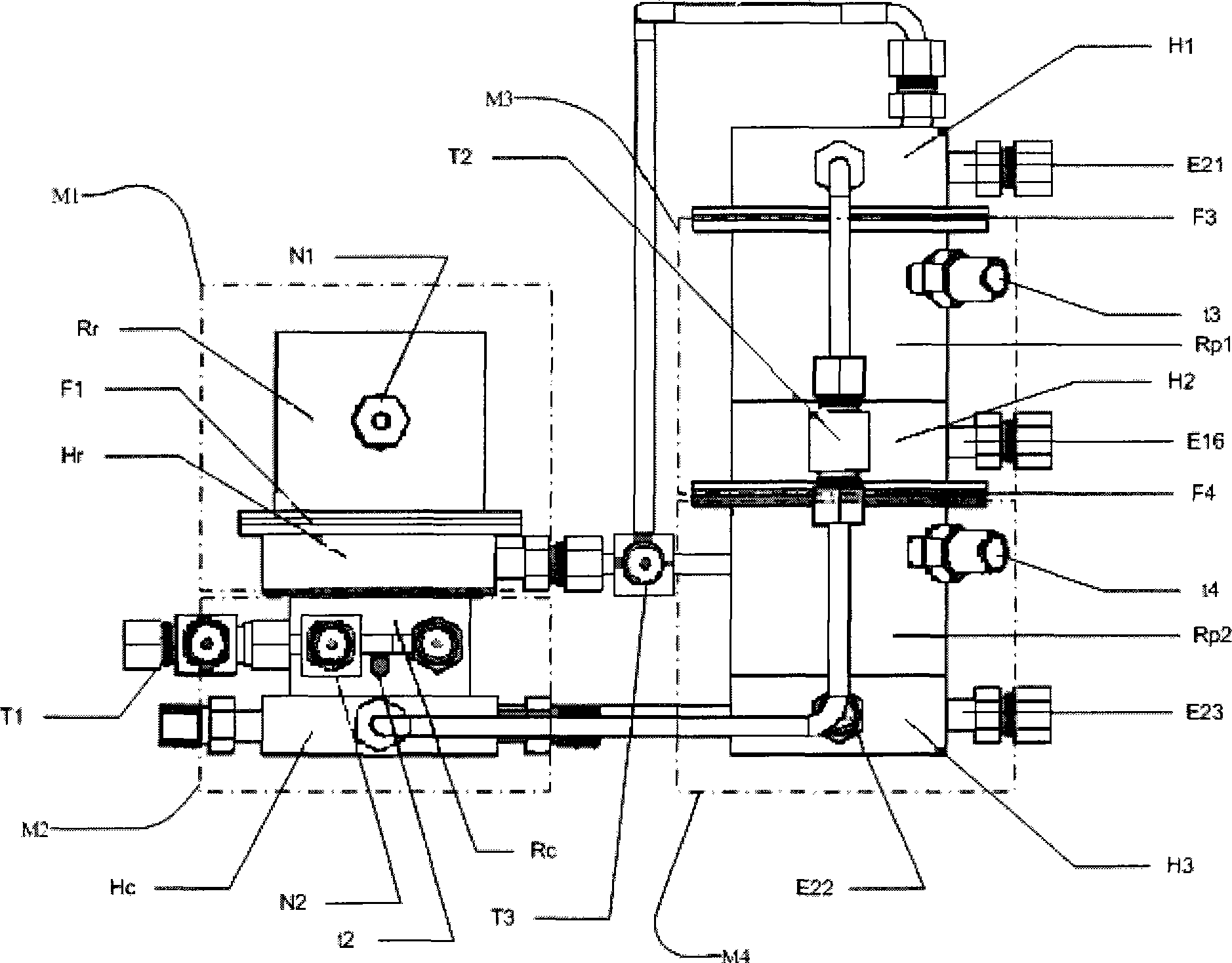

[0049] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

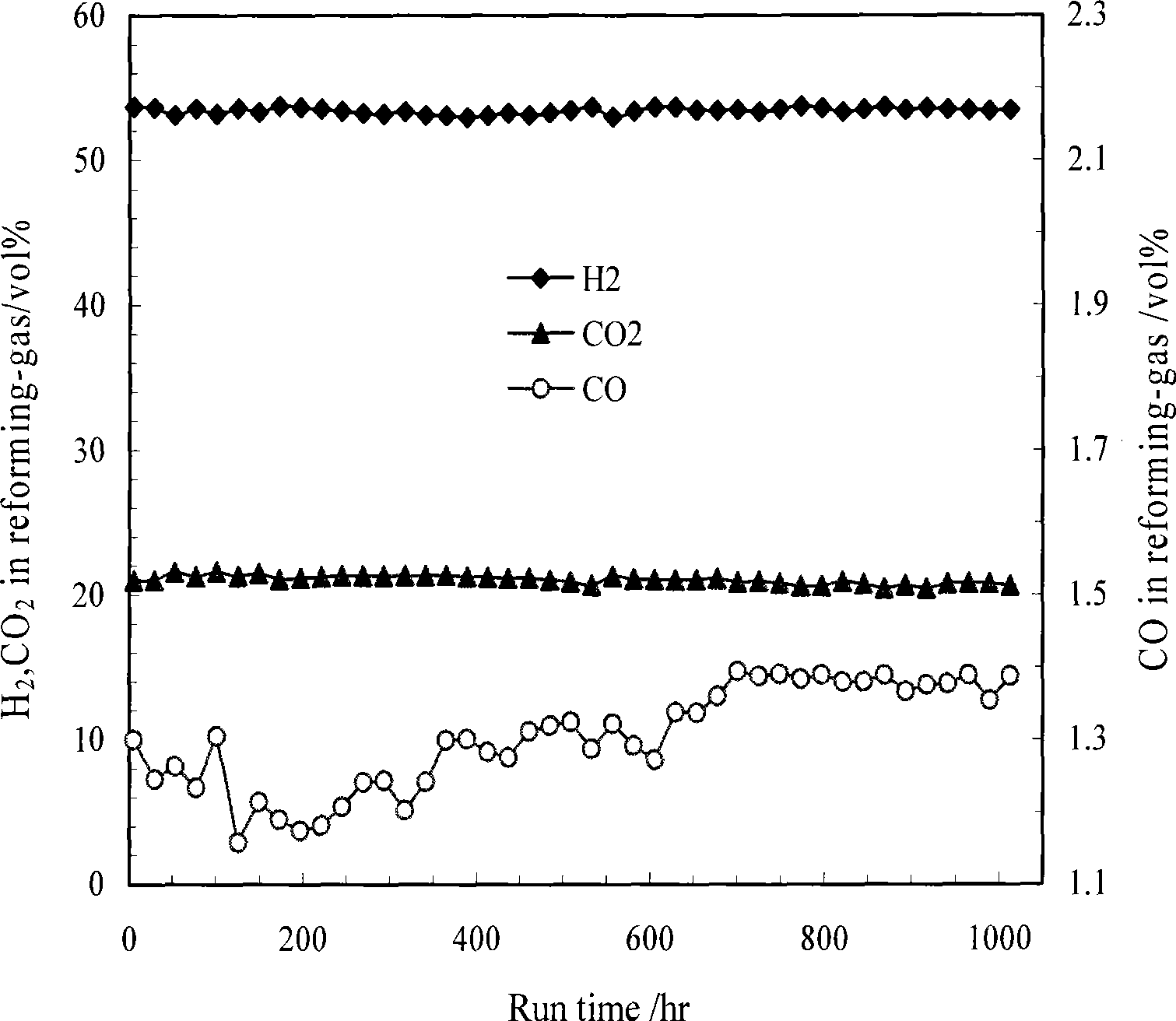

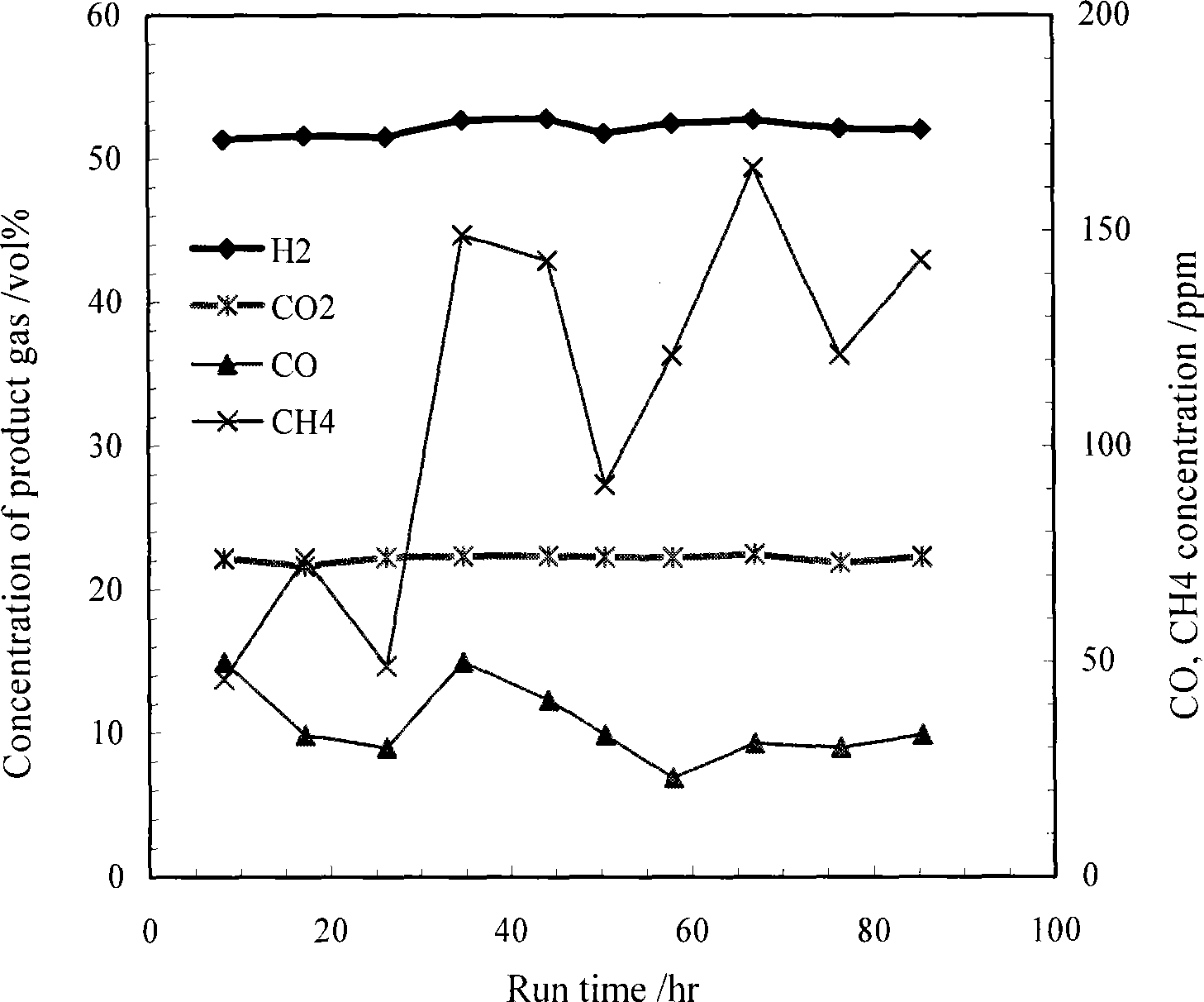

[0050] The invention proposes an integrated system and a hydrogen production technical solution suitable for the system. The system includes a group of reforming / heat exchange, a group of fuel combustion / vaporization, and two groups of CO selective oxidation / heat exchange integrated four modular structural units, the four modular structural units are integral catalytic reactor and microchannel heat exchange connected in an integrated manner. The hydrogen production technology scheme applicable to this system includes methanol oxidation reforming hydrogen production process, CO two-step selective oxidation process in reformed gas, fuel combustion / vaporization process and reforming feedstock in heat exchangers in each process unit The process of cascade heat exchange.

[0051] 1. Integrated system. A miniaturized hydrogen source system integrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com