Patents

Literature

45 results about "PROX" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

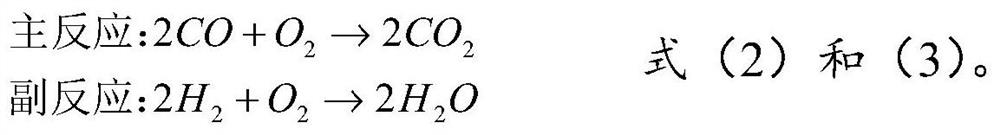

PROX is an acronym for PReferential OXidation, and refers to the preferential oxidation of a gas on a catalyst. The catalyst preferentially oxidises carbon monoxide (CO) using a heterogeneous catalyst placed upon a ceramic support. Catalysts include metals such as platinum, platinum/iron, platinum/ruthenium, gold nanoparticles as well as novel copper oxide/ceramic conglomerate catalysts.

Carbon monoxide adsorption for carbon monoxide clean-up in a fuel cell system

InactiveUS6964692B2Eliminate useReduce carbon monoxide contentThermal non-catalytic crackingCombination devicesSorbentHydrogen fuel cell

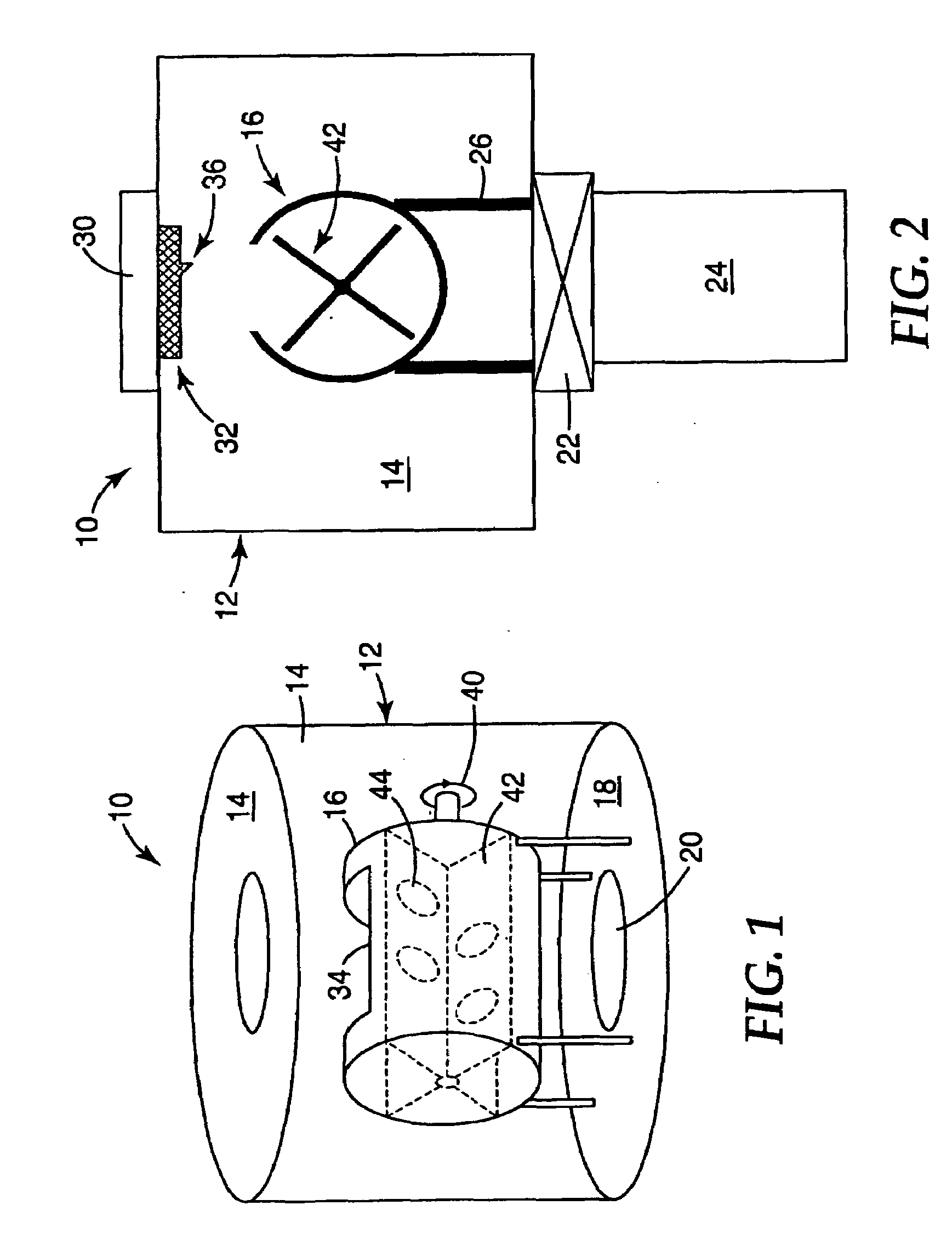

An apparatus removes carbon monoxide (CO) from a hydrogen-rich gas stream in a hydrogen fuel cell system. CO fouls costly catalytic particles in the membrane electrode assemblies of proton exchange membrane (PEM) fuel cells. A vessel houses a carbon monoxide adsorbent. The vessel may be a rotating pressure swing adsorber. A water gas shift reactor is upstream of the rotating pressure swing adsorber. The water gas shift reactor may include a second adsorbent adapted to adsorb carbon monoxide at low temperatures and to desorb carbon monoxide at high temperatures. The apparatus advantageously eliminates the use of a preferential oxidation (PROX) reactor, by providing an apparatus which incorporates CO adsorption in the place of the PROX reactor. This cleans up carbon monoxide without hydrogen consumption and the concomitant, undesirable excess low grade heat generation. The present invention reduces start-up duration, and improves overall fuel processor efficiency during normal operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

Selective Oxidation of Carbon Monoxide Relative to Hydrogen Using Catalytically Active Gold

InactiveUS20090011293A1Readily oxidizes COHigh catalytic activityMaterial nanotechnologyFuel cell auxillariesHydrogenNanoparticle

The present invention provides technology for controlling, or tuning, the catalytic activity of gold provided upon nanoporous supports such as those derived from nanoparticulate, crystalline titania. In some aspects of practice, the surface of nanoparticulate media incorporated into a catalyst system of the present invention is provided with chemical modifications of the surface that dramatically suppress the ability of the resultant catalyst system to oxidize hydrogen. Yet, the system still readily oxidizes CO. In other words, by selecting and / or altering the nanoparticulate surface via the principles of the present invention, PROX catalysts are readily made from materials including catalytically active gold and nanoparticulate media. Additionally, the nanoparticulate support also may be optionally thermally treated to further enhance selectivity for CO oxidation with respect to hydrogen. Such thermal treatments may occur before or after chemical modification, but desirably occur prior to depositing catalytically active gold onto the support incorporating the nanoparticles.

Owner:3M INNOVATIVE PROPERTIES CO

Diagnostic and therapeutic uses for prox 1

Methods and compositions based on the elucidation of the role of Prox1 in lymphatic tissue development in normal and tumor tissue are provided. Included are methods for determining the extent of lymphatic involvement in a tumor, methods for purifying endothelial precursor cells predisposed to develop into lymphatic tissue, and methods for promoting the development of lymphatic tissue. Pharmaceutical compositions and gene therapy vectors useful in the latter methods are provided.

Owner:ST JUDE CHILDRENS RES HOSPITAL INC

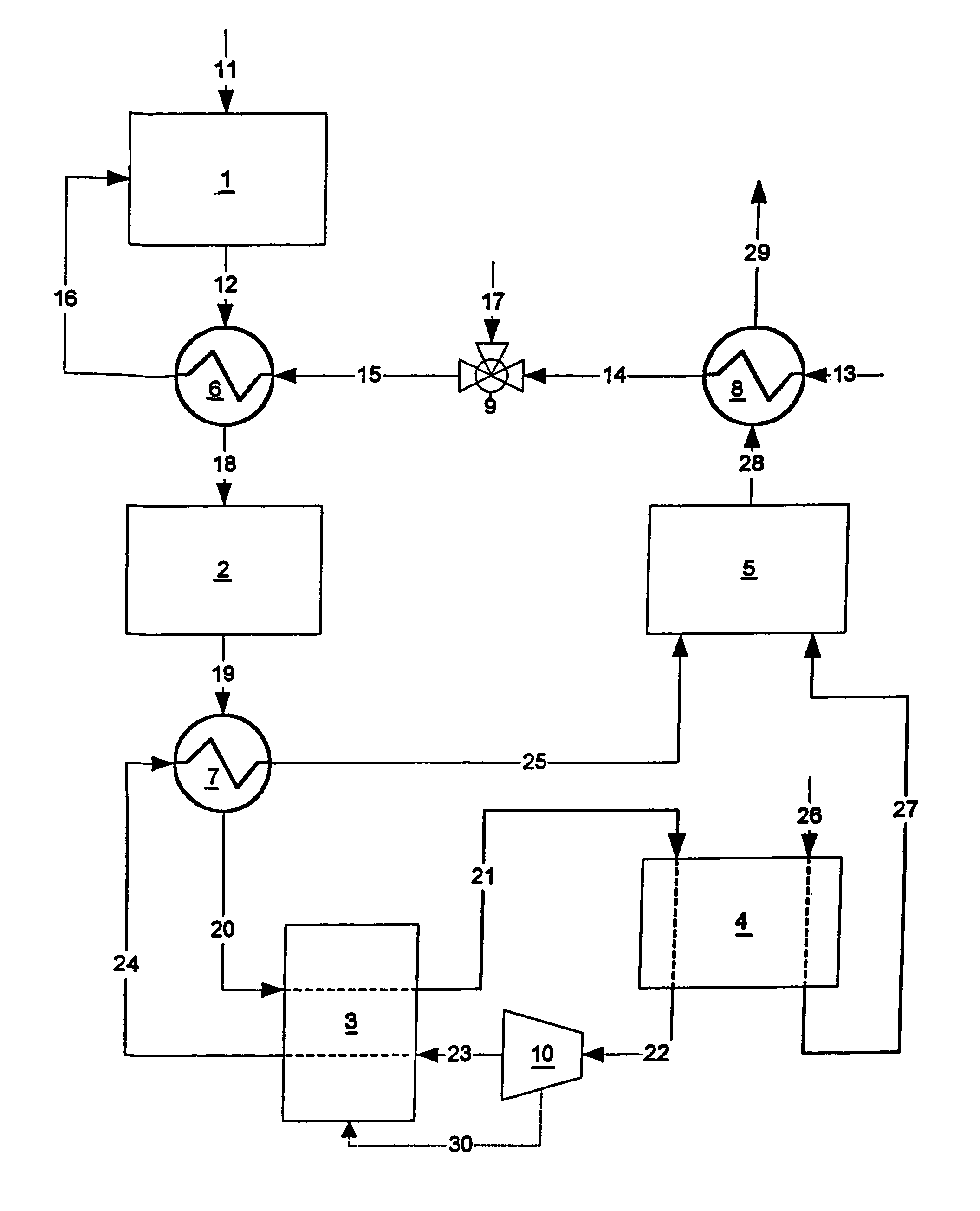

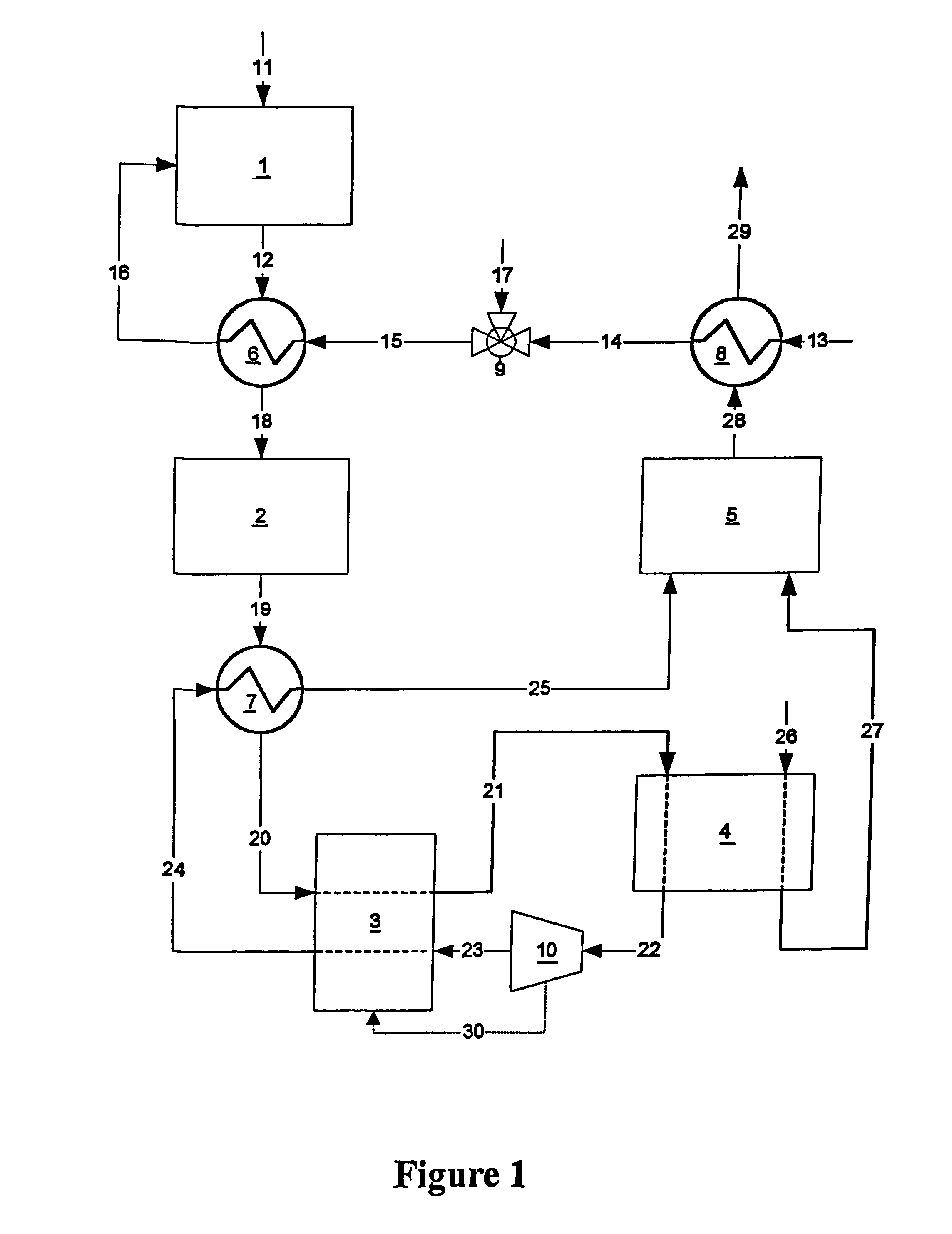

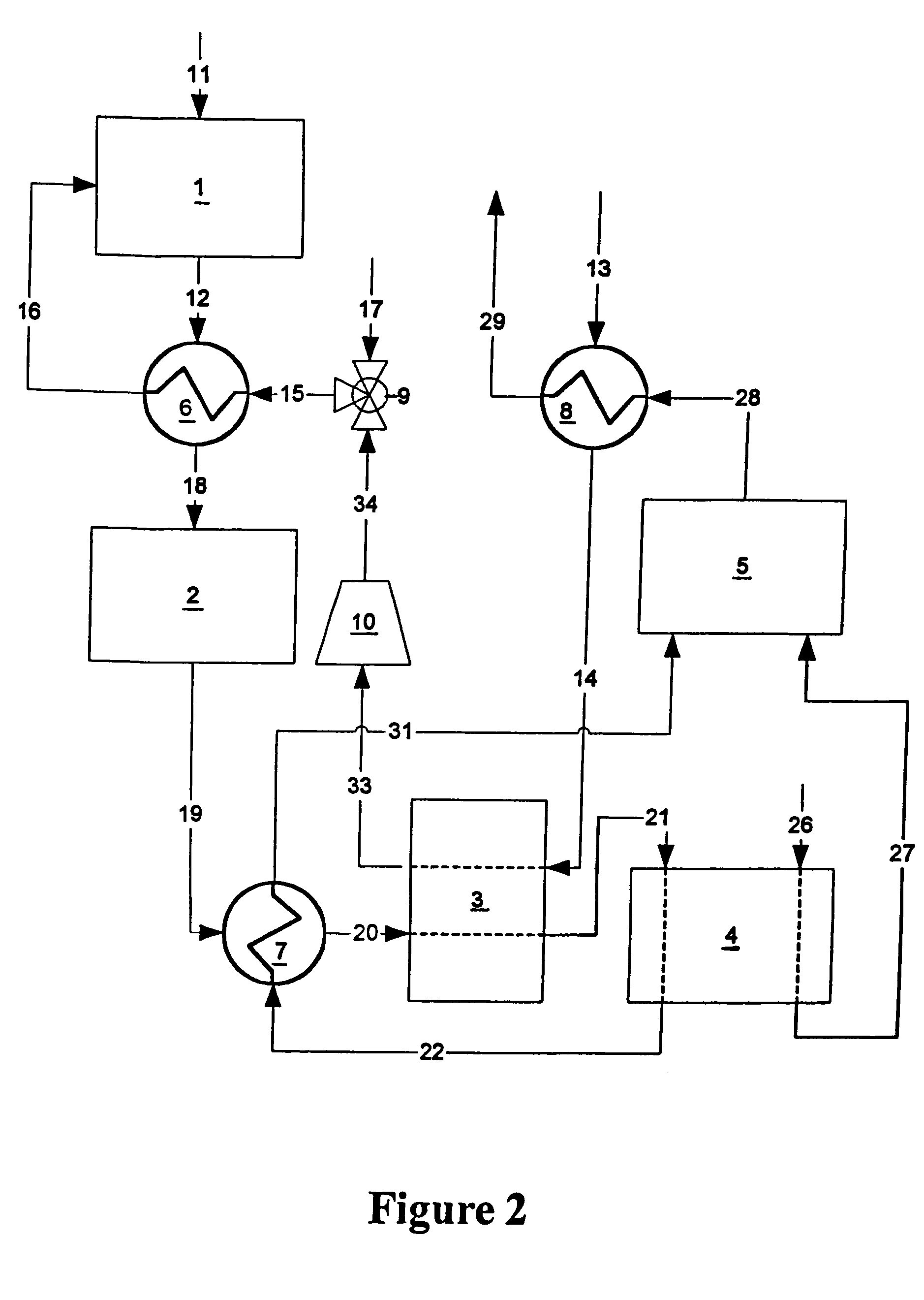

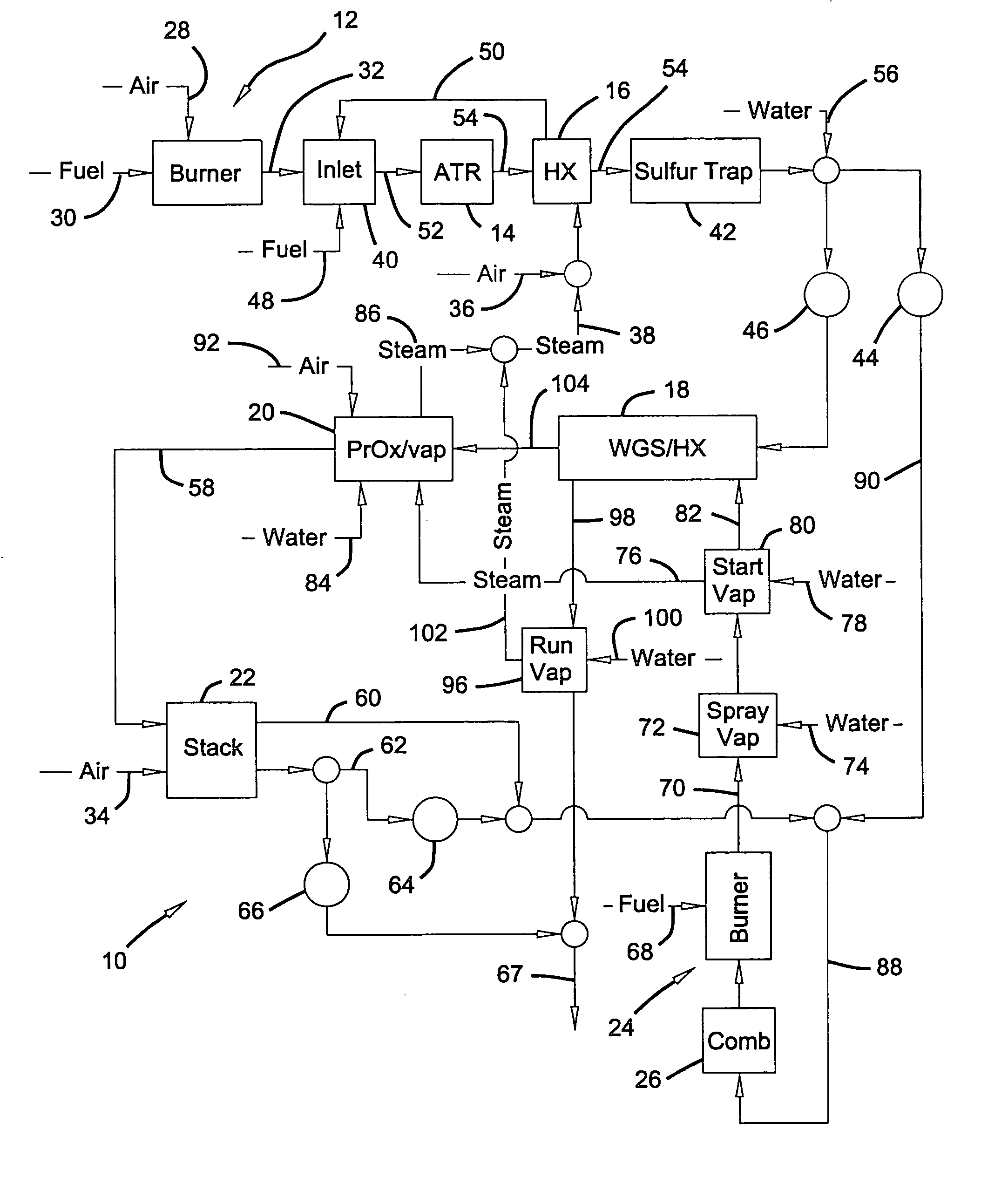

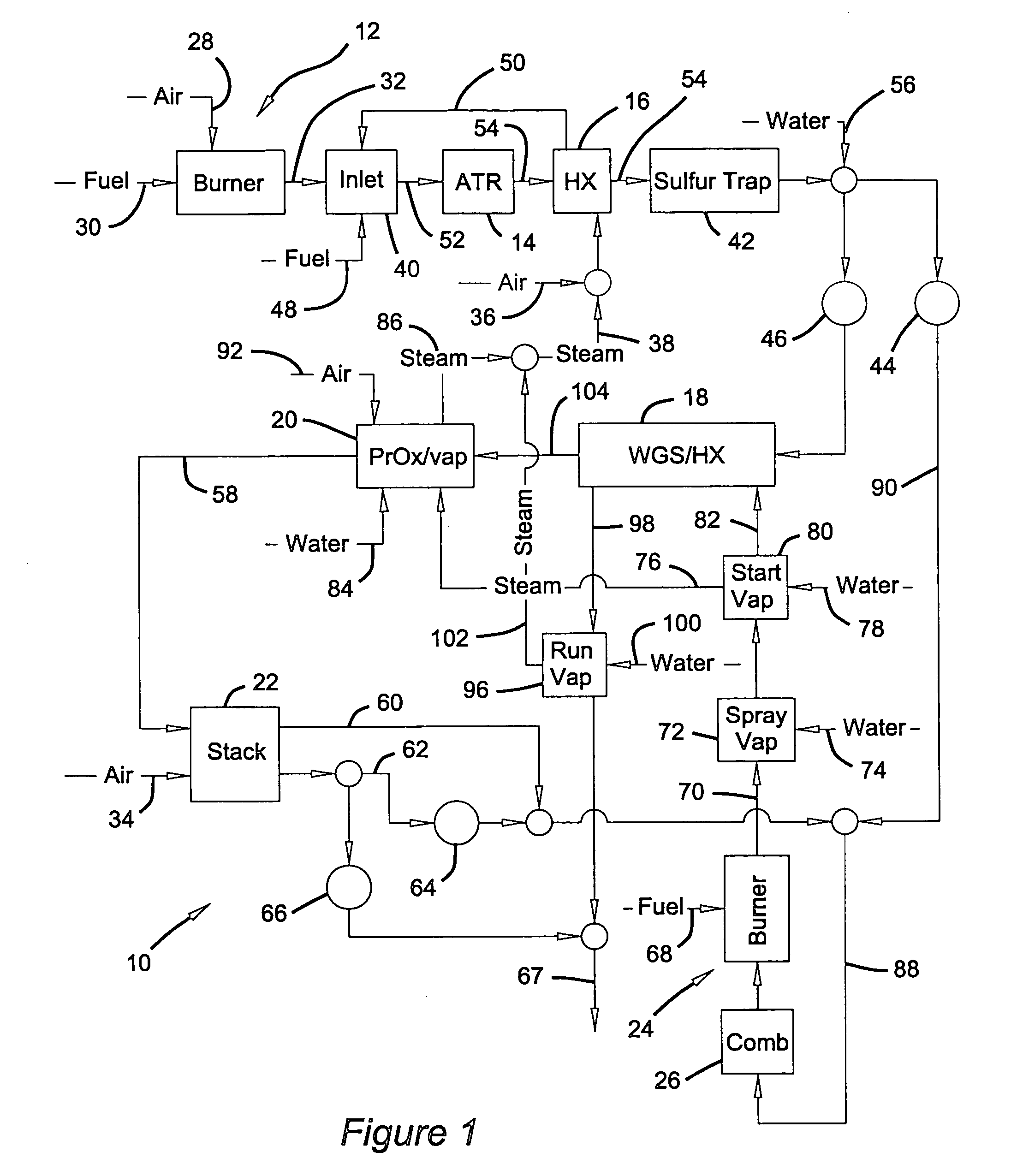

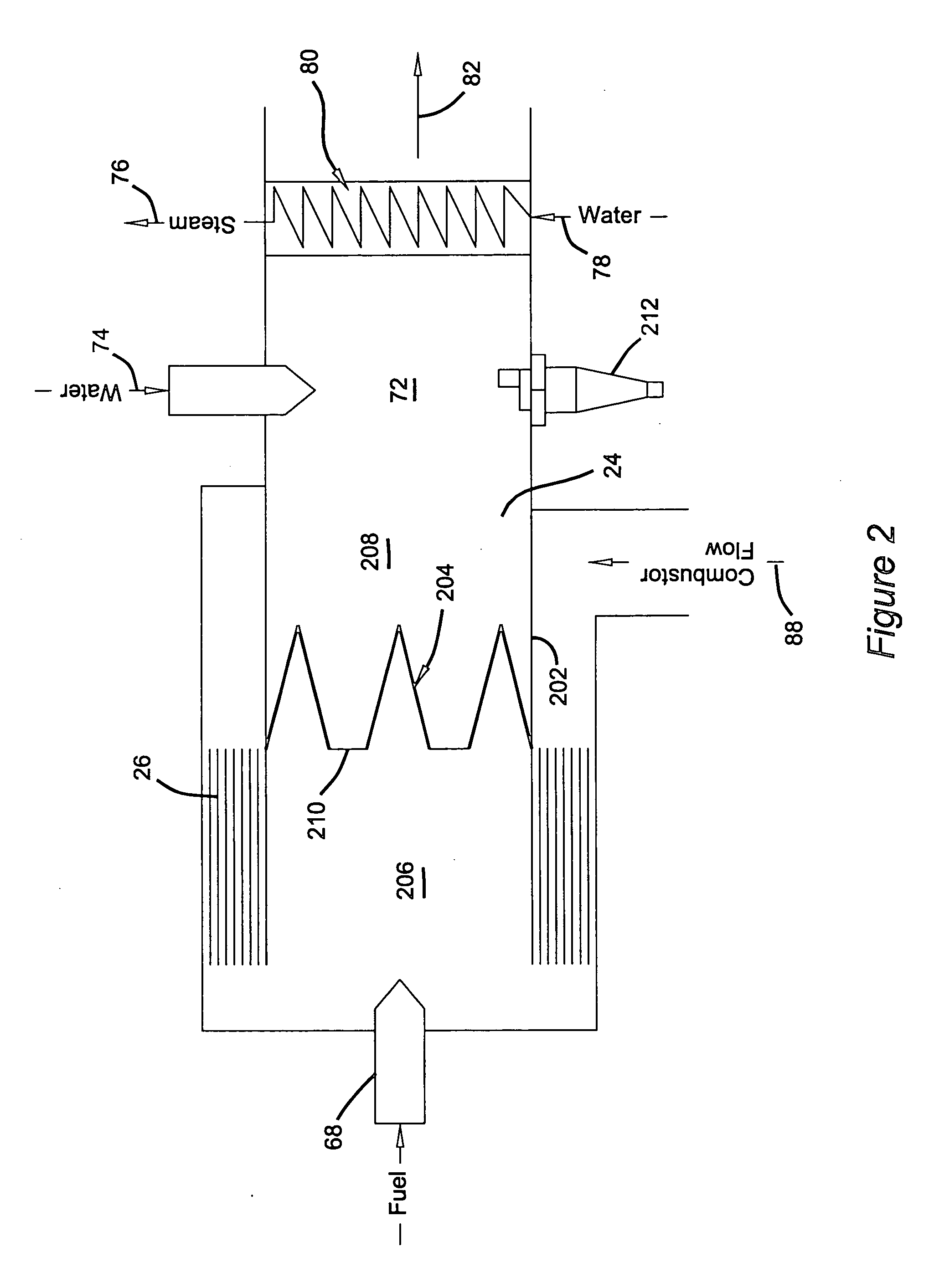

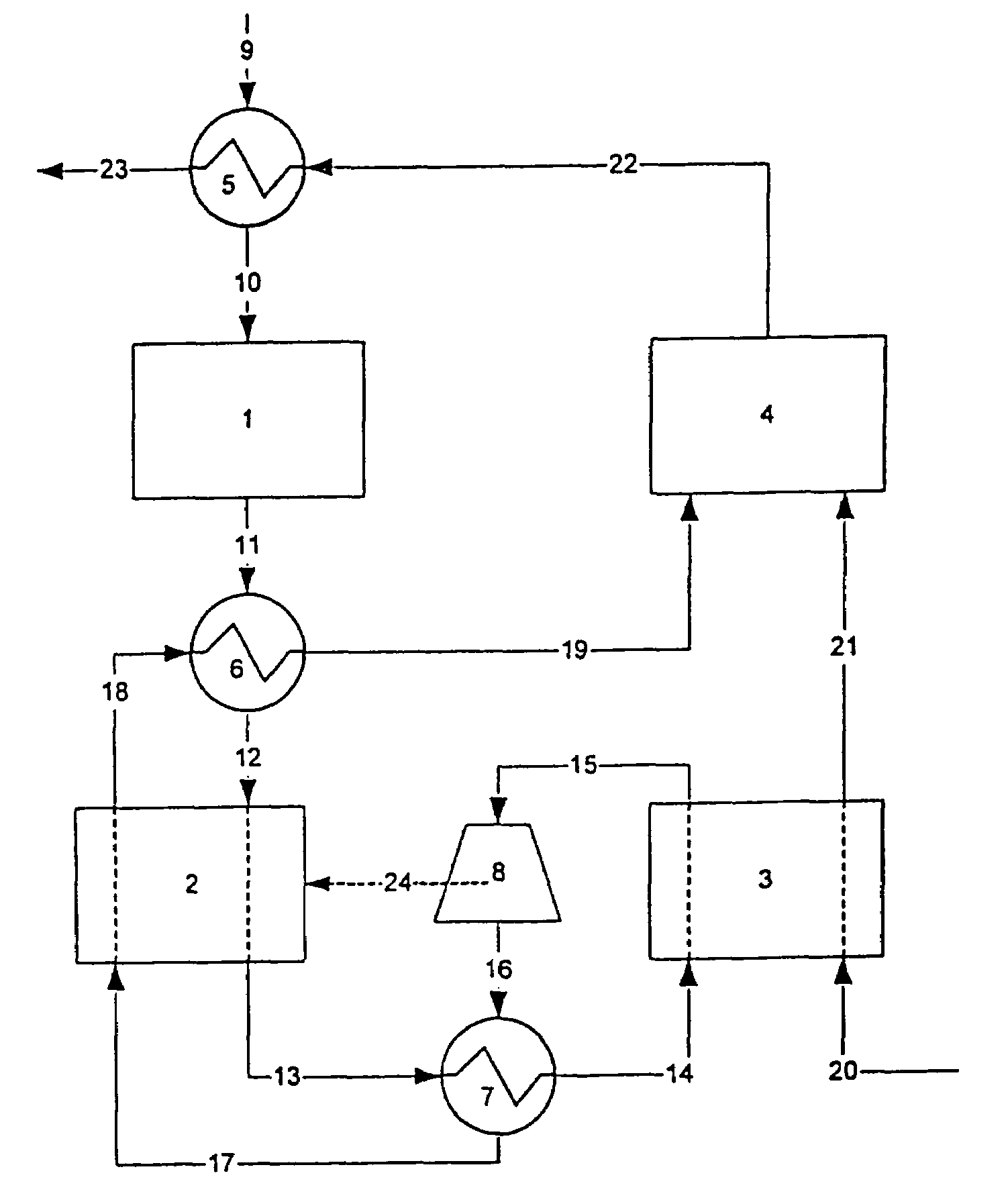

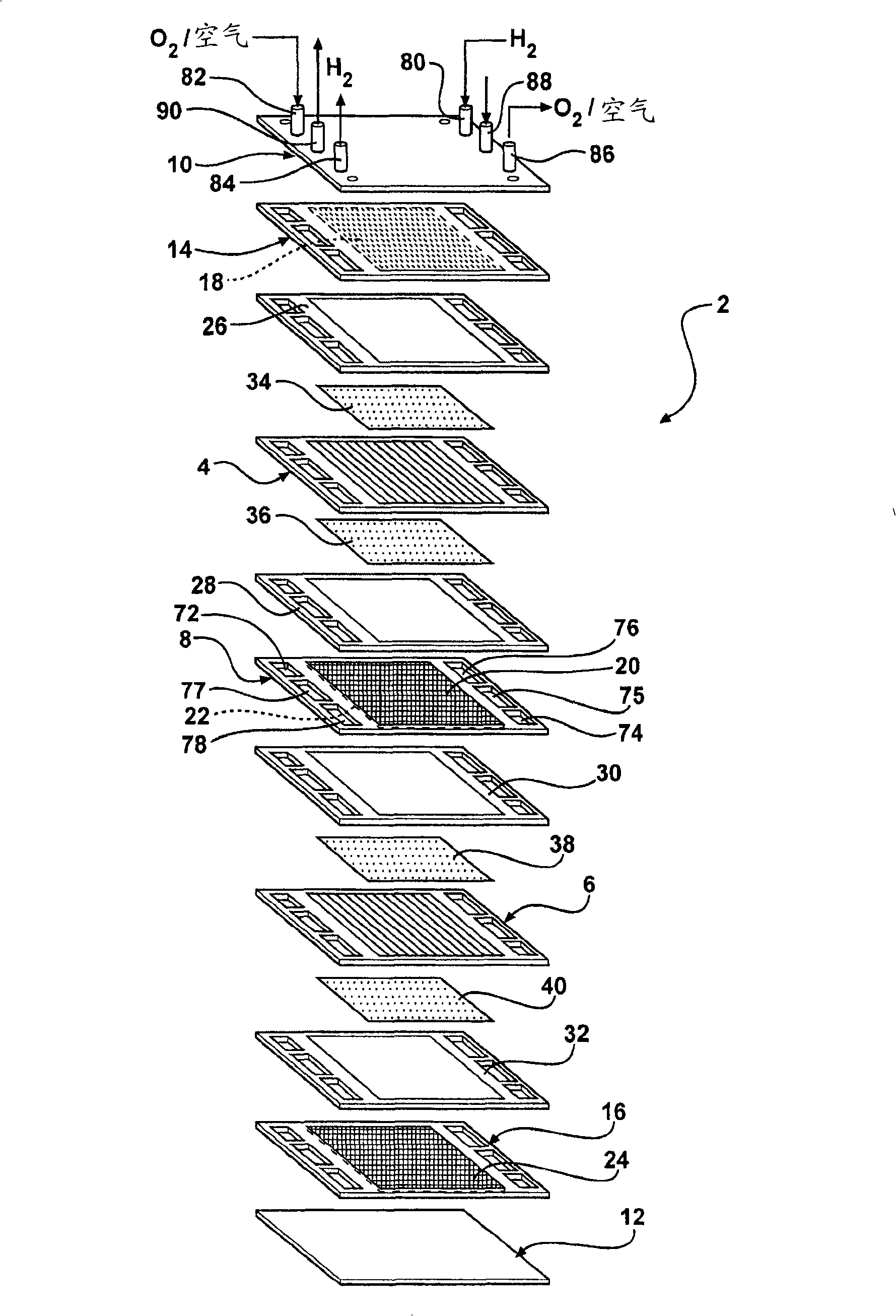

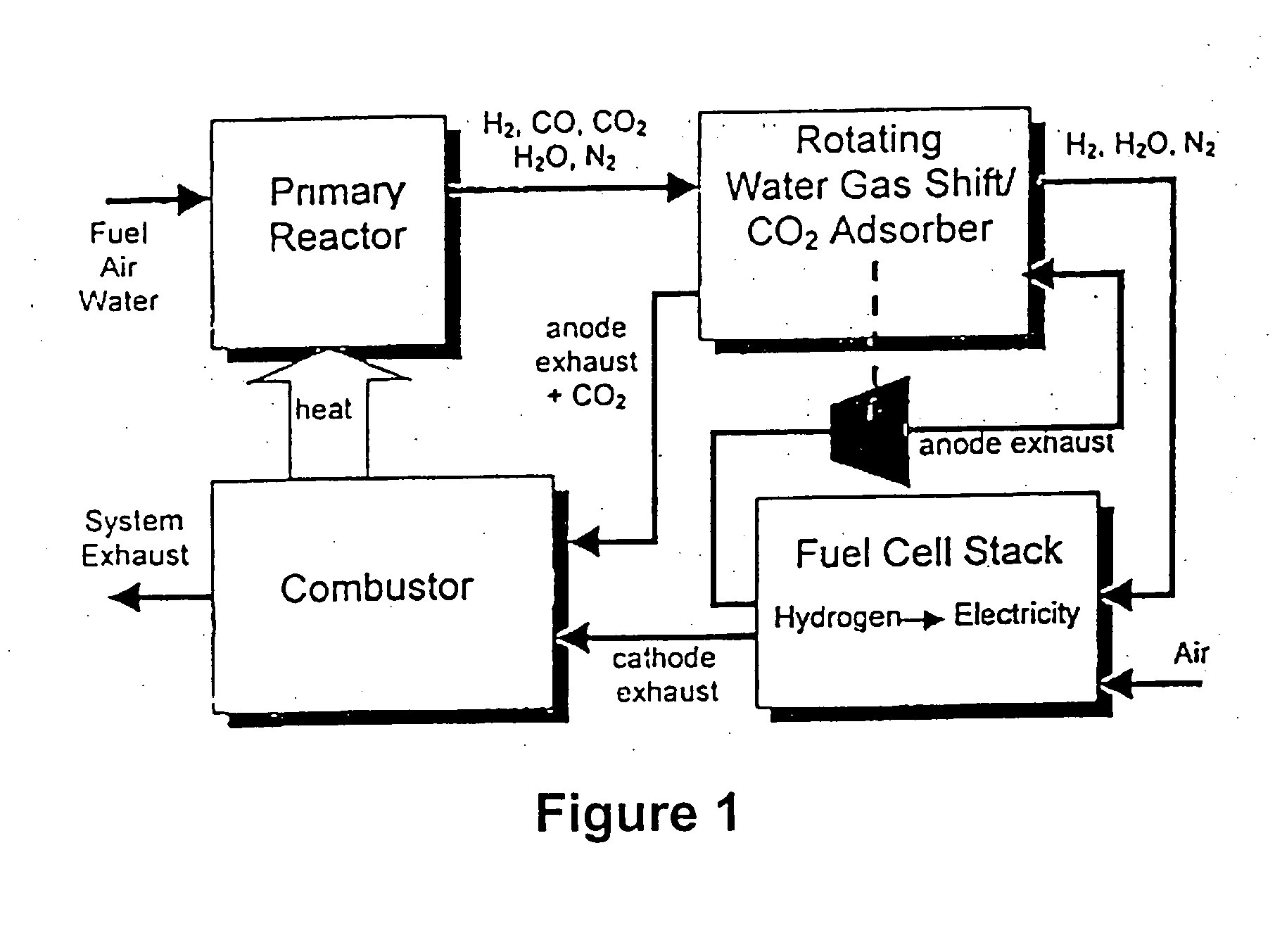

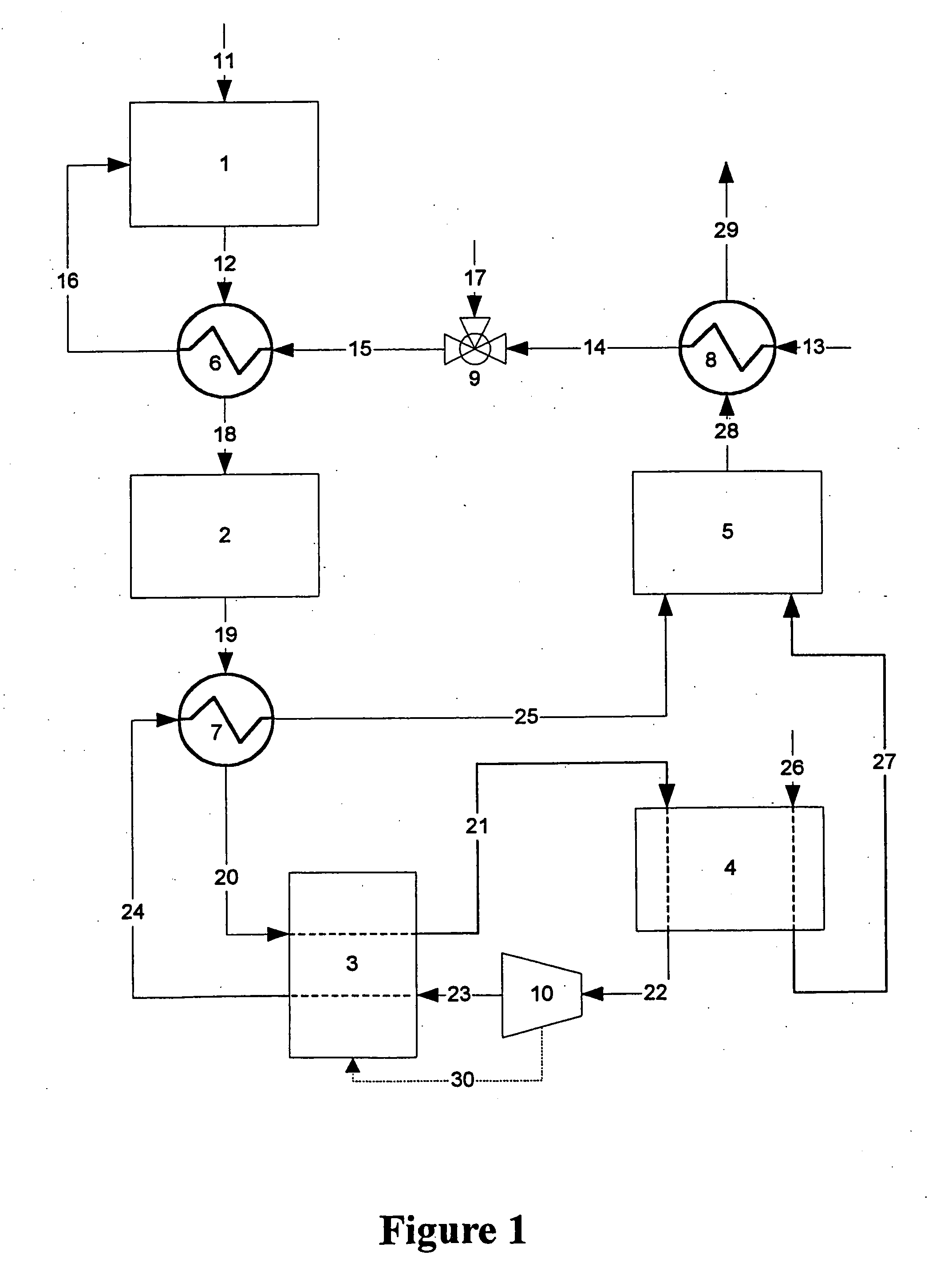

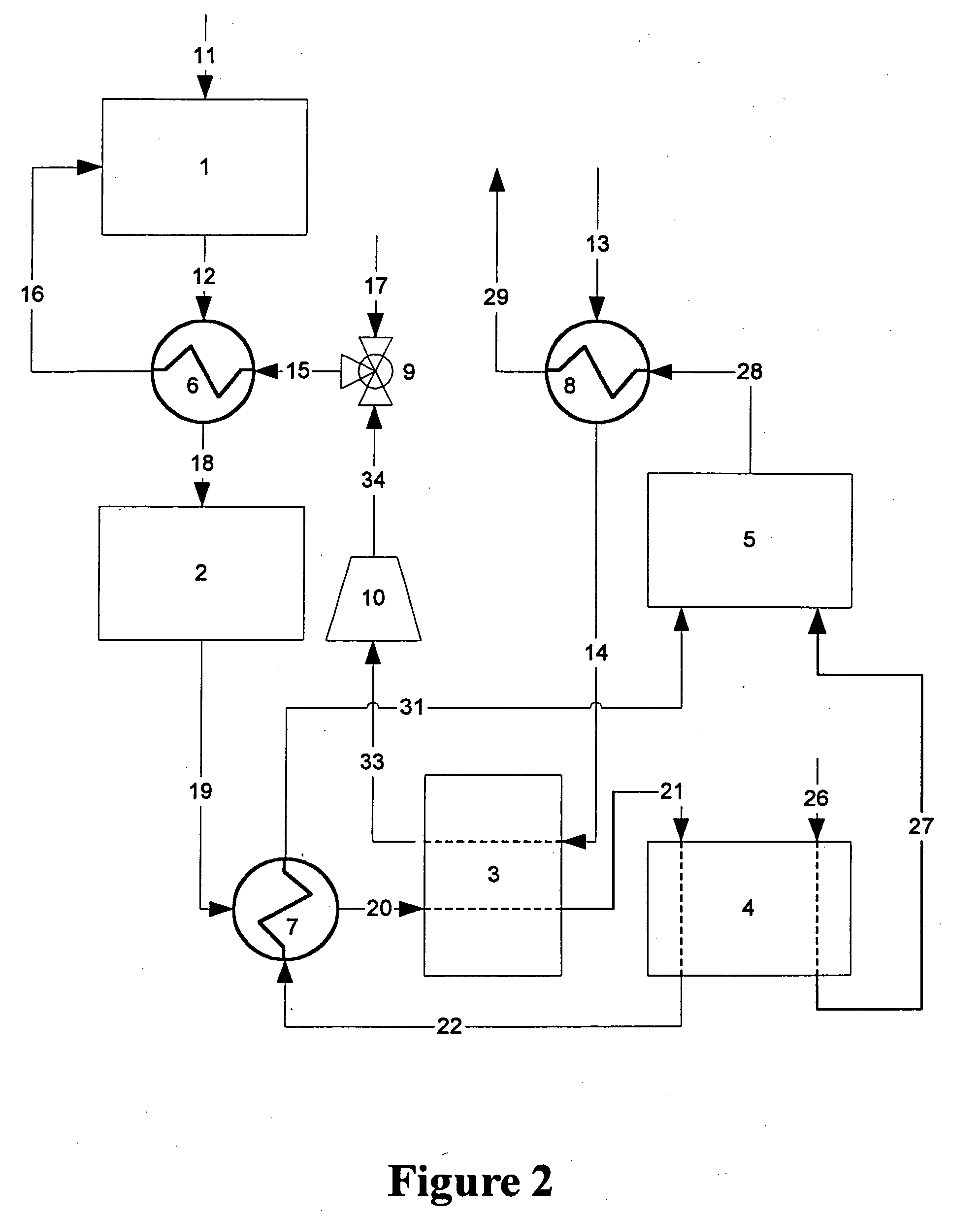

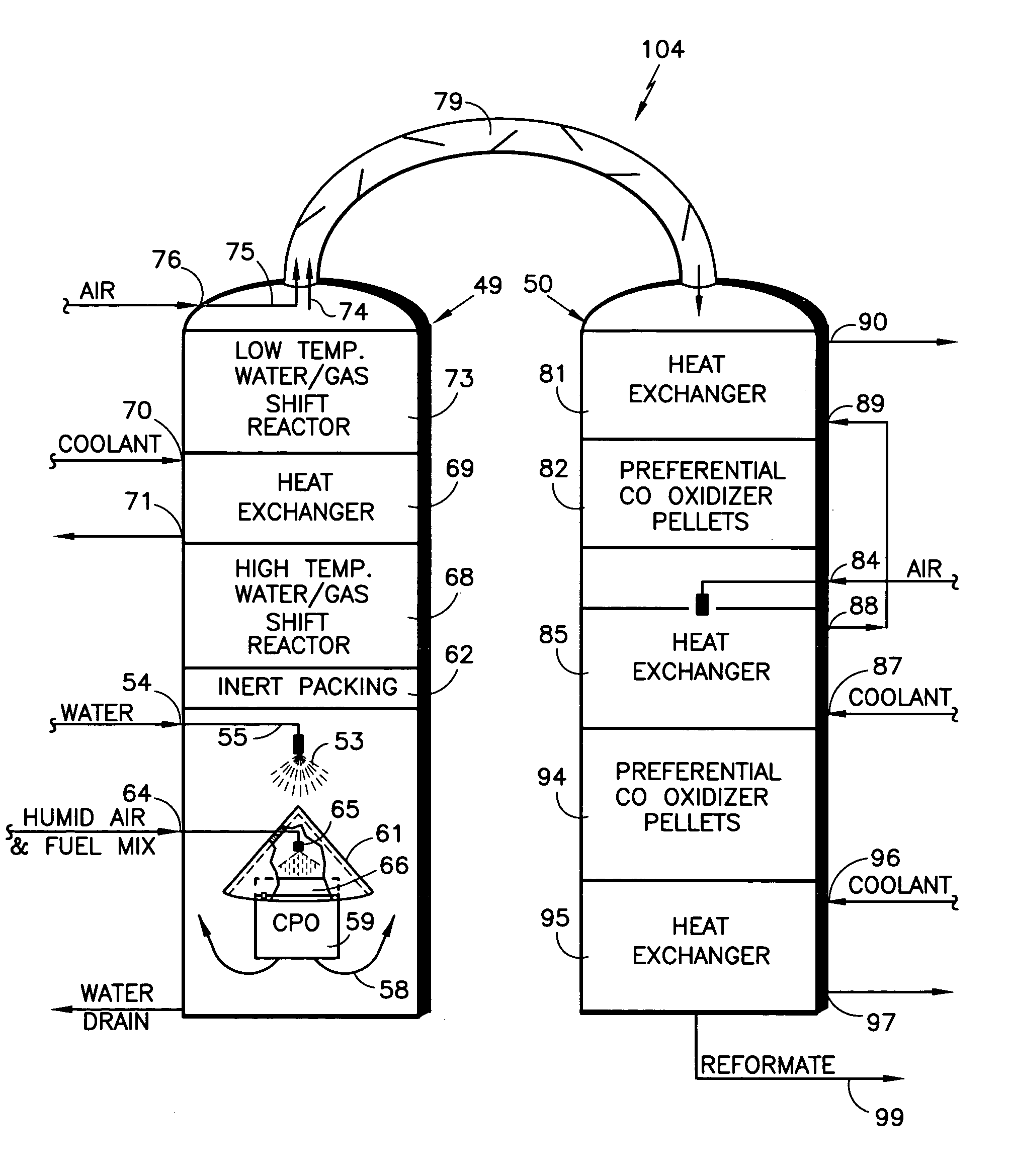

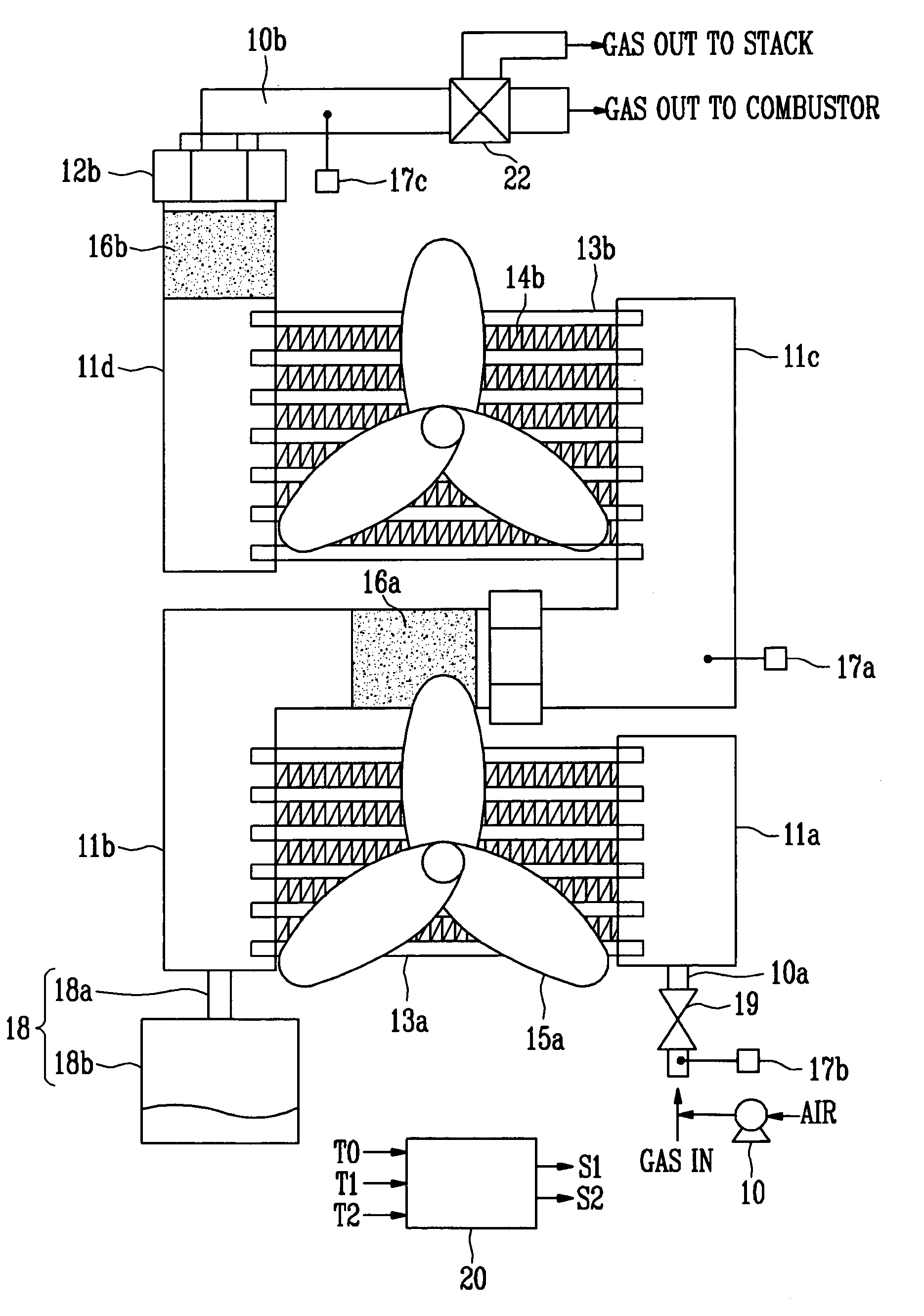

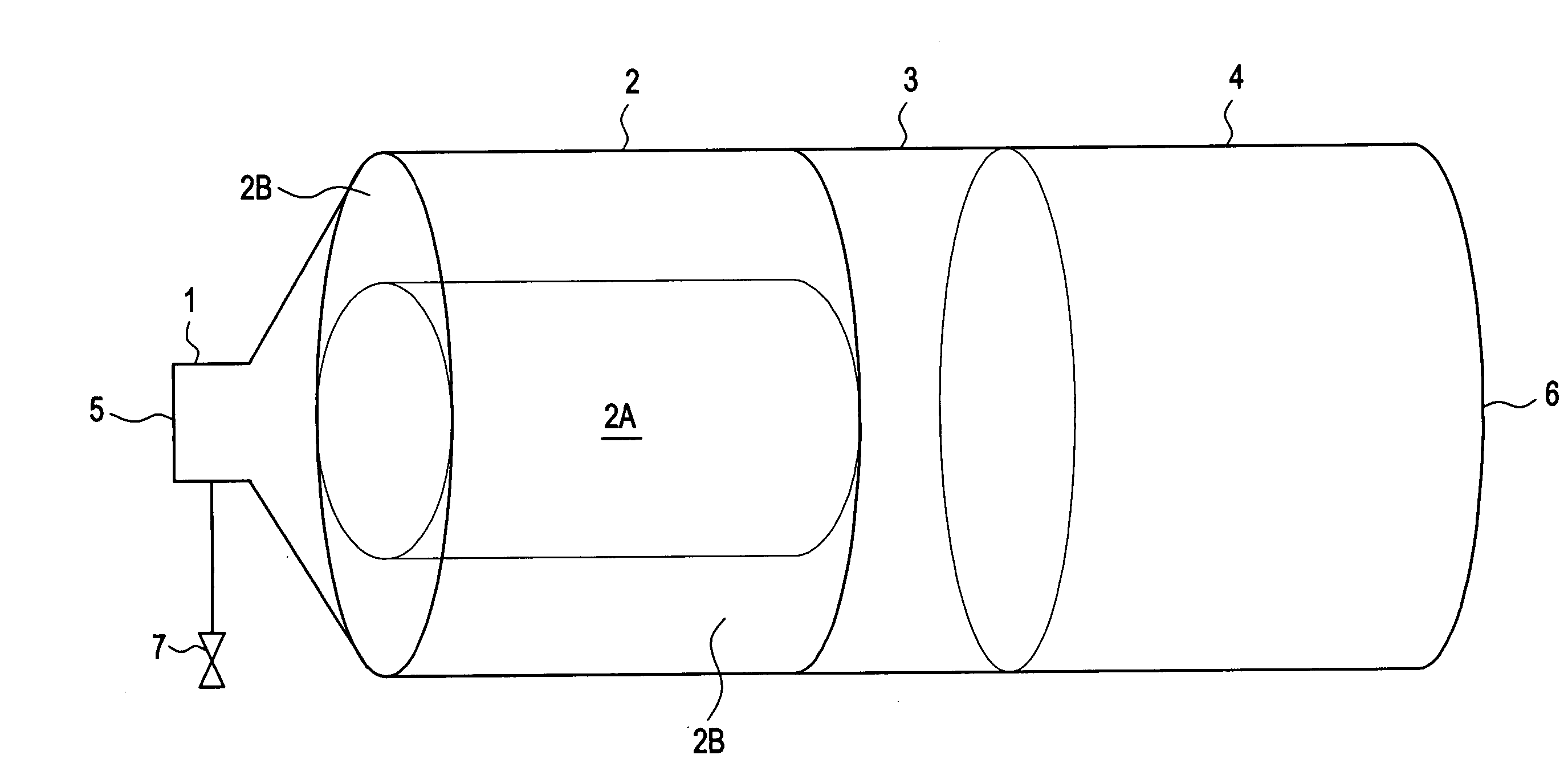

Integrated fuel processor for rapid start and operational control

A fuel processor for rapid start and operational control. The fuel processor includes a reformer, a shift reactor, and a preferential oxidation reactor for deriving hydrogen for use in creating electricity in a plurality of H2—O2 fuel cells. A heating and cooling mechanism is coupled to at least the shift reactor for controlling the critical temperature operation of the shift reactor without the need for a separate cooling loop. This heating and cooling mechanism produces or removes thermal energy as a product of the temperature of the combustion of air and fuel. Anode effluent and cathode effluent or air are used to control the temperature output of the heating mechanism. A vaporizer is provided that heats the PrOx reactor to operating temperature.

Owner:GM GLOBAL TECH OPERATIONS LLC

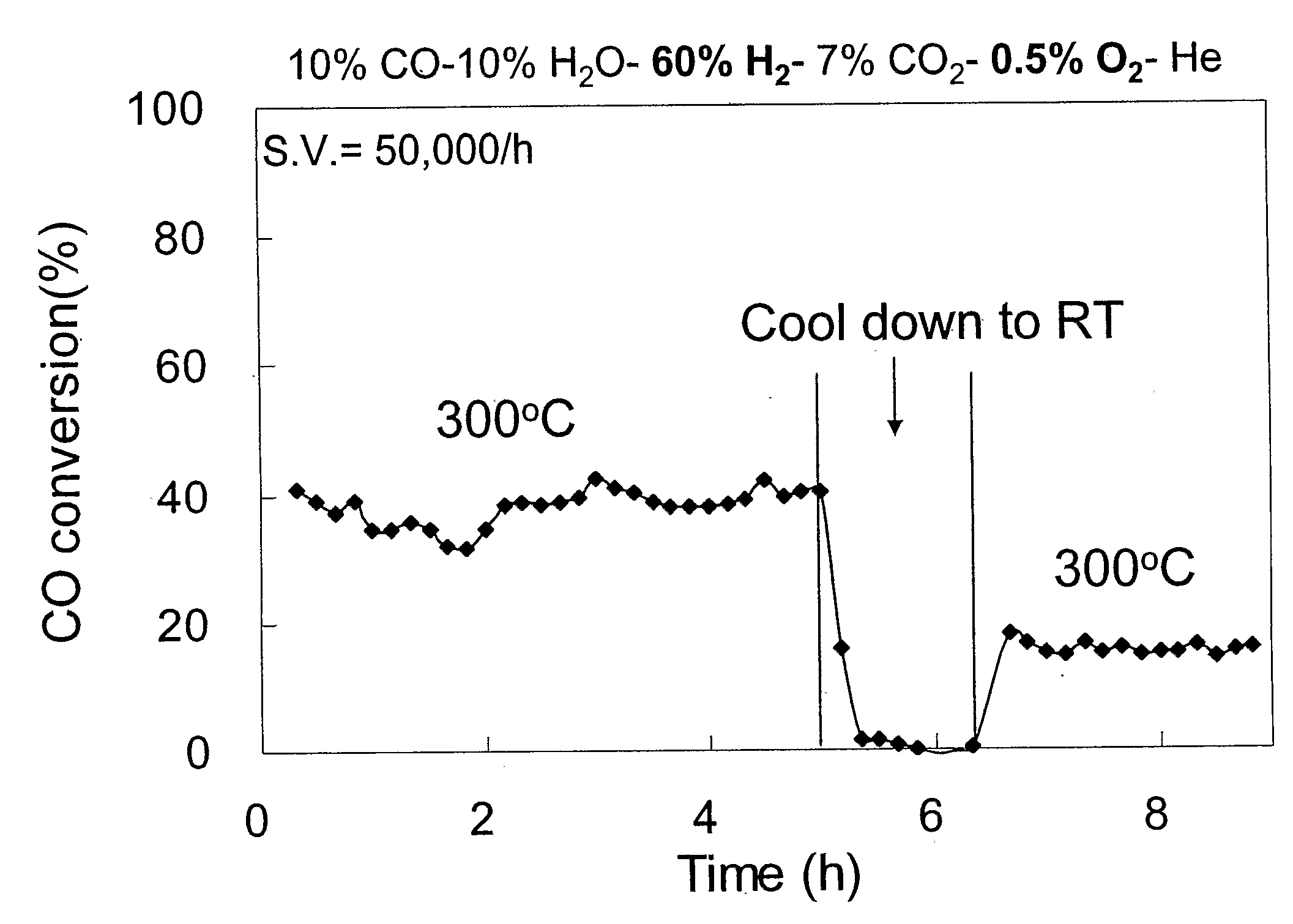

Treatment of Gold-Ceria Catalysts with Oxygen to Improve Stability Thereof in the Water-Gas Shift and Selective Co Oxidation Reactions

A method for improving the performance of catalysts by the addition of small amounts of oxygen to feed stock streams. Examples are shown for the improved operation of gold-ceria catalysts in the water-gas shift (WGS) and PROX reactions. The catalytic material is made by depositing catalytic metals, such as gold or platinum, on substrate materials, such as doped or undoped ceria. The deposited metal, which comprises both crystalline and non-crystalline structures, is treated, for example with aqueous basic NaCN solution, to remove at least some of the crystalline metallic component. The remaining noncystalline metallic component associated with the substrate exhibits catalytic activity that is substantially similar to the catalyst as prepared. The use of the catalyst is contemplated in efficient, cost-effective reactions, such as removal of carbon monoxide from fuel gases, for example by performing the water gas shift reaction and / or the PROX reaction.

Owner:TUFTS UNIV

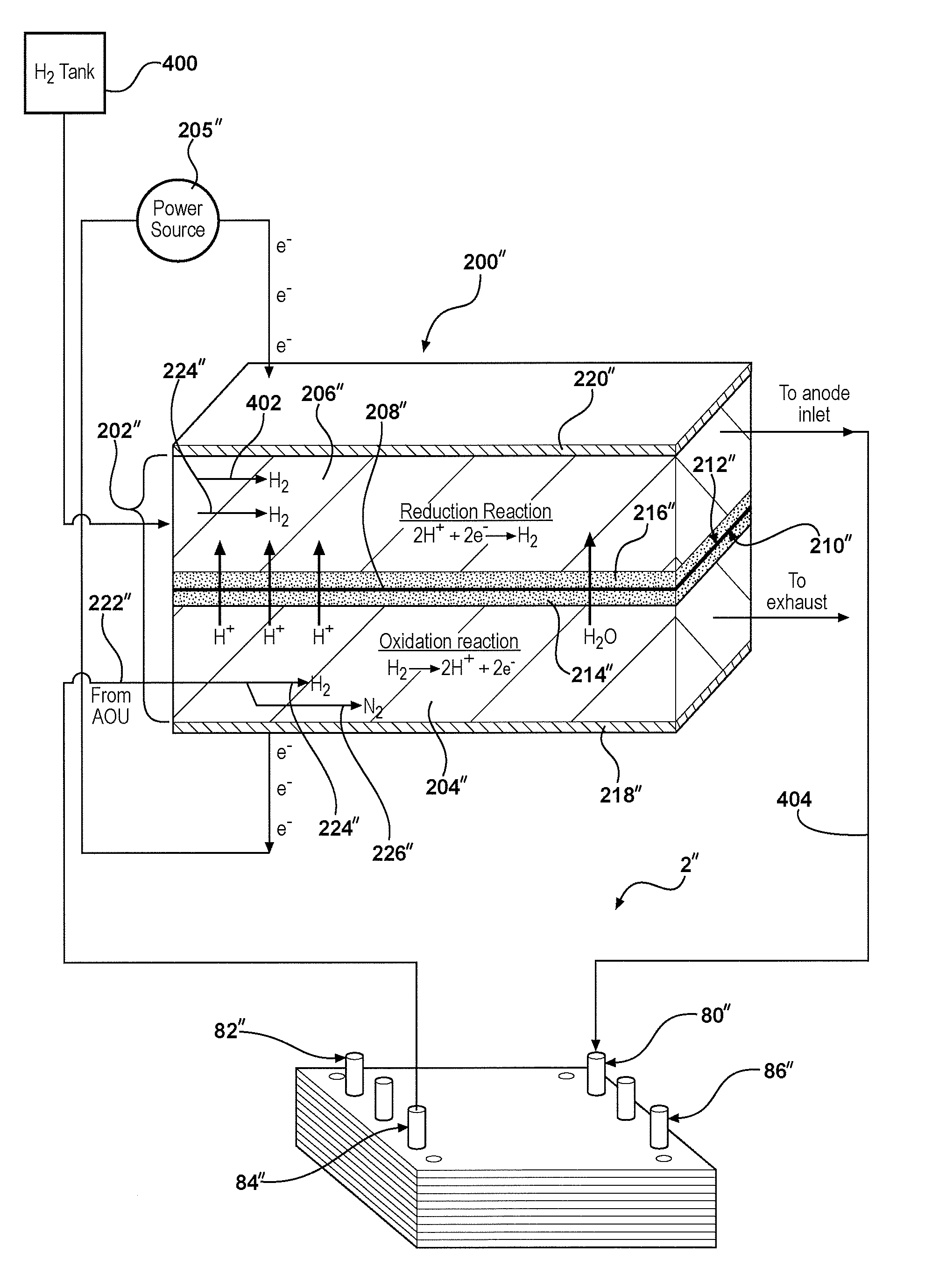

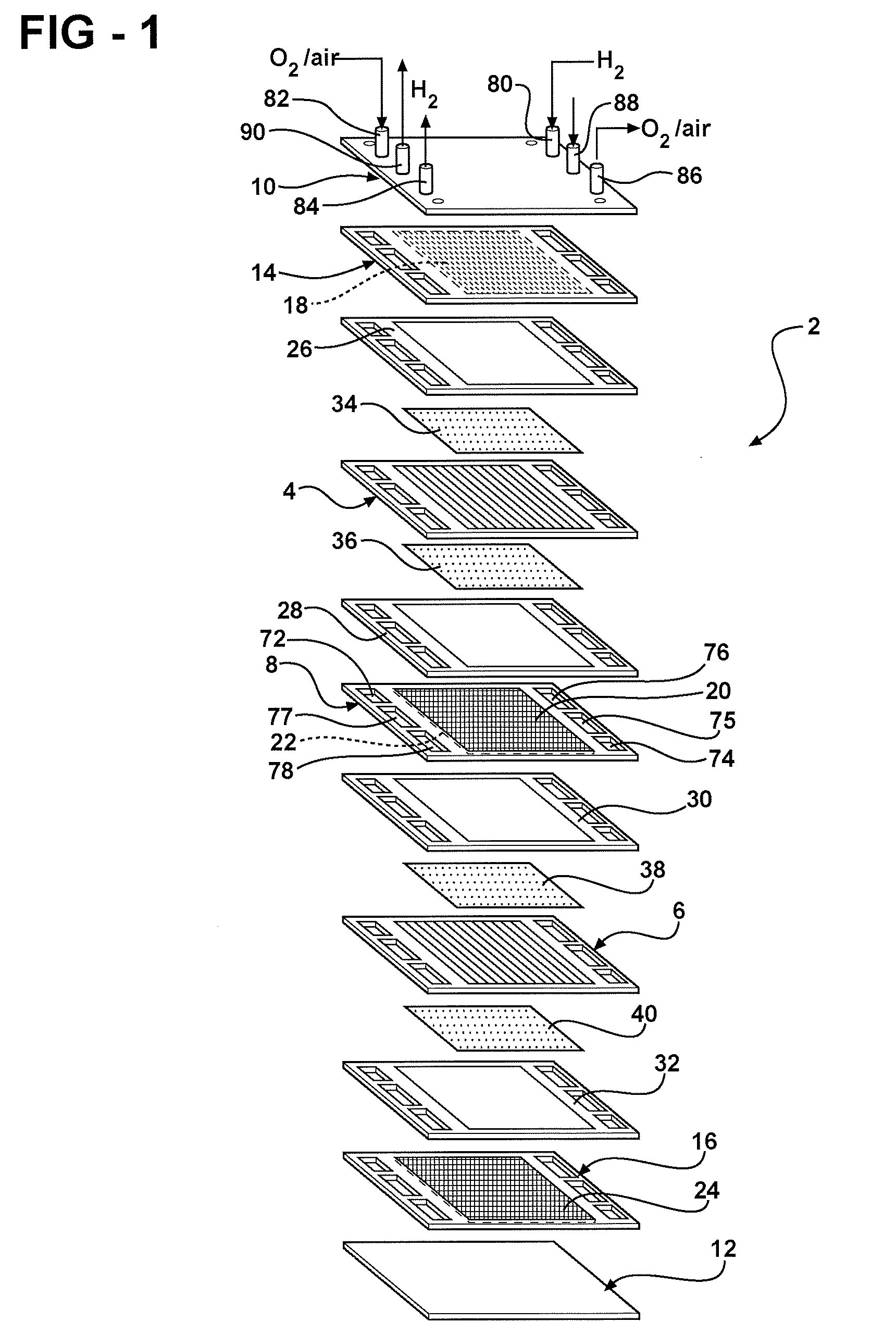

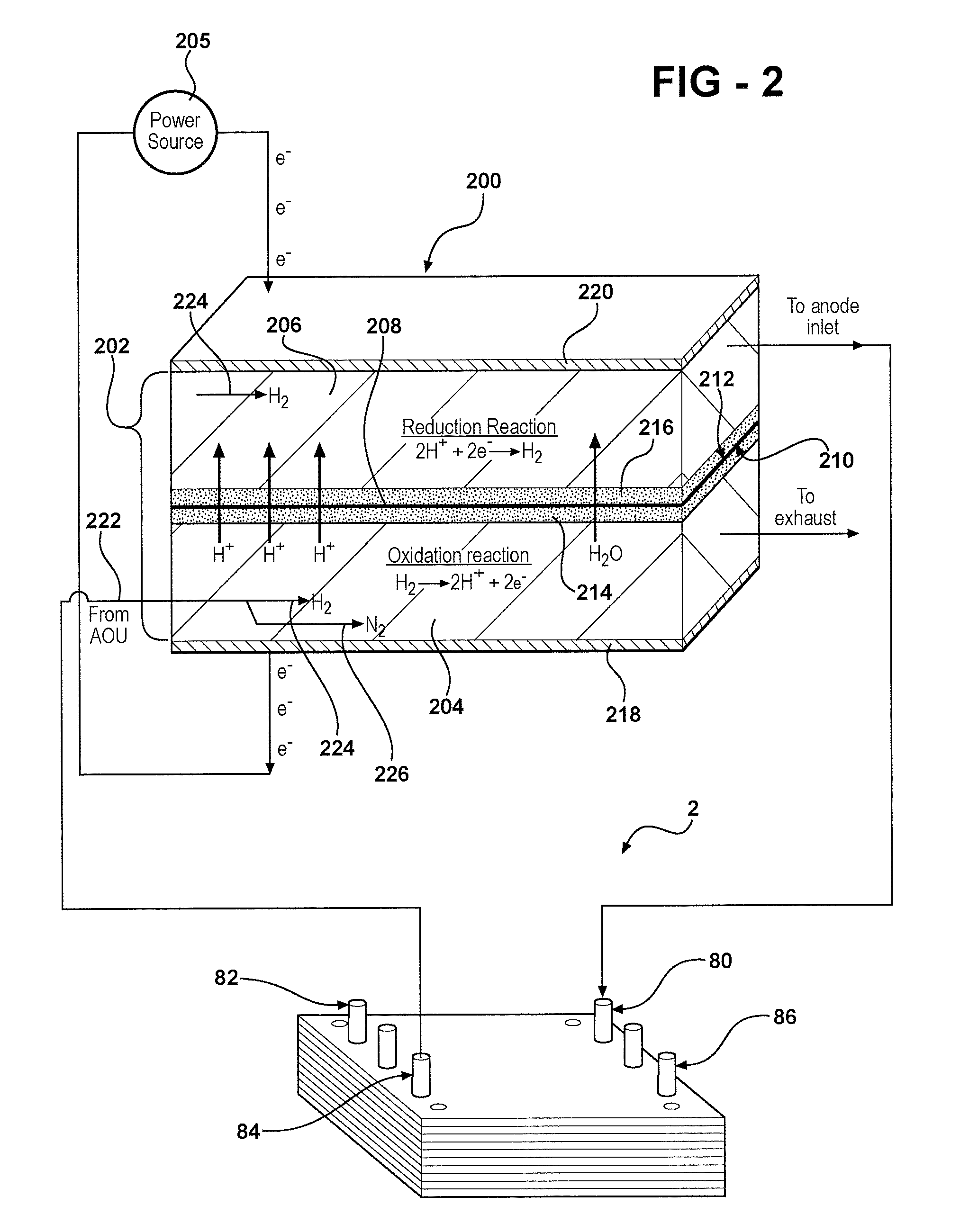

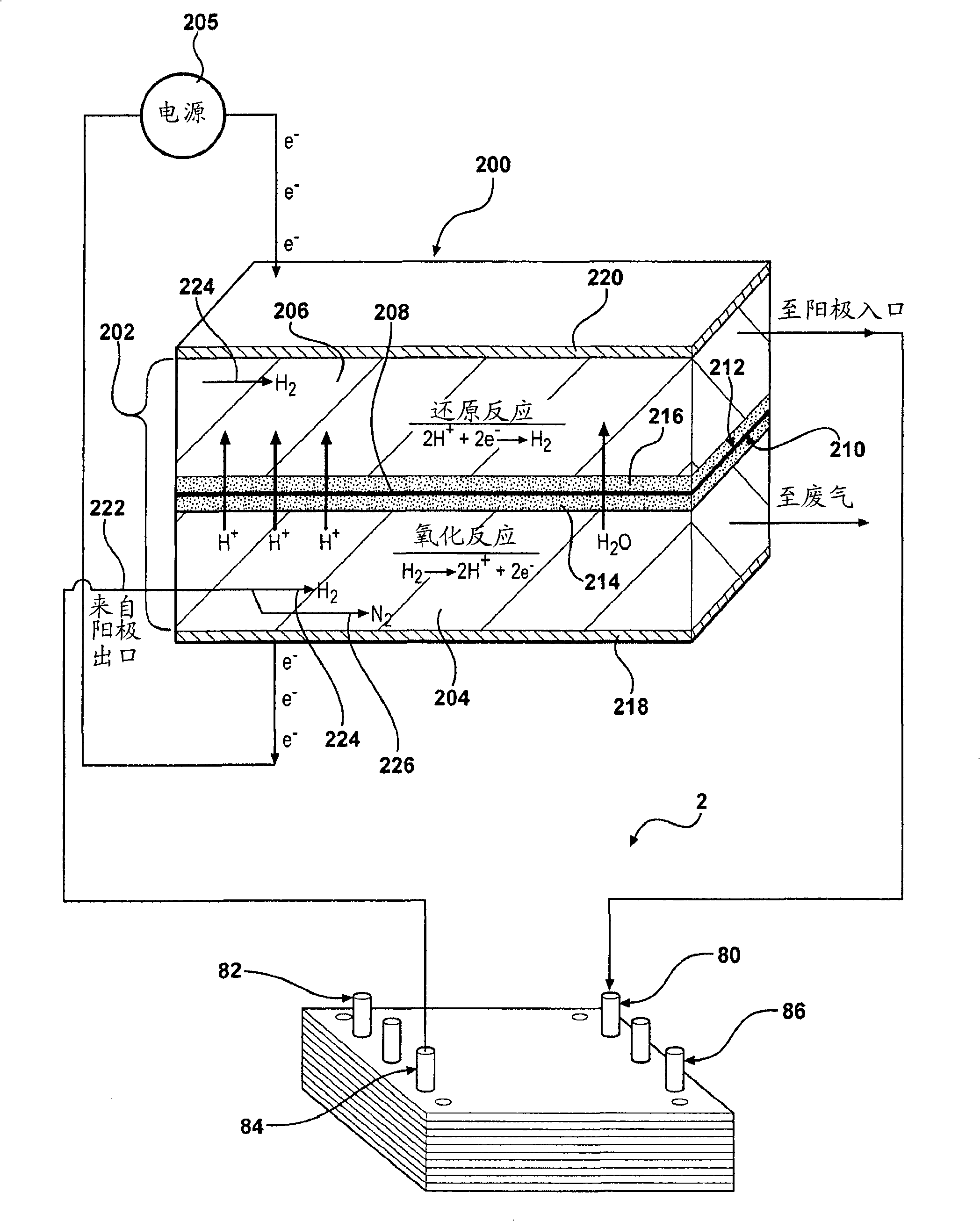

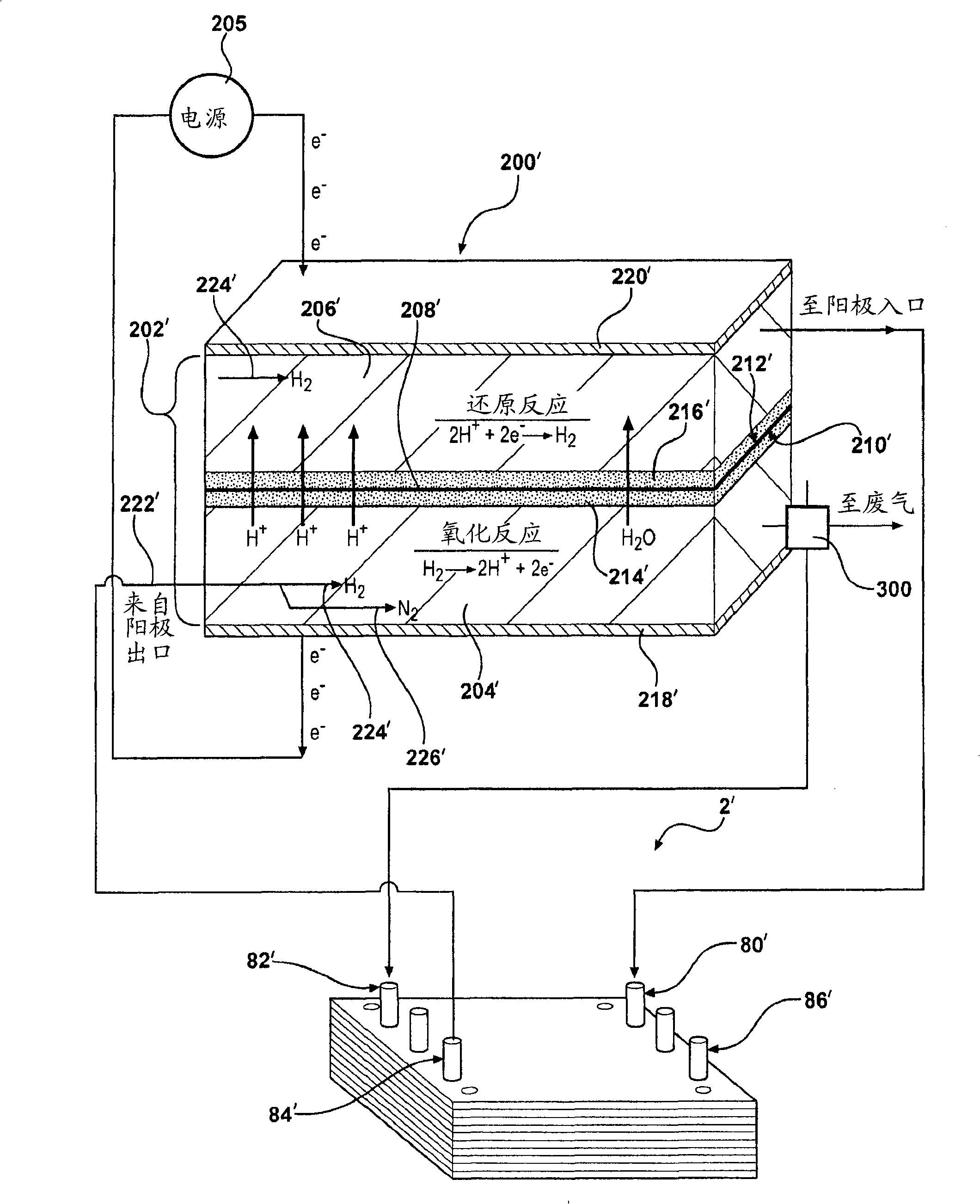

Recovery of inert gas from a fuel cell exhaust stream

A fuel cell system is provided including a fuel cell stack having a fuel cell having an anode, an anode outlet, an anode inlet, and a cathode. The fuel cell system further includes a hydrogen pump in communication with the anode outlet and the anode inlet. The hydrogen pump features a proton exchange membrane disposed between a first electrode and a second electrode. The first electrode is configured to accept an anode outlet stream from the anode outlet, the anode outlet stream including a hydrogen gas and an inert gas, the first electrode being configured to exhaust the inert gas. In one embodiment, the hydrogen pump is in communication with a PROX unit and configured to provide the hydrogen gas to the fuel cell stack. Further provided are methods employing the hydrogen pump wherein a start-stop degradation of the fuel cell is militated against and a hydrogen feed stream is humidified.

Owner:GM GLOBAL TECH OPERATIONS LLC

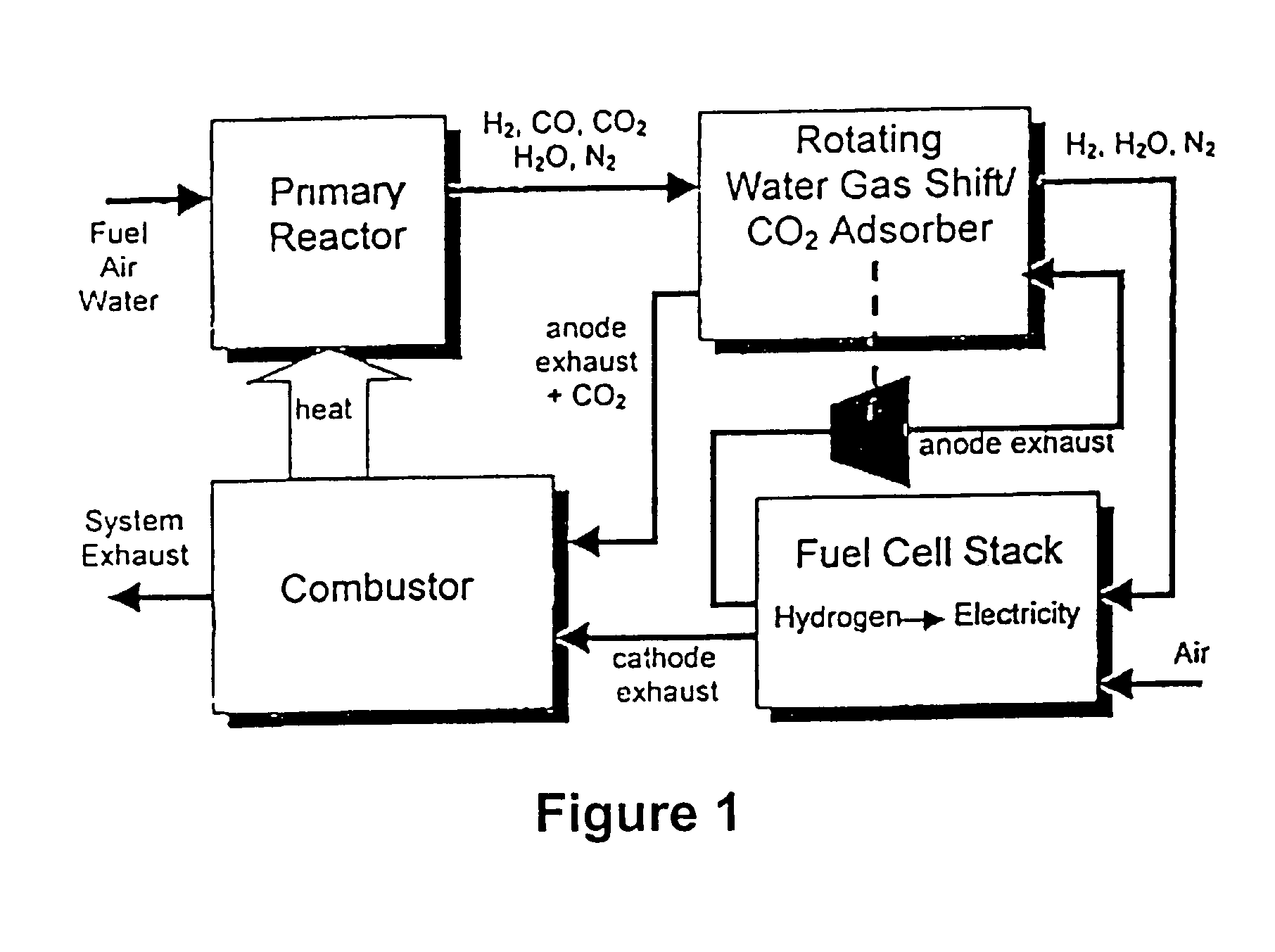

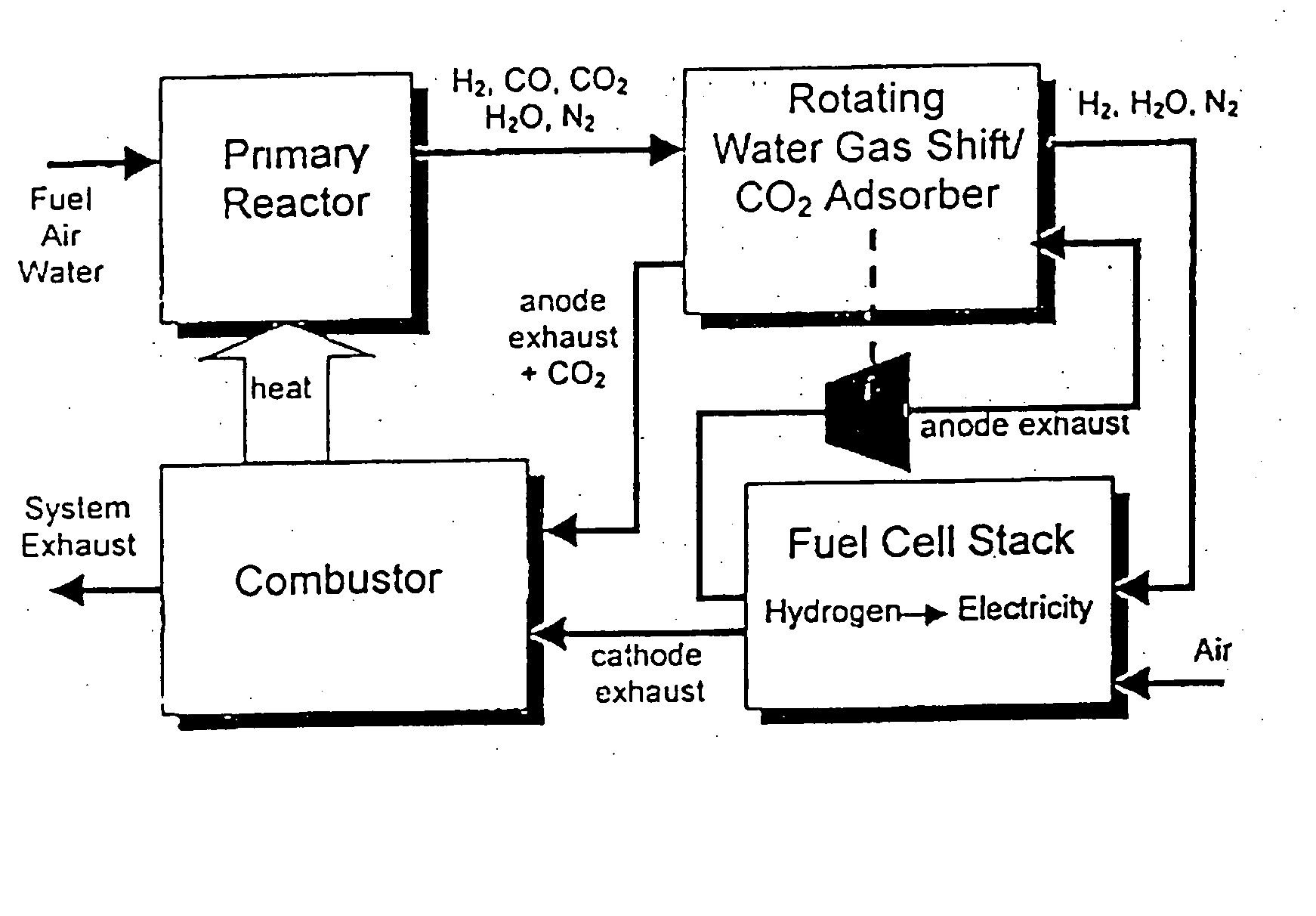

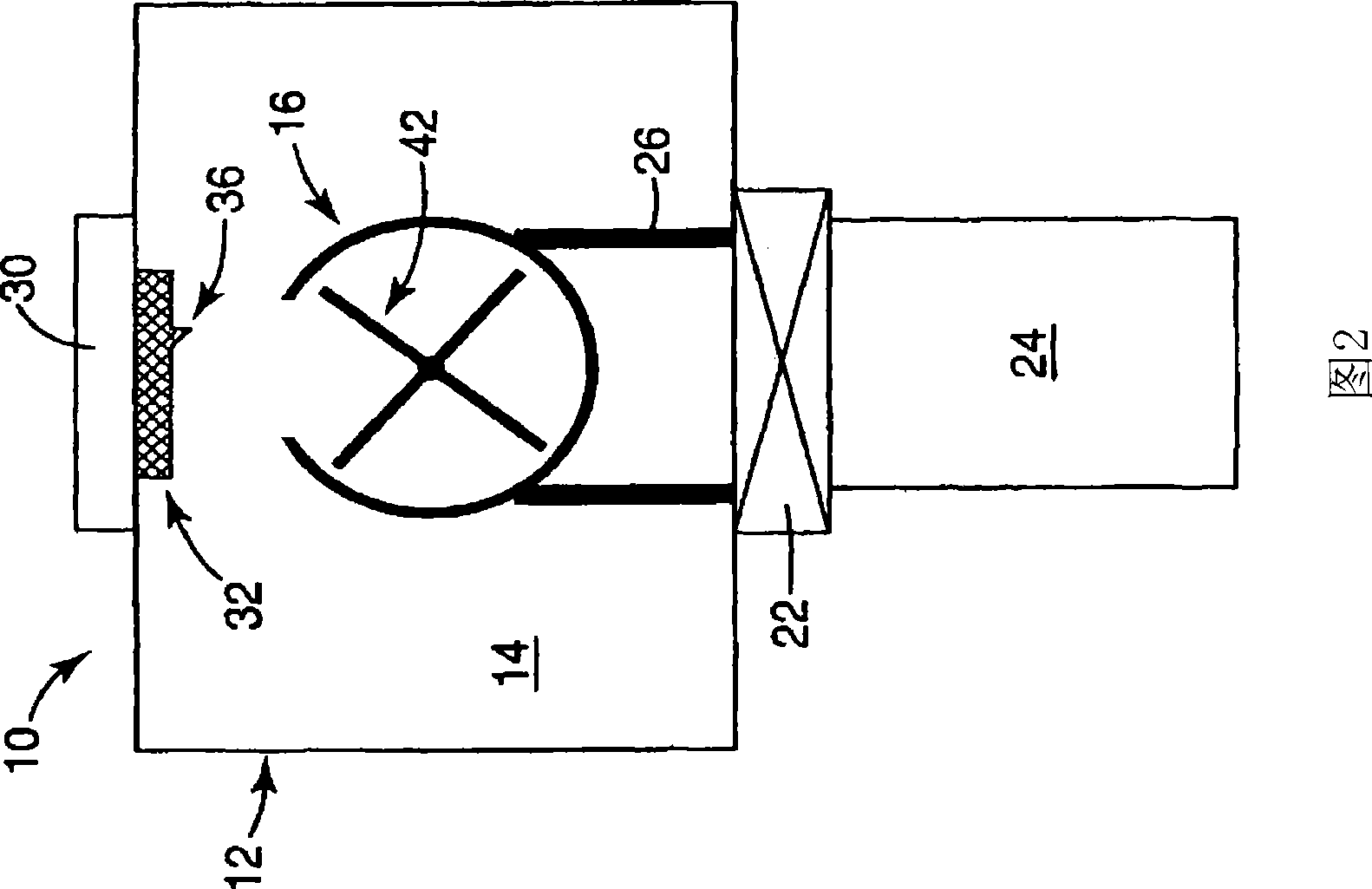

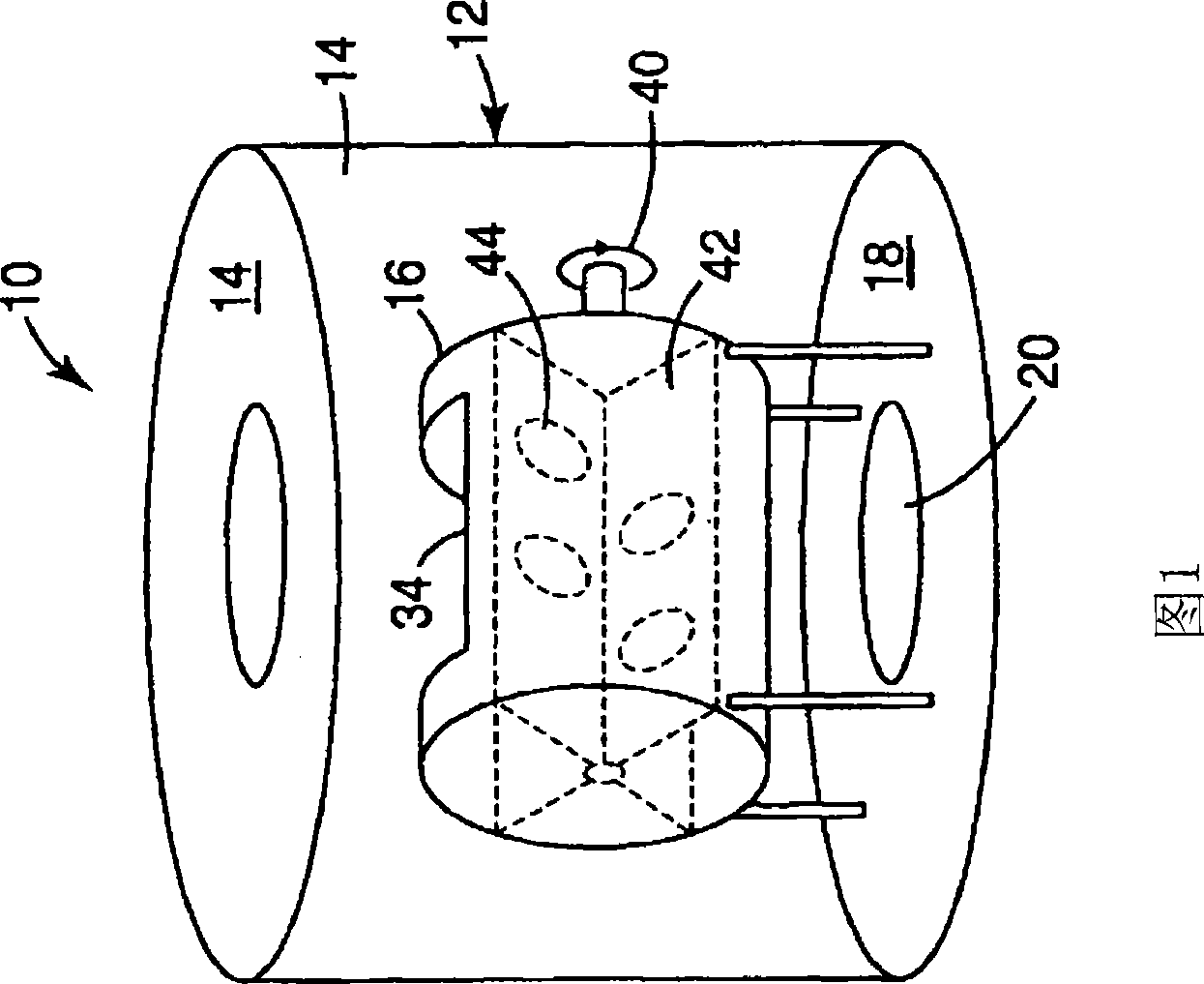

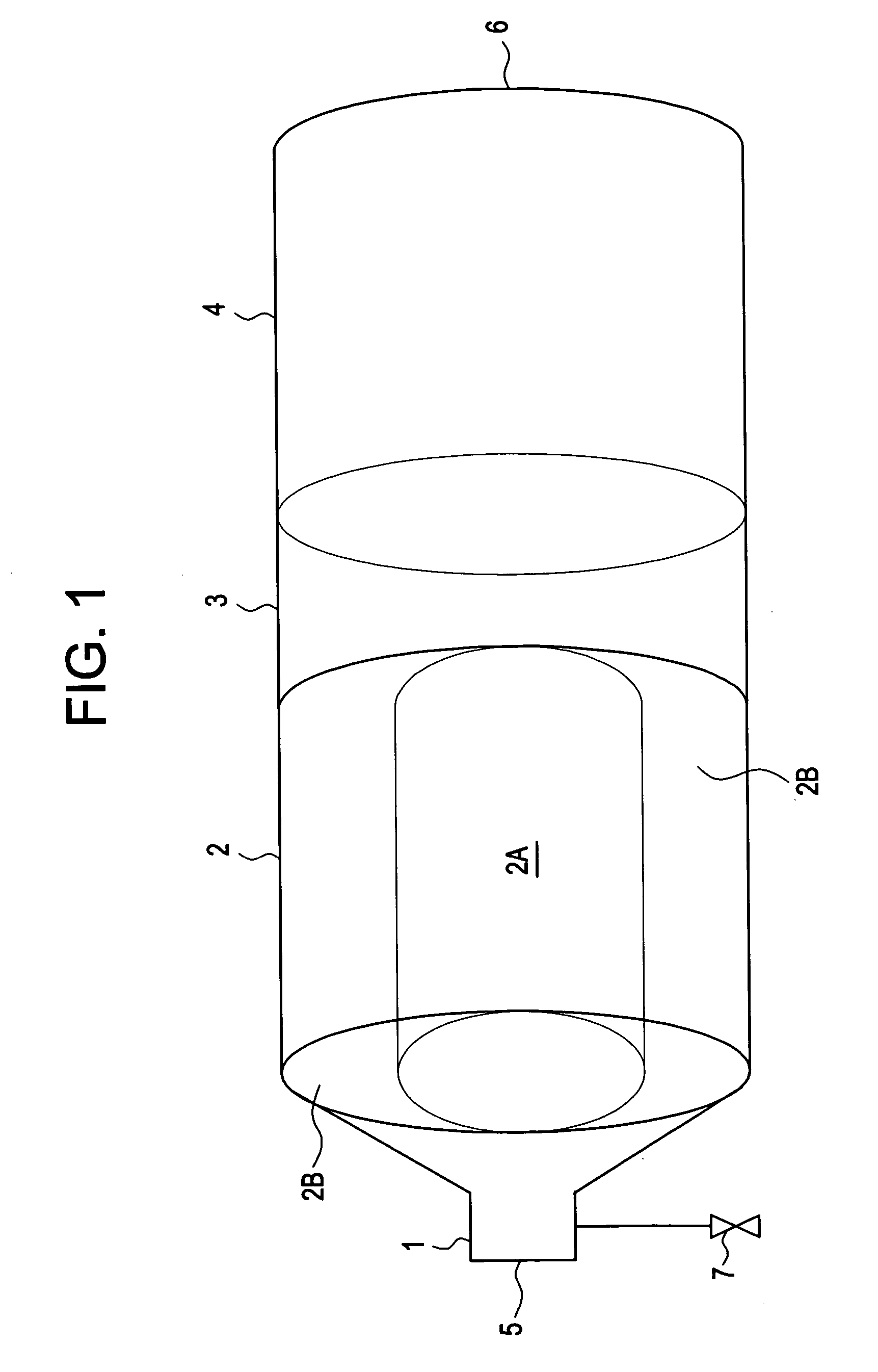

Combined water gas shift reactor/carbon dioxide adsorber for use in a fuel cell system

InactiveUS7361199B2Eliminate operationSmall sizeThermal non-catalytic crackingMuffle furnacesSorbentHydrogen fuel cell

An apparatus removes CO from a hydrogen-rich gas stream in a hydrogen fuel cell system. CO fouls costly catalytic particles in the membrane electrode assemblies. Both a catalyst adapted to perform a water gas shift reaction, and a carbon dioxide adsorbent are disposed in a rotating pressure swing adsorber housing. The adsorption of carbon dioxide shifts equilibrium toward carbon monoxide consumption. A second adsorbent may be disposed in the housing for adsorbing carbon monoxide at low temperatures, and is adapted to desorb carbon monoxide at high temperatures. The present invention advantageously eliminates a unit operation from a space-constrained fuel cell vehicle by combining the WGS catalyst and a CO2 adsorbent in a single reactor / housing. The apparatus further eliminates the use of a PROX reactor, by providing an apparatus which incorporates CO2 adsorption and consequent carbon monoxide consumption in the place of the PROX reactor.

Owner:GM GLOBAL TECH OPERATIONS LLC

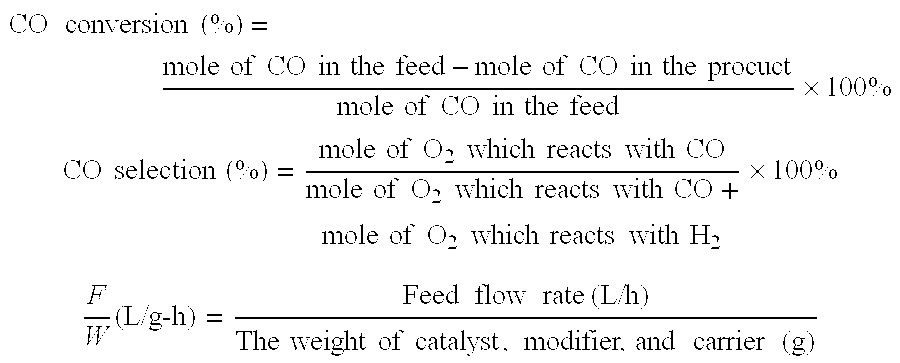

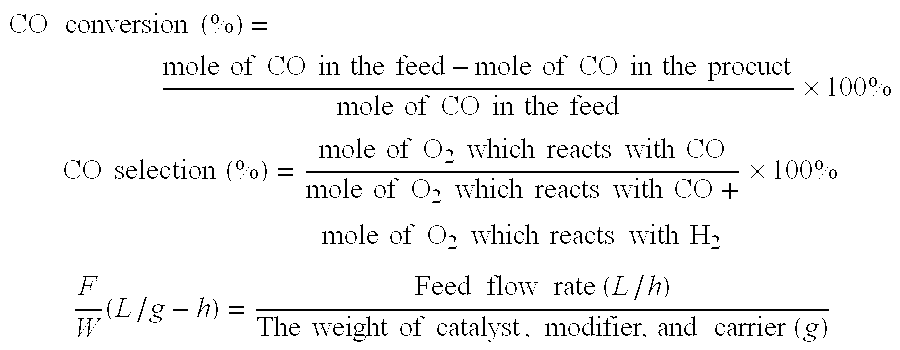

Vermiculite supported catalyst for CO preferential oxidation and the process of preparing the same

InactiveUS7541311B2Improve efficiencyImprove heat resistanceHydrogenCatalyst activation/preparationOrganic chemistryCalcination

A vermiculite supported catalyst for carbon monoxide (CO) preferential oxidation (PROX) is disclosed. The CO PROX catalyst comprises at least one catalytic agent, one optional modifier agent, one carrier material, and a vermiculite support. The process for preparing the vermiculite supported catalyst in this invention includes depositing first the carrier material on a vermiculite support followed by calcination to form the carrier-containing support, and wet impregnating the catalytic agent and the optional modifier agent on the carrier-containing support followed by drying and calcination to form the CO preferential oxidation catalyst.

Owner:INST NUCLEAR ENERGY RES ROCAEC

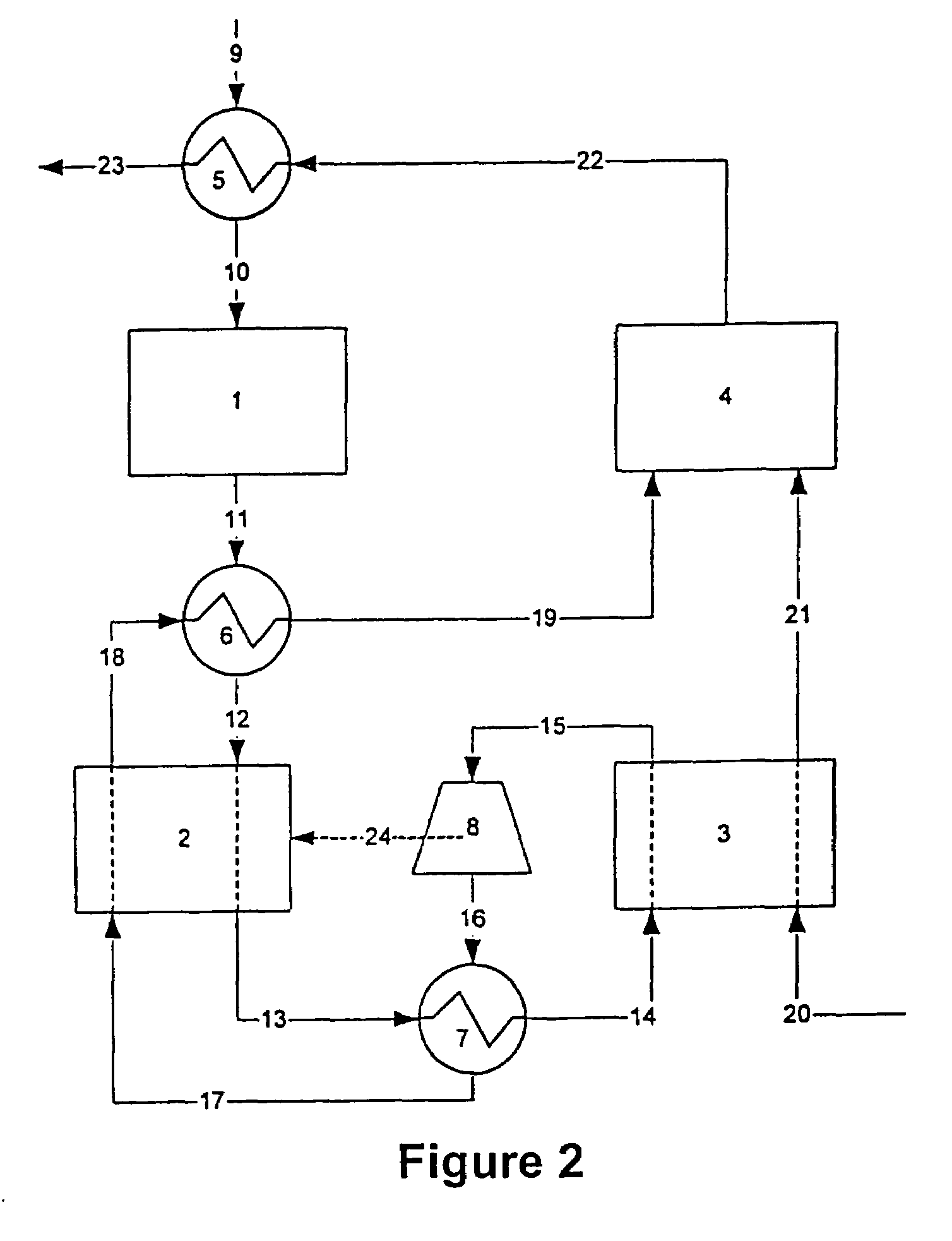

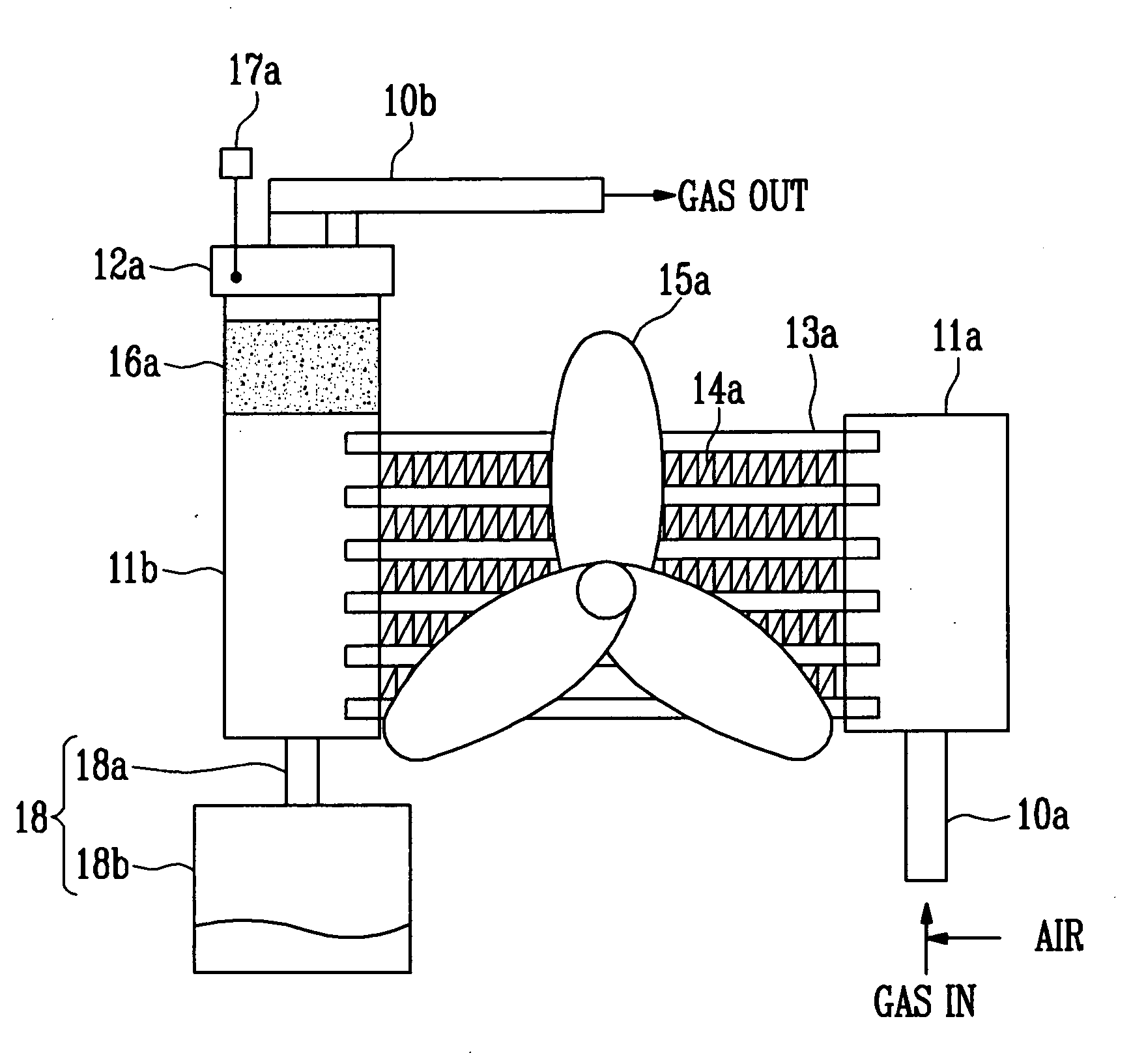

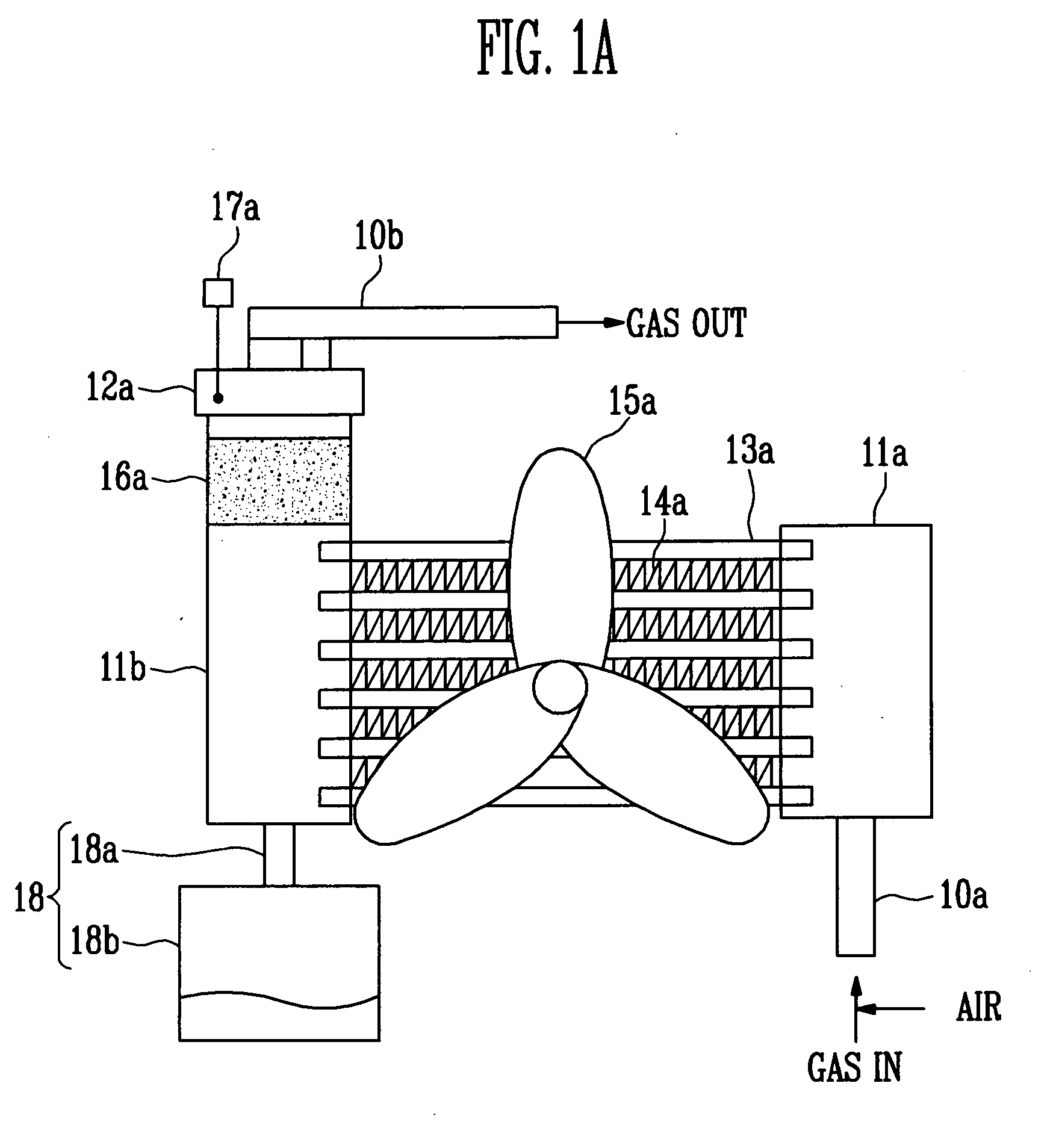

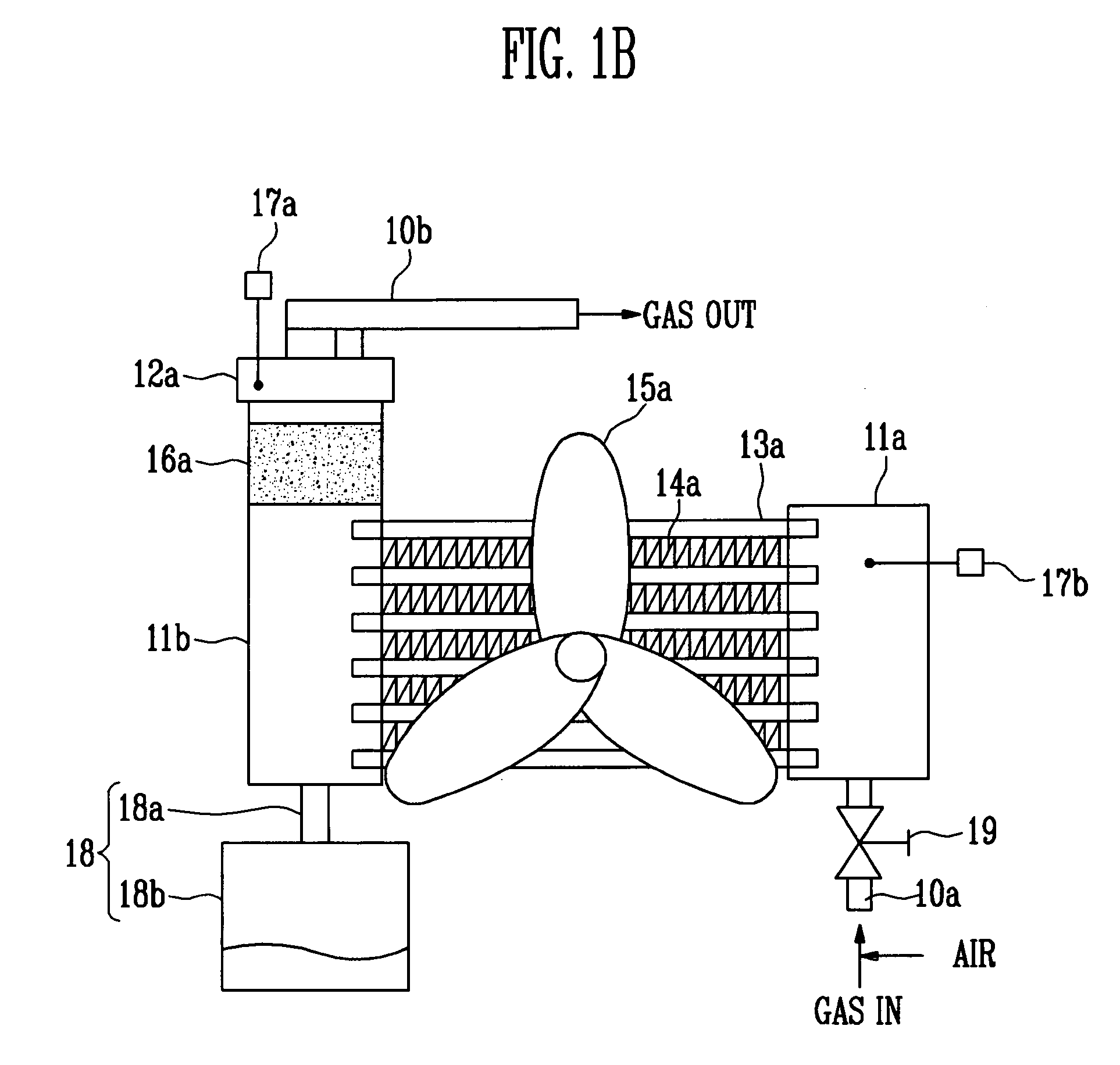

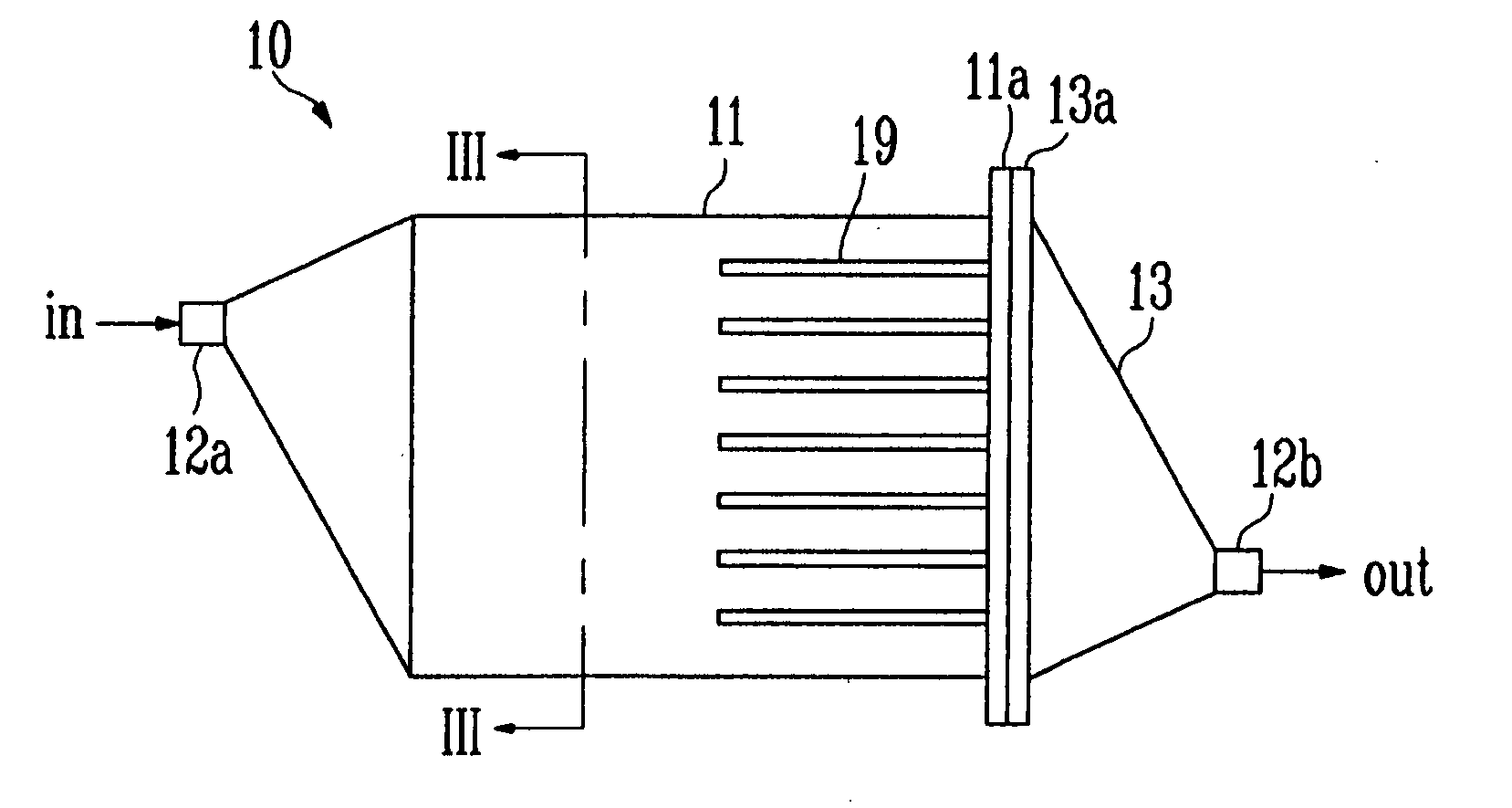

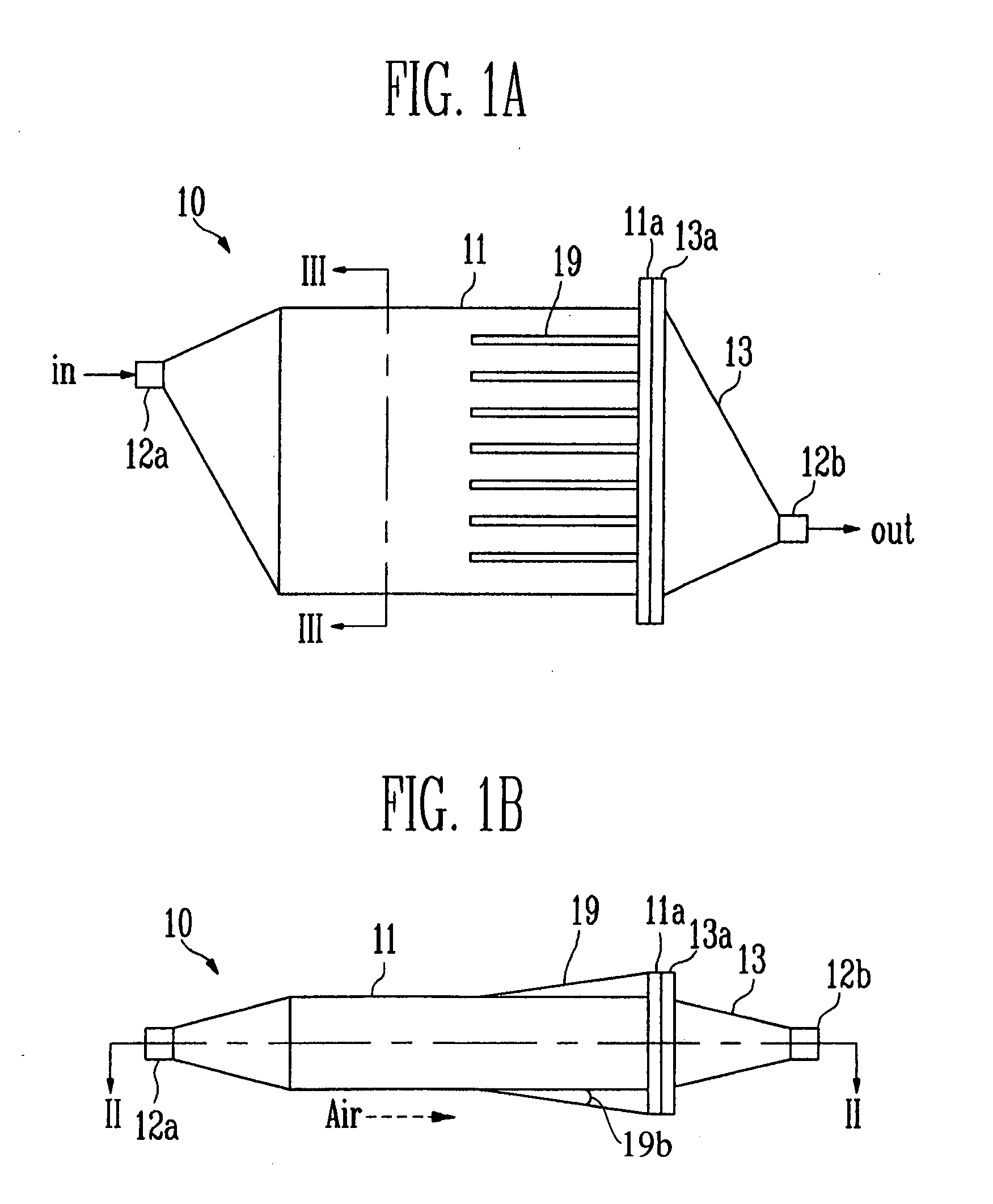

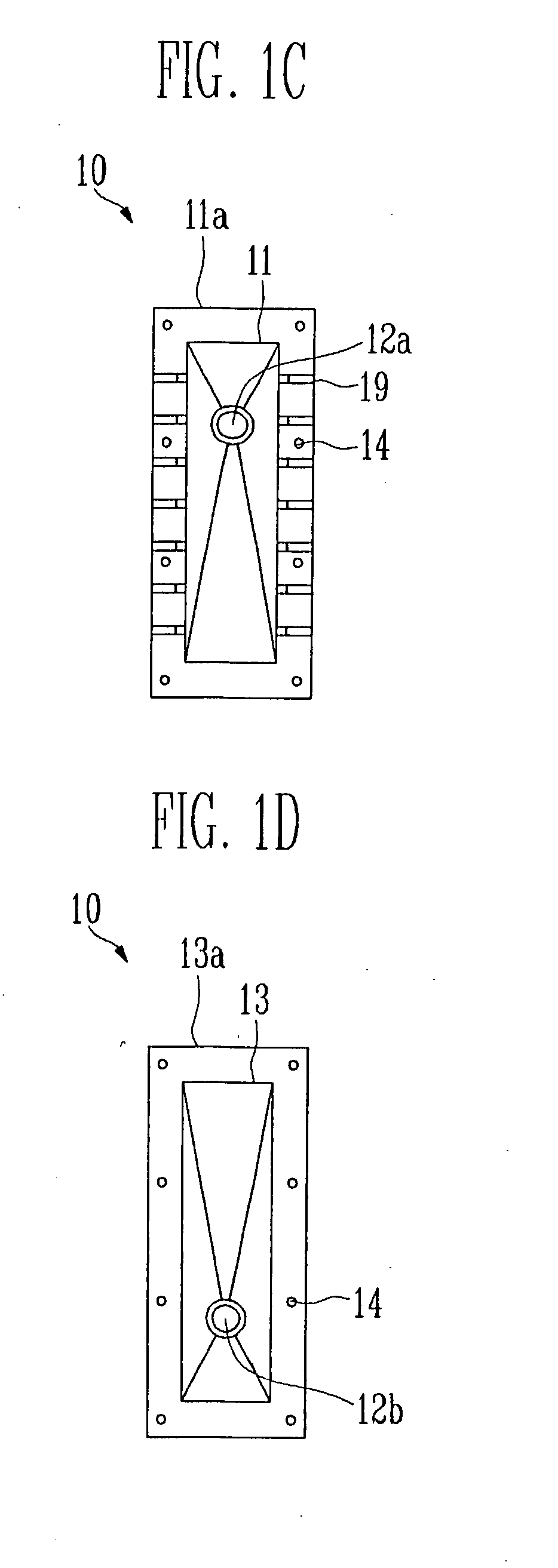

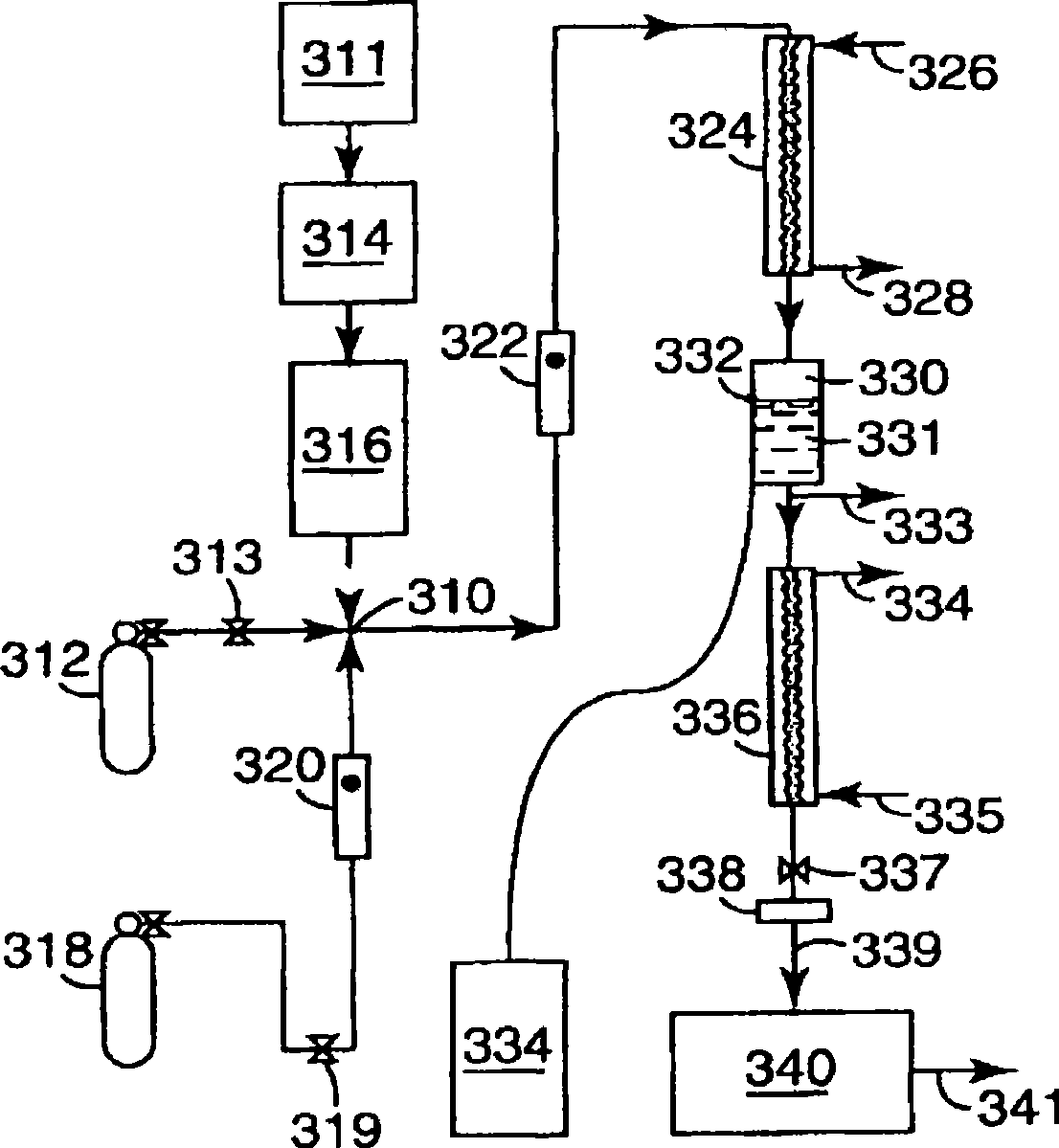

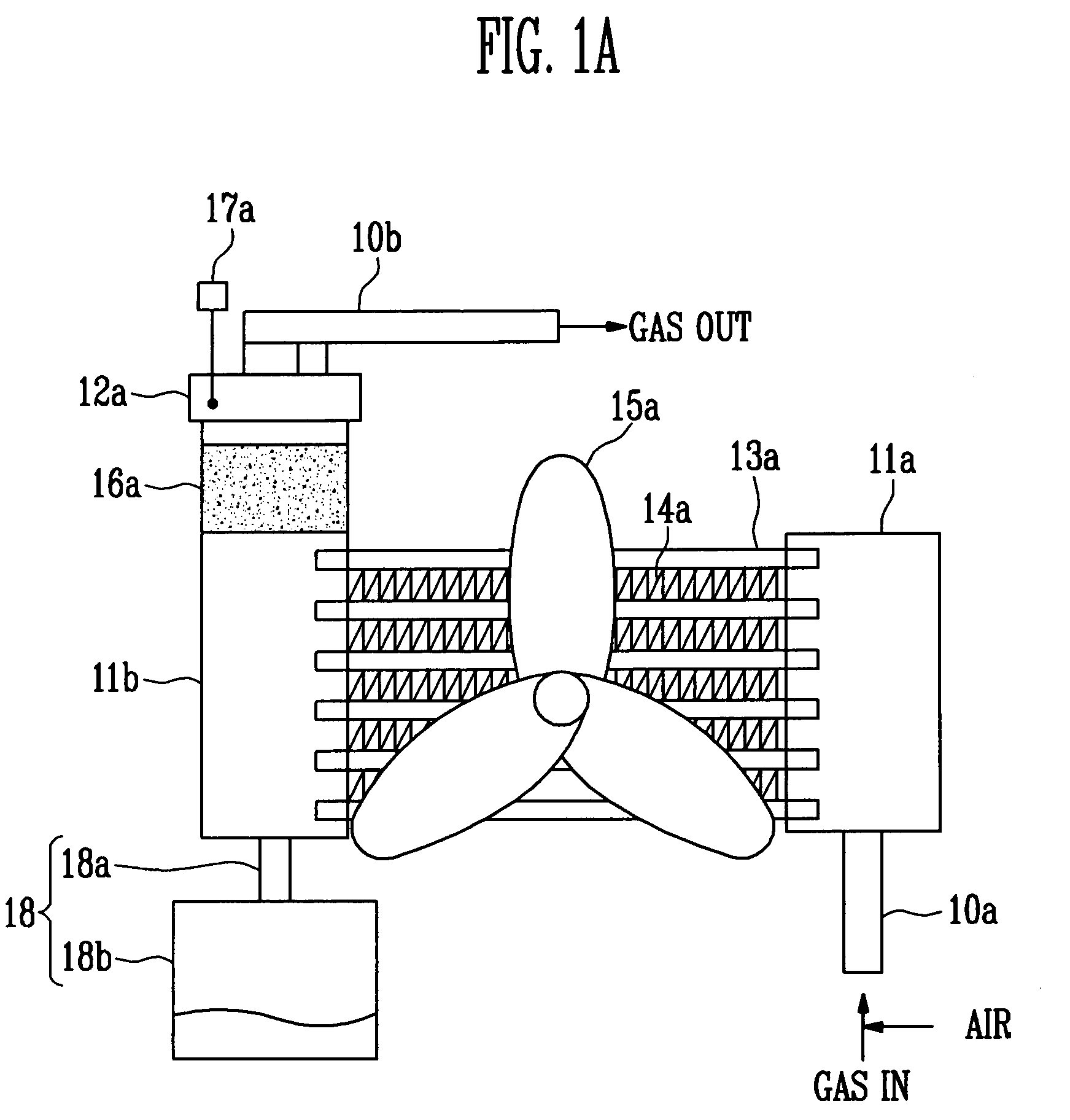

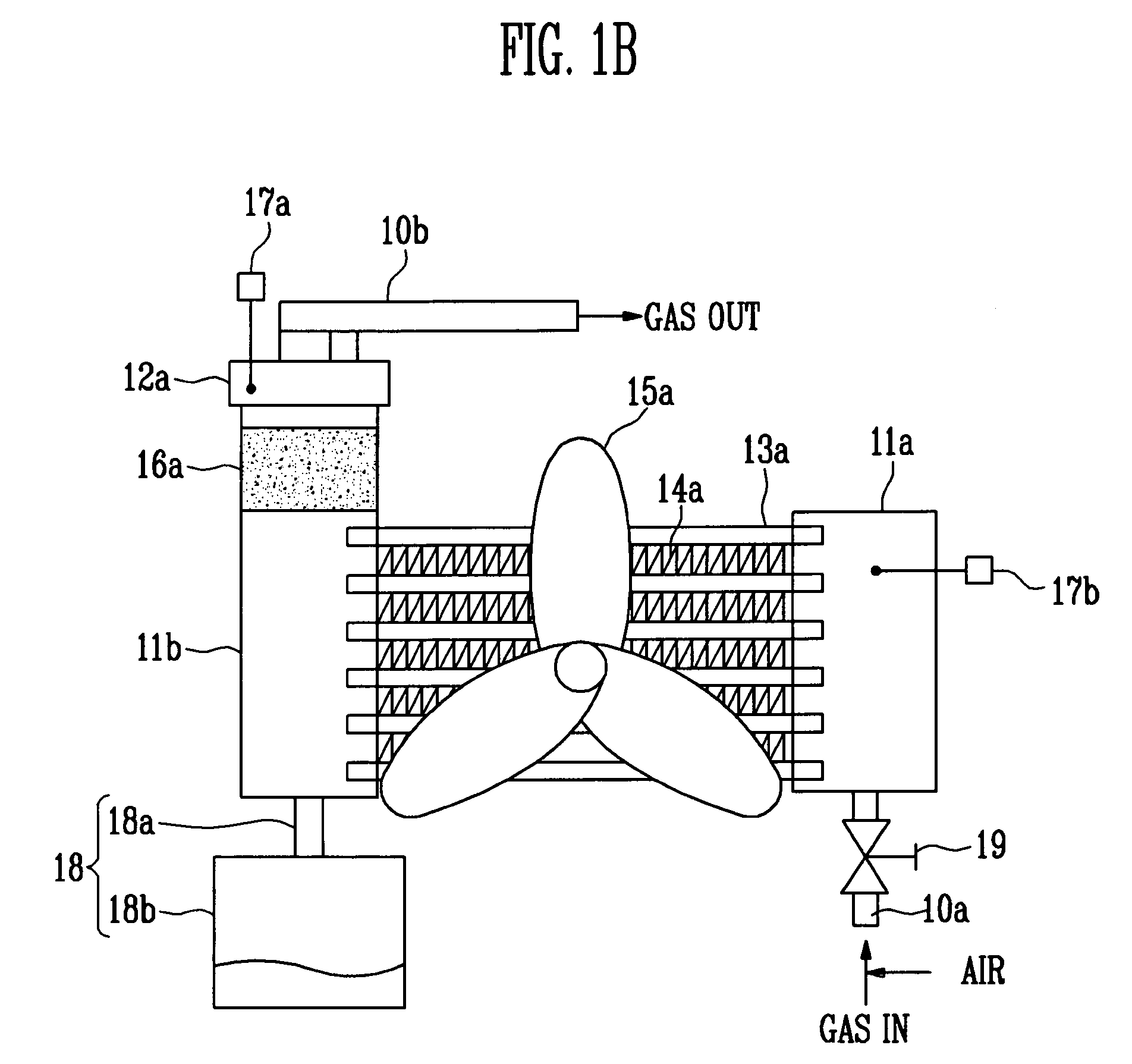

Preferential oxidation reactor integrated with heat exchanger and operating method thereof

InactiveUS20080166284A1Effective controlPromote activationMaterial analysis by electric/magnetic meansMaterial analysis by optical meansComing outGas passing

A PROX reactor integrated with a heat exchanger and an operating method thereof capable of effectively controlling temperature of a preferential oxidation reactor so as to obtain optimal activation and yield. The PROX reactor integrated with a heat exchanger of the present invention includes a pipe having an inlet and an outlet, a heat exchanger cooling gas passing through the pipe, a catalyst part positioned at the rear end of the heat exchanger, upon considering the flow of gas, and shifting carbon monoxide contained in the gas into other substances; and a temperature sensor measuring the temperature of the gas coming out through the catalyst part.

Owner:SAMSUNG SDI CO LTD

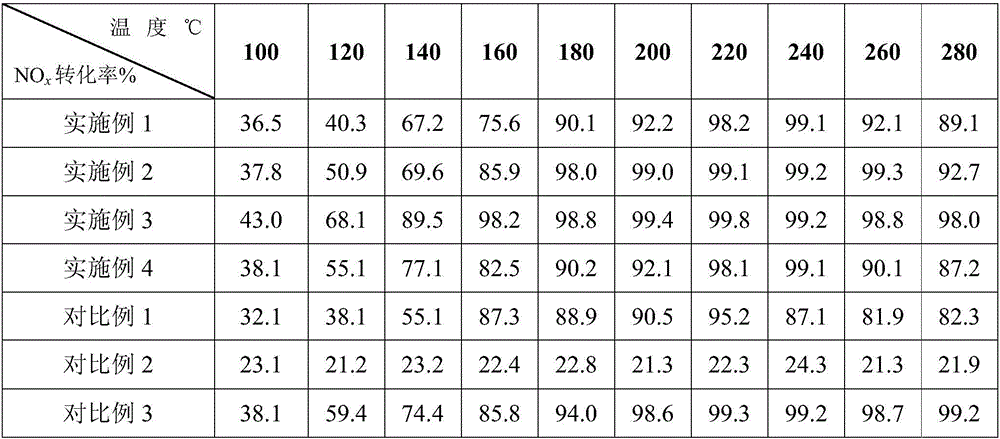

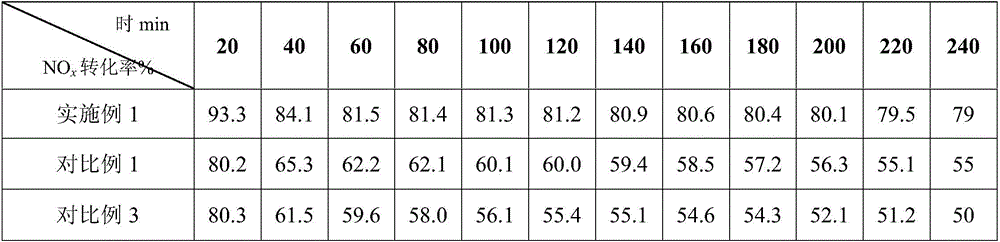

PrOx-MnOx/SAPO-34 low-temperature SCR smoke denitration catalyst and preparation method and application thereof

ActiveCN105833901ARegular structureGood dispersionMolecular sieve catalystsDispersed particle separationMolecular sieveDispersity

The invention discloses a PrOx-MnOx / SAPO-34 low-temperature SCR smoke denitration catalyst and a preparation method and application thereof .In the preparation method, an SAPO-34 molecular sieve serves as the carrier, Mn and Pr are loaded on the SAPO-34 molecular sieve through a solvent dispersion method, and then the PrOx-MnOx / SAPO-34 low-temperature SCR smoke denitration catalyst is prepared through roasting; in the PrOx-MnOx / SAPO-34 low-temperature SCR smoke denitration catalyst, the mass percentage of Mn and the SAPO-34 molecular sieve is 15-25%, and the molar ratio of Pr to Mn is 0-0.3 .The dispersity of active components is improved, the specific surface area and acidity of the catalyst are increased, and the catalyst presents excellent NH3-SCR performance at a low temperature of 200 DEG C or below and has certain SO2 poisoning resistant performance .

Owner:SOUTH CHINA UNIV OF TECH

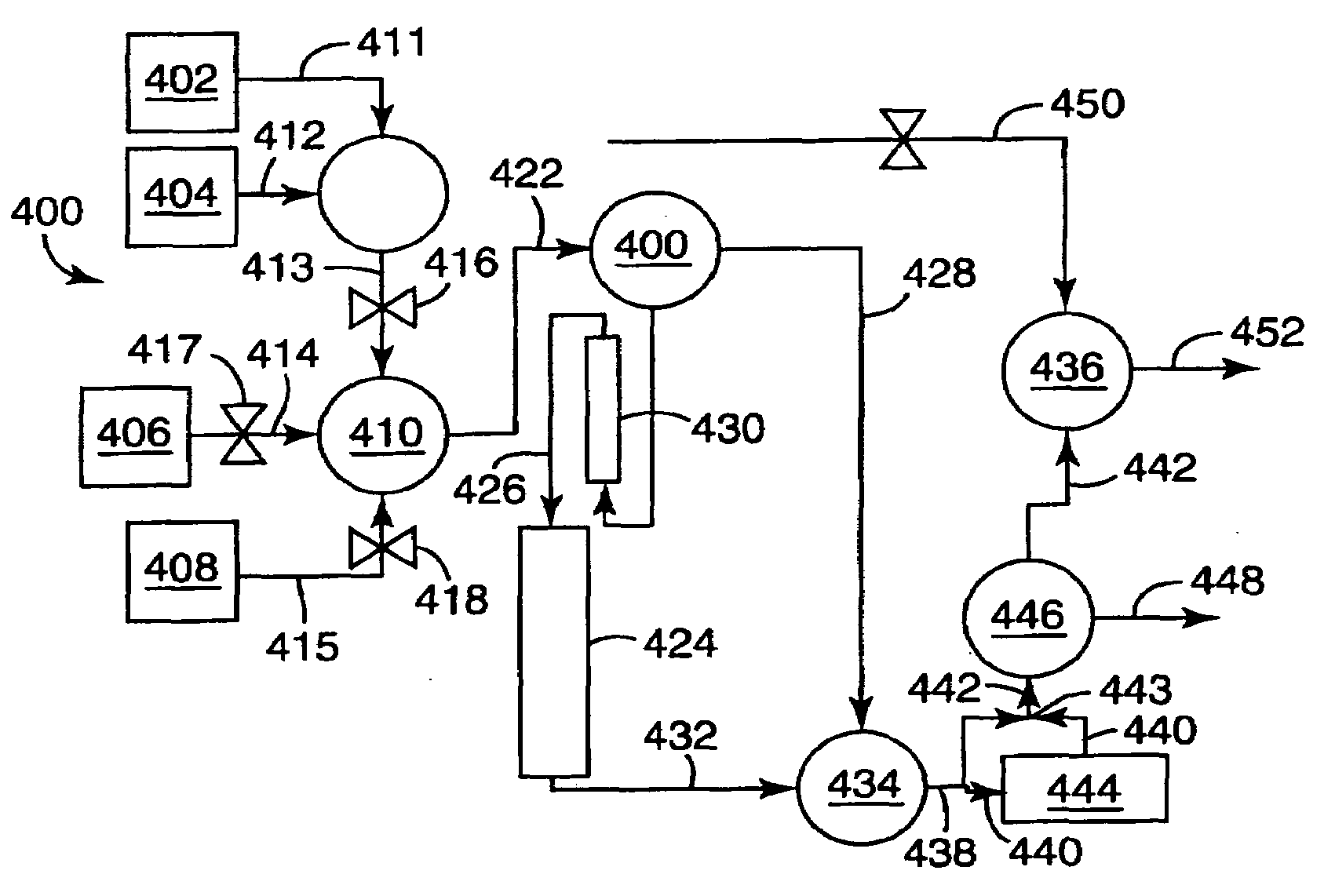

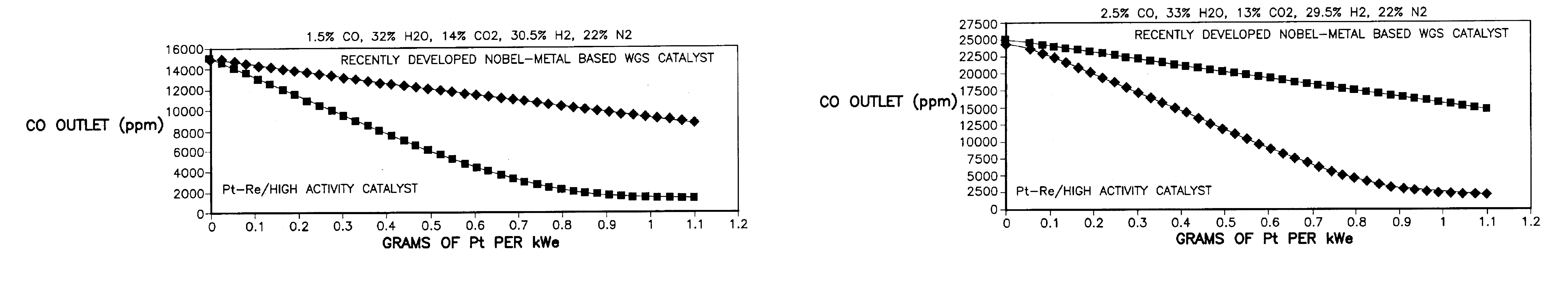

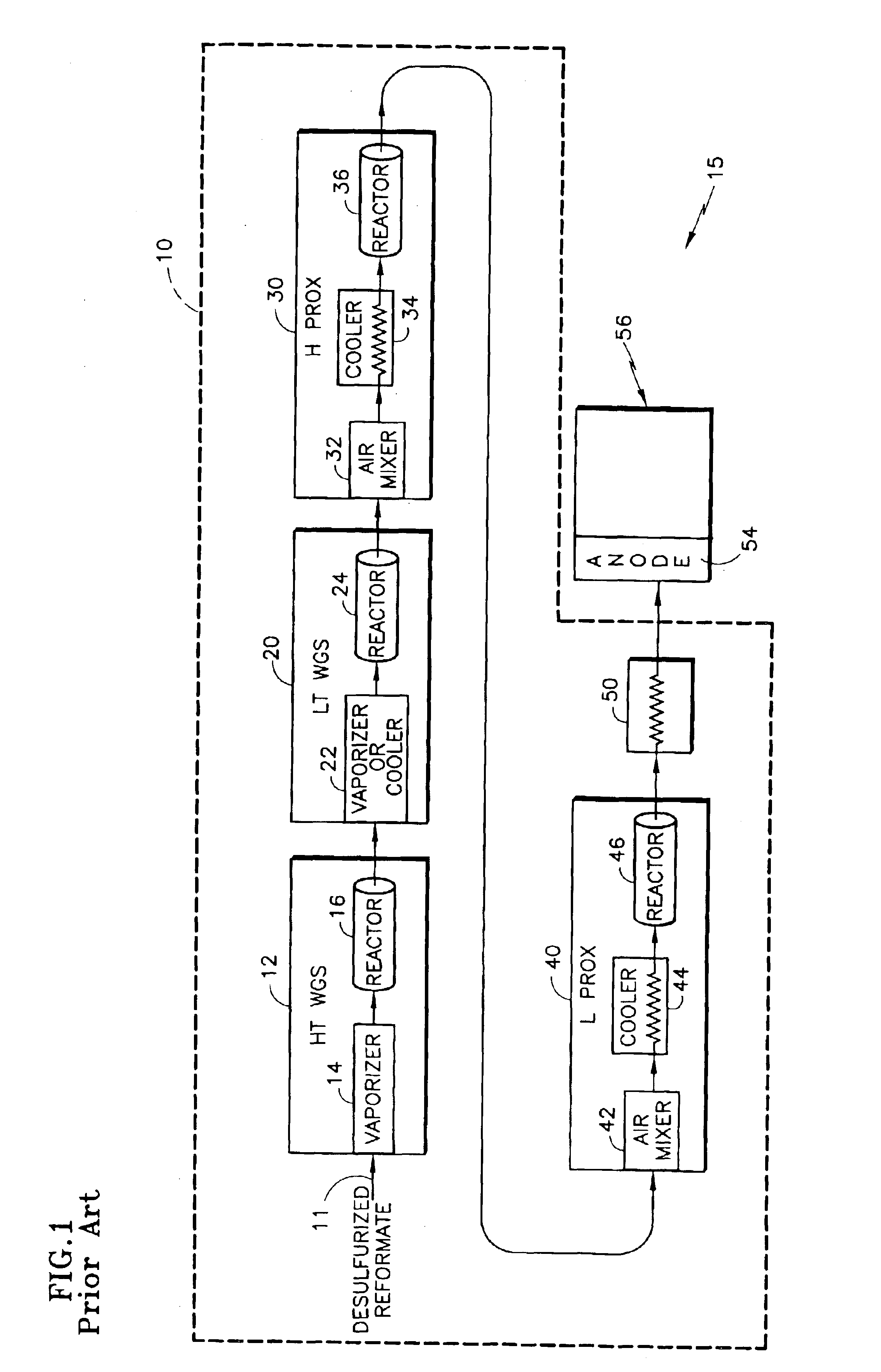

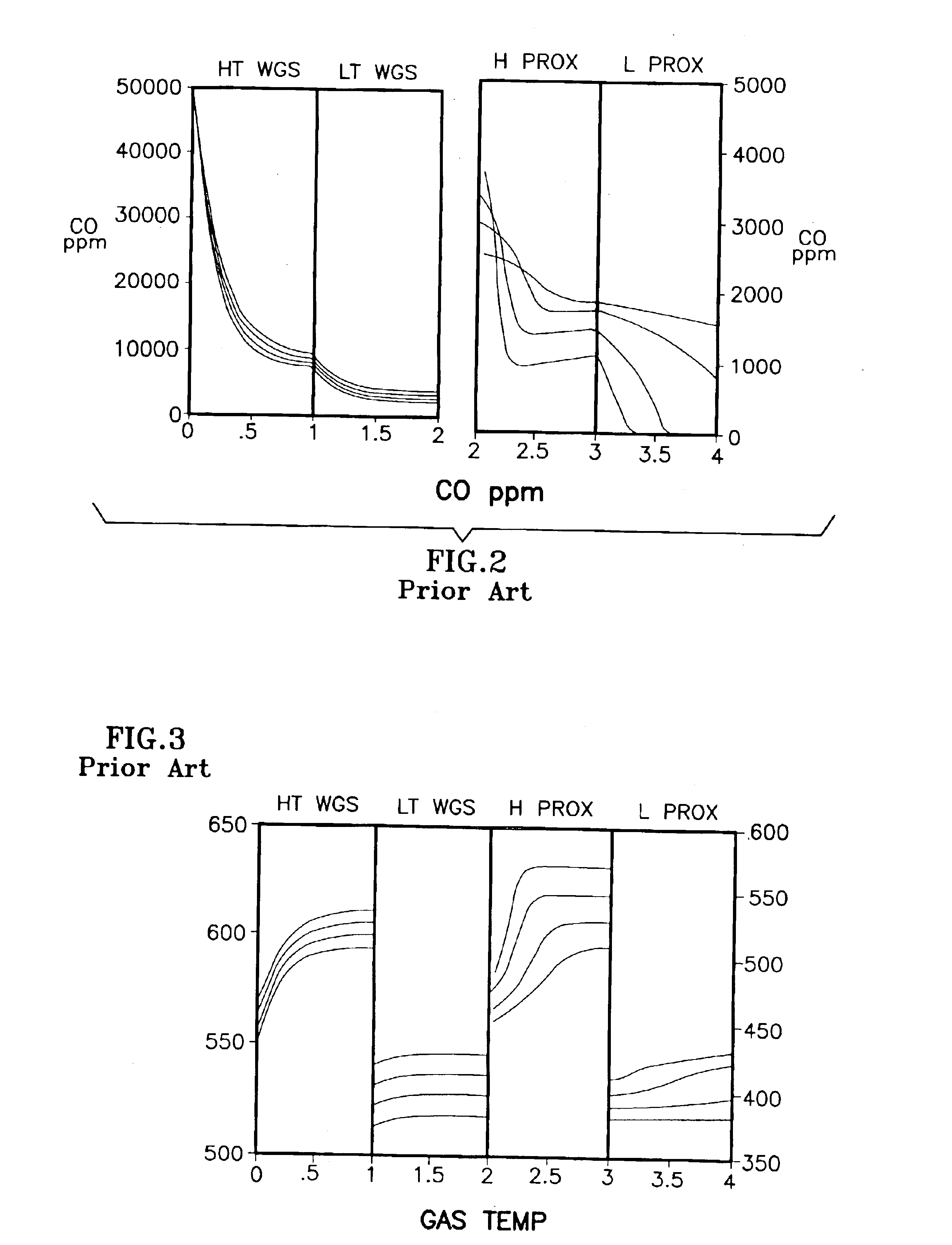

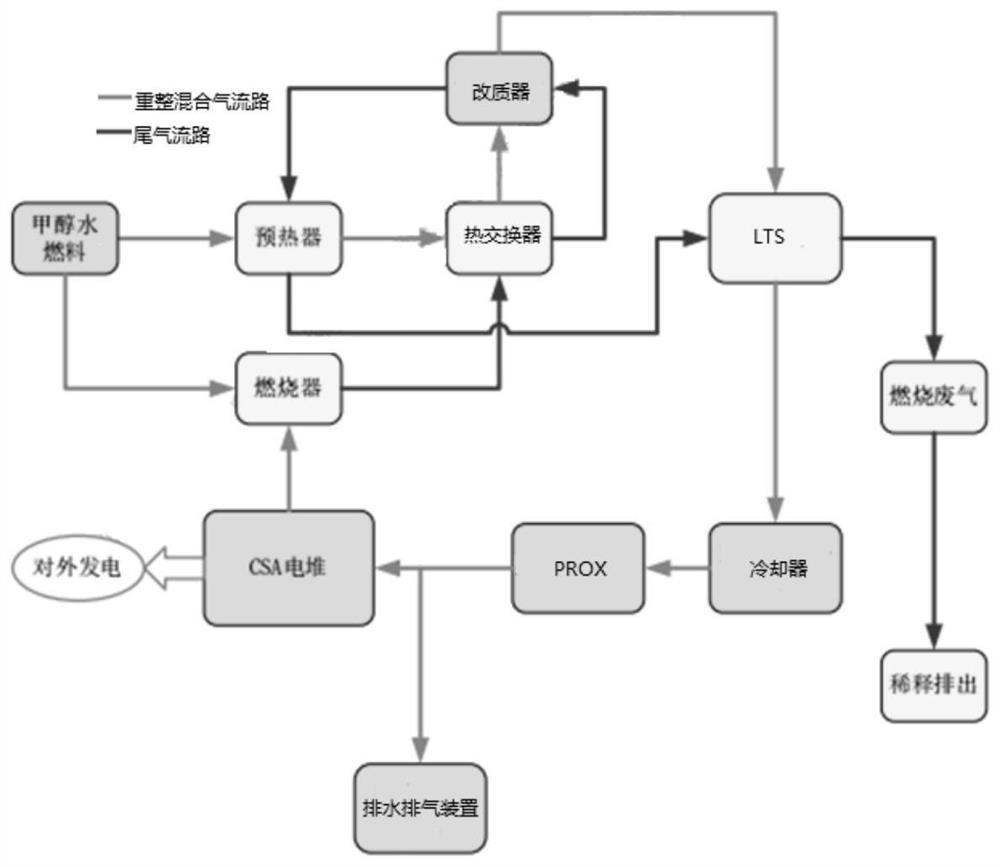

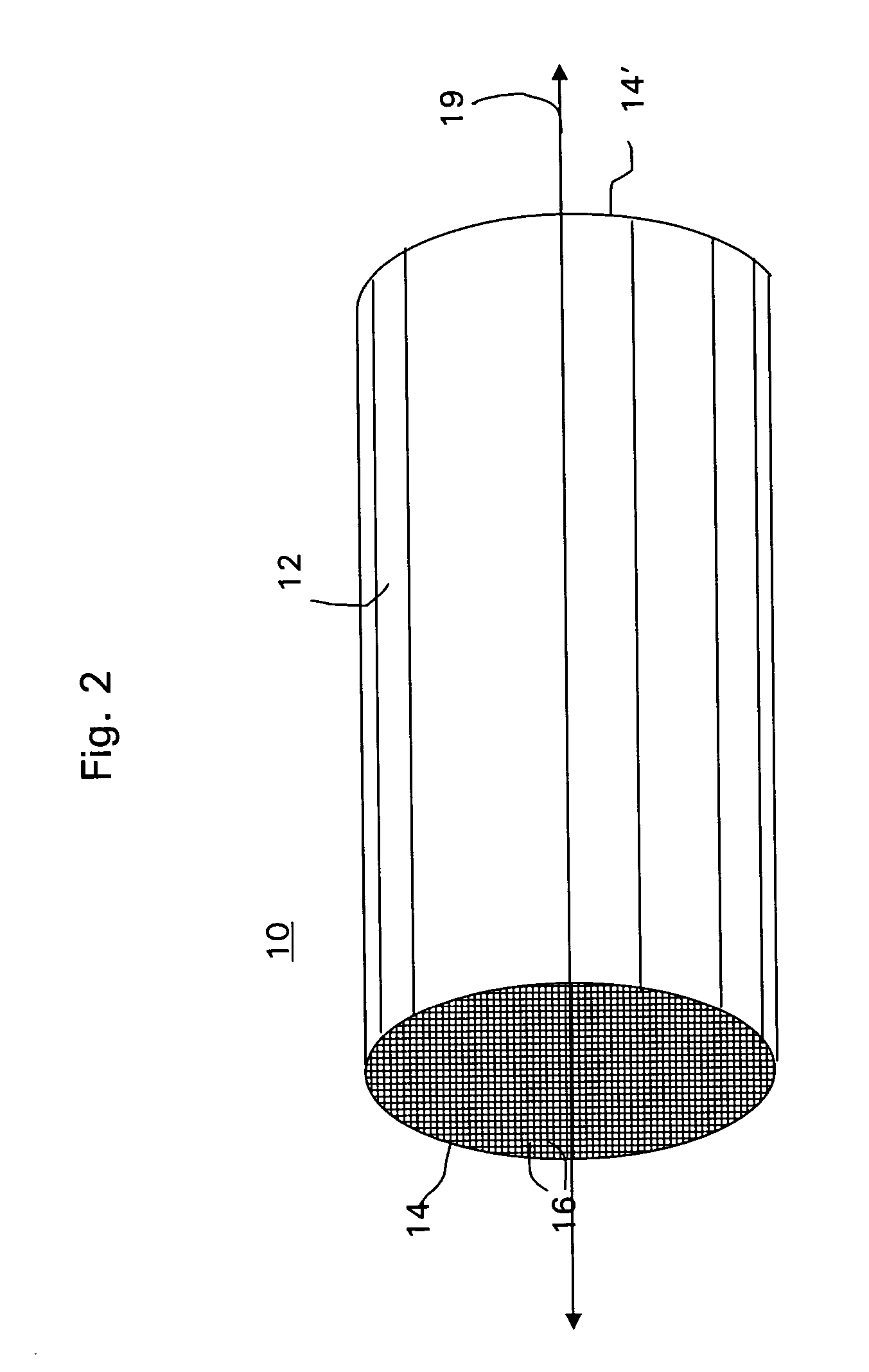

High performance fuel processing system for fuel cell power plant

InactiveUS6932848B2Small sizeSmall weightCombination devicesHydrogen separation using solid contactPower stationFuel cells

A fuel processing system (FPS) (110) is provided for a fuel cell power plant (115) having a fuel cell stack assembly (CSA) (56). A water gas shift (WGS) reaction section (12, 120) of the FPS (110) reduces the concentration of carbon monoxide (CO) in the supplied hydrocarbon reformate, and a preferred oxidation (PROX) section (40) further reduces the CO concentration to an acceptable level. The WGS section (12, 120) includes a reactor (124) with a high activity catalyst for reducing the reformate Co concentration to a relatively low level, e.g., 2,000 ppmv or less, thereby relatively reducing the structural volume of the FPS (110). The high activity catalyst is active at temperatures as low as 250° C., and may be a noble-metal-on-ceria catalyst of Pt and Re on a nanocrystaline, cerium oxide-based support. Then only a low temperature PROX reactor (46) is required for preferential oxidation in the FPS (110).

Owner:INT FUEL CELLS

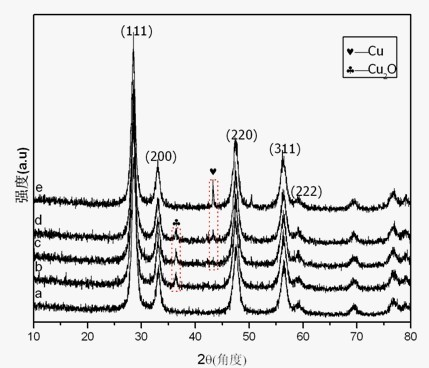

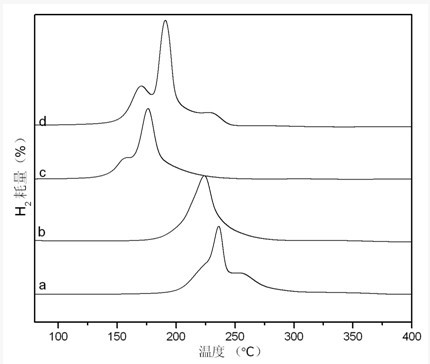

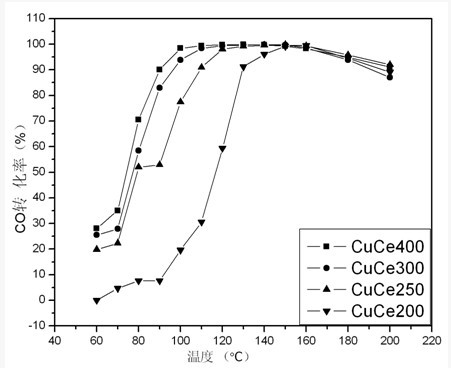

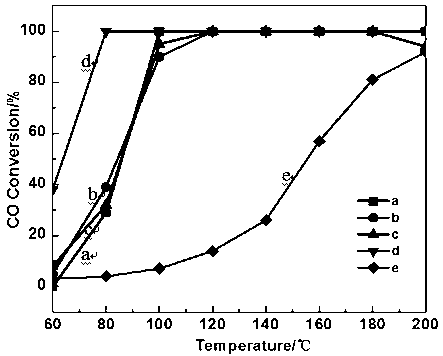

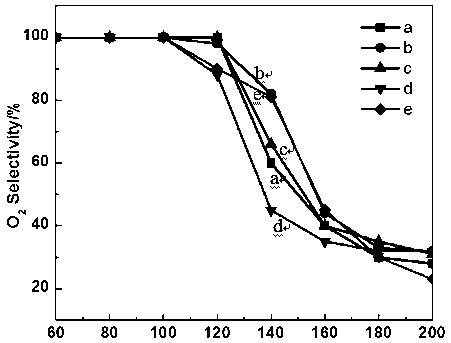

Preparation method of CuOx/CeO2 catalyst with high CO-PROX activity

InactiveCN102671666AHigh catalytic activity at low temperatureGood choiceDispersed particle separationCatalyst activation/preparationPtru catalystEthylic acid

The invention relates to a preparation method of a CuOx / CeO2 catalyst with high CO-PROX activity and various Cu species. Copper acetate and CeO2 carrier are placed into a mortar, are ground for certain time and are calcined for 3 hours respectively at the temperature of 200-400 DEG C in the N2 atmosphere, and thus the CuOx / CeO2 catalyst with various Cu species can be prepared. The preparation method has the advantages that no solvent is needed in the preparation process, and the loss of active species and the resulting pollution of water environment can be avoided effectively. More importantly, the catalyst has high CO-PROX activity and selectivity, the base metal Cu which can be easily obtained is used as an active ingredient, and high activity comparable with the activity of noble metal can be achieved.

Owner:NANJING UNIV

Recovery of inert gas from a fuel cell exhaust stream

A fuel cell system is provided including a fuel cell stack having a fuel cell having an anode, an anode outlet, an anode inlet, and a cathode. The fuel cell system further includes a hydrogen pump in communication with the anode outlet and the anode inlet. The hydrogen pump features a proton exchange membrane disposed between a first electrode and a second electrode. The first electrode is configured to accept an anode outlet stream from the anode outlet, the anode outlet stream including a hydrogen gas and an inert gas, the first electrode being configured to exhaust the inert gas. In one embodiment, the hydrogen pump is in communication with a PROX unit and configured to provide the hydrogen gas to the fuel cell stack. Further provided are methods employing the hydrogen pump wherein a start-stop degradation of the fuel cell is militated against and a hydrogen feed stream is humidified.

Owner:GM GLOBAL TECH OPERATIONS LLC

PROX catalyst for oxidizing carbon monoxide

InactiveUS7105468B2Improve the immunityIncreased durabilityOther chemical processesHydrogen separation using solid contactHydrogenChemical composition

A catalyst for preferentially reducing carbon monoxide in a hydrogen stream. The catalyst is formed from a chemical composition including a hexaaluminate, a metal hydroxide and a precious metal. The composition may be disposed on a support or may be extruded or cast into or onto a support. Incorporation of hexaaluminates allows inclusion of metal hydroxides that flux the active precious metal surface at higher temperatures than can aluminum oxide-based catalytic compositions, thereby enhancing resistance of the catalyst and monolithic support and increasing the durability and thermal range of the PROX catalyst. An additional advantage is that lesser amounts of precious metal oxides need be deposited onto the hexaaluminate, while retaining activity similar to aluminum oxide compositions.

Owner:UMICORE AG & CO KG

Catalyst Au/MnOx-CeO2 used for preferential oxidation of carbon monoxide and preparation method thereof

InactiveCN101623637AAvoid enrichmentNot prone to sintering and agglomerationHydrogen separation using solid contactFinal product manufactureMANGANESE ACETATEUltrasound assisted

The invention relates to a catalyst Au / MnOx-CeO2 used for preferential oxidation of carbon monoxide and a preparation method thereof. Au serves as an active component, compound oxide MnOx-CeO2 serves as a carrier, the mass ratio of the compound oxide and Au is 100:0.5-5.0, the contents of compound oxide MnOx and compound oxide CeO2 are based on Ce / Mn mole ratio of 1:1. Cerous nitrate, manganese acetate and chloroauric acid are taken as raw materials to prepare MnOx-CeO2 compound oxide carrier; after the carrier is dispersed by ultrasound, the precipitation product obtained by taking chloroauric acid as the raw material and sodium hydroxide as a precipitator is roasted to obtain Au / MnOx-CeO2 compound oxide load gold catalyst. By introducing ultrasound assisting dispersion technology, the active component is evenly dispersed on the surface of the carrier in the deposition-precipitation process, thus enrichment phenomenon of Au particles in deposition and precipitation is avoided when using the traditional deposition-precipitation method to prepare the catalyst, the sintering agglomeration of the Au particles is unlikely to happen when roasting, thus greatly improving PROX catalytic activity and thermostability and better satisfying the requirement of reducing the CO concentration to below 10ppm in proton exchange membrane fuel cells (PEMFCs).

Owner:TIANJIN UNIV

Plate type preferential oxidation reactor

The present invention provides a plate-shaped preferential oxidation (PROX) reactor. The plate-shaped PROX reactor of the present invention includes a plate-shaped chamber having an inlet to supply gas and an outlet to discharge fluid, a distributor for distributing gas supplied into the inlet, a main reactor having a catalyst for converting carbon monoxide contained in the gas into another material, and a radiator disposed on an outer surface of the chamber to dissipate heat.

Owner:SAMSUNG SDI CO LTD

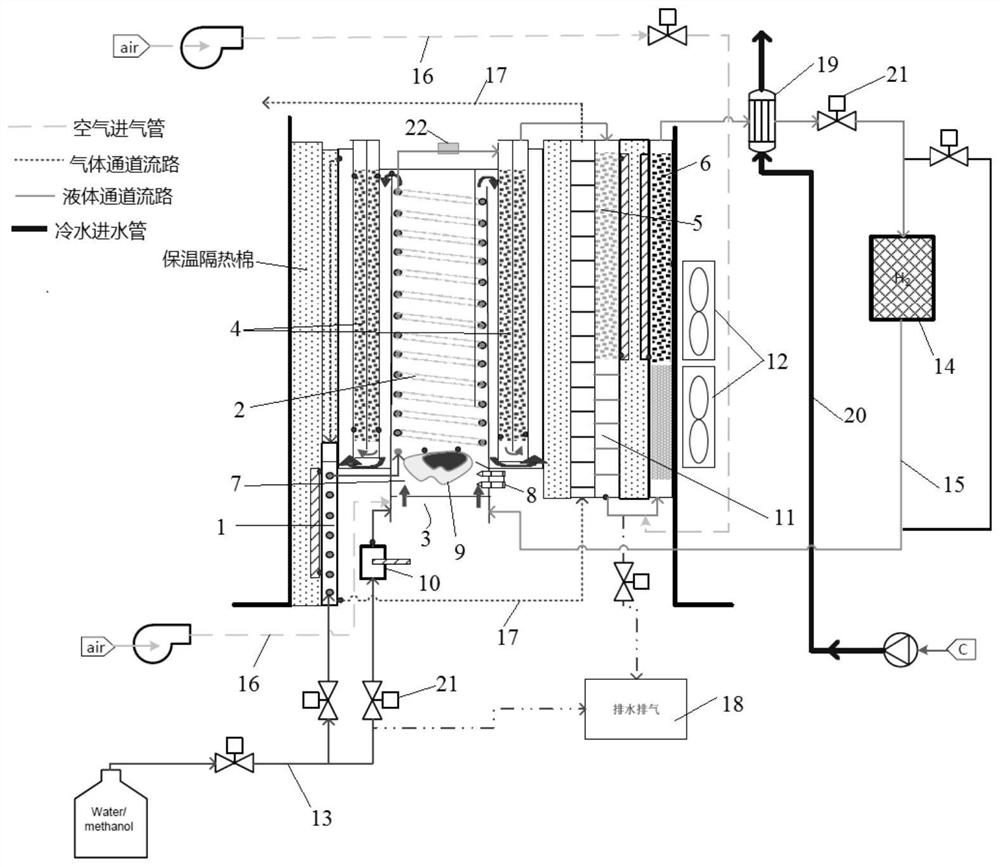

Methanol-water fuel reforming hydrogen production system

PendingCN111747378AReduce CO concentrationImprove the purification effectHydrogen separation using solid contactHydrogen/synthetic gas productionPtru catalystCatalytic oxidation

The invention discloses a methanol-water fuel reforming hydrogen production system. The system comprises a methanol-water fuel feeding pipe, an evaporator, a modifier, a CO oxidation removal device and a hydrogen-rich mixed gas conveying pipe which are connected in sequence. The CO oxidation removal device comprises an LTS catalytic oxidizer and a PROX catalytic oxidizer, a copper-zinc-based catalyst is arranged in the LTS catalytic oxidizer, and a ruthenium-based catalyst is arranged in the PROX catalytic oxidizer. The hydrogen-rich mixed gas is subjected to staged oxidation treatment throughthe LTS catalytic oxidizer and the PROX catalytic oxidizer, so that the CO concentration in the gas is gradually reduced to guarantee that CO is completely removed. According to the system, the conversion rate of methanol can reach 100%, CO in the reformed mixed gas can be completely removed, the starting time of the system is short, the reforming hydrogen production condition can be rapidly achieved, energy consumption is low, the hydrogen production speed is high, the hydrogen production cost is low, the energy conversion efficiency is high, environmental protection and energy conservationare achieved, and the power generation efficiency is high after the system is in butt joint with a fuel cell stack.

Owner:摩氢科技有限公司

Combined water gas shift reactor/carbon dioxide adsorber for use in a fuel cell system

InactiveUS20050204629A1Eliminate operationSmall sizeThermal non-catalytic crackingMuffle furnacesSorbentUnit operation

An apparatus removes CO from a hydrogen-rich gas stream in a hydrogen fuel cell system. CO fouls costly catalytic particles in the membrane electrode assemblies. Both a catalyst adapted to perform a water gas shift reaction, and a carbon dioxide adsorbent are disposed in a rotating pressure swing adsorber housing. The adsorption of carbon dioxide shifts equilibrium toward carbon monoxide consumption. A second adsorbent may be disposed in the housing for adsorbing carbon monoxide at low temperatures, and is adapted to desorb carbon monoxide at high temperatures. The present invention advantageously eliminates a unit operation from a space-constrained fuel cell vehicle by combining the WGS catalyst and a CO2 adsorbent in a single reactor / housing. The apparatus further eliminates the use of a PROX reactor, by providing an apparatus which incorporates CO2 adsorption and consequent carbon monoxide consumption in the place of the PROX reactor.

Owner:GM GLOBAL TECH OPERATIONS LLC

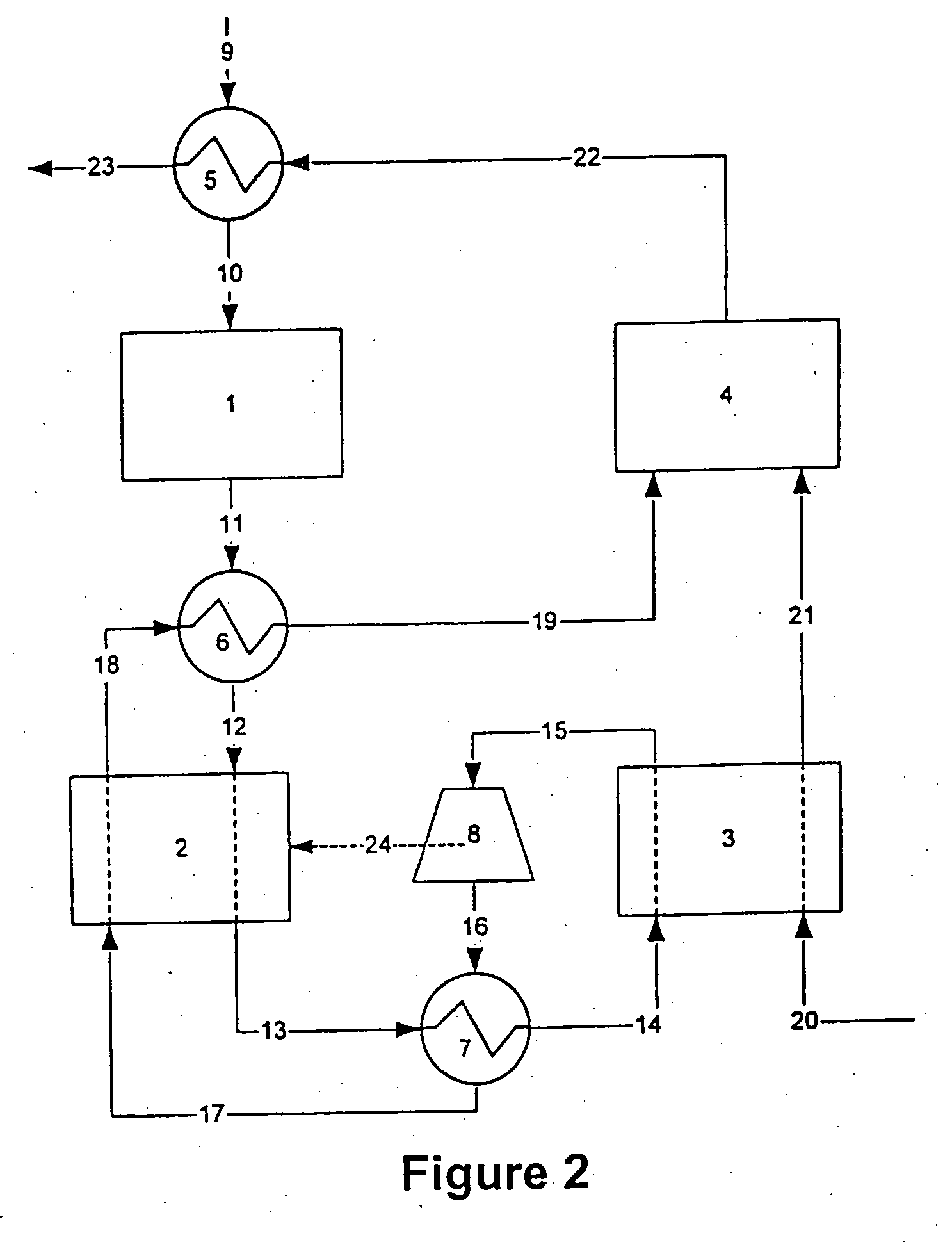

Compositions and methods for the treatment of cast nephropathy and related conditions

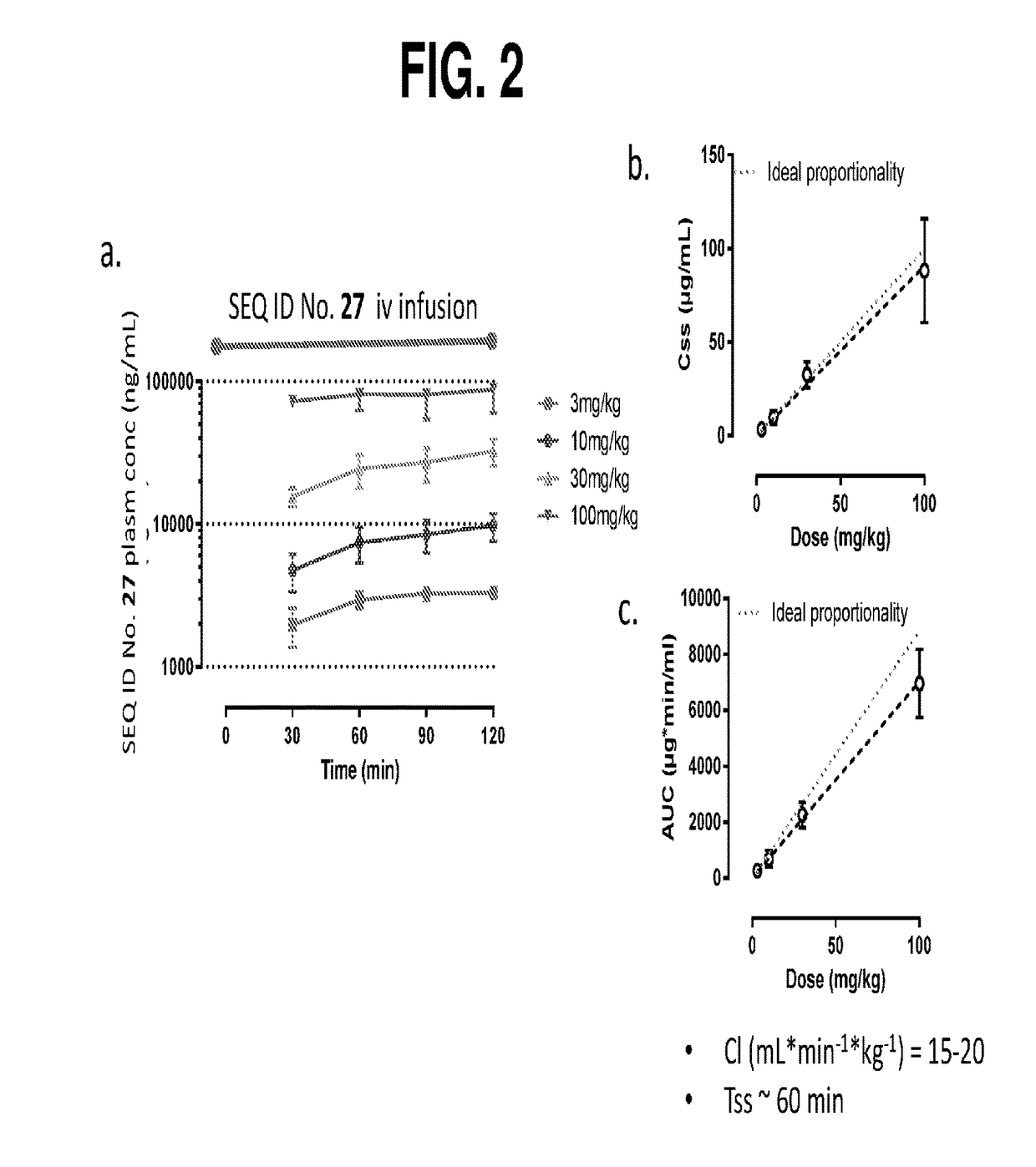

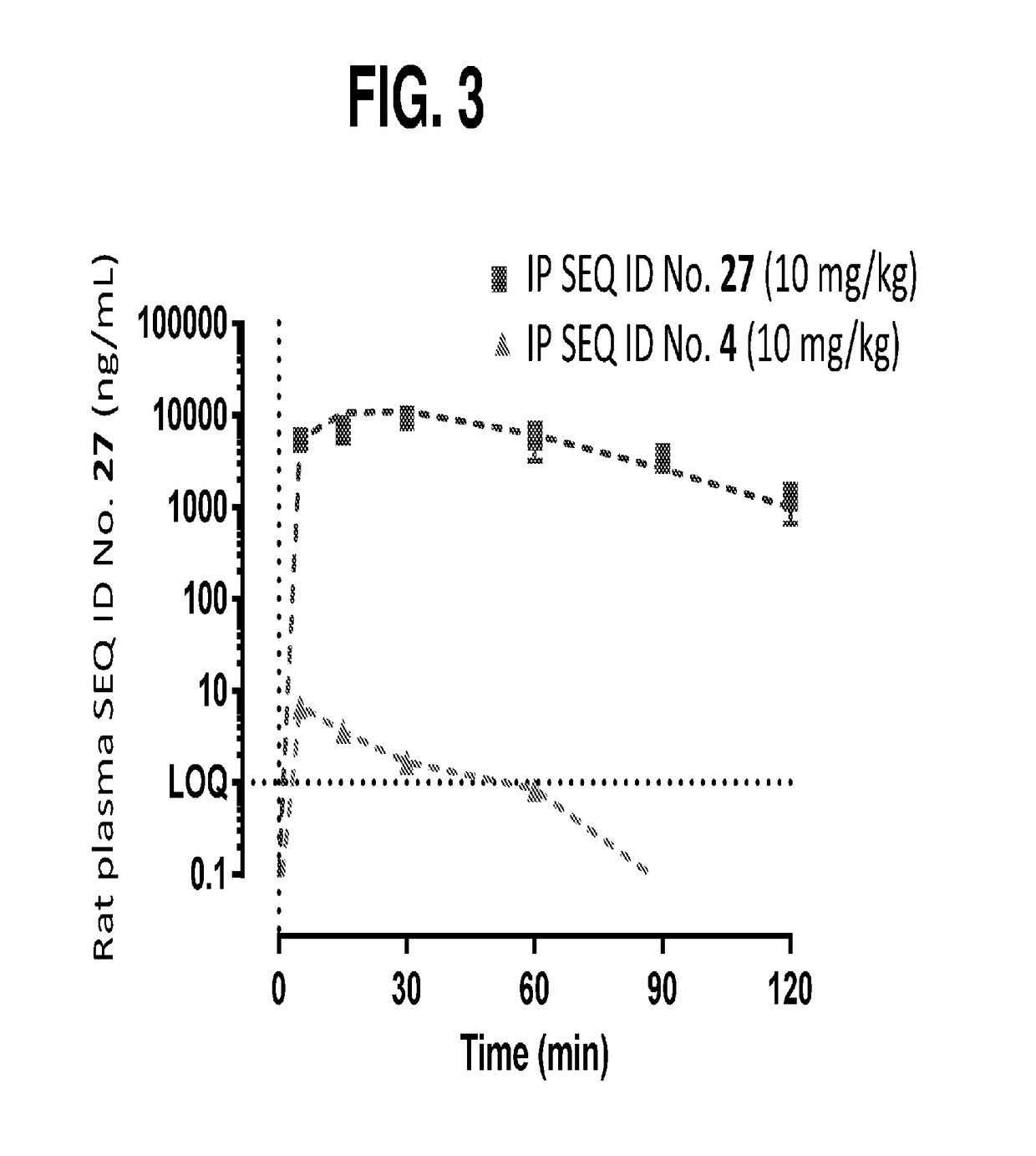

Provided are novel peptides of Formula SEQ ID No. 1:J1CysX1X2X3X4X5X6ProX7ThrCysJ2J3(J4)s(J5)t; (SEQ ID No. 1)pharmaceutically acceptable salts thereof, and pharmaceutical compositions thereof, which are effective inhibitors of light chains to uromodulin.

Owner:THRASOS THERAPEUTICS

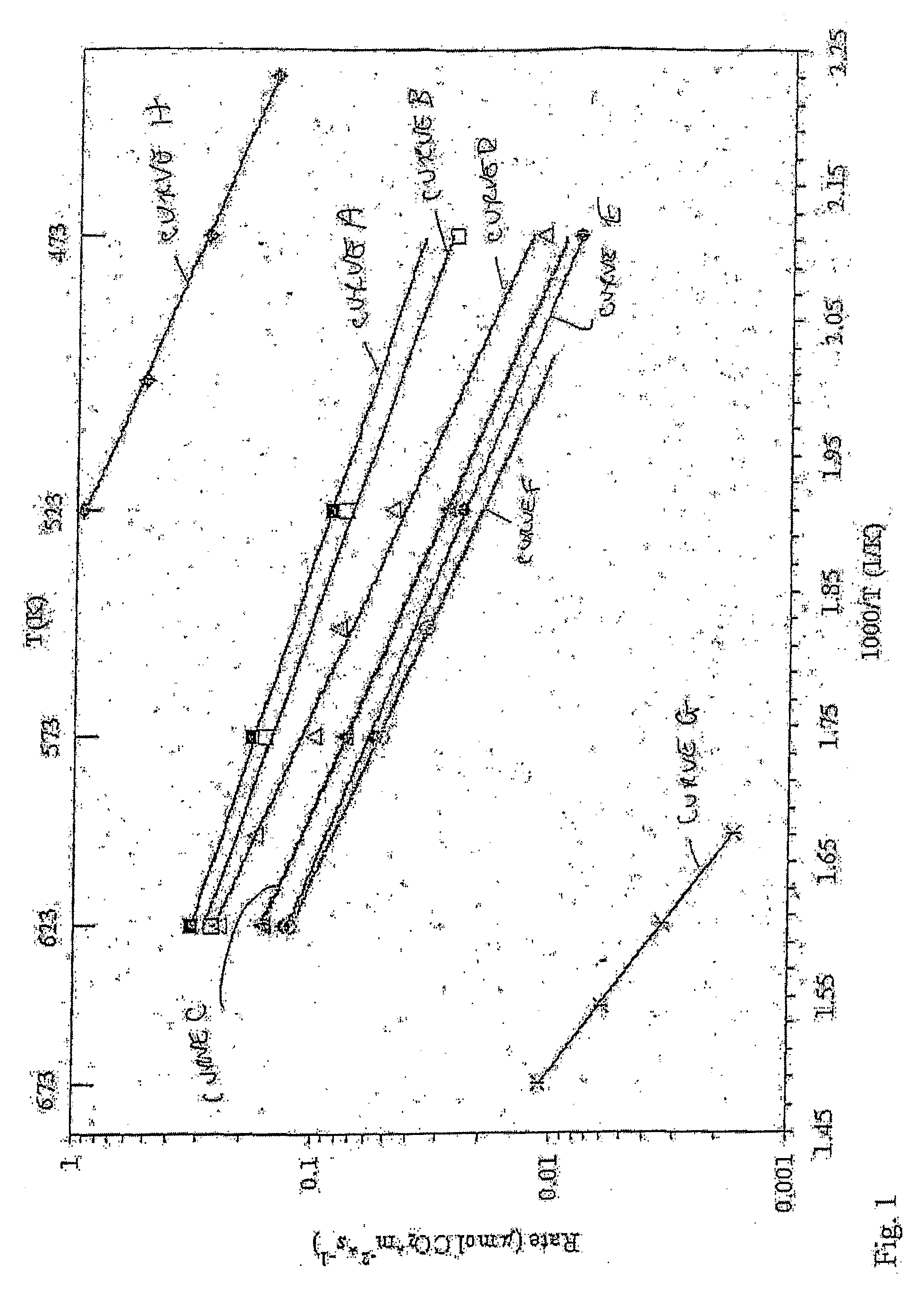

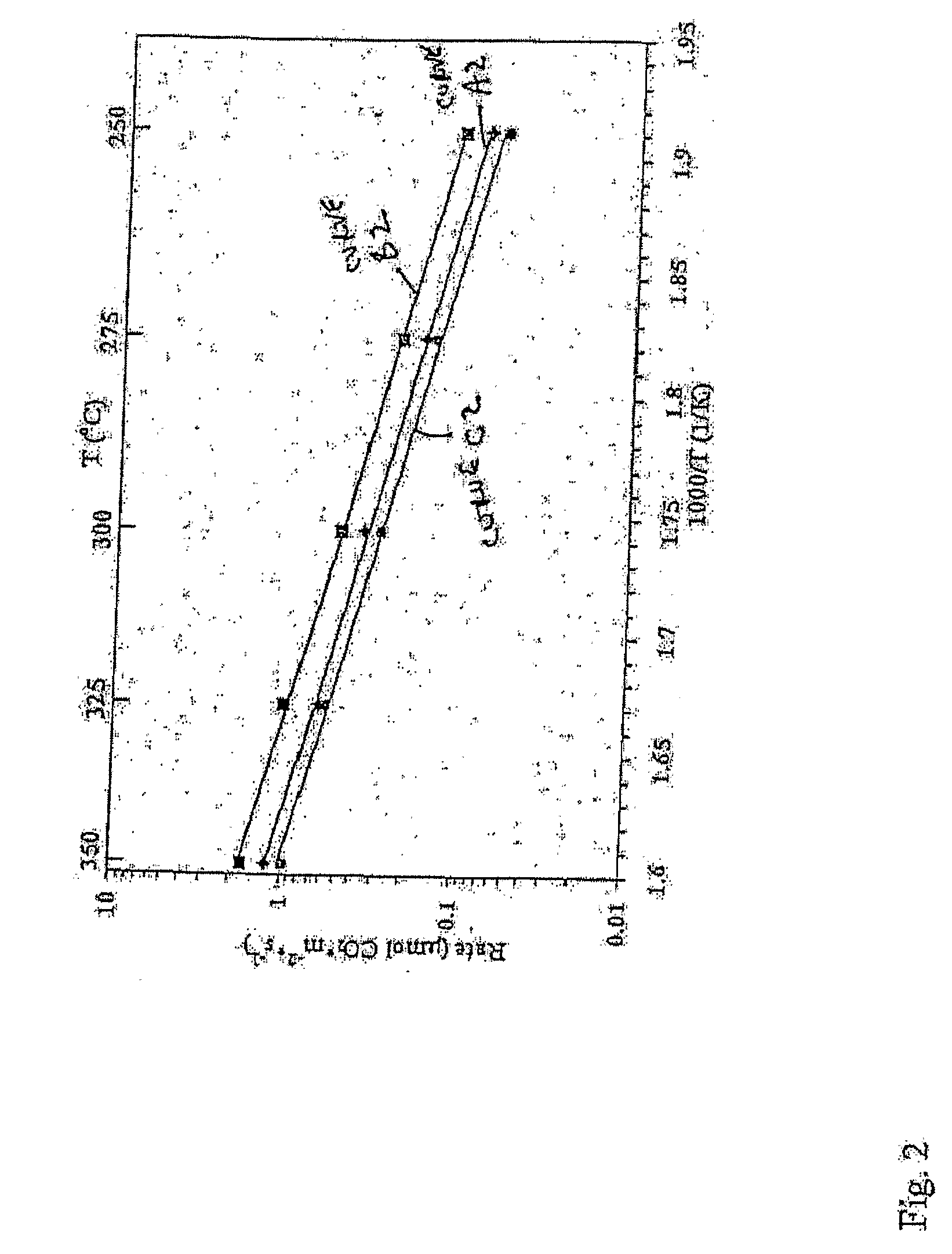

Selective oxidation of carbon monoxide relative to hydrogen using catalytically active gold

The present invention provides technology for controlling, or tuning, the catalytic activity of gold provided upon nanoporous supports such as those derived from nanoparticulate, crystalline titania. In some aspects of practice, the surface of nanoparticulate media incorporated into a catalyst system of the present invention is provided with chemical modifications of the surface that dramatically suppress the ability of the resultant catalyst system to oxidize hydrogen. Yet, the system still readily oxidizes CO. In other words, by selecting and / or altering the nanoparticulate surface via the principles of the present invention, PROX catalysts are readily made from materials including catalytically active gold and nanoparticulate media. Additionally, the nanoparticulate support also may be optionally thermally treated to further enhance selectivity for CO oxidation with respect to hydrogen. Such thermal treatments may occur before or after chemical modification, but desirably occur prior to depositing catalytically active gold onto the support incorporating the nanoparticles.

Owner:3M INNOVATIVE PROPERTIES CO

Carbon monoxide adsorption for carbon monoxide clean-up in a fuel cell system

InactiveUS20060032138A1Eliminate useReduce contentGas treatmentPhysical/chemical process catalystsSorbentHydrogen fuel cell

An apparatus removes carbon monoxide (CO) from a hydrogen-rich gas stream in a hydrogen fuel cell system. CO fouls costly catalytic particles in the membrane electrode assemblies of proton exchange membrane (PEM) fuel cells. A vessel houses a carbon monoxide adsorbent. The vessel may be a rotating pressure swing adsorber. A water gas shift reactor is upstream of the rotating pressure swing adsorber. The water gas shift reactor may include a second adsorbent adapted to adsorb carbon monoxide at low temperatures and to desorb carbon monoxide at high temperatures. The apparatus advantageously eliminates the use of a preferential oxidation (PROX) reactor, by providing an apparatus which incorporates CO adsorption in the place of the PROX reactor. This cleans up carbon monoxide without hydrogen consumption and the concomitant, undesirable excess low grade heat generation. The present invention reduces start-up duration, and improves overall fuel processor efficiency during normal operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

Vermiculite supported catalyst for CO preferential oxidation and the process of preparing the same

InactiveUS20090062116A1Improve efficiencyEasy-to-handle (inert)HydrogenCatalyst activation/preparationOrganic chemistryCalcination

A vermiculite supported catalyst for carbon monoxide (CO) preferential oxidation (PROX) is disclosed. The CO PROX catalyst comprises at least one catalytic agent, one optional modifier agent, one carrier material, and a vermiculite support. The process for preparing the vermiculite supported catalyst in this invention includes depositing first the carrier material on a vermiculite support followed by calcination to form the carrier-containing support, and wet impregnating the catalytic agent and the optional modifier agent on the carrier-containing support followed by drying and calcination to form the CO preferential oxidation catalyst.

Owner:INST NUCLEAR ENERGY RES ROCAEC

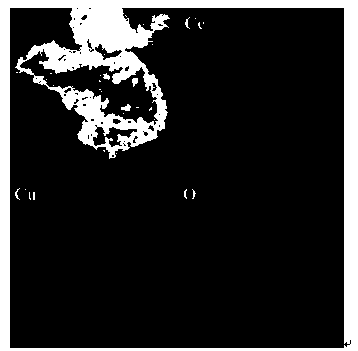

Preparation method of copper cerium catalyst with high dispersion of active species

InactiveCN110433814AReduce manufacturing costLarge specific surface areaGas treatmentDispersed particle separationCeriumMetal-organic framework

The invention discloses a preparation method of a copper cerium catalyst with high dispersion of active species. The preparation method of the copper cerium catalyst with high dispersion of the activespecies comprises the steps that S1, metal copper salt or cerium salt is dispersed in water, further a dispersed organic ligand is added, and the mixture is stirred uniformly; and the mixed solutionis placed in an oven for crystallization, hydrothermal synthesis is carried out to obtain a copper metal organic framework compound or a cerium metal organic framework compound or a copper cerium bimetallic organic framework compound; S2, when the synthesis product is a copper metal organic framework compound, the copper metal organic framework compound is loaded with cerium ions by an equal volume impregnation method; when the synthesis product is the cerium metal organic framework compound, the cerium metal organic framework compound is loaded with copper ions by an impregnation method to obtain a catalyst precursor; S3, and the obtained catalyst precursor is dried and placed in a muffle furnace for calcination to obtain the copper cerium catalyst. The synthesized copper cerium catalysthas the following advantages that (1) a large specific surface area is achieved, so that efficient conversion of CO is facilitated; (2) orderly pores are achieved, and gas mass transfer during the reaction is accelerated; and (3) better CO-PROX effect is achieved, complete conversion of CO can be achieved at 100 DEG C with good selectivity.

Owner:NANCHANG UNIV

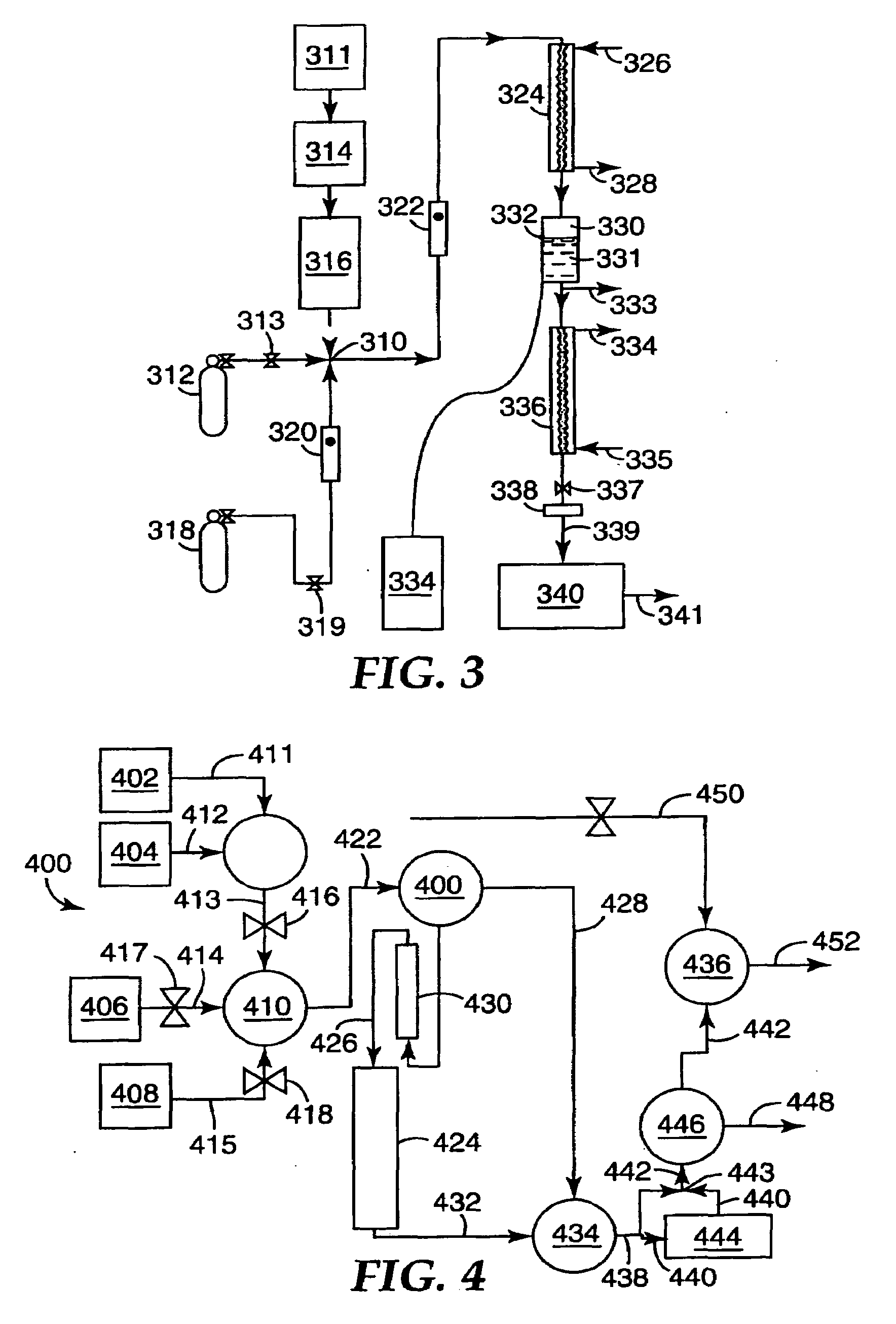

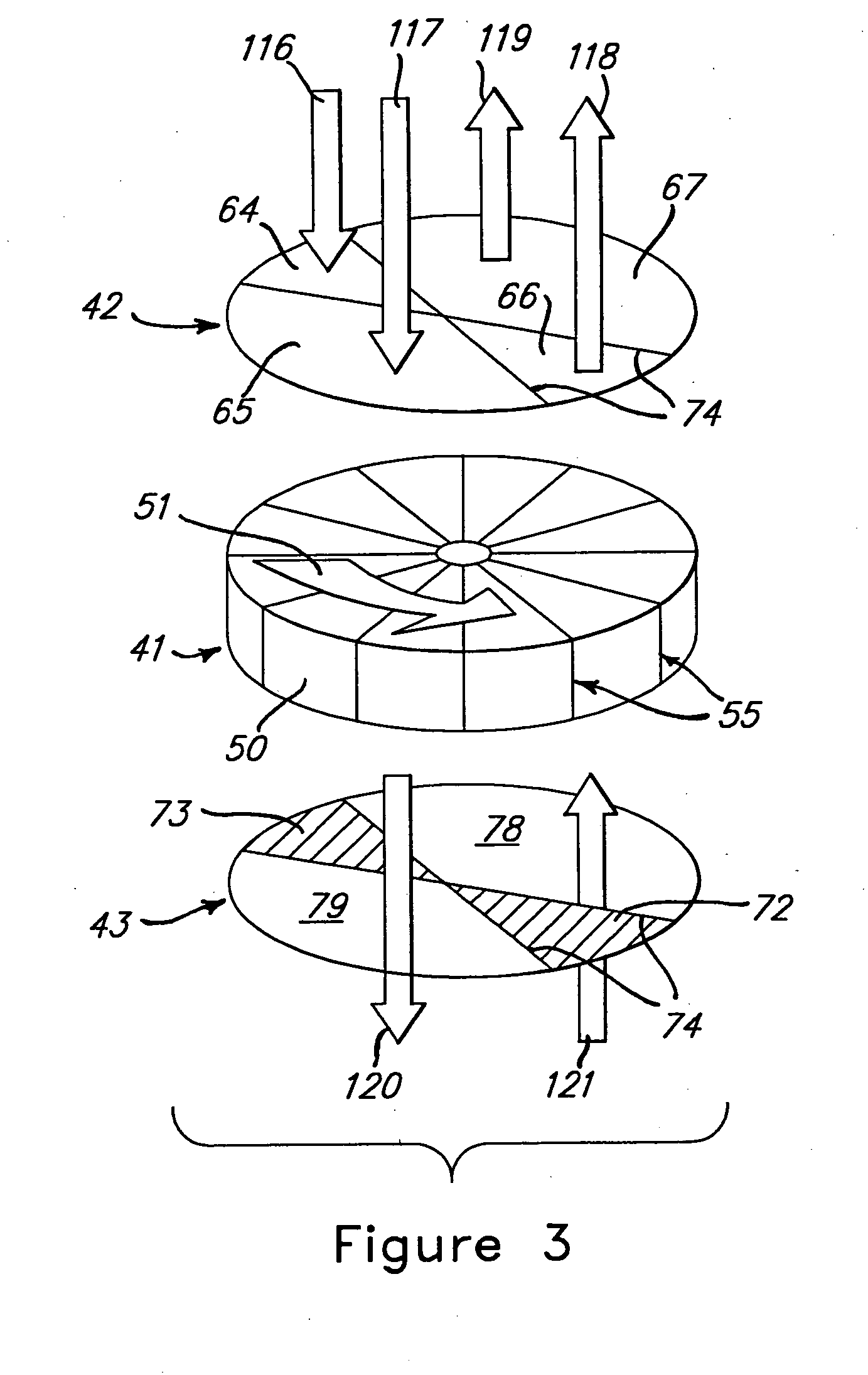

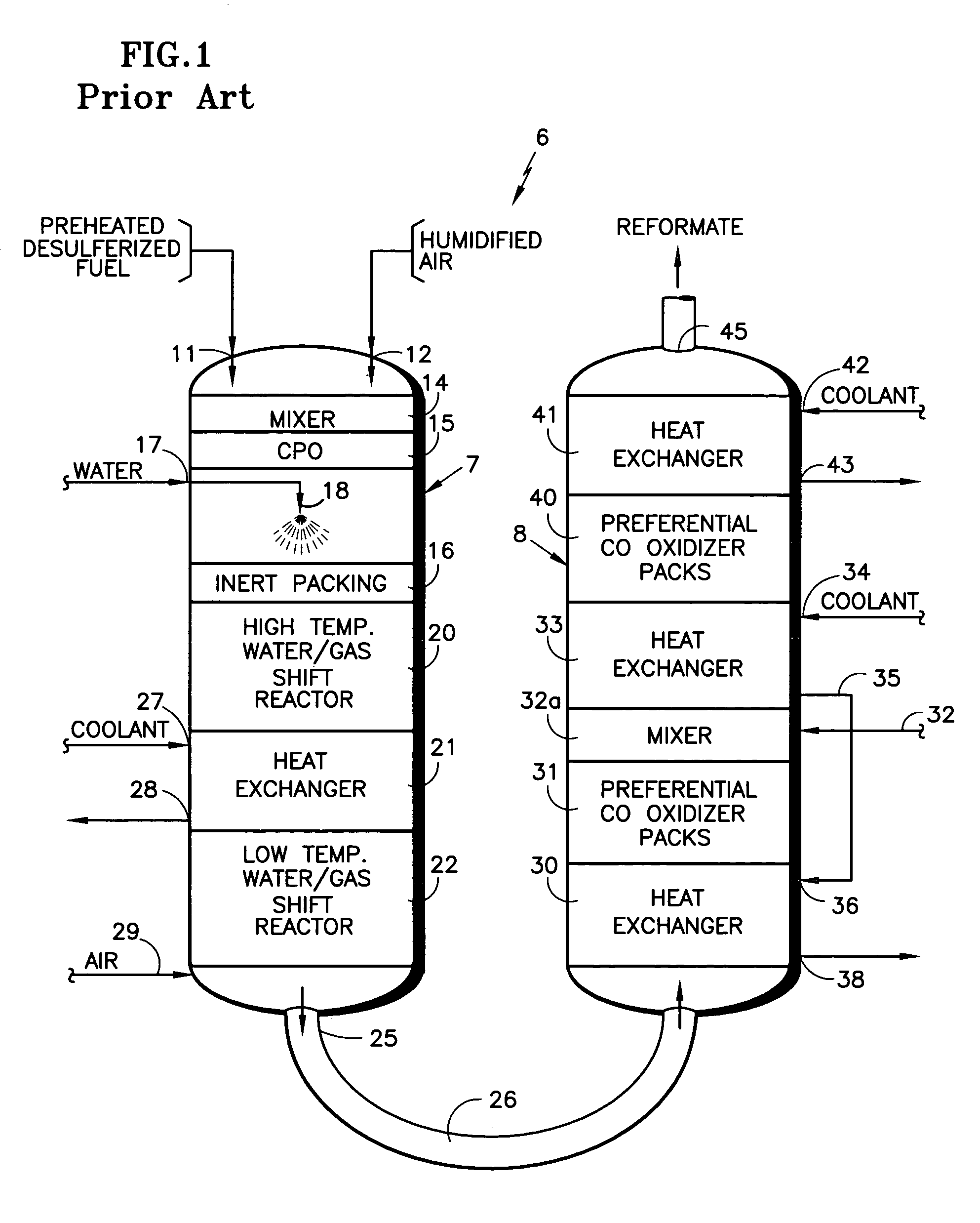

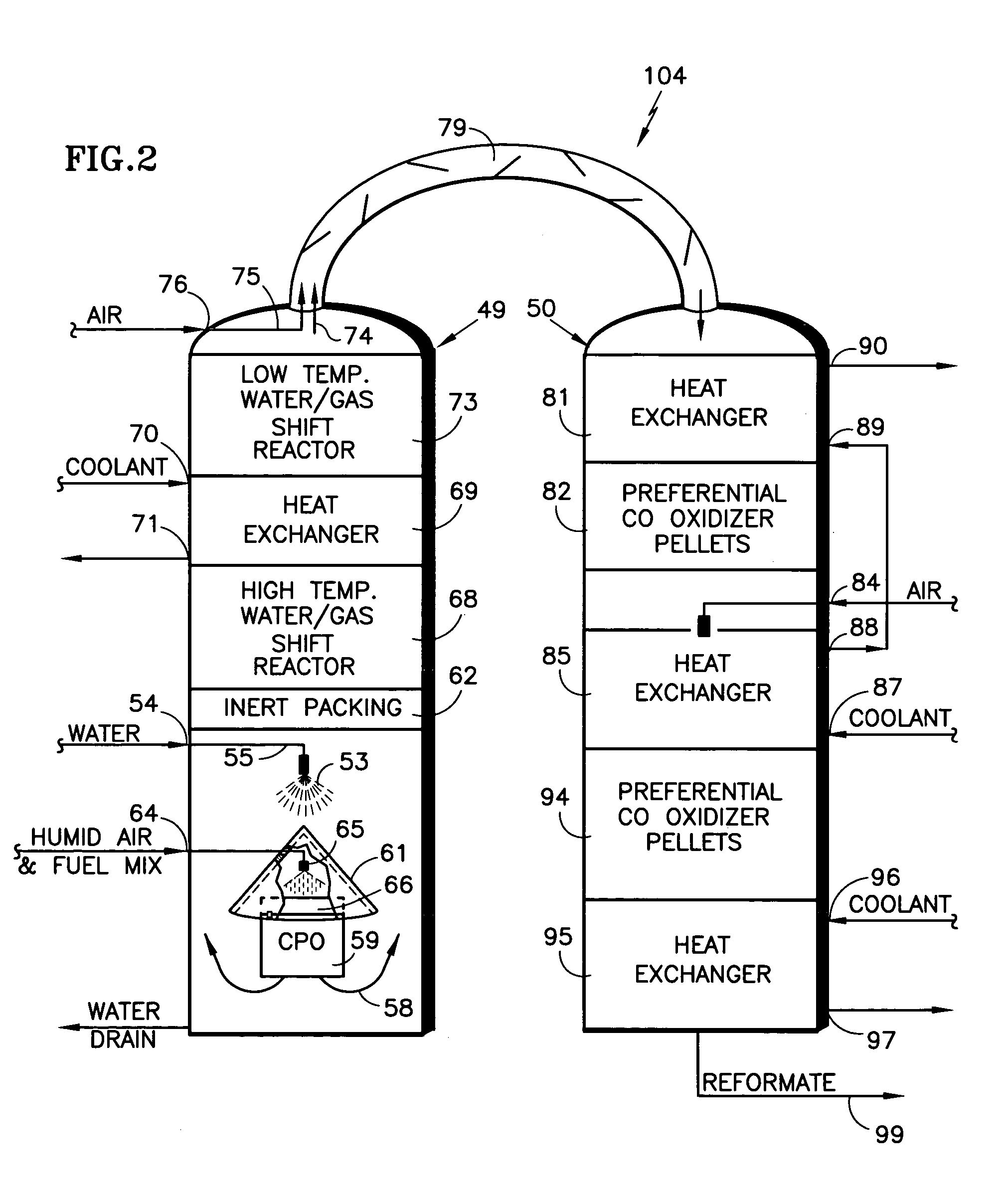

Compact production of reformate and segregated H2, N2 and CO2

ActiveUS7575610B2Reduce spacingGenerationHydrogenHydrogen/synthetic gas productionWater-gas shift reactionNitrogen

Substantially pure oxygen is provided to an up flow reformer (49a) from a separator (108) downwardly impelled water droplets (53) mix with the outflow (58) of a CPO (59), flowing upwardly through high temperature (68) and low temperature (73) water gas shift reactors. The reformer output flows through a mixer (79) to a down-flow PrOx containing two beds (82, 94) of preferential CO oxidation catalyst therein. A series of compressors (120-122) compress water and carbon dioxide out of the gaseous flow to provide pure, pressurized hydrogen. Oxygen (111) is separated (105, 108) from nitrogen (112).

Owner:INT FUEL CELLS

PROX catalyst for oxidizing carbon monoxide

InactiveUS7253137B2Improve the immunityIncreased durabilityOther chemical processesLaminationChemical compositionHydrogen

A catalyst for preferentially reducing carbon monoxide in a hydrogen stream. The catalyst is formed from a chemical composition including a hexaaluminate, a metal hydroxide and a precious metal. The composition may be disposed on a support or may be extruded or cast into or onto a support. Incorporation of hexaaluminates allows inclusion of metal hydroxides that flux the active precious metal surface at higher temperatures than can aluminum oxide-based catalytic compositions, thereby enhancing resistance of the catalyst and monolithic support and increasing the durability and thermal range of the PROX catalyst. An additional advantage is that lesser amounts of precious metal oxides need be deposited onto the hexaaluminate, while retaining activity similar to aluminum oxide compositions.

Owner:UMICORE AG & CO KG

Preferential oxidation reactor integrated with heat exchanger and operating method thereof

InactiveUS7771676B2Effective controlPromote activationMaterial analysis by electric/magnetic meansMaterial analysis by optical meansComing outGas passing

A PROX reactor integrated with a heat exchanger and an operating method thereof capable of effectively controlling temperature of a preferential oxidation reactor so as to obtain optimal activation and yield. The PROX reactor integrated with a heat exchanger of the present invention includes a pipe having an inlet and an outlet, a heat exchanger cooling gas passing through the pipe, a catalyst part positioned at the rear end of the heat exchanger, upon considering the flow of gas, and shifting carbon monoxide contained in the gas into other substances; and a temperature sensor measuring the temperature of the gas coming out through the catalyst part.

Owner:SAMSUNG SDI CO LTD

PROX catalyst for oxidizing carbon monoxide

InactiveUS20060258530A1Improve the immunityIncreased durabilityOther chemical processesActive material electrodesChemical compositionHydrogen

A catalyst for preferentially reducing carbon monoxide in a hydrogen stream. The catalyst is formed from a chemical composition including a hexaaluminate, a metal hydroxide and a precious metal. The composition may be disposed on a support or may be extruded or cast into or onto a support. Incorporation of hexaaluminates allows inclusion of metal hydroxides that flux the active precious metal surface at higher temperatures than can aluminum oxide-based catalytic compositions, thereby enhancing resistance of the catalyst and monolithic support and increasing the durability and thermal range of the PROX catalyst. An additional advantage is that lesser amounts of precious metal oxides need be deposited onto the hexaaluminate, while retaining activity similar to aluminum oxide compositions.

Owner:UMICORE AG & CO KG

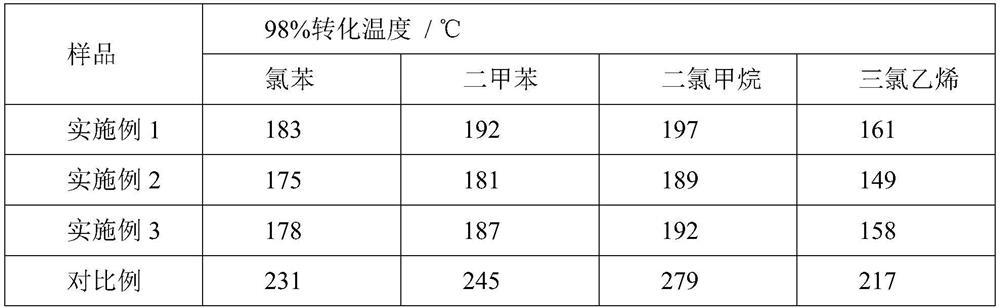

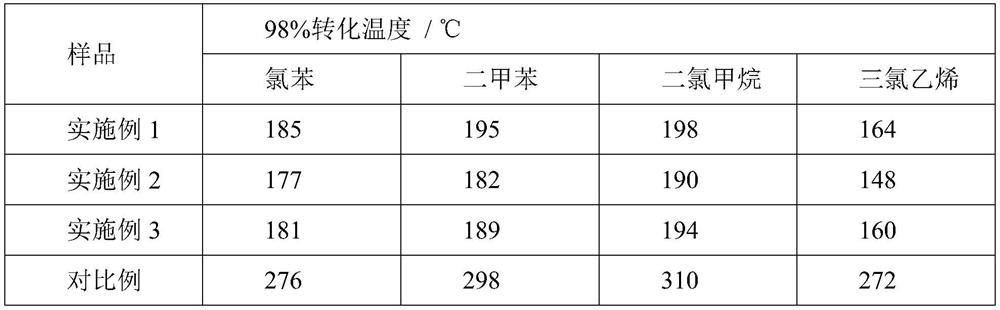

Catalytic oxidation catalyst for removing chlorine-containing VOCs and preparation method of catalytic oxidation catalyst

ActiveCN113941345AGood activity at low temperatureEasy to removeCatalyst carriersHeterogenous catalyst chemical elementsPtru catalystCatalytic oxidation

The invention provides a catalytic oxidation catalyst for removing chlorine-containing VOCs and a preparation method of the catalytic oxidation catalyst. The catalyst disclosed by the invention is prepared from RuO2, SnO2, Ce-Zr-La-PrOx and hydroxyapatite. The preparation method comprises the following steps: firstly, preparing a hydroxyapatite carrier and a Ce-Zr-La-PrOx composite metal oxide by adopting a coprecipitation method, then adding a precursor solution of Ru and Sn into mixture powder, then adding carboxymethyl cellulose and polyoxyethylene, carrying out grinding by using a ball mill to obtain slurry, and then drying and roasting the slurry to obtain the catalytic oxidation catalyst. The catalyst is high in low-temperature activity and strong in chlorine poisoning resistance and carbon poisoning resistance, and can be used for catalytic oxidation of chlorine-containing volatile organic compound flue gas.

Owner:UNIV OF SCI & TECH OF CHINA

Catalyst Au/MnOx-CeO2 used for preferential oxidation of carbon monoxide and preparation method thereof

InactiveCN101623637BAvoid enrichmentNot prone to sintering and agglomerationHydrogen separation using solid contactFinal product manufactureMANGANESE ACETATEPtru catalyst

The invention relates to a catalyst Au / MnOx-CeO2 used for the preferential oxidation of carbon monoxide and a preparation method thereof. Au serves as an active component and compound oxide MnOx-CeO2 serves as a carrier. The mass ratio of the compound oxide and Au is 100:0.5-5.0. The contents of compound oxide MnOx and compound oxide CeO2 are based on Ce / Mn mole ratio of 1:1. Cerous nitrate, manganese acetate and chloroauric acid are taken as raw materials to prepare MnOx-CeO2 compound oxide carrier. After the carrier is dispersed by ultrasound, the precipitation product obtained by taking chloroauric acid as the raw material and sodium hydroxide as a precipitator is roasted to obtain Au / MnOx-CeO2 compound oxide load gold catalyst. By introducing ultrasound assisting dispersion technology, the active component is evenly dispersed on the surface of the carrier in the deposition-precipitation process. Therefore, the enrichment phenomenon of Au particles in deposition and precipitation is avoided when using the traditional deposition-precipitation method to prepare the catalyst. The sintering agglomeration of the Au particles is unlikely to happen during roasting, thereby greatly improving PROX catalytic activity and thermostability and better satisfying the requirement of reducing the CO concentration to below 10ppm in proton exchange membrane fuel cells (PEMFCs).

Owner:TIANJIN UNIV

Use of a radial zone coating to facilitate a two-stage prox system with single air injection

InactiveUS20070025894A1Low efficiencyAvoid large emissionsCatalytic gas-gas reactionPhysical/chemical process catalystsSingle injectionProduct gas

A two stage-carbon monoxide preferential oxidation article and method that uses a single injection of an O2-containing gas.

Owner:BASF CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com