Patents

Literature

42results about How to "Polygeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing chitin and chitosan through hydrothermal/two-step enzymic method from shrimp and crab shells and application of the method

InactiveCN110256603AImprove accessibilityRealize multilinkOrganic compound preparationCarboxylic acid salt preparationPollutionImpurity

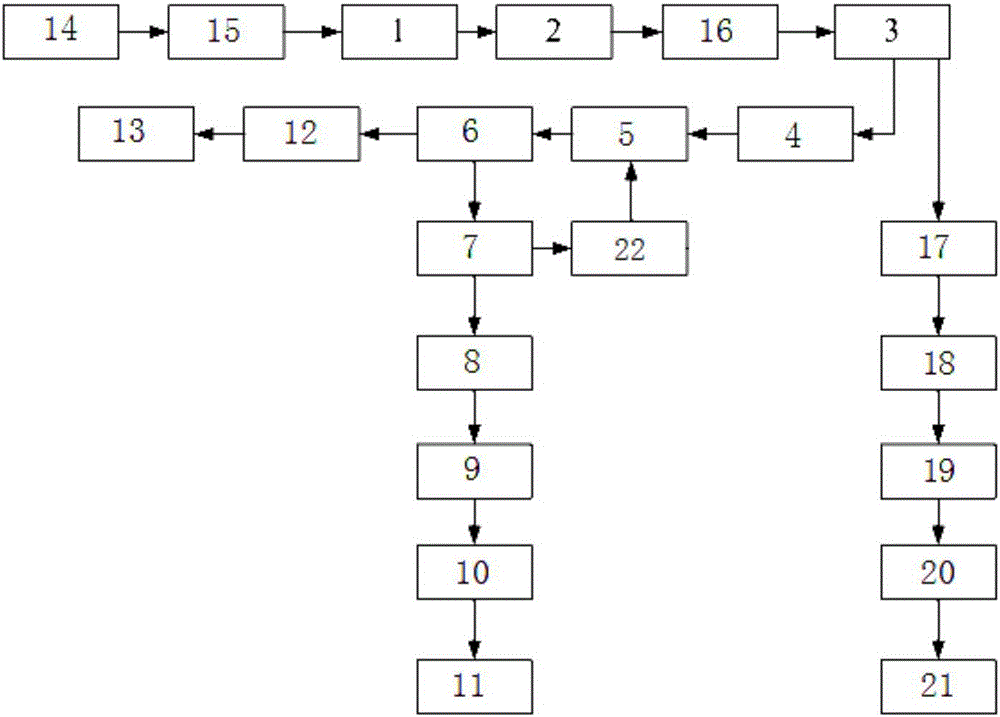

The invention relates to a method for preparing chitin and chitosan by coupling shrimp and crab shells through a hydrothermal / two-step enzymic method. The method comprises the following steps: removing impurities from shrimp and crab shells, and crushing the shrimp and crab shells; adding organic acid for decalcification treatment, placing filter residues into a hydrothermal reactor, and feeding a reaction medium for hydrothermal reaction; then rapidly relieving the pressure in the reactor, collecting a hydro-thermal treatment product, carrying out solid-liquid separation, and adding protease into a solid material to carry out enzymolysis deproteinization treatment; separating the deproteinized product to obtain solid residues, drying the solid residues to obtain chitin, and adding chitin deacetylase into the chitin for enzyme treatment to prepare chitosan; and finally, treating the organic acid decalcification solution and the protein enzymatic hydrolysate to obtain organic calcium and protein peptide. According to the method, the decalcified shrimp and crab shells are modified through a hydrothermal method, the compact structure of the shrimp and crab shells is broken, the accessibility of subsequent protease and deacetylase is promoted, the enzymolysis efficiency is improved, poly-generation of organic acid calcium, protein peptide, chitin and chitosan is achieved, the production process is rapid, stable and free of pollution, and large-scale industrial application is easy to achieve.

Owner:TIANJIN UNIV OF SCI & TECH

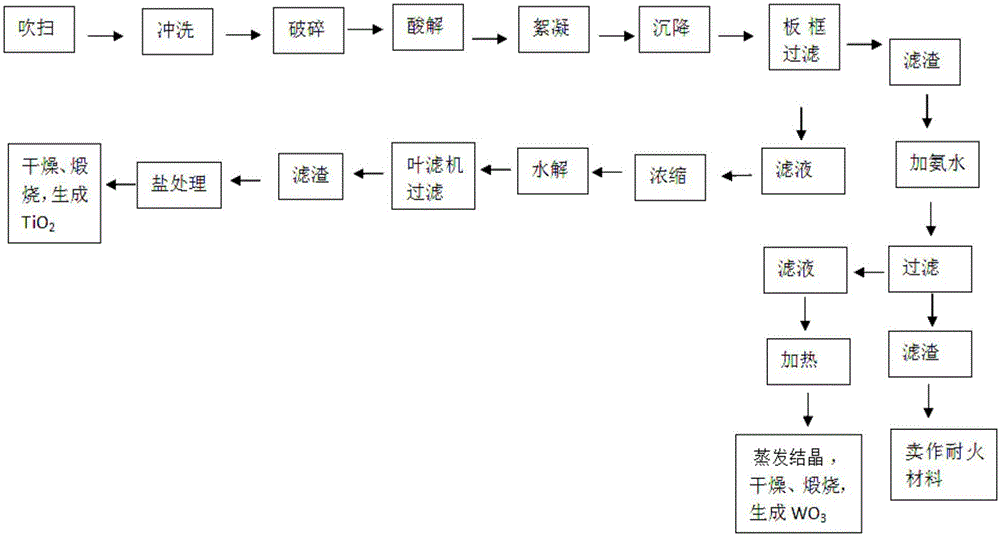

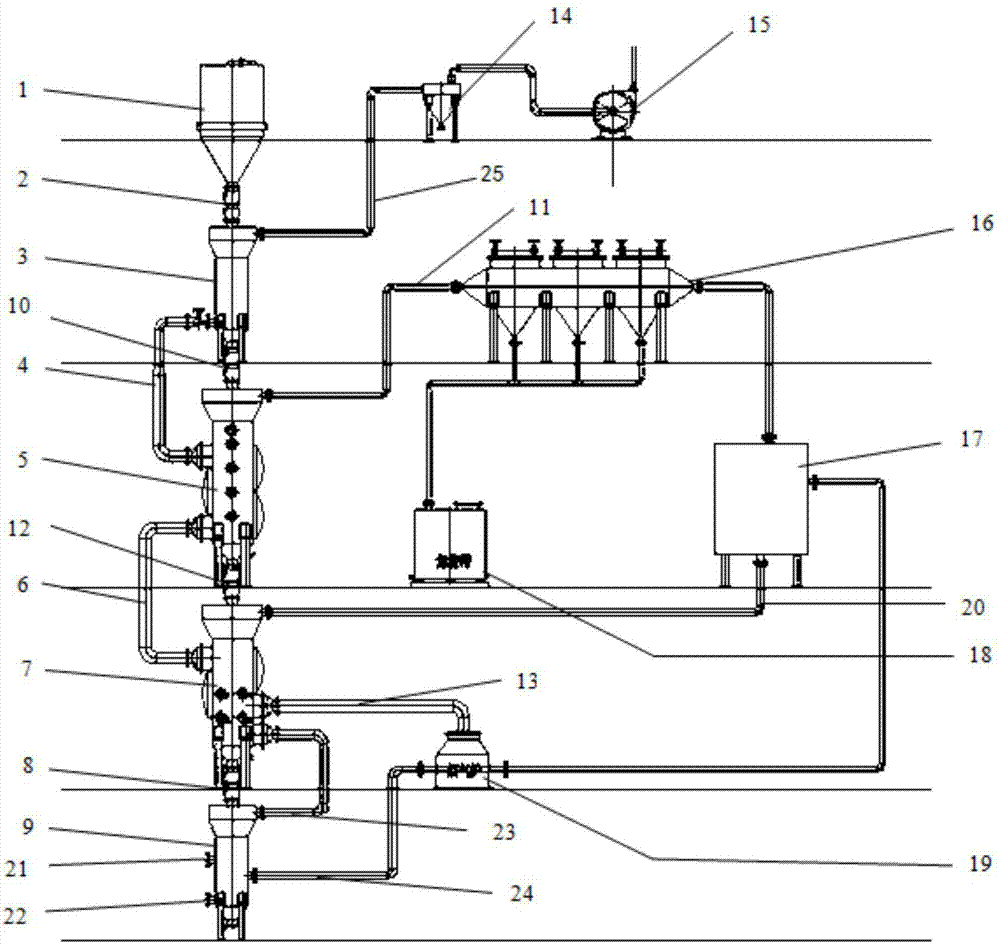

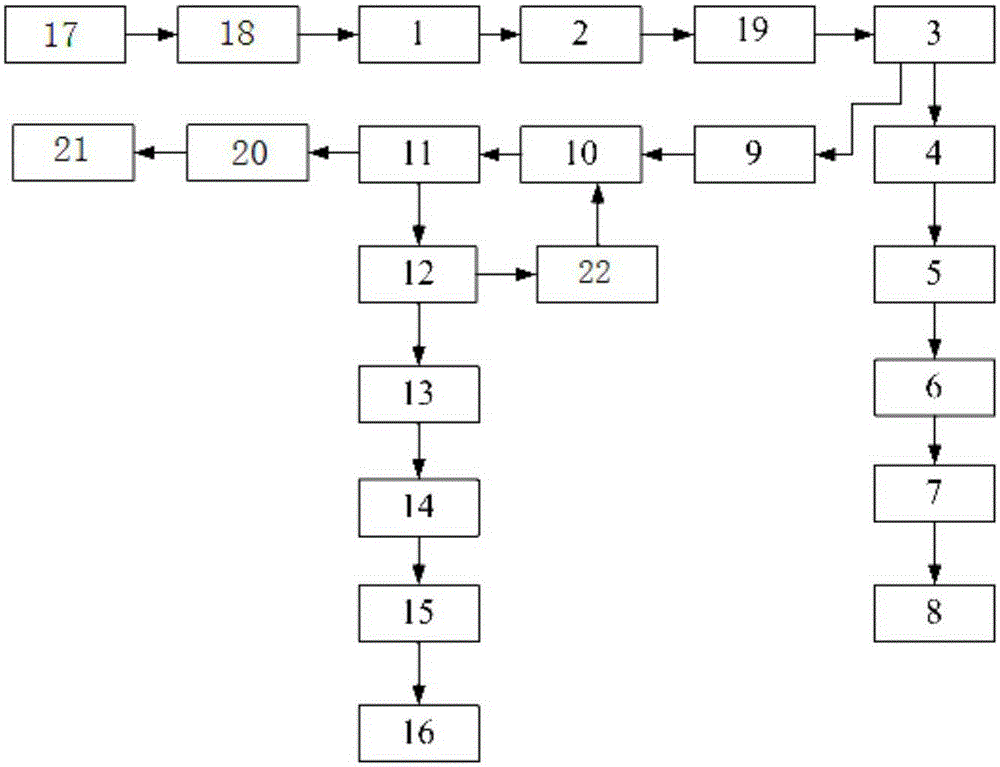

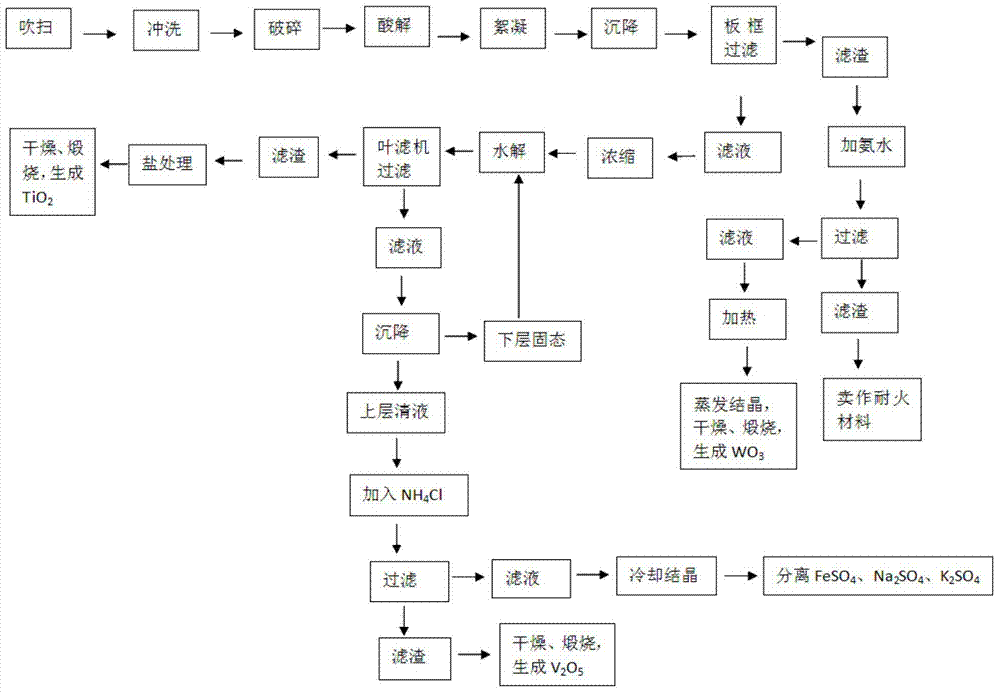

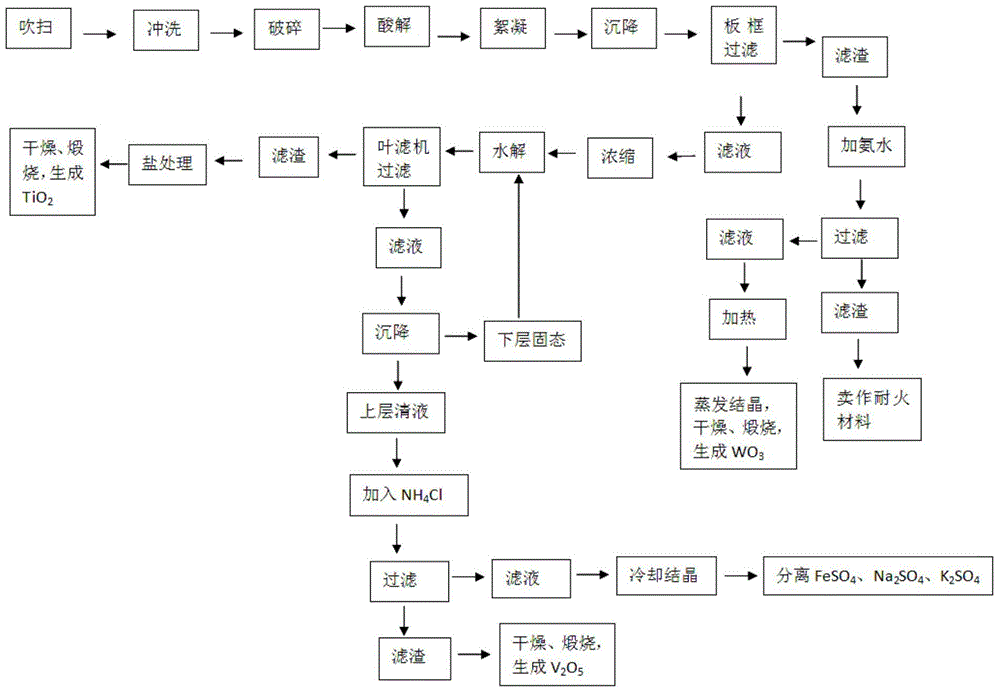

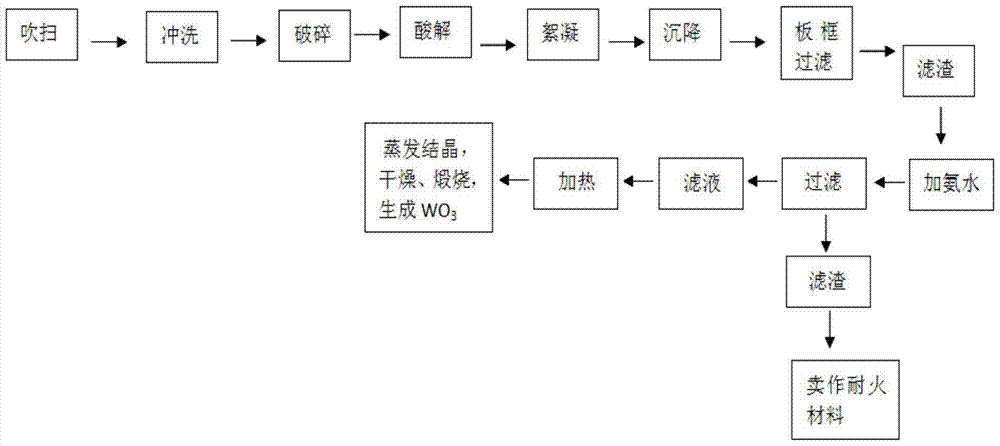

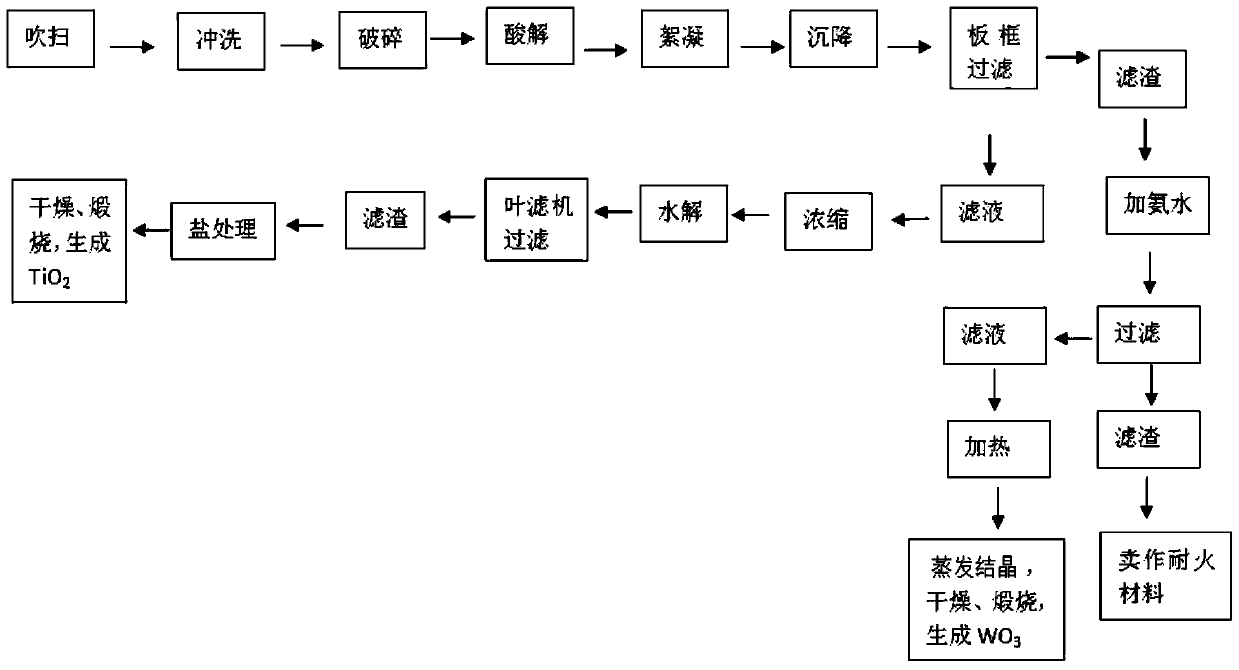

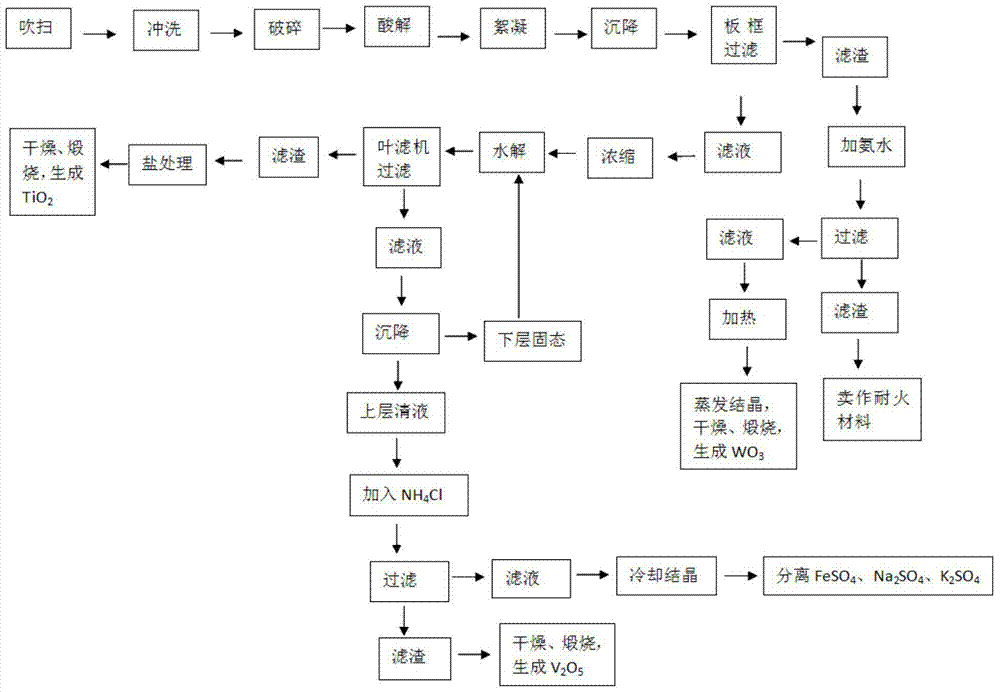

Method and device for recycling Ti and W from waste flue gas denitrification catalyst

ActiveCN105152216ANo wasteRecycling technology saves energyTungsten oxides/hydroxidesTitanium dioxideAmmonium paratungstateHydrolysis

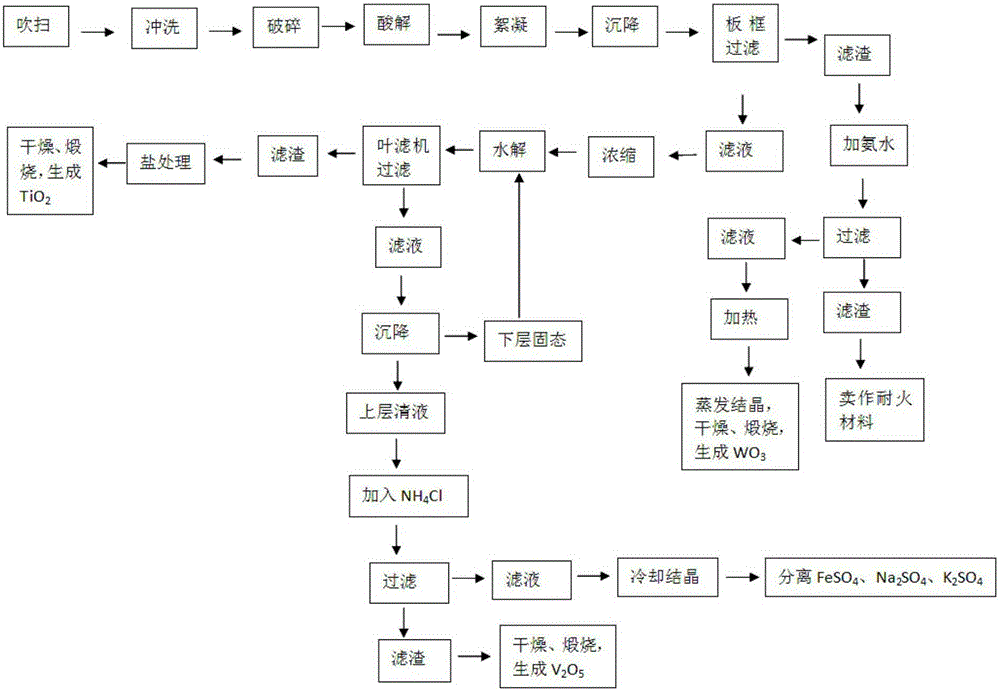

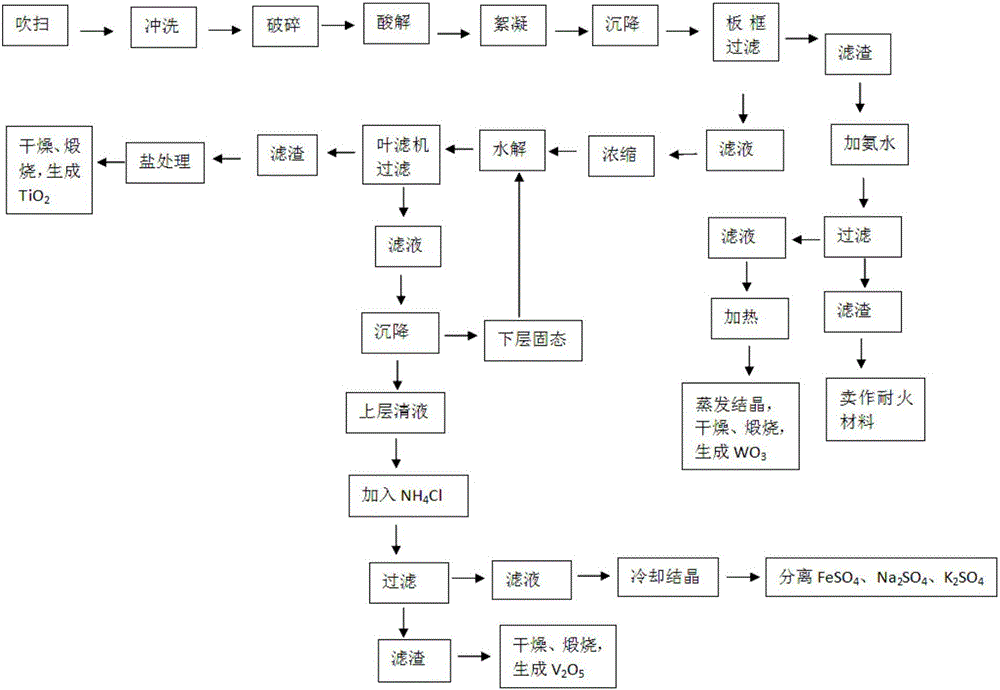

The invention discloses a method and device for recycling Ti and W from a waste flue gas denitrification catalyst. The method comprises the steps that 1, the catalyst is smashed, concentrated sulfuric acid is added for acidolysis, and water is added after acidolysis is performed to obtain a titanyl sulfate solution; 2, the titanyl sulfate solution is filtered, filter residues are collected for use, and a filtrate is heated and concentrated for hydrolysis to obtain a hydrolysis product; 3, the hydrolysis product is filtered to obtain a filtrate and metatitanic acid sedimentation; 4, salt treatment, drying and roasting are performed on the metatitanic acid sedimentation to obtain a finished product TiO2; 5, excessive ammonium hydroxide is added into the filter residues in the second step, and filtering is performed, and the filtrate is heated to generate ammonium paratungstate crystals; the ammonium paratungstate crystals are dried and roasted to obtain pure WO3. The method can recycle pure TiO2 and WO3 from the waste flue gas denitrification catalyst. After the method is adopted, the recycling efficiency of TiO2 and the recycling efficiency of WO3 reach 95% and 93% respectively, and the purity of TiO2 and the purity of WO3 can reach 99% and 90% respectively.

Owner:CHINA HUADIAN ENG +1

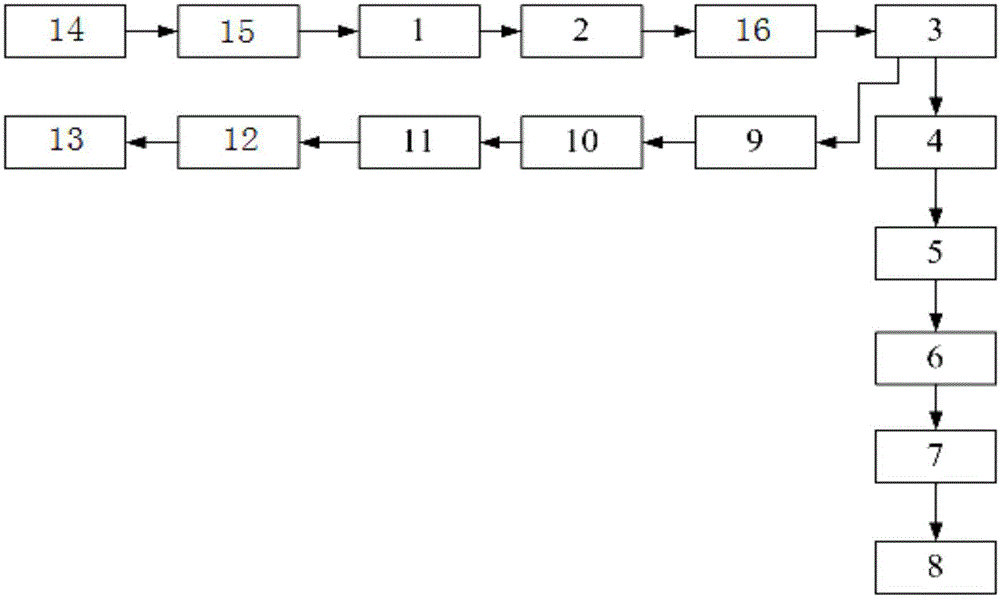

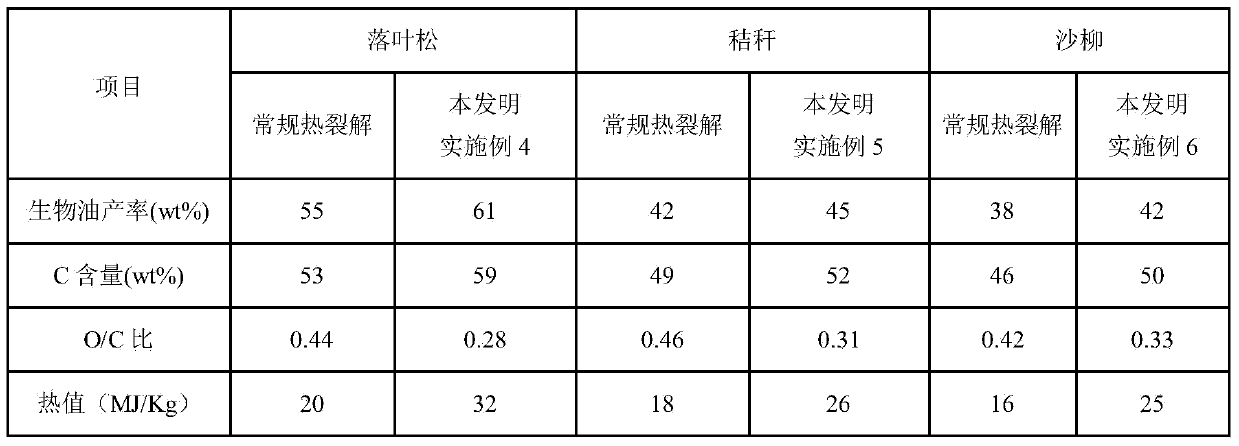

Catalyst for rapid pyrolysis and liquefaction of biomass as well as preparation method and application thereof

InactiveCN103691429ARealize targeted regulationSolve the problem of high value-added utilizationBiofuelsLiquid hydrocarbon mixture productionActive componentAdditional values

The invention relates to a catalyst for rapid pyrolysis and liquefaction of biomass as well as a preparation method and application of the catalyst and belongs to the technical field of biomass energy. The catalyst consists of a carrier and an active component, wherein the active component is loaded onto the carrier through an immersion method. The carrier is a side product rapid pyrolysis carbon produced from the rapid pyrolysis and liquefaction of biomass; the rapid pyrolysis carbon is deoiled, delimed, activated and oxidized to form a middle-large hole structure with holes of 20-80 nanometers; the active component is a transition metal which is immersed onto the carrier through the steps of loading and reducing; then the catalyst for the rapid pyrolysis and liquefaction of biomass is prepared. By adopting the catalyst provided by the invention, the problem of high additional value utilization of the side product rapid pyrolysis carbon is solved, the adaptability to a pyrolysis reaction environment is strong, and the directional adjustment and control for the rapid pyrolysis and liquefaction of biomass can be realized.

Owner:BEIJING FORESTRY UNIVERSITY

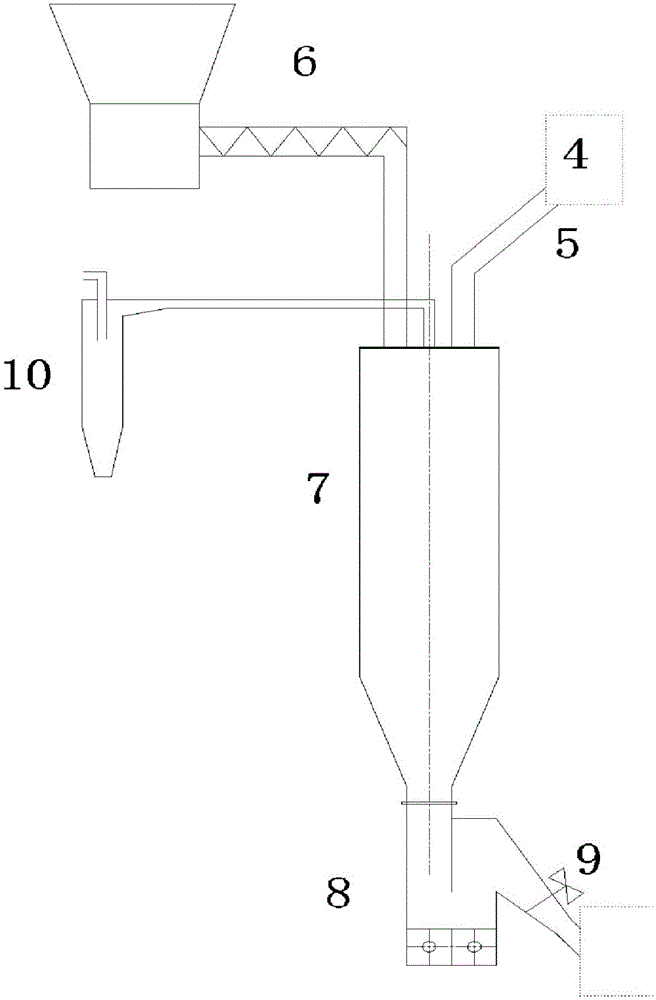

Device and method for preparation of liquid smoke and co-production of activated carbon by pyrolysis of Chinese hawthorn seeds

PendingCN107032351AExpand the scope of useBroaden the fieldCarbon compoundsFood thermal treatmentLiquid smokeWater vapor

The invention discloses a device and a method for preparation of liquid smoke and co-production of activated carbon by pyrolysis of Chinese hawthorn seeds. The device comprises a feed hopper, a drying chamber, a pyrolyzing furnace, an activating furnace, a gas condensation system, a gas cabinet, a combustor, an activated carbon cooling discharge system and a tail gas treatment device. According to the device, co-production of activated carbon can be realized while the liquid smoke is prepared, comprehensive utilization of the resources is realized, the phenomenon that attention is only paid to production of single product while the economic value of byproducts is neglected is avoided, pollution to the environment is avoided while energy is saved, heat required for the processes of drying, pyrolysis, carbonization, activation and the like of the Chinese hawthorn seeds is supplied by combustible gas of non-condensable gas, activating reaction gas and the like obtained by pyrolysis of the Chinese hawthorn seeds, self-sufficiency of the heat can be realized; according to the system, heat exchange is realized by low temperature air used for combustion of the combustor, vapor required for activation and high temperature activated carbon, each takes what it needs, at the same time, high temperature flue gas is exhausted after passing by the high temperature section and the low temperature section sequentially, gradient utilization of different layers of energy is realized, and the energy utilization efficiency is high.

Owner:SHANDONG UNIV +1

Method and device for recycling W and V from waste flue gas denitration catalyst

ActiveCN105200236ATake advantage ofImprove protectionProcess efficiency improvementAmmonium paratungstateAmmonium metavanadate

The invention discloses a method and device for recycling W and V from a waste flue gas denitration catalyst. The method includes the steps that 1, the catalyst is crushed, concentrated sulfuric acid is added for acidolysis, water is added after acidolysis, and an oxygen titanium sulfate solution is obtained; 2, the oxygen titanium sulfate solution is filtered, filter residues are collected for standby application, the filter liquor is heated, concentrated and hydrolyzed, and a hydrolysis product is obtained; 3, the hydrolysis product is filtered, and settlement treatment is conducted on the filter liquor; 4, filtering is conducted after settlement treatment, supernatant liquid is taken, an excessive amount of NH<4>Cl is added to the clear liquid for a reaction, then filtering is conducted, and ammonium metavanadate sediment is obtained; the ammonium metavanadate sediment is calcined, and V<2>O<5> is obtained; 5, an excessive amount of ammonium hydroxide with the concentration being 10%-28% is added to the filter residues in step 2 for a reaction, and then filtering is conducted; the filter liquid is heated to be 80 DEG C-100 DEG C, and an ammonium paratungstate crystal is obtained; the ammonium paratungstate crystal is dried and calcined, and the WO<3> is obtained. By means of the method and device, the V<2>O<3> and the WO<3> which are both high in purity and recovery rate can be extracted from the waste flue gas denitration catalyst.

Owner:CHINA HUADIAN ENG +1

Method and device for recycling Ti and V from waste flue gas denitrification catalyst

ActiveCN105152205AImprove protectionSuitable for industrial productionTitanium dioxideVanadium oxidesFlue gasSulfate

The invention discloses a method and device for recycling Ti and V from a waste flue gas denitrification catalyst. The method comprises the following steps that 1, the catalyst is smashed, concentrated sulfuric acid is added for acidolysis, and water is added after acidolysis is performed to obtain a titanyl sulfate solution; 2, the titanyl sulfate solution is filtered, filter residues are collected for use, and a filtrate is heated and concentrated for hydrolysis to obtain a hydrolysis product; 3, the hydrolysis product is filtered to obtain a filtrate and metatitanic acid sedimentation; 4, salt treatment, drying and roasting are performed on the metatitanic acid sedimentation to obtain a finished product TiO2; 5, sedimentation treatment and filtering are performed on the filtrate in the third step, a supernatant is taken, excessive NH4Cl is added into the supernatant for a reaction, and filtering is performed to obtain ammonium metavanadate sedimentation; the ammonium metavanadate sedimentation is roasted to obtain pure V2O5. The method can recycle pure TiO2 and V2O5 from the waste flue gas denitrification catalyst.

Owner:CHINA HUADIAN ENG +1

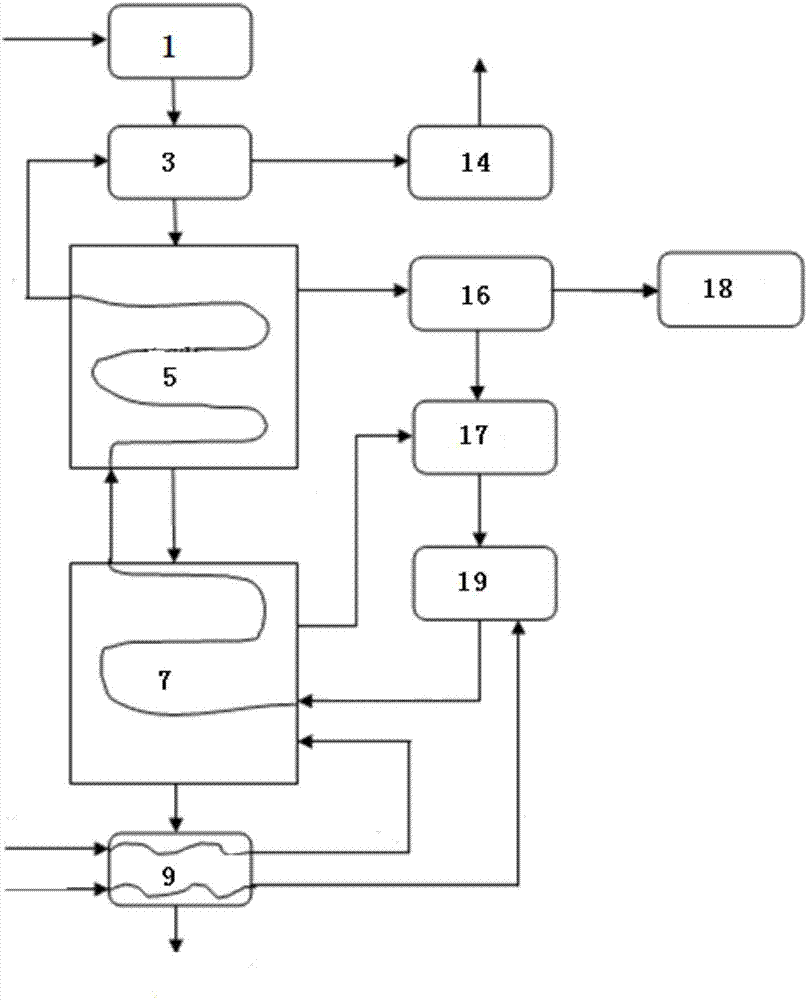

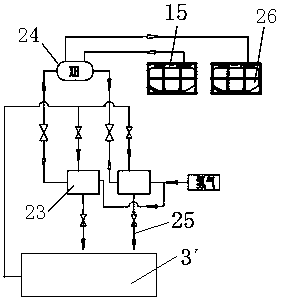

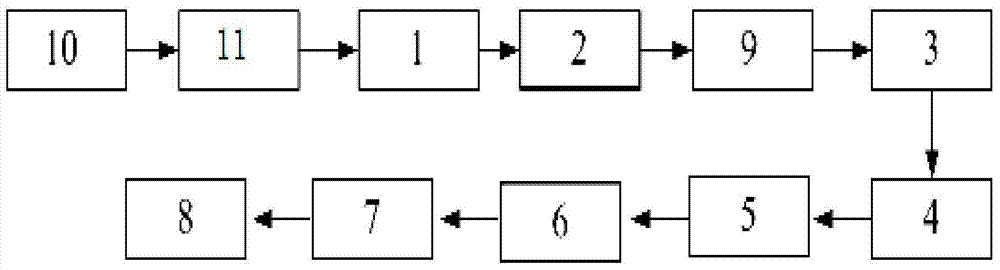

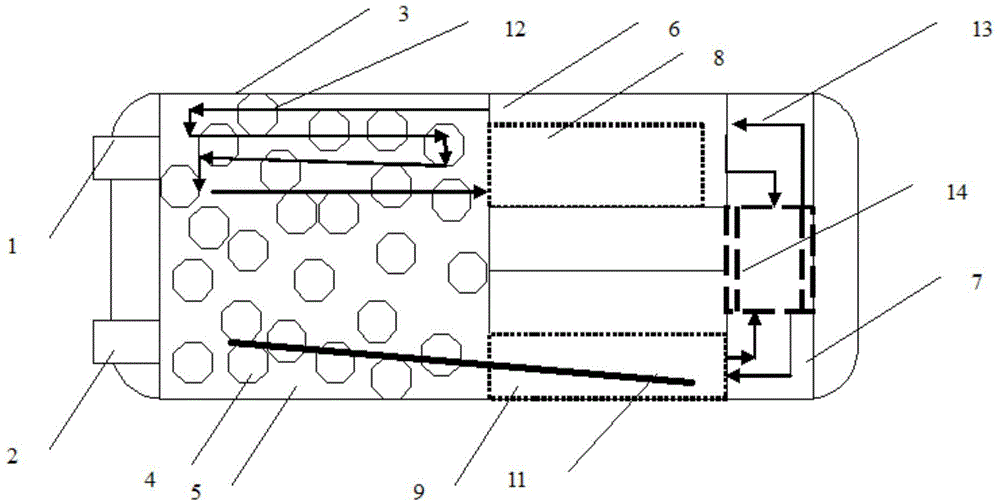

Distributed-type non-tracking solar power generation and poly-generation system

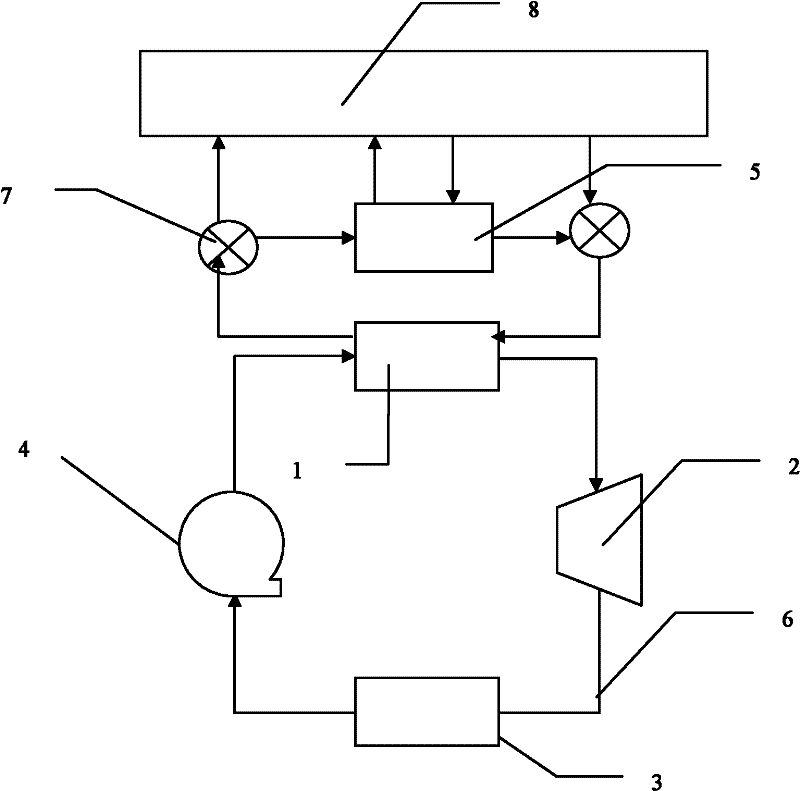

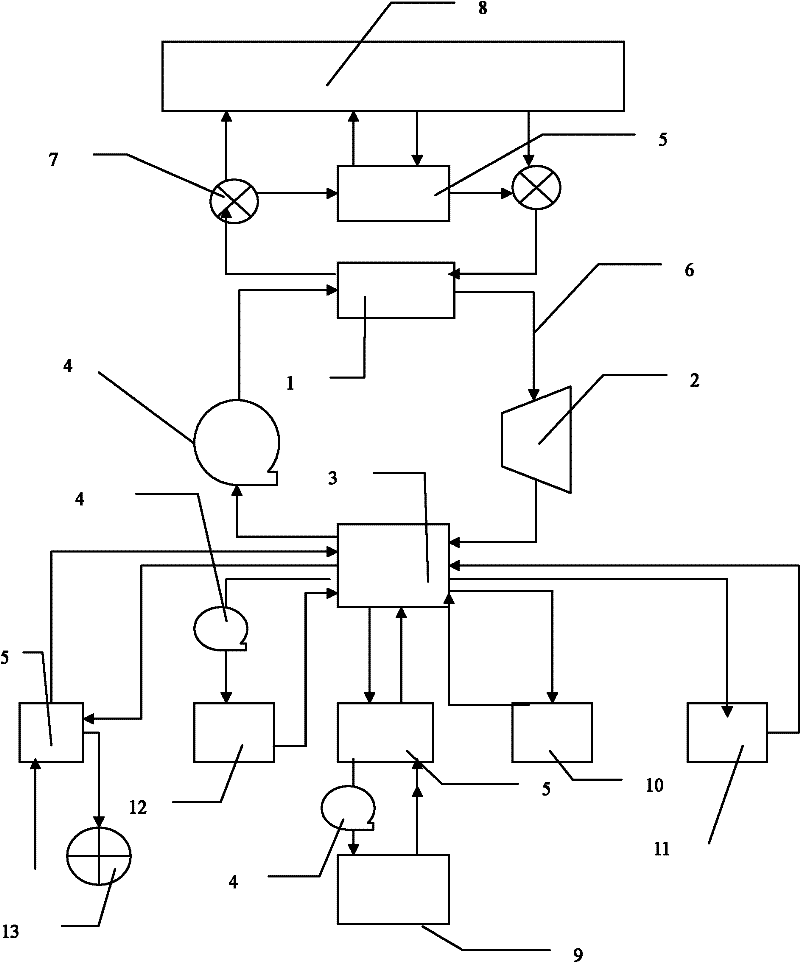

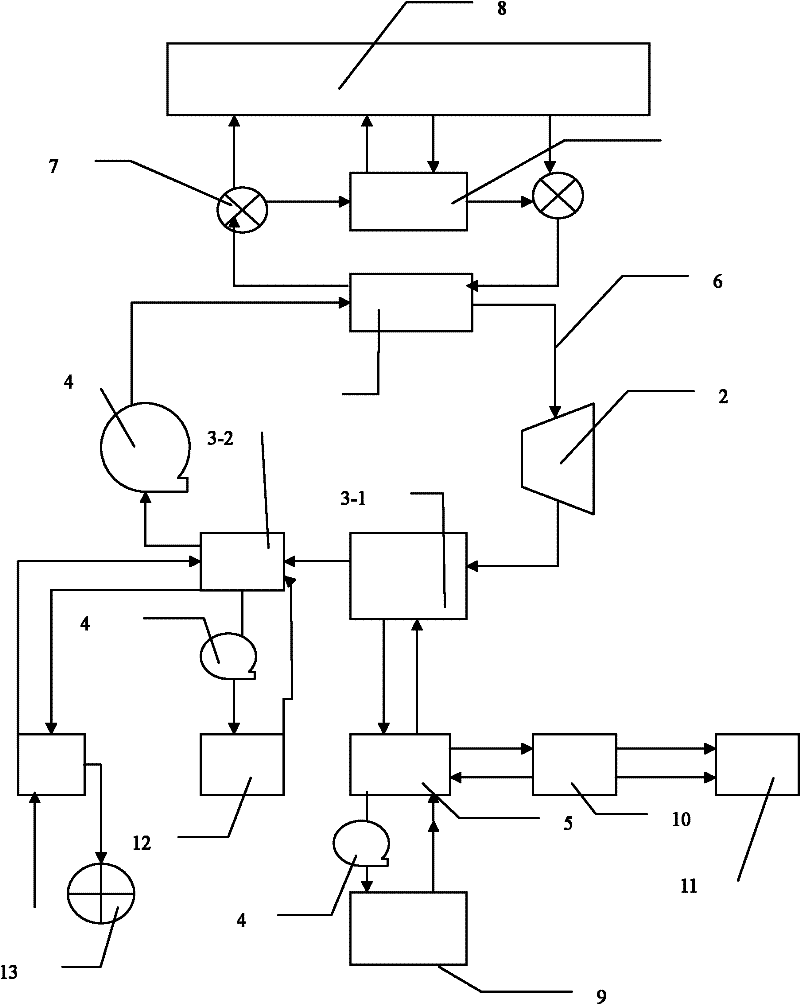

InactiveCN102242697ARealize low temperature thermal power generationPolygenerationFrom solar energySteam engine plantsEngineeringSolar power

The invention aims to provide a distributed-type non-tracking solar expander power generation and poly-generation system. A solar non-tracking collecting system (8) is connected with an evaporator (1) or a heat accumulator (5); the evaporator (1) is arranged in the solar non-tracking collecting system or the heat accumulator, wherein the evaporator (1), a fluid generator (2), a condenser (3) and a working medium circulating pump are connected in series to form an enclosed circulating cavity; a power generating working medium is enclosed into the enclosed circulating cavity; the power generating working medium in the evaporator (1) is heated by the heat energy which is collected by the solar non-tracking collecting system (8); the power generating working medium converts the heat energy which is collected by solar energy into power energy through the fluid generator (2); the power generating working medium enters the condenser (3) and is condensed after passing through the fluid generator; and the condensed power generating working medium is sent into the evaporator (1) again through the working medium circulating pump and is evaporated, thus the circulating power generation is realized.

Owner:BEIJING WISWORD HI TECH

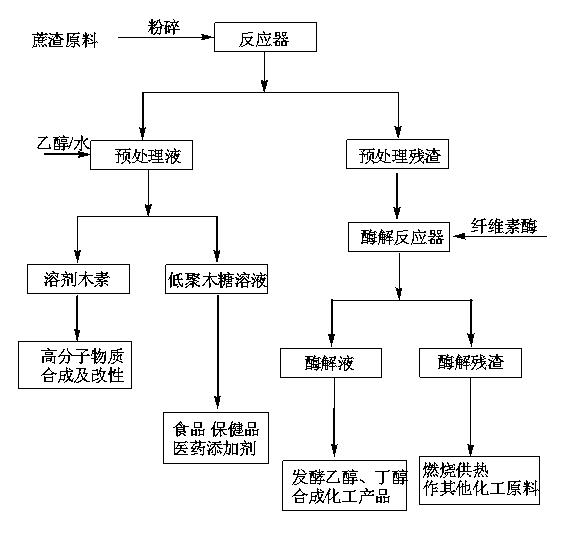

High-value comprehensive utilization method of bagasse fibers

The invention provides a high-value comprehensive utilization method of bagasse fibers, which comprises the steps of preparation of xylooligosaccharide and solvent lignin by ethanol / water solution pretreatment, preparation of glucose by enzymolysis and the like. The method specifically comprises the following steps: mixing aired and pulverized bagasse raw material with the ethanol / water solution (v / v, 40 / 60-80 / 20), carrying out pretreatment at 160-200 DEG C in the presence of 0-10 wt% acetic acid for 30-90 minutes to obtain a pretreated solution, and adding a composite cellulase into the pretreated residue to carry out enzymolysis, thereby obtaining the enzymolysis saccharification solution and enzymolysis residue. The ethanol adopted in the pretreatment can be recovered by distillation, thereby reducing the chemical consumption, lowering the pollutant emission and relieving the environmental pollution. The ethanol pretreatment implements coproduction of the xylooligosaccharide and solvent lignin, and enhances the subsequent enzymolysis and saccharification efficiency; and the enzymolysis performed on the pretreated residue can convert the cellulose in the raw material into glucose, thereby implementing comprehensive utilization of the three major components in the wood fiber raw material.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing silicon dioxide aerogel from quartz tailings as raw material

ActiveCN106430220ARaw materials are cheap and easy to getLow equipment requirementsSilicaAlkaneSilicon dioxide

The invention provides a method for preparing silicon dioxide aerogel from quartz tailings as a raw material. The method comprises the following steps: step 1, the quartz tailings are washed, dried, ground and sieved and then ground and mixed with sodium carbonate powder, a mixture is calcined, and a calcination product is obtained; step 2, the calcination product is ground and sieved, undersized matter is added to hot water to be stirred and dissolved, the solution is filtered, a filtrate is taken, and water glass is obtained; step 3, the pH value of the water glass is regulated with hydrochloric acid, a sol-gel reaction is performed, a product is left to stand for aging, and hydrogel is obtained; step 4, free water in the hydrogel is filtered out, residual moisture is replaced with absolute ethyl alcohol, and alcogel is obtained; step 5, the alcogel is soaked with an n-hexane solution of trimethylchlorosilane, and hydrophobically modified alkane gel is obtained; step 6, drying is performed, and the silicon dioxide aerogel is obtained. The raw materials are cheap and available, the preparation process adopts mild conditions and has low equipment requirements, so that the production cost of the silicon dioxide aerogel is reduced greatly, and the prepared aerogel has good performance.

Owner:SHANGLUO UNIV

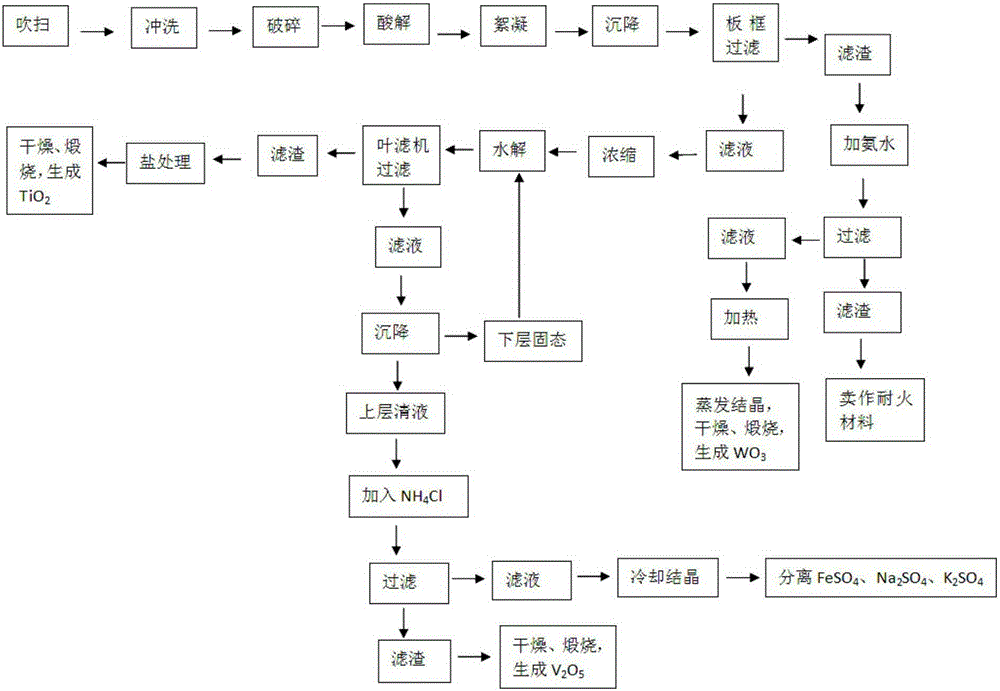

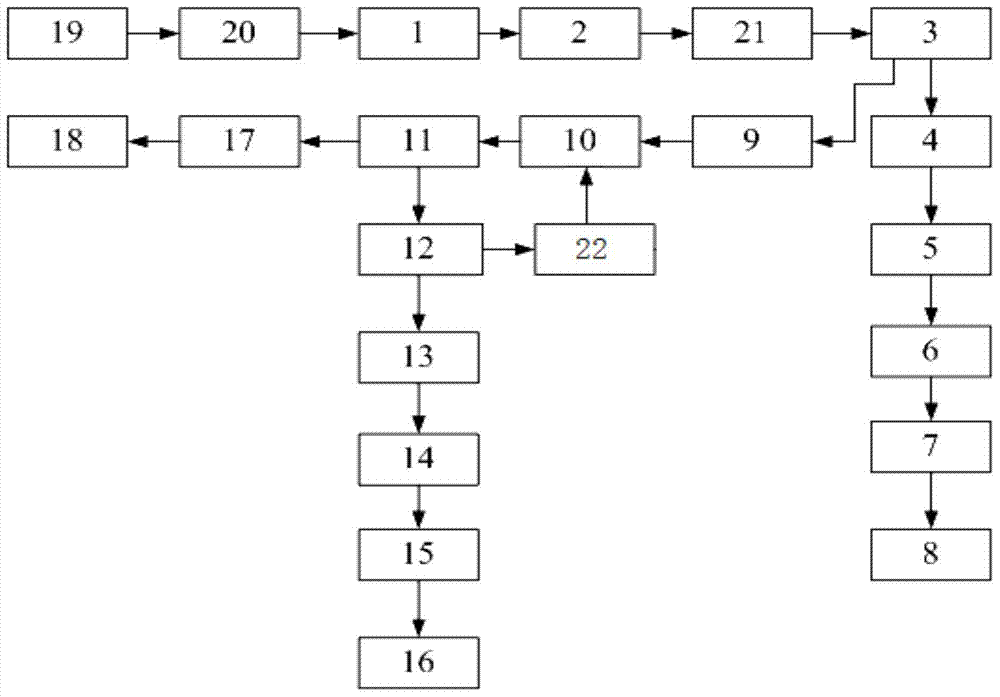

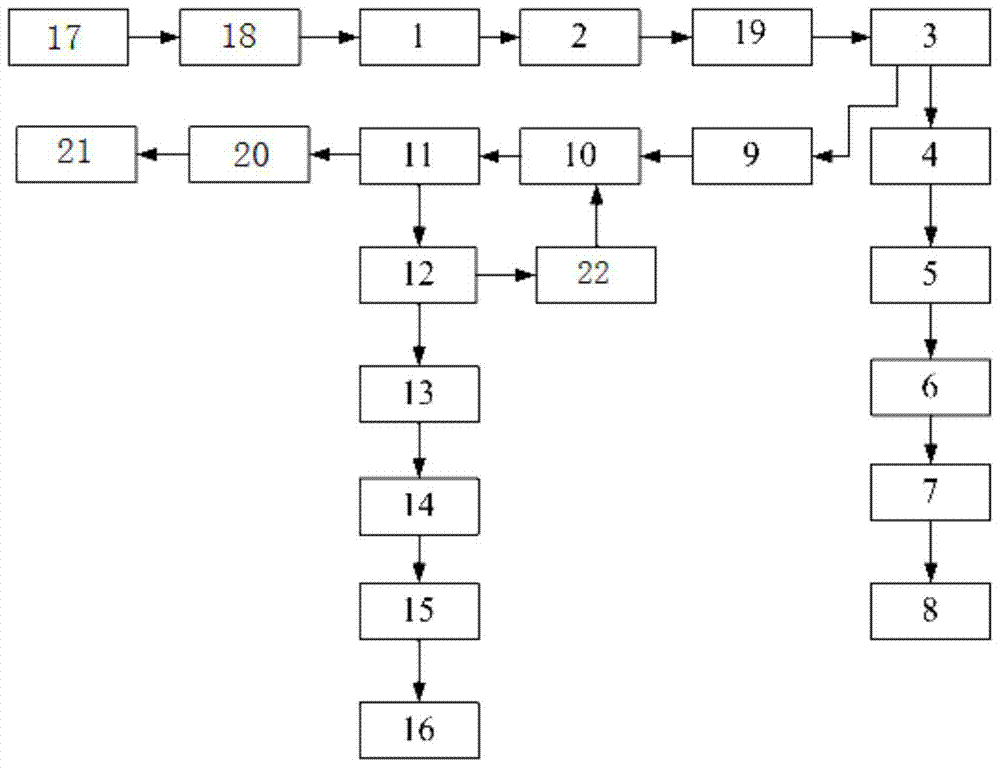

Method and apparatus for recycling metal oxide from waste flue gas denitration catalyst

ActiveCN105217686AIncrease profitNo wasteTungsten oxides/hydroxidesIron sulfatesAmmonium paratungstateHydrolysate

The invention discloses a method and an apparatus for recycling metal oxide from a waste flue gas denitration catalyst. The method comprises the following steps: S1, the catalyst is crushed and concentrated sulfuric acid is added for acidolysis, after acidolysis, water is added to obtain a titanyl sulfate solution; S2, the titanyl sulfate solution is filtered, filter residues are standby, a filtrate is heated, condensed and hydrolyzed for obtaining a hydrolysate; S3, the hydrolysate is filtered to obtain a filtrate and a metatitanic acid deposition; S4, salt treatment, a drying and a calcination are carried out for the metatitanic acid deposition, and TiO2 is obtained; S5: sedimentation treatment is carried out for the filtrate in the S3, after filtering, a upper level clear liquid is taken, excessive NH4Cl is added into the clear liquid for reaction, after filtering, andammonium metavanadate deposition is obtained; the ammonium metavanadate deposition is calcined, and V2O5 is obtained; S6, excessive ammoniacal liquor is added into the filter residues in the S2 for reaction, and a filtering is carried out; a filtrate is heated to generate a ammonium paratungstate crystal; the ammonium paratungstate crystal is dried and calcined, and WO3 is obtained. According to the method, V, Ti and W three components can be completely separated.

Owner:CHINA HUADIAN ENG +1

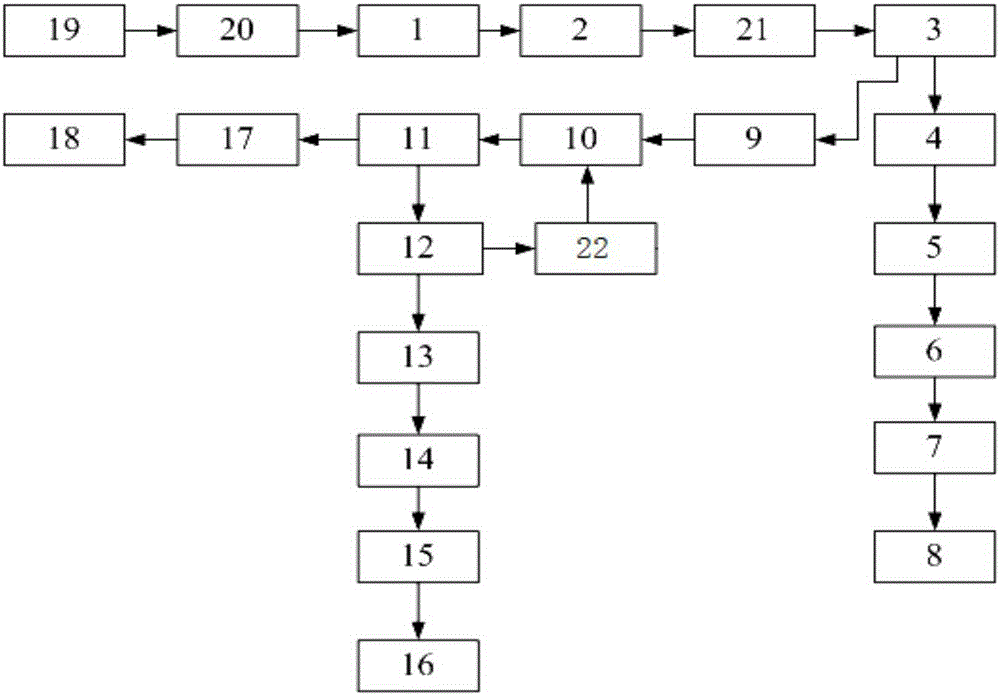

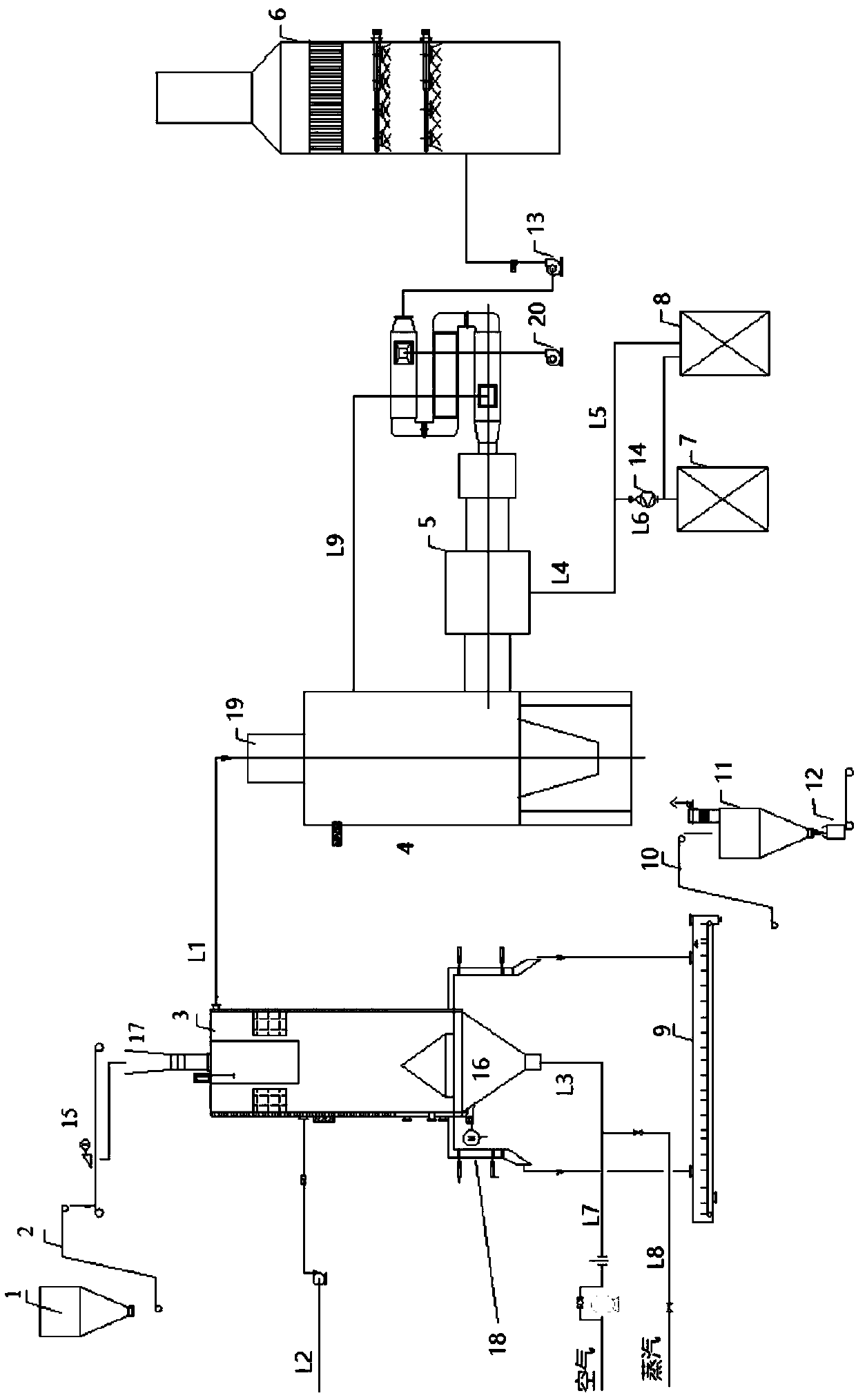

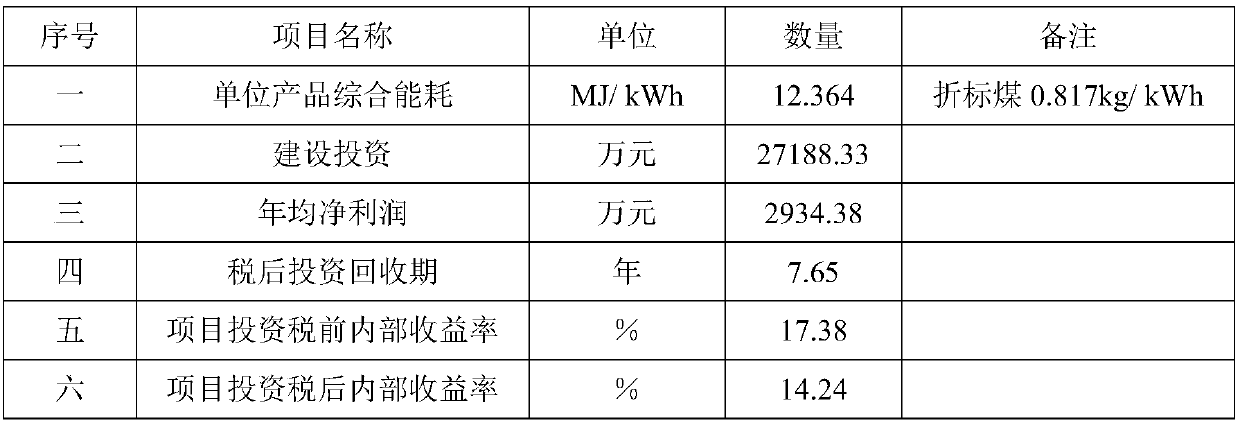

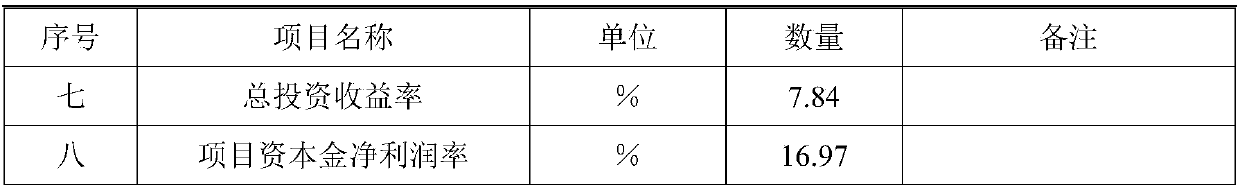

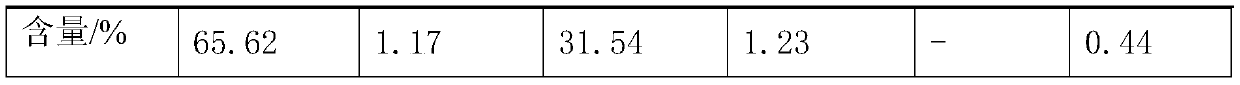

Device and technology for poly-generation of carbon, heat and electricity based on biomass gasification

PendingCN109679695ADevelop circular economyReduce dosageEnergy inputGasification processes detailsElectricityFixed bed

The invention discloses a device and a technology for poly-generation of carbon, heat and electricity based on biomass gasification. The technology comprises steps of biomass transport, biomass gasification, boiler processing, electricity generation, desulphurization and dust removal. A large-dip-angle belt is adopted to perform continuous automatic feeding for biomass transport; a composite gasification fixed bed gasification technology with combination of upper and lower suction is adopted for biomass gasification, and a byproduct is a carbonized material; steam produced by a boiler after burning of gasified gas enters a steam turbine for generating electricity and then passes through a heat exchange station for providing a heat source for heating; a scattering tower based desulphurization and dust removal integration technology is adopted for desulphurization and dust removal. The device and the technology have the advantages of being environmentally friendly and safe and realizingpoly-generation of carbon, heat and electricity.

Owner:XINDI ENERGY ENG TECH

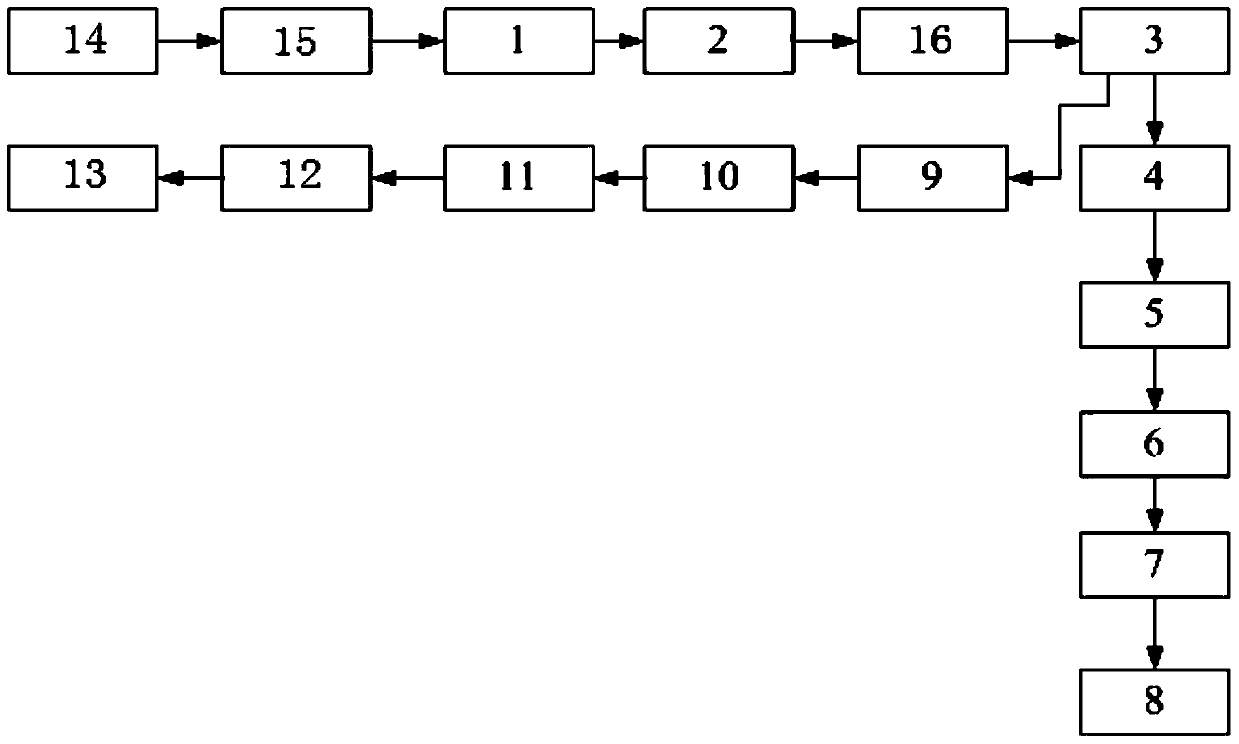

Poly-generation production system of magnesium metal and hydride of magnesium metal

ActiveCN107857238AReduce shipping costsReduce energy consumptionAlkali/alkaline-earth/beryllium/magnesium hydridesChemical industryEconomic benefitsElectric power

The invention relates to a poly-generation production system of magnesium metal and hydride of magnesium metal. The system comprises a calcium carbide production device, a crystallization chamber, a magnesium refining and crushing device, a reaction vessel, a magnesium hydroxide calcining furnace, a magnesium hydroxide container and an inert gas pipeline; a calcium carbide liquid outlet of a rotary kiln is connected with a calcium carbide liquid inlet of the reaction vessel; the magnesium hydroxide container is connected with the magnesium hydroxide calcining furnace; a magnesium oxide outletof the magnesium hydroxide calcining furnace is connected with a magnesium oxide inlet of the reaction vessel; the inert gas pipeline is respectively connected with the magnesium hydroxide calcining furnace and the magnesium oxide inlet of the reaction vessel; a magnesium steam outlet is connected with the crystallization chamber; a solid outlet of the crystallization chamber is connected with a magnesium metal container by means of a magnesium refining and crushing device; a gas outlet is connected with the inert gas pipeline by means of an induced draft fan. The poly-generation production system effectively utilizes the heat of all technological processes, thus being energy-saving and environmentally-friendly; the poly-generation production system realizes the poly-generation of multipleproducts such as magnesium metal, magnesium hydride, pure carbon maple energy and electric power, thus being considerable in economic benefit.

Owner:SHANGHAI KELAIPU ENERGY TECH CO LTD

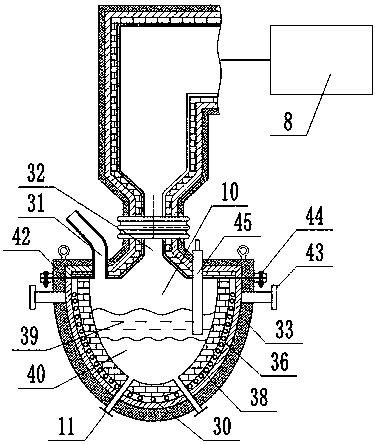

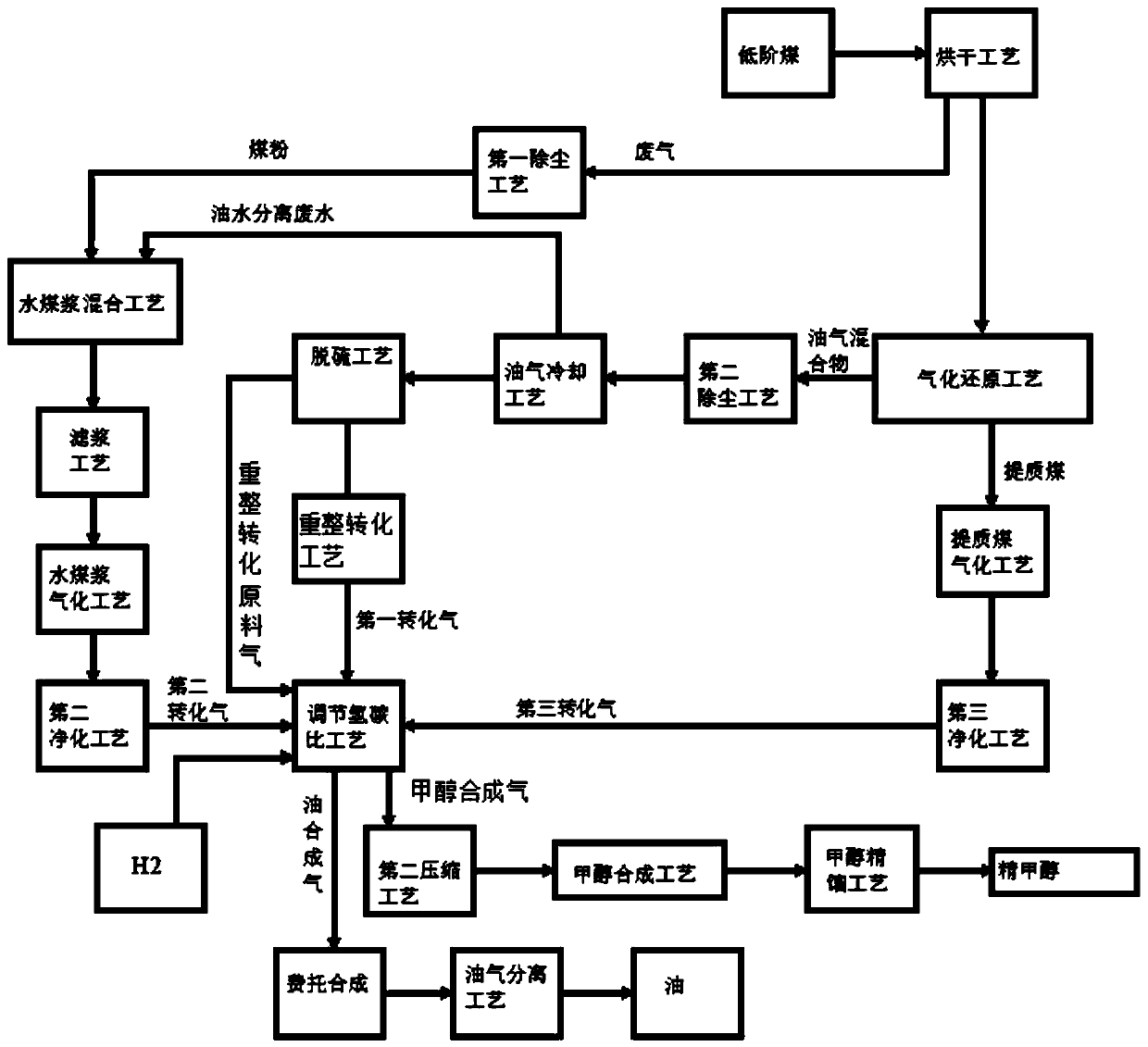

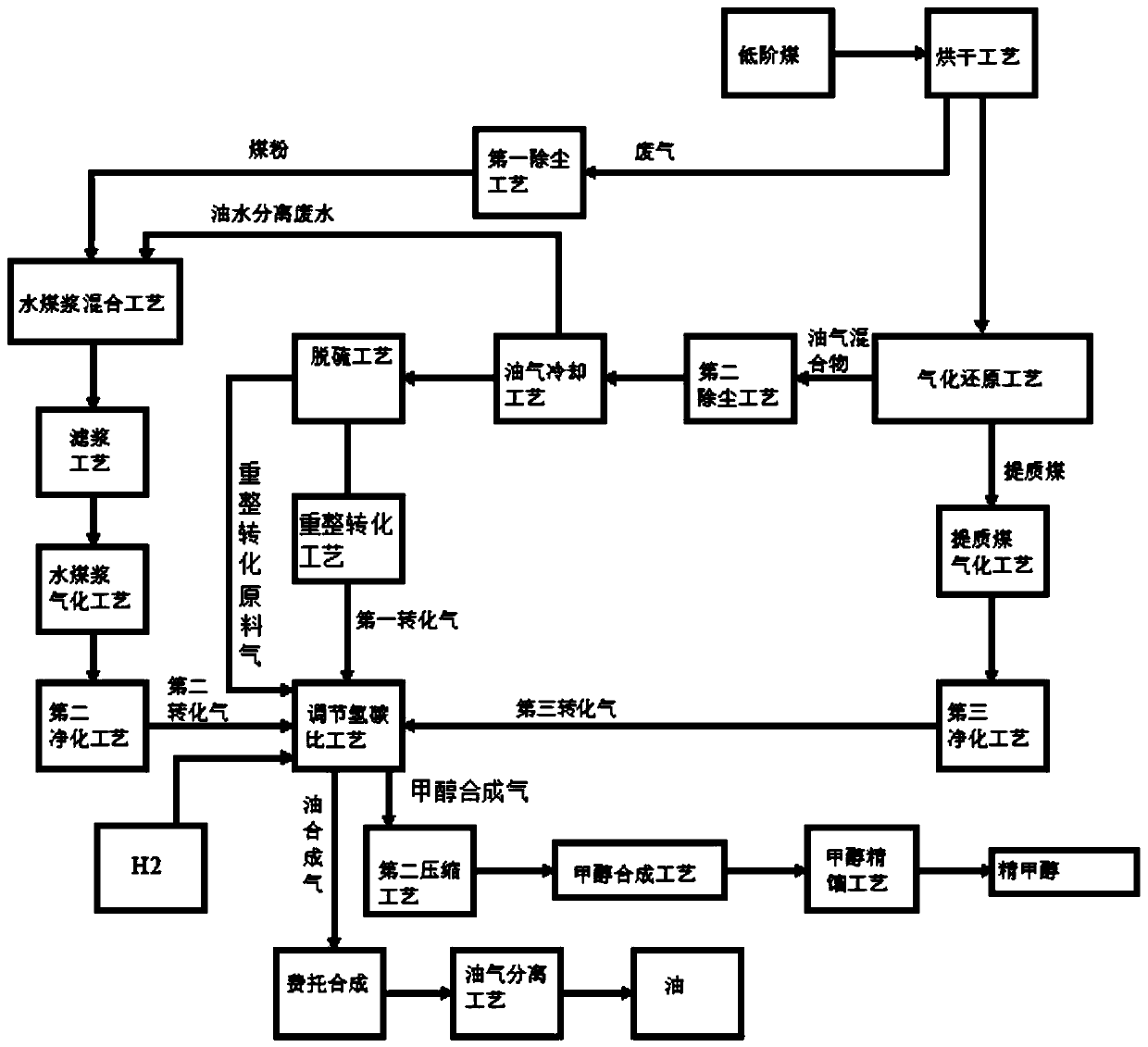

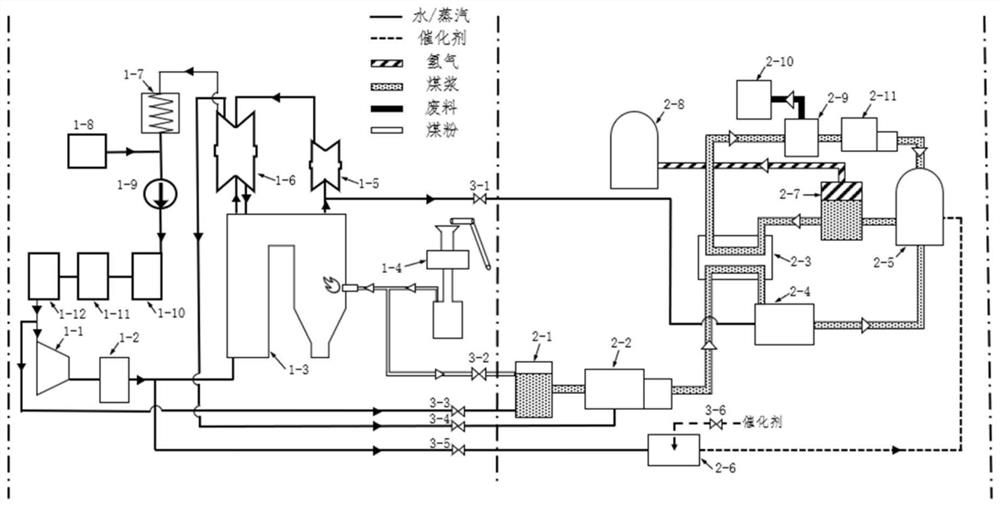

Method using quality-based utilization of low-rank coal to prepare methanol and oil in poly-generation manner

ActiveCN110055106AIncrease profitPolygenerationGasification processes detailsLiquid carbonaceous fuelsGeneration rateImpurity

The invention provides a method using the quality-based utilization of low-rank coal to prepare methanol and oil in a poly-generation manner. The method has the advantages that the dried low-rank coalis subjected to gasification reduction to obtain volatile components, hydrocarbon and the like in the volatile components is reformed and converted to obtain CO and H2 needed by oil synthesizing so as to prepare the methanol and the oil, and the volatile components in the low-rank coal are sufficiently and effectively utilized; by using the quality-improved coal obtained by the gasification reduction of the low-rank coal as the raw material to prepare the methanol and the oil, the coal substances in the low-rank coal are fully utilized; the methanol and the oil are prepared in the poly-generation manner, byproducts generated by the synthesizing process of the methanol or the oil can be effectively recycled, resources can be saved, multiple approaches are achieved, the prepared oil and methanol are few in impurities and high in quality, the utilization rate of the low-rank coal is increased greatly, and the method conforms to efficient and clean coal utilization vigorously advocated byChina.

Owner:浙江天禄环境科技有限公司

Carbon/oil/gas co-production integrated device and method

The invention discloses a carbon / oil / gas co-production integrated device and method. The carbon / oil / gas co-production integrated device comprises a carbonization and activation integrated furnace which is composed of an inner sleeve and an outer sleeve; the outer sleeve sleeves the inner sleeve; a channel in the inner sleeve serves as a flue gas channel, and an annular channel formed between the inner sleeve and the outer sleeve serves as a material conveying channel; the carbonization and activation integrated furnace is provided with a spiral conveyor, and a spiral blade of the spiral conveyor is arranged in the material conveying channel along the outer wall of the inner sleeve; the carbonization and activation integrated furnace is sequentially divided into an activation section, a pyrolysis section and a drying section; gas chambers are formed in the upper parts of all the sections correspondingly, and ventilating openings are formed in the outer sleeve walls connected with all the gas chambers correspondingly; a flue gas inlet of the flue gas channel and a material inlet of the material conveying channel are located in the two ends of the carbonization and activation integrated furnace correspondingly; an activation gas inlet is formed in the outer sleeve wall of the activation section; and a pyrolysis gas outlet of the gas chamber of the pyrolysis section is connected with an inlet of a cyclone separator, and a gas phase outlet of the cyclone separator is connected with a condenser.

Owner:SHANDONG UNIV +1

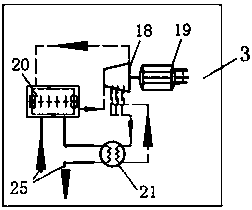

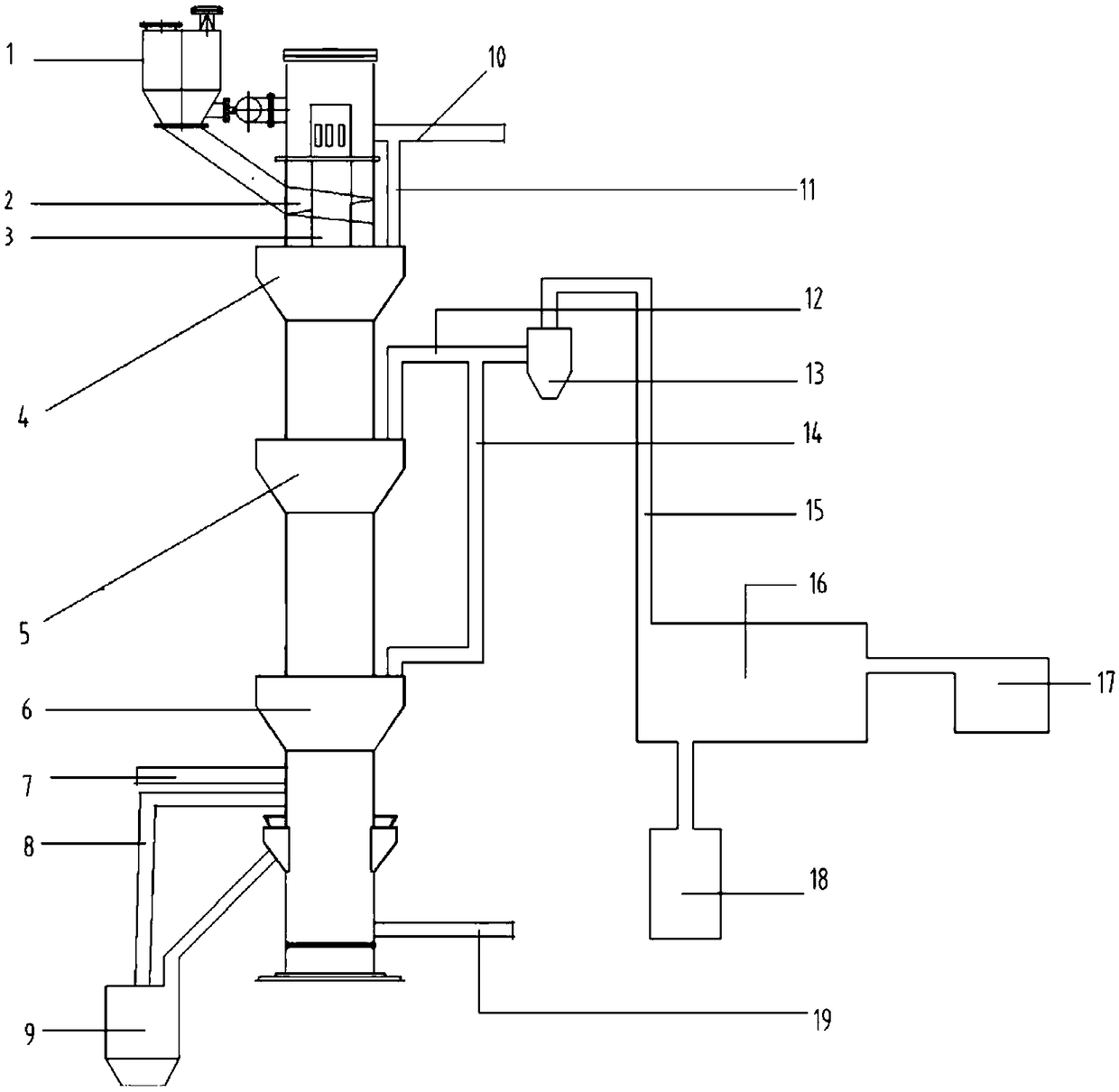

Moving bed coal pyrolysis based polygeneration device and method

InactiveCN105087025ARealize comprehensive utilizationImprove utilization efficiencyFluidized bed combustionDirect heating destructive distillationBoiler furnaceFluidized bed

The invention provides a moving bed coal pyrolysis based polygeneration device and method. The device comprises a circulating fluidized bed (CFB) boiler furnace, wherein the top of the CFB boiler furnace is communicated with a boiler separator; the bottom of the boiler separator is communicated with a riser; the bottom of the riser is communicated with the bottom of the CFB boiler furnace by a boiler return feeder; a hot ash shunting device is arranged in the middle of the riser and is communicated with the top of a moving bed pyrolysis reactor by a moving bed hot ash shunting pipeline; the top of the moving bed pyrolysis reactor is also communicated with a moving bed reactor feeding device and a cyclone dust collector; the cyclone dust collector is also communicated with a coal gas cooler and a coal gas bag-type dust collector in sequence; an outlet of the coal gas bag-type dust collector is connected with a chimney; a moving bed return device is arranged at the bottom of the moving bed pyrolysis reactor and is communicated with the bottom of the CFB boiler furnace by a return pipeline; and a return gate valve is arranged on the return pipeline. The invention also discloses the coal pyrolysis based polygeneration method. A set of polygeneration process of heat, power and gas in systems is achieved by adopting the device and the method.

Owner:HUANENG CLEAN ENERGY RES INST

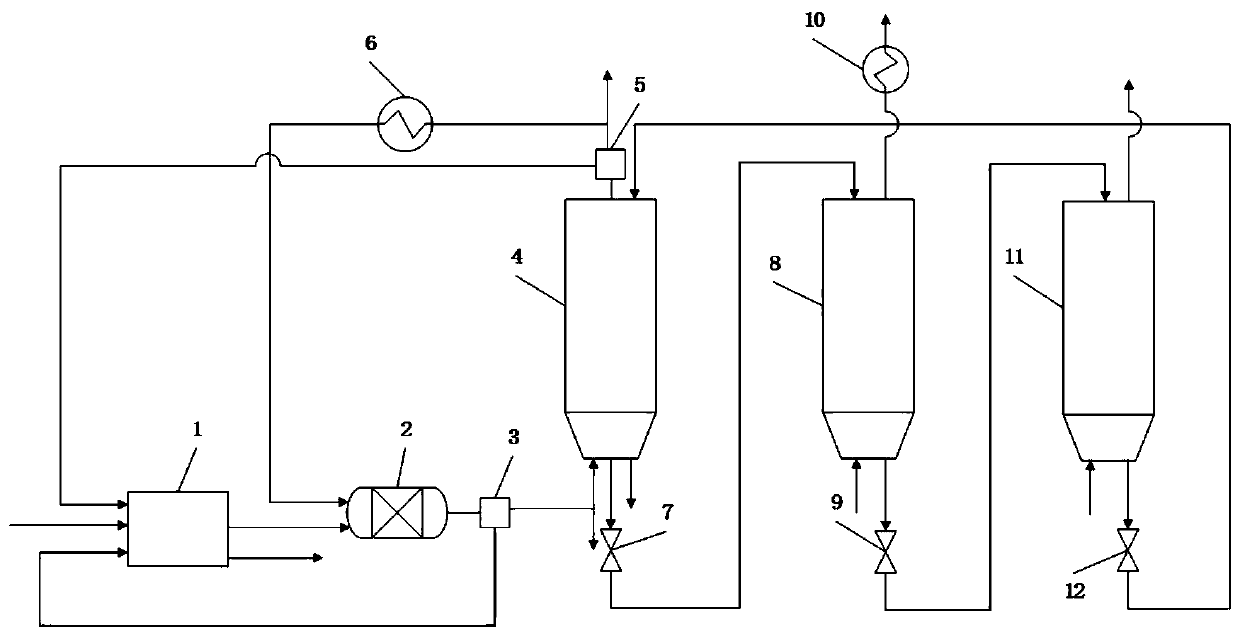

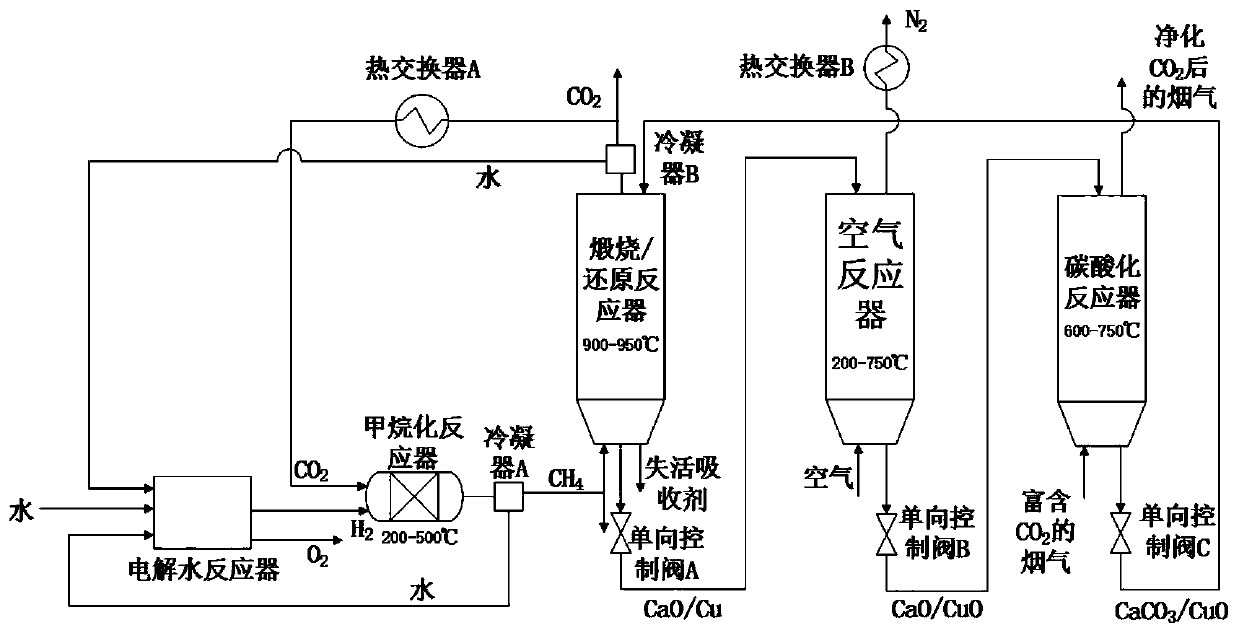

System and method for capturing and utilizing CO2 in low energy consumption by coupling new energy

InactiveCN110305704AAvoid putting into useReduce energy consumptionElectrolysis componentsChemical industryHigh concentrationElectrolysis

The invention discloses a system and a method for capturing and utilizing CO2 in low energy consumption by coupling new energy. The system comprises an electrolytic water reactor, a methanation reactor, a calcining / reducing reactor, an air reactor and a carbonation reactor, the calcining / reducing reactor, the air reactor and the carbonation reactor are circularly connected and used for capturing CO2 in flue gas in a low energy consumption manner, the electrolytic water reactor and the methanation reactor are sequentially connected, and the methanation reactor is connected with the calcining / reducing reactor and used for synthesizing methane. According to the system and the method, the CO2 is captured, utilized and coupled, the new energy electrolyzes water to prepare hydrogen, methanationof the CO2 by hydrogenation is achieved, zero-carbon emission of the system is achieved, and poly-generation of gases such as high-concentration CO2, CH4, O2, N2 and H2 is achieved.

Owner:SOUTHEAST UNIV

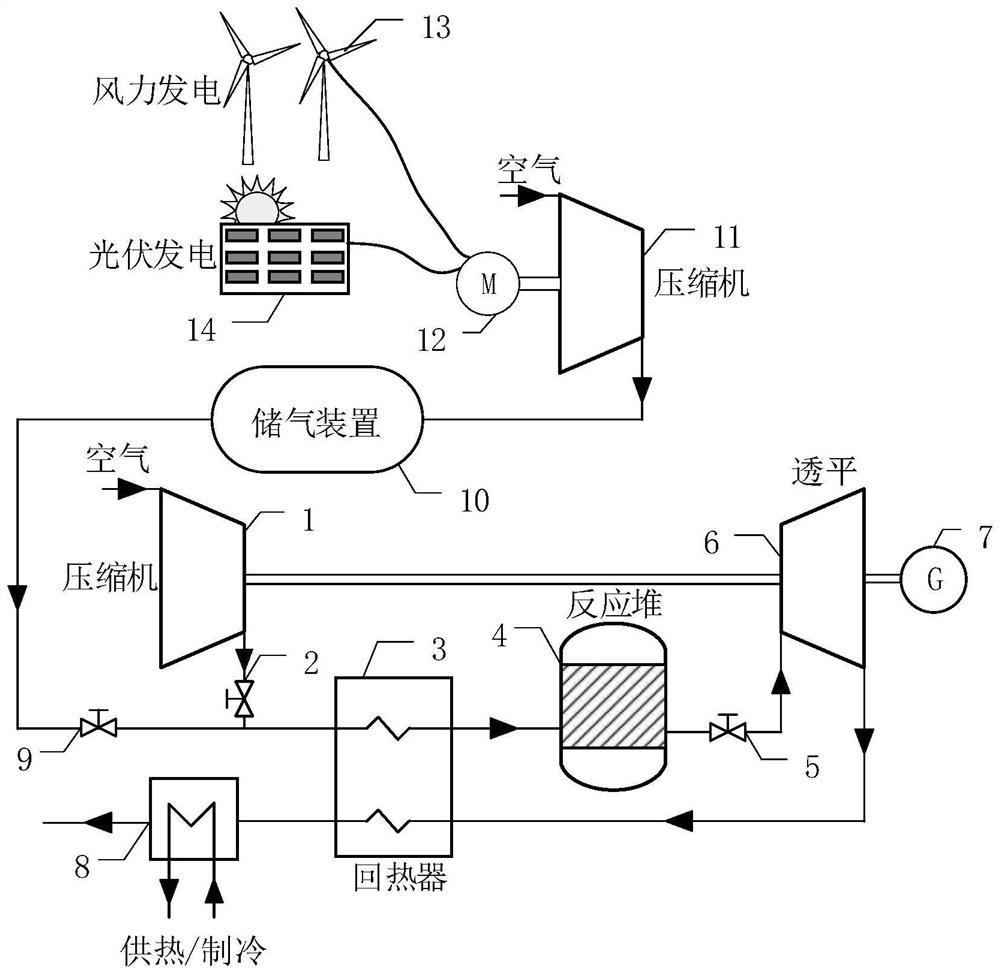

Nuclear reactor open type air circulation system coupled with wind and light energy storage

PendingCN114687940AEasy accessImprove securityWind motor with solar radiationPV power plantsAir cycleWind driven

The invention discloses a nuclear reactor open type air circulation system coupled with wind and light energy storage. The system mainly comprises a compressor, a turbine, a generator, a heat regenerator, a reactor, a heat exchanger, a gas storage device, a regulating valve, a wind driven generator, a photovoltaic power generation device, a motor and the like. According to the system, a nuclear reactor open type air Brayton cycle is used for outputting basic electric load to the outside; meanwhile, a wind and light energy storage system is coupled, clean and unstable wind energy and solar energy are converted into compressed air to be stored, and in the peak period of electricity utilization, the stored compressed air is added into a Brayton cycle to improve the external generating capacity; the turbine exhaust after power generation can also be used for supplying heat to the outside or driving a refrigeration cycle after heat is recovered through a heat regenerator. The system is low-carbon and clean, gradient utilization of energy can be achieved, and the comprehensive utilization efficiency of energy can be effectively improved.

Owner:XI AN JIAOTONG UNIV

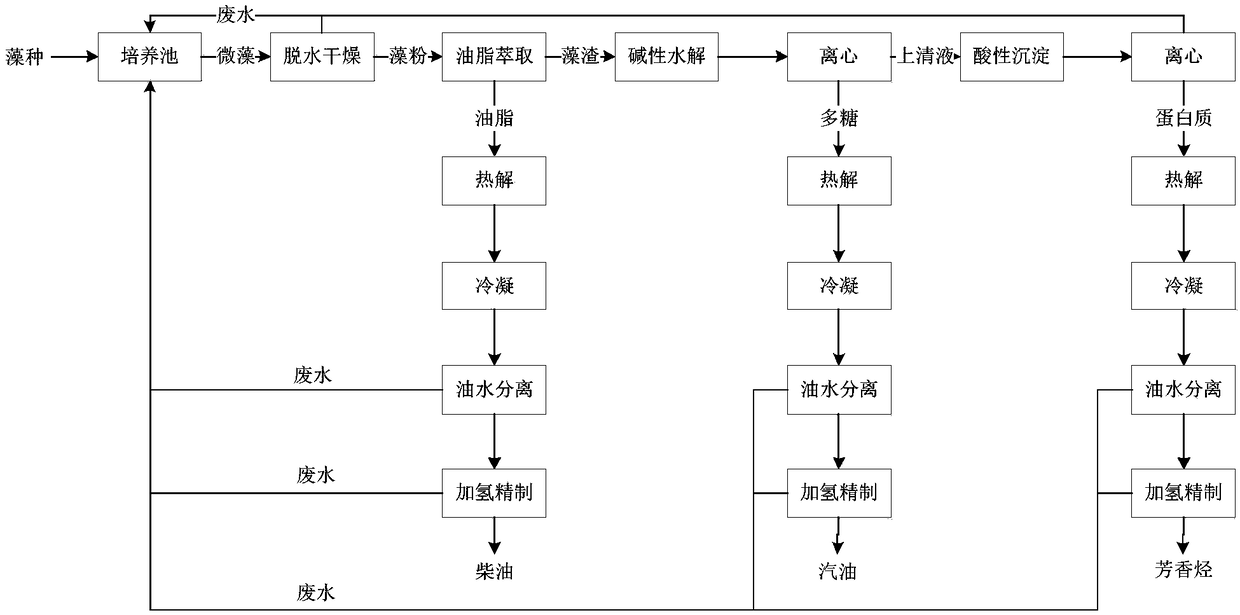

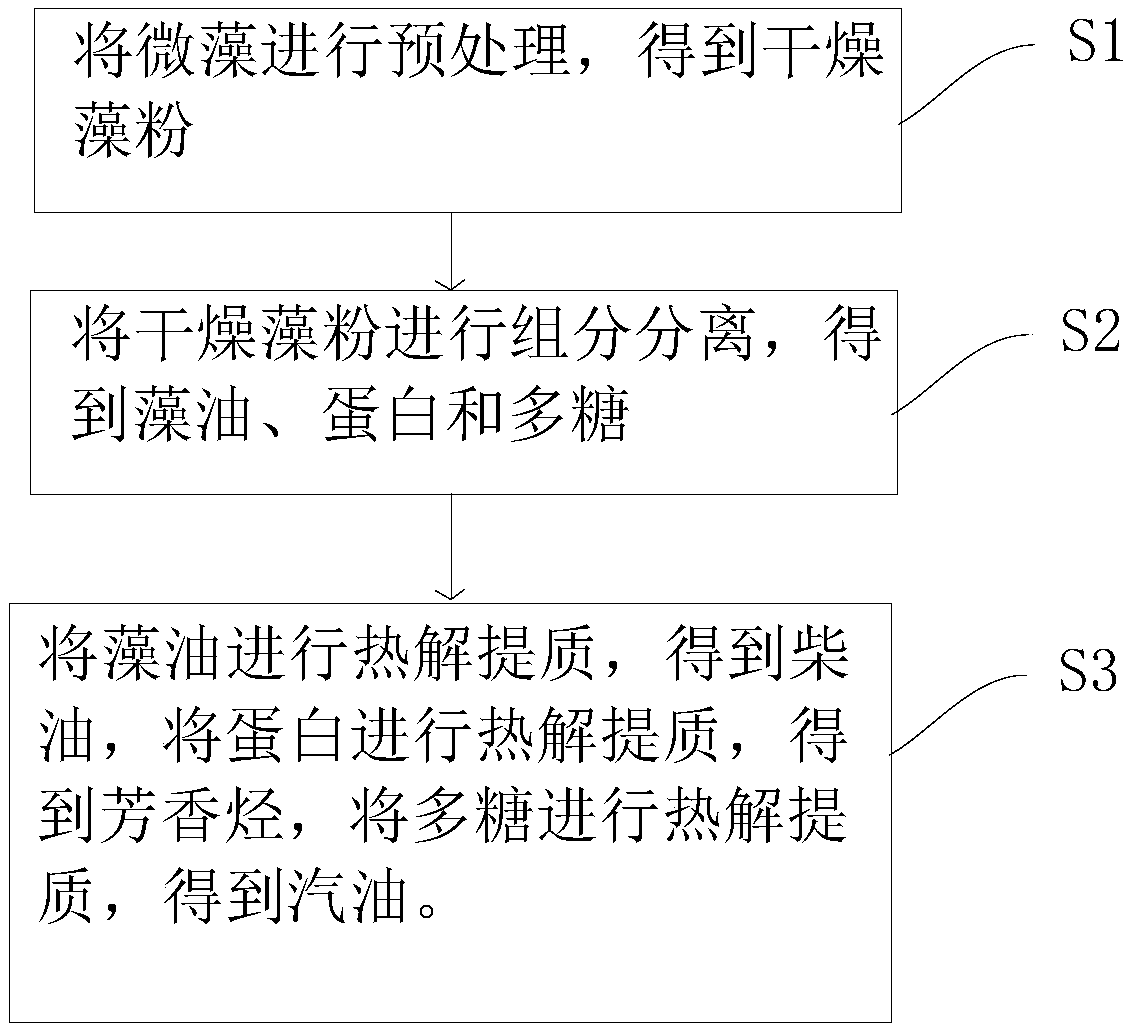

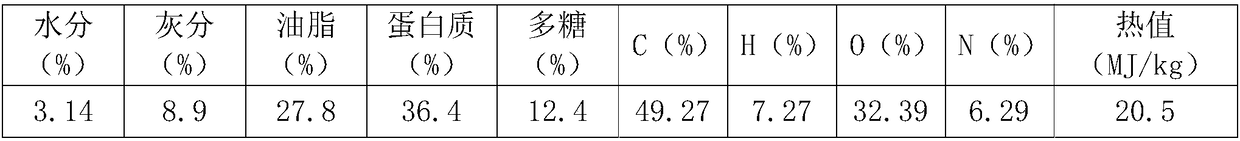

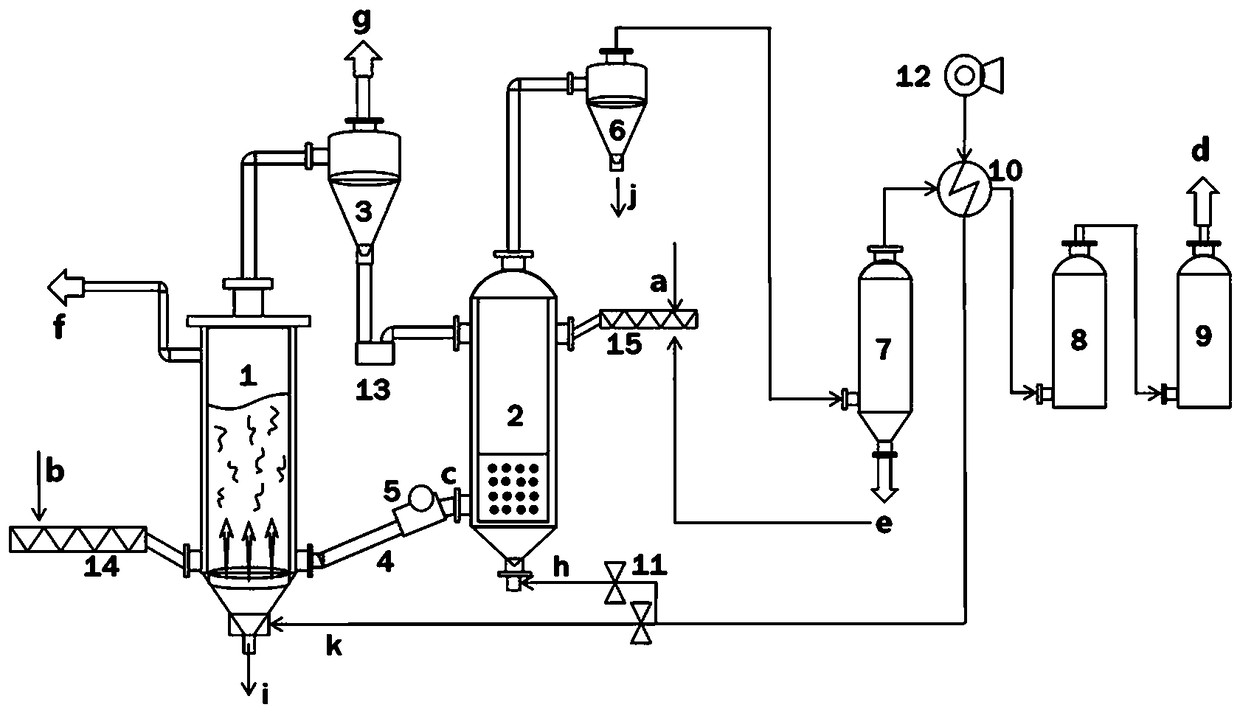

Microalga-based biomass refining method and system for implementing microalga-based biomass refining method

PendingCN109504527APolygenerationEasy to changeBiofuelsLiquid hydrocarbon mixture productionBiomassKerosene

The invention discloses a microalga-based biomass refining method and a system for implementing the microalga-based biomass refining method. The method comprises the following steps: S1, pretreating microalgae to obtain dry alga powder; S2, separating components of the dry alga powder to obtain alga oil, proteins and polysaccharides; and S3, performing pyrolysis on the alga oil for upgrading to obtain diesel, performing pyrolysis on the proteins for upgrading to obtain aromatic hydrocarbons, and performing pyrolysis on the polysaccharides for upgrading to obtain gasoline. Therefore, by adopting the microalga biomass as a raw material source, the refining method also realizes co-production of multiple oil products such as gasoline, diesel and kerosene on the basis of realizing co-productionof coke, fuel gas and oil products, and promotes the conversion from the petroleum-based refining industry to the bio-based refining industry. Furthermore, the refining method can select different raw materials for different needs of gasoline, diesel and kerosene in actual production activities, thereby flexibly adjusting the yields of bio-based liquid fuels and greatly improving the economy.

Owner:石首市博锐德生物科技有限公司

Double-bed power generation system for fire coal coupled living garbage pyrolysis and method

PendingCN109385308AReduce investmentEfficient disposalGasification processes detailsCombustible gas productionFixed bedTreatment system

The invention discloses a double-bed power generation system for fire coal coupled living garbage pyrolysis and a method. The system comprises a fluidized bed fire coal system, a fixed bed garbage gasification system and a synthetic gas treatment system, wherein a heat carrying bed material of a fluidized bed is fed into a gasifier through material circulation to provide energy for gasification; garbage coke generated in gasification is fed back into the fluidized bed through a backflow roller and mixed and combusted with coal powder, and then material balance and carbon conversion and immobilization are ensured; and a gasifier synthetic gas can be used as a combustible gas after being cooled and purified. As two processes of combustion and gasification are coupled, living garbage is converted into combustible gases and coke through gasification, and the coke is subjected to mixed combustion in a coal-fired furnace to replace a part of original coal, a function of combined production of heat, power and gases is achieved, the living garbage is effectively treated while fire coal is saved, pollutants such as dioxin and the like caused by direct garbage incineration are avoided, and the problem that coal cannot be directly mixed and combusted with garbage because of physical parameter differences can be solved.

Owner:ZHEJIANG UNIV OF TECH

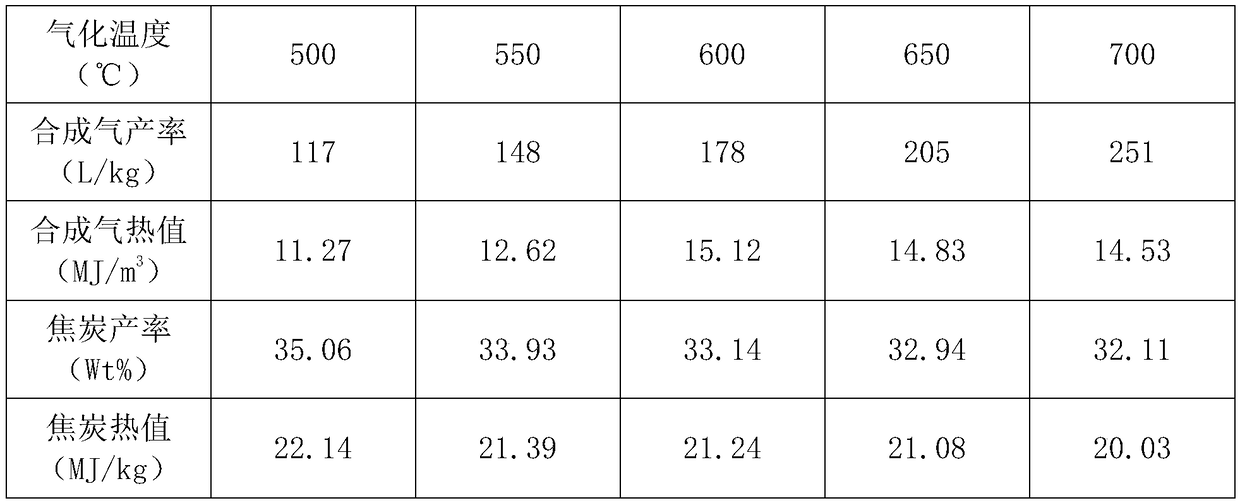

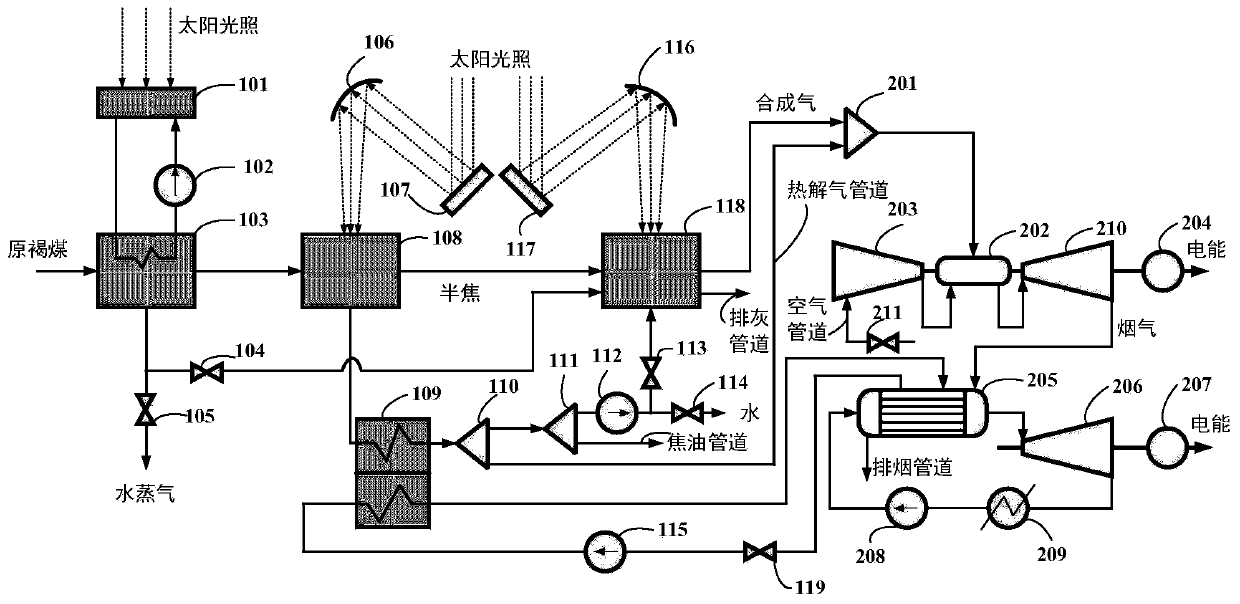

Solar-driven lignite multi-generation power generation system and operation method

InactiveCN110847991ARealize clean utilizationAchieve near-zero emissionsFrom solar energySteam engine plantsCombustion chamberCogeneration

The invention discloses a solar-driven lignite multi-generation power generation system and an operation method. The system comprises a steam dryer, a tower type solar pyrolyzer, a tower type solar gasifier, a mixer, a combustion chamber and a gas turbine which sequentially communicate, and further comprises a waste heat utilization system which is formed by sequentially communicating a waste heatboiler, a steam turbine, a condenser and a water pump; a tower type solar reflector field is used for focusing solar energy as a heat source of the tower type solar gasifier and the tower type solarpyrolyzer, and a groove type solar energy collector is used for focusing solar energy as a heat source of the steam dryer, and the purpose is that the heat sources of the tower type solar gasifier, the tower type solar pyrolyzer and the steam dryer are maintained at the optimal temperature on the basis of fully utilizing solar energy; and the water and waste steam flow entering the tower type solar gasifier are adjusted through waste steam regulating valves, and the purpose is that water and the semi-coke ratio in the tower type solar gasifier is guaranteed to maintain at an optimal value. Thesystem realizes the multi-cogeneration of electricity and tar, and is clean and efficient.

Owner:XI AN JIAOTONG UNIV

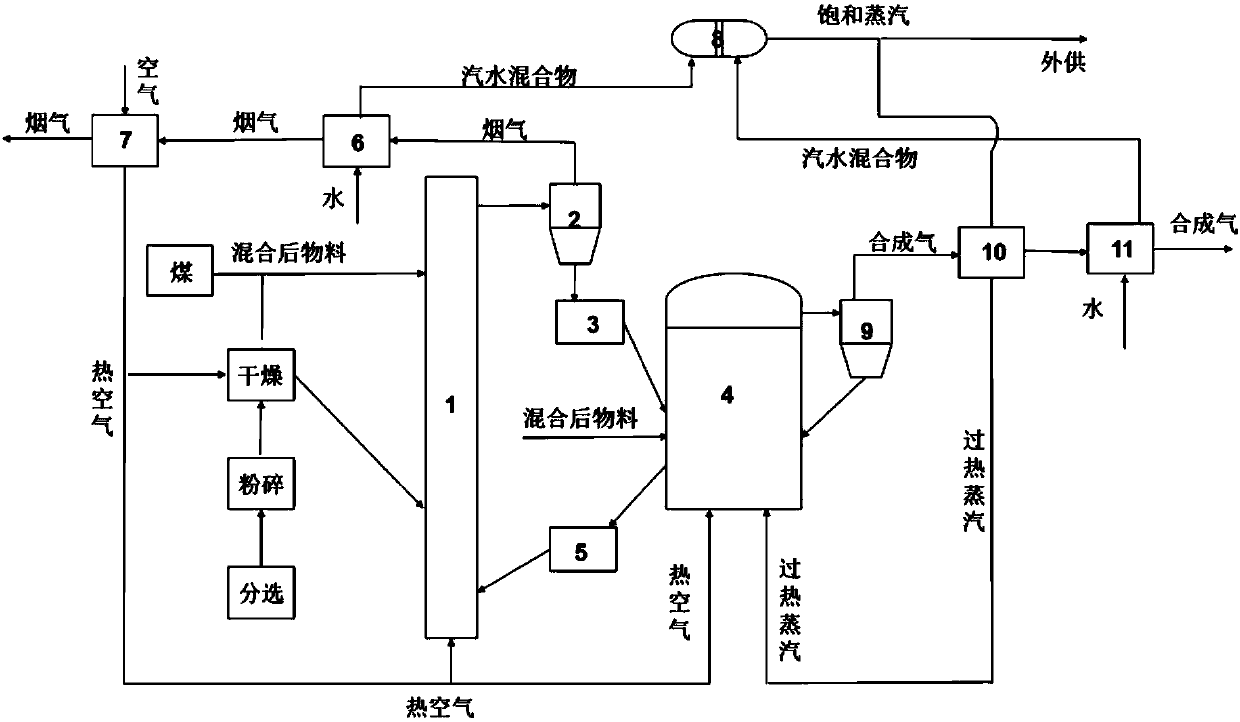

Method and device for high-temperature co-gasification of combustible solid waste, biomass and coal

InactiveCN108034457AReduce processing energy consumptionAchieve recyclingGasification processes detailsGranular/pulverulent flues gasificationGas solidFlue gas

The invention discloses a method and device for high-temperature co-gasification of combustible solid waste, biomass and coal. The method includes the following steps: performing sorting on the combustible solid waste and the biomass, performing crushing, performing drying, and performing mixing with the coal to obtain a mixed material; performing gasification on the mixed material, performing combustion, sending a mixed material which is not completely reacted in the gasification process to the combustion process for combustion, performing gas-solid separation on a flue gas which has high-temperature ash and is generated in the combustion process, and sending the separated high-temperature ash to the gasification process to provide heat for a gasification reaction, so as to make the gasification process coupled with the combustion process. The method provided by the invention not only improves the coal gas calorific value and energy utilization rate of gasified coal, saves the production costs of coal gasification, but also is environmentally friendly, solves the comprehensive treatment and utilization problems of the combustible solid waste and the biomass, and realizes the maximum utilization of energy sources.

Owner:BEIJING LEIHAO ENVIRONMENTAL PROTECTION ENERGY TECH

A method and device for recovering metal oxides from waste flue gas denitrification catalyst

ActiveCN105217686BNo wasteImprove protectionTungsten oxides/hydroxidesIron sulfatesHydrolysateAmmonium paratungstate

The invention discloses a method and an apparatus for recycling metal oxide from a waste flue gas denitration catalyst. The method comprises the following steps: S1, the catalyst is crushed and concentrated sulfuric acid is added for acidolysis, after acidolysis, water is added to obtain a titanyl sulfate solution; S2, the titanyl sulfate solution is filtered, filter residues are standby, a filtrate is heated, condensed and hydrolyzed for obtaining a hydrolysate; S3, the hydrolysate is filtered to obtain a filtrate and a metatitanic acid deposition; S4, salt treatment, a drying and a calcination are carried out for the metatitanic acid deposition, and TiO2 is obtained; S5: sedimentation treatment is carried out for the filtrate in the S3, after filtering, a upper level clear liquid is taken, excessive NH4Cl is added into the clear liquid for reaction, after filtering, andammonium metavanadate deposition is obtained; the ammonium metavanadate deposition is calcined, and V2O5 is obtained; S6, excessive ammoniacal liquor is added into the filter residues in the S2 for reaction, and a filtering is carried out; a filtrate is heated to generate a ammonium paratungstate crystal; the ammonium paratungstate crystal is dried and calcined, and WO3 is obtained. According to the method, V, Ti and W three components can be completely separated.

Owner:CHINA HUADIAN ENG +1

A method and device for recovering ti and v from waste flue gas denitrification catalyst

ActiveCN105152205BImprove protectionSuitable for industrial productionTitanium dioxideVanadium oxidesSulfateFlue gas

The invention discloses a method and device for recycling Ti and V from a waste flue gas denitrification catalyst. The method comprises the following steps that 1, the catalyst is smashed, concentrated sulfuric acid is added for acidolysis, and water is added after acidolysis is performed to obtain a titanyl sulfate solution; 2, the titanyl sulfate solution is filtered, filter residues are collected for use, and a filtrate is heated and concentrated for hydrolysis to obtain a hydrolysis product; 3, the hydrolysis product is filtered to obtain a filtrate and metatitanic acid sedimentation; 4, salt treatment, drying and roasting are performed on the metatitanic acid sedimentation to obtain a finished product TiO2; 5, sedimentation treatment and filtering are performed on the filtrate in the third step, a supernatant is taken, excessive NH4Cl is added into the supernatant for a reaction, and filtering is performed to obtain ammonium metavanadate sedimentation; the ammonium metavanadate sedimentation is roasted to obtain pure V2O5. The method can recycle pure TiO2 and V2O5 from the waste flue gas denitrification catalyst.

Owner:CHINA HUADIAN ENG +1

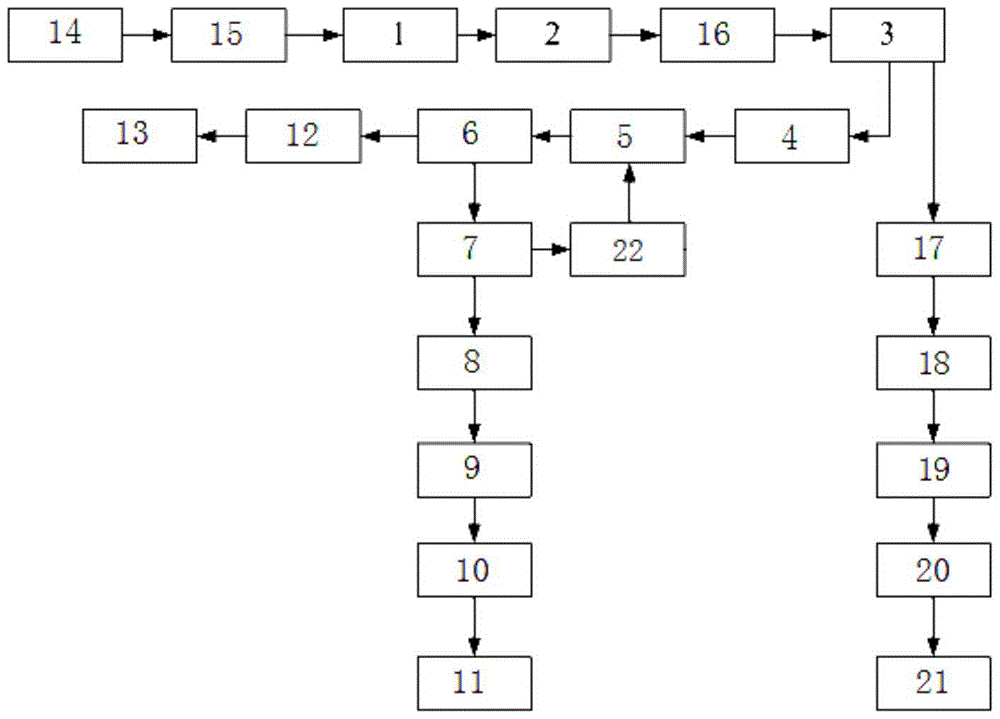

A method and device for recovering tungsten trioxide from waste flue gas denitration catalyst

ActiveCN105217689BNo wasteSuitable for industrial productionTungsten oxides/hydroxidesSolid waste disposalAmmonium paratungstateSulfate

The invention discloses a method and device for recovering tungsten trioxide from a waste flue gas denitrification catalyst. The method includes: S1, pulverizing the catalyst and adding concentrated sulfuric acid for acidolysis, adding water after the acidolysis to obtain a titanyl sulfate solution ; S2, filter the titanyl sulfate solution, add excess ammonia water to the filter residue for reaction, and perform secondary filtration; S3, heat the filtrate obtained from the secondary filtration to generate ammonium paratungstate crystals; dry and calcinate the ammonium paratungstate crystals to obtain pure WO 3 . The present invention can obtain pure WO 3 ; And according to a large number of data statistics show that after adopting the scheme of the present invention, WO 3 The recovery efficiency can reach 93%, and the purity can reach 90%. The recovery technology of the present invention does not need high-temperature roasting, so it is relatively energy-saving and suitable for industrial production. At the same time, the present invention adopts acid treatment, no reagent waste, and effectively saves resources.

Owner:CHINA HUADIAN ENG +1

A method and device for recovering ti and w from waste flue gas denitrification catalyst

ActiveCN105152216BNo wasteRecycling technology saves energyTungsten oxides/hydroxidesTitanium dioxidePtru catalystAmmonium paratungstate

Owner:CHINA HUADIAN ENG +1

A method for preparing methanol and oil from low-rank coal by polygeneration

ActiveCN110055106BIncrease profitPolygenerationGasification processes detailsLiquid carbonaceous fuelsPhysical chemistryProcess engineering

The invention provides a method using the quality-based utilization of low-rank coal to prepare methanol and oil in a poly-generation manner. The method has the advantages that the dried low-rank coalis subjected to gasification reduction to obtain volatile components, hydrocarbon and the like in the volatile components is reformed and converted to obtain CO and H2 needed by oil synthesizing so as to prepare the methanol and the oil, and the volatile components in the low-rank coal are sufficiently and effectively utilized; by using the quality-improved coal obtained by the gasification reduction of the low-rank coal as the raw material to prepare the methanol and the oil, the coal substances in the low-rank coal are fully utilized; the methanol and the oil are prepared in the poly-generation manner, byproducts generated by the synthesizing process of the methanol or the oil can be effectively recycled, resources can be saved, multiple approaches are achieved, the prepared oil and methanol are few in impurities and high in quality, the utilization rate of the low-rank coal is increased greatly, and the method conforms to efficient and clean coal utilization vigorously advocated byChina.

Owner:浙江天禄环境科技有限公司

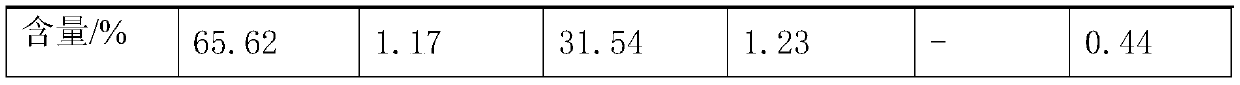

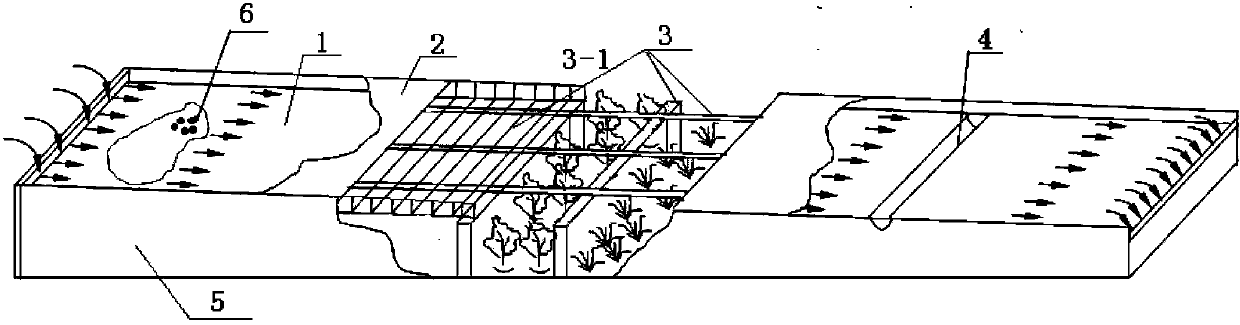

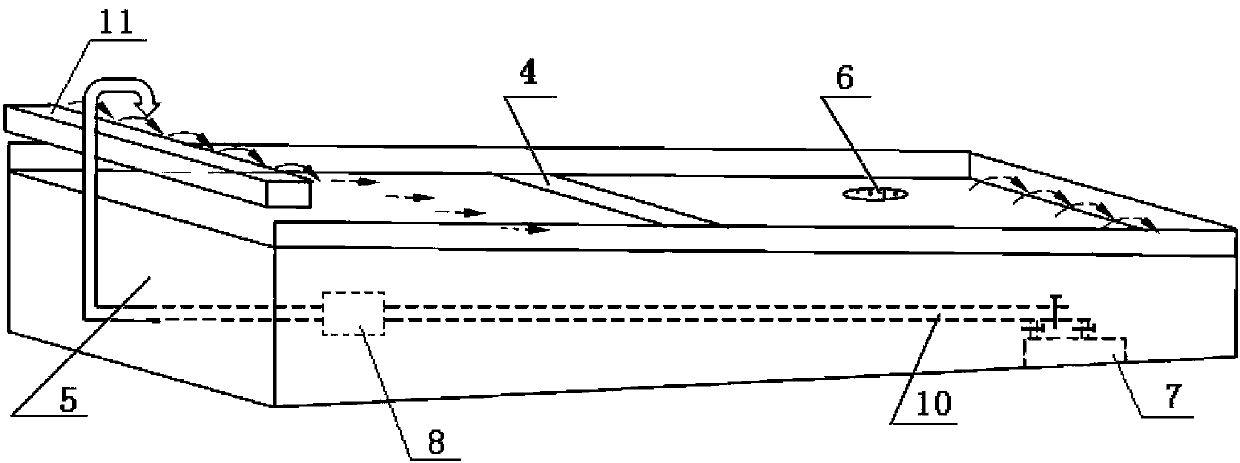

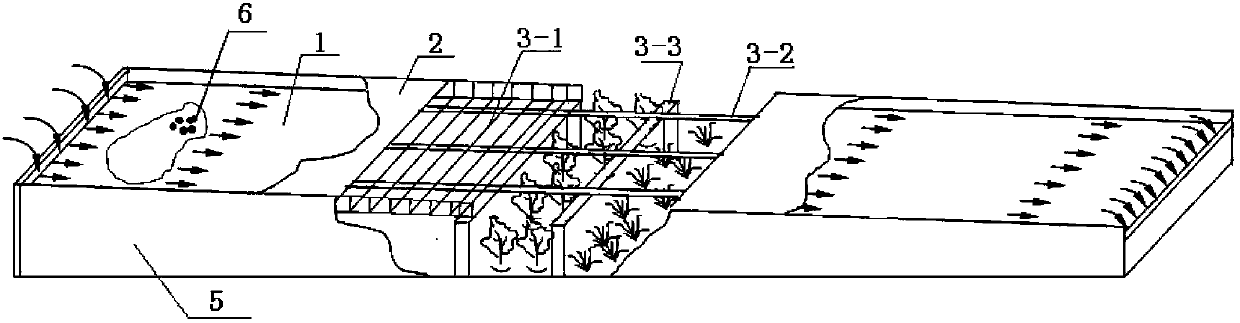

Thin-layer breeding multiple production system

ActiveCN103361259ARealize three-dimensionalRealize resource utilizationBioreactor/fermenter combinationsBiological substance pretreatmentsGreenhouseClosed loop

The invention relates to a thin-layer breeding multiple production system. The multiple production system comprises a thin-layer breeding system and a greenhouse system, wherein the thin-layer breeding system comprises a breeding device and a circulatory system; the breeding device comprises a bottom surface and a corresponding support frame; the breeding device is in a closed loop connection with the circulatory system; and the greenhouse system is disposed below the breeding device. The support frame of the thin-layer breeding system, as a main structure body of the greenhouse system, combines the thin-layer breeding system and the greenhouse system, so that plant and animal breeding can be developed while carrying on microalgae breeding, thereby realizing stereoscopic and resourceful utilization of land and providing novel mode for developing ecology energy and ecological agriculture.

Owner:ENN SCI & TECH DEV

A method and device for recovering W and V from waste flue gas denitrification catalyst

ActiveCN105200236BTake advantage ofImprove protectionProcess efficiency improvementAmmonium paratungstateFlue gas

The invention discloses a method and device for recycling W and V from a waste flue gas denitration catalyst. The method includes the steps that 1, the catalyst is crushed, concentrated sulfuric acid is added for acidolysis, water is added after acidolysis, and an oxygen titanium sulfate solution is obtained; 2, the oxygen titanium sulfate solution is filtered, filter residues are collected for standby application, the filter liquor is heated, concentrated and hydrolyzed, and a hydrolysis product is obtained; 3, the hydrolysis product is filtered, and settlement treatment is conducted on the filter liquor; 4, filtering is conducted after settlement treatment, supernatant liquid is taken, an excessive amount of NH<4>Cl is added to the clear liquid for a reaction, then filtering is conducted, and ammonium metavanadate sediment is obtained; the ammonium metavanadate sediment is calcined, and V<2>O<5> is obtained; 5, an excessive amount of ammonium hydroxide with the concentration being 10%-28% is added to the filter residues in step 2 for a reaction, and then filtering is conducted; the filter liquid is heated to be 80 DEG C-100 DEG C, and an ammonium paratungstate crystal is obtained; the ammonium paratungstate crystal is dried and calcined, and the WO<3> is obtained. By means of the method and device, the V<2>O<3> and the WO<3> which are both high in purity and recovery rate can be extracted from the waste flue gas denitration catalyst.

Owner:CHINA HUADIAN ENG +1

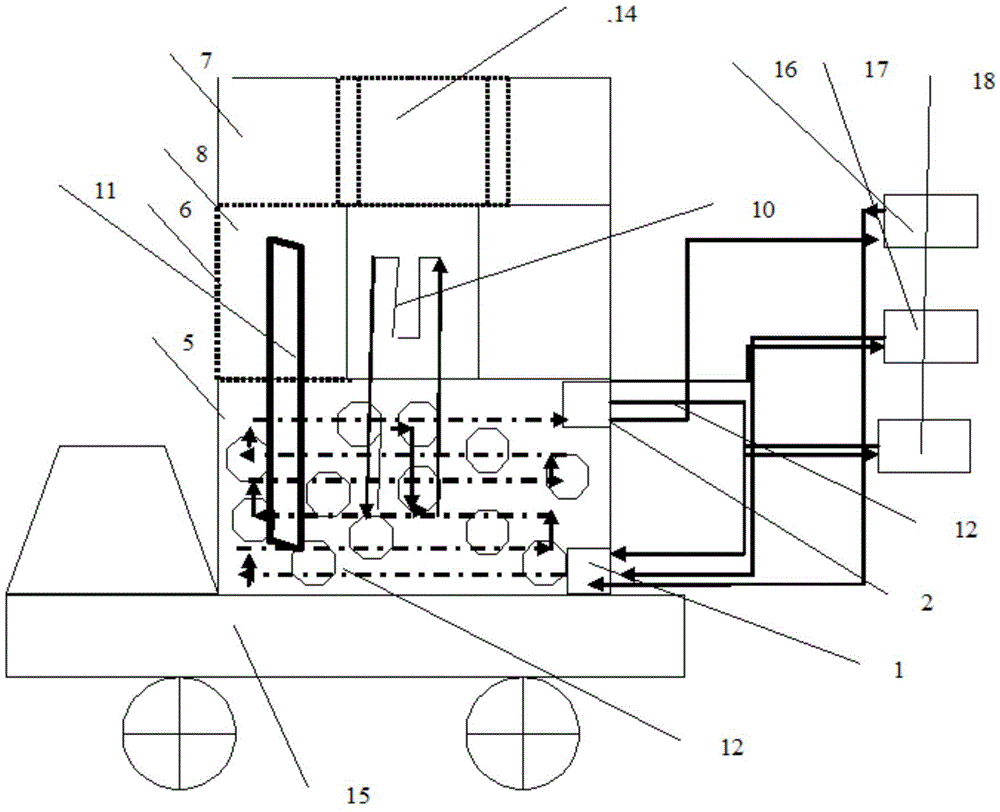

Solid grain block heat accumulating type multi-generation unit and trolley

InactiveCN104654868ATo achieve complementary usePolygenerationHeat storage plantsItem transportation vehiclesThermal energyControl system

The utility model provides a solid grain block heat accumulating type multi-generation unit realizing low-cost and high efficient energy utilization via mutual use of various energies and heat accumulation via a heat accumulator, and in particular realize effective utilization of waste heat and low ebb power. Solid grains are employed as heat accumulating material; the solid grains are transferred to a container; at least three chambers are formed in the container, one heat accumulating chamber, one multi-generation component chamber and one control system chamber; a heat exchanging component is arranged between the solid grains and a multi-generation component; heat is exchanged between heat energy and the solid grains in the container via the fluid; and when heat energy is required, heat energy is used via the fluid. The utility model also aims to provide a solid grain block heat accumulating type multi-generation unit trolley moving the heat accumulator to an area requiring heat energy for utilization; and movable heat accumulation can be achieved.

Owner:CHENGDU AONENGPU TECH

Supercritical and above parameter coal power unit coupling supercritical water hydrogen production system and method thereof

ActiveCN113583714AGuaranteed uptimeImprove efficiencySteam engine plantsBulk chemical productionThermodynamicsProcess engineering

The invention provides a supercritical and above parameter coal power unit coupling supercritical water hydrogen production system and a method thereof, and the system comprises a supercritical and above parameter coal power unit thermodynamic system which is used for providing supercritical water, pulverized coal and low-pressure medium-temperature water; and a supercritical and coupling hydrogen production system used for producing hydrogen by using supercritical water, pulverized coal and low-pressure medium-temperature water. The residual load space of the coal power unit can be fully utilized, the unit is in a high-load-level operation state, the operation level and efficiency of the coal power unit are improved, when the unit participates in load reduction and peak regulation, under the condition that the evaporation capacity of a boiler is not reduced, generated supercritical water can be effectively utilized, the generating capacity is reduced, flexible peak regulation is achieved, and the unit service life is prolonged. The thermodynamic system of the supercritical and above parameter coal generator set can be directly transformed through the existing widely adopted supercritical and above parameter coal power unit thermodynamic system, so that the related cost of supercritical water hydrogen production is greatly reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com