Double-bed power generation system for fire coal coupled living garbage pyrolysis and method

A technology of domestic waste and power generation system, which is applied in the manufacture of combustible gas, gasification process, petroleum industry, etc. It can solve the problems of large differences in physical parameters of pulverized coal, high water content of domestic waste, and large geometric dimensions, so as to achieve less dust entrainment , Small flue gas emissions, and the effect of reducing coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

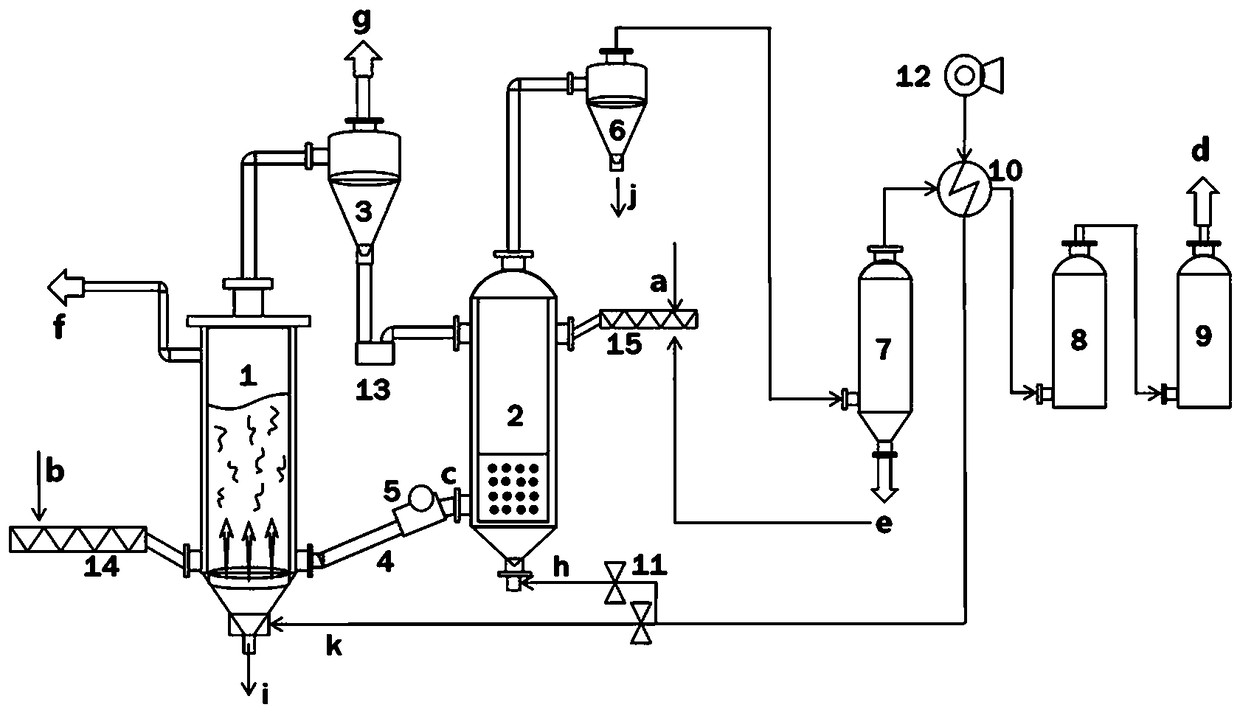

[0033] See attached image. This embodiment includes a circulating fluidized bed coal-fired system, a fixed bed garbage gasification system, and a syngas processing system. Among them, the design of the coal-fired system is based on the HG-480 / 13.7L.MG31 circulating fluidized bed boiler with a power of 135MW, and the design of the gasification system is based on the experimental data of the fixed bed.

[0034] The circulating fluidized bed coal-fired system includes: a fluidized bed combustion furnace 1 , a cyclone separator 3 at the outlet of the combustion furnace, a return leg 4 and a combustion furnace screw feeder 14 . A pulverized coal feeding port is provided at the lower part of the left wall surface of the furnace chamber of the fluidized bed combustion furnace 1, which is connected to the combustion furnace screw feeder 14, and the lower part of the furnace chamber right wall surface is connected to the material return leg 4. The bottom of the fluidized bed combustio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com