Microalga-based biomass refining method and system for implementing microalga-based biomass refining method

A biomass and microalgae technology, which is applied in the preparation of biological raw materials, biofuels, liquid hydrocarbon mixtures, etc., can solve problems such as chemical structure, pyrolysis characteristics differences, and pyrolysis equipment development and pyrolysis products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

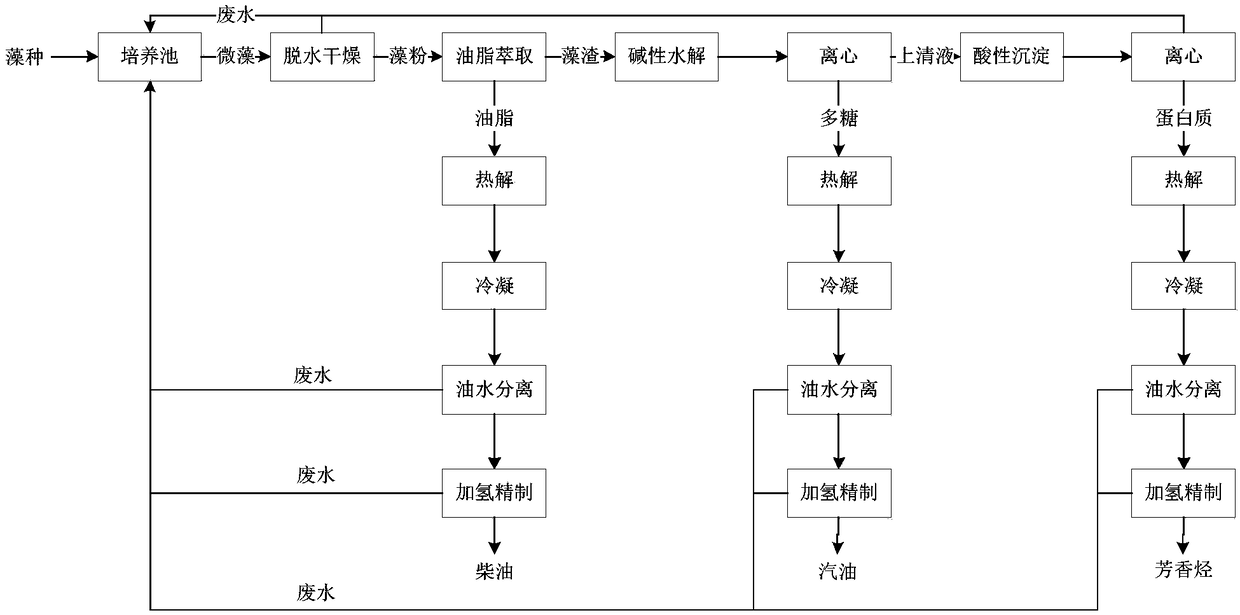

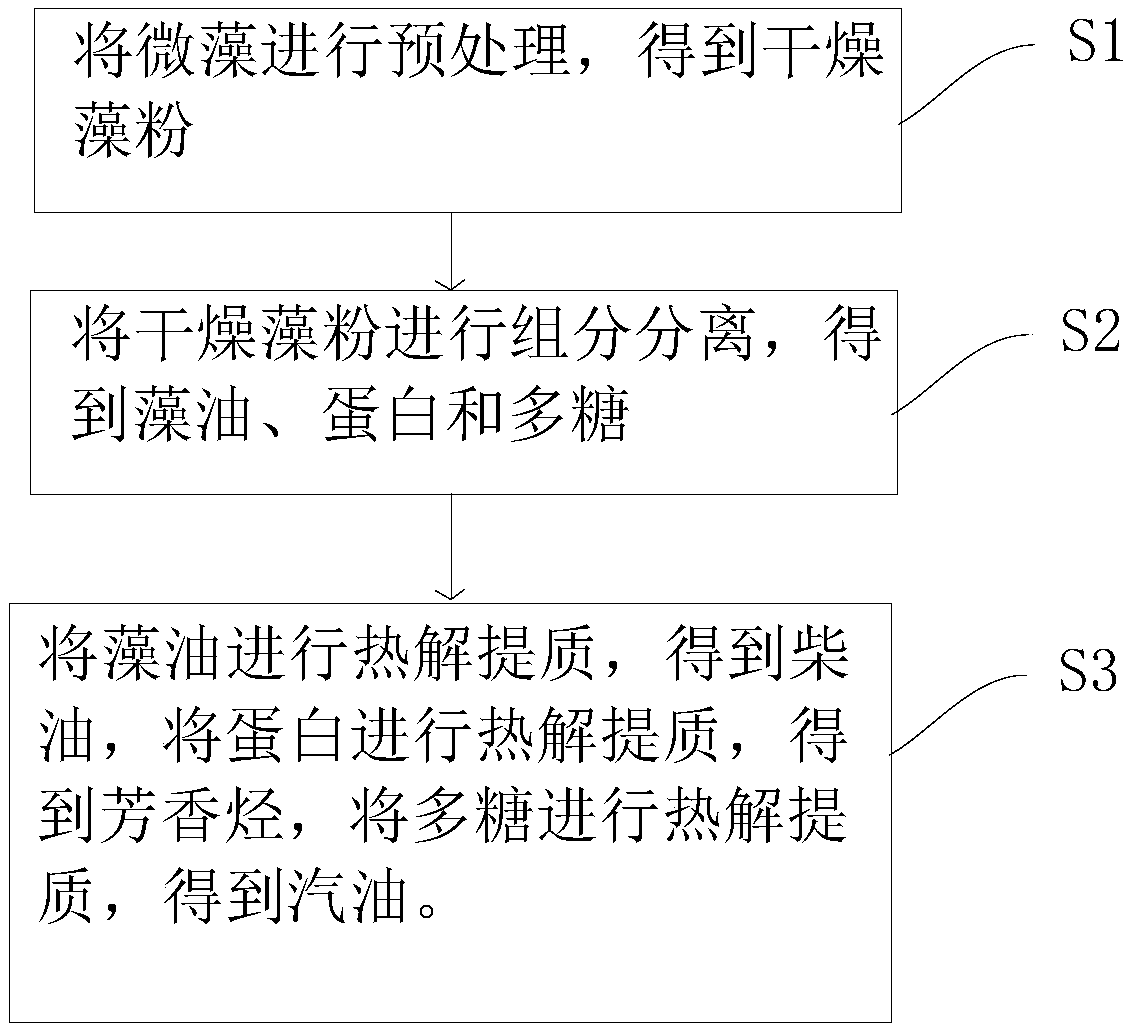

[0020] Refer below Figure 1-Figure 2 A microalgae-based biomass refining method according to an embodiment of the present invention is described.

[0021] like figure 1 and figure 2 As shown, the microalgae-based biomass refining method according to the embodiment of the present invention includes the following steps: S1, pretreating the microalgae to obtain dry algal powder, wherein the pretreatment includes: cultivating the microalgae in a culture tank, The microalgae in the culture tank are dried to obtain dry algae powder. The cultivation pool includes an algae seed inlet, waste water inlet and microalgae outlet, the dryer includes a microalgae inlet and an algae powder outlet, and the microalgae outlet is connected with the microalgae inlet of the dryer. Through the above pretreatment, the microalgae can be processed into dry algae powder, which can facilitate the subsequent extraction and pyrolysis steps.

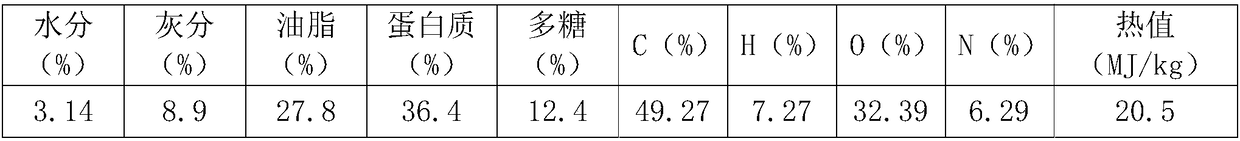

[0022] Among them, the moisture content of the microalgae ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com