Supercritical and above parameter coal power unit coupling supercritical water hydrogen production system and method thereof

A technology for supercritical water and hydrogen production systems, which is applied in mechanical equipment, steam engine installations, and the manufacture of combustible gases, etc., can solve the problems of occupying the power generation space of thermal power generating units, low efficiency of thermal power generating units, and low utilization hours, etc. The effect of downsizing, reducing power generation, improving operation level and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

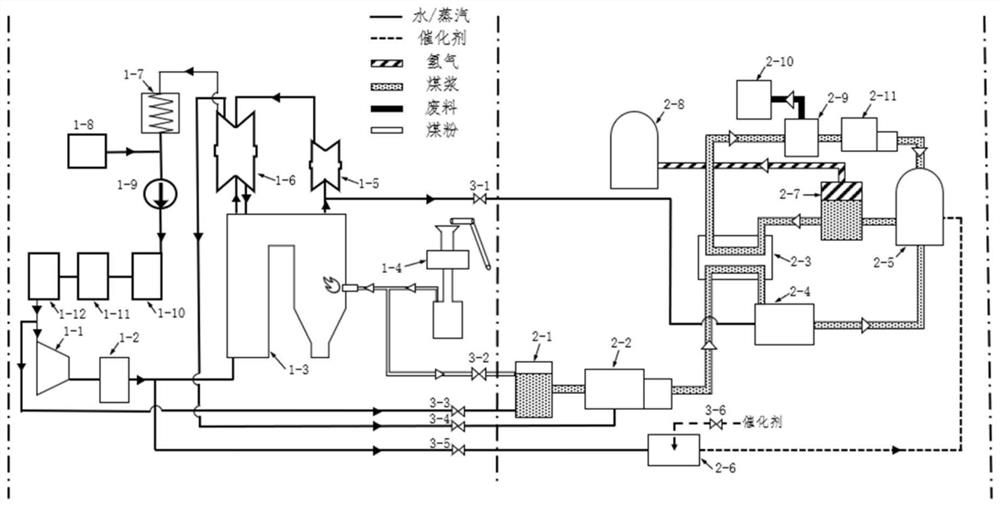

[0029] Such as figure 1 As shown, a supercritical and above-parameter coal-fired power unit coupling supercritical water hydrogen production system provided by the present invention includes a supercritical and above-parameter coal-fired power unit thermodynamic system, a supercritical coupling hydrogen production system and a valve control system, wherein :

[0030] The thermal system of coal-fired power units with supercritical and above parameters is a pulverized coal combustion boiler with parameters above supercritical (generally referring to steam cycle parameters, temperature greater than 374 degrees Celsius, pressure greater than 22.1MPa) adopted by the mainstream in the world at present. The main equipment includes feed water pump 1-1, high pressure heater 1-2, boiler 1-3, pulverizing system 1-4, high pressure cylinder 1-5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com