Poly-generation production system of magnesium metal and hydride of magnesium metal

A production system, metal magnesium technology, applied in the direction of alkali metal/alkaline earth metal/beryllium/magnesium hydride, carbon compounds, non-metallic elements, etc., can solve the problems of high content, low thermal efficiency, poor activity and quality, etc., to achieve Low transportation costs, reduced production costs, and environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

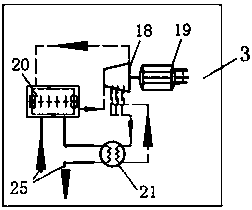

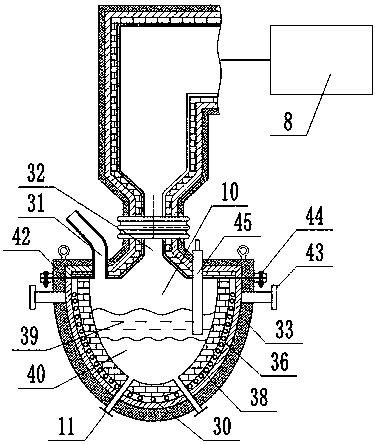

[0027] The polygeneration production system of the metal magnesium and its hydride of the present invention is such as figure 1 As shown, it includes a calcium carbide production device, a crystallization chamber 8, a magnesium refining and pulverizing device 9, a maple energy preparation unit, a reaction pot 10, a magnesium hydroxide calciner 28, a magnesium hydroxide container 41 and an inert gas pipeline 16. Calcium carbide production equipment includes calcium carbide raw material warehouse, rotary kiln 1, functional gasifier 35, ash cooler 47, waste heat power generation equipment 2, Kolaipu unit 3, conversion and separation equipment 4, carbon dioxide purification equipment 5, hydrogen production unit 6, Metal magnesium container 15, hazardous substance removal equipment 37, metal magnesium hydride container 26, raw material preheater 34, carbon dioxide finished product tank 49. The rotary kiln is provided with a kiln body, a raw material inlet, a calcium carbide liquid ou...

Embodiment 2

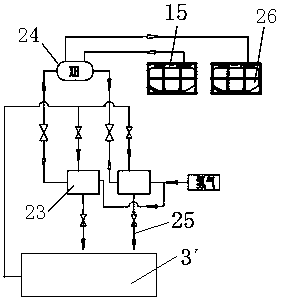

[0038] Another embodiment of the present invention is as figure 2 As shown, it includes a calcium carbide production device, a crystallization chamber 8, a magnesium refining and crushing device 9, a reaction pot 10, a magnesium hydroxide calciner 28, a magnesium hydroxide container 41, and an inert gas pipeline 16. The calcium carbide production equipment includes calcium carbide raw material warehouse, rotary kiln 1, waste heat power generation equipment 2, Kolaipu unit 3, conversion and separation equipment 4, carbon dioxide purification equipment 5, hydrogen production unit 6, metal magnesium container 15, hazardous substance removal equipment 37, metal Magnesium hydride container 26, raw material preheater 34, carbon dioxide product tank 49. The rotary kiln is provided with a kiln body, a raw material inlet, a calcium carbide liquid outlet, a burner and a flue gas outlet, and a sealed box 48 is arranged on the outside of the kiln body. The burner fuel inlet is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com