High-value comprehensive utilization method of bagasse fibers

A bagasse fiber and high-value technology, which is applied in the field of high-value comprehensive utilization, can solve the problems of low economic benefit, ignoring the utilization of other components, and less consideration for the comprehensive utilization of hemicellulose and lignin, so as to achieve the goal of reducing resources The effect of consumption and emission reduction of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

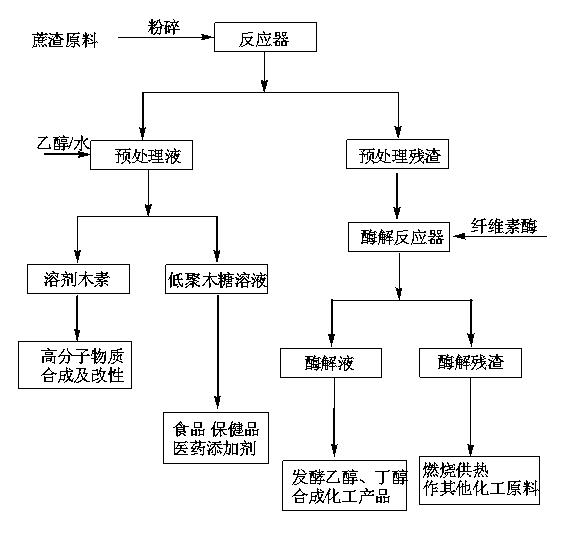

[0033] like figure 1 As shown, weigh 500 grams of dry bagasse raw material and place it in a closed reactor equipped with a thermocouple, add 4000 mL of water / ethanol solution (60 / 40, v / v), and add 25 grams of acetic acid, turn on stirring, heating system , make the temperature rise to 180 ℃ quickly and start timing, when the reaction time reaches 60 minutes, stop heating, and immediately use condensed water to bring the reaction down to room temperature, and use the method of filtration to separate the pretreatment liquid and the pretreatment residue.

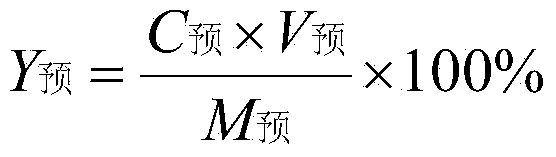

[0034] Take 1000 mL of ethanol pretreatment solution, add 2000 mL of deionized water, and then the solvent lignin begins to precipitate, and the solvent lignin is separated from the diluted pretreatment solution by centrifugation. Add 50 mL of diluted pretreatment solution to 250 mL of 3% (w / w) H 2 SO 4 and boiled for 4h to hydrolyze the xylo-oligosaccharides into xylose, and determine the xylose content by ion chromatograph...

Embodiment 2

[0038] Weigh 500 grams of dry bagasse raw material and place it in a closed reactor equipped with a thermocouple, add 4000 mL of water / ethanol solution (60 / 40, v / v), and add 25 grams of acetic acid, open the stirring and heating system, and make the temperature Rapidly rise to 190°C and start timing. When the reaction time reaches 60 minutes, stop heating, and immediately cool the reaction to room temperature with condensed water, and separate the pretreatment liquid and the pretreatment residue by filtration.

[0039] Take 1000 mL of ethanol pretreatment solution, add 2000 mL of deionized water, and then the solvent lignin begins to precipitate, and the solvent lignin is separated from the diluted pretreatment solution by centrifugation. Add 50 mL of diluted pretreatment solution to 250 mL of 3% (w / w) H 2 SO 4 and boiled for 4h to hydrolyze the xylo-oligosaccharides into xylose, and determine the xylose content by ion chromatography.

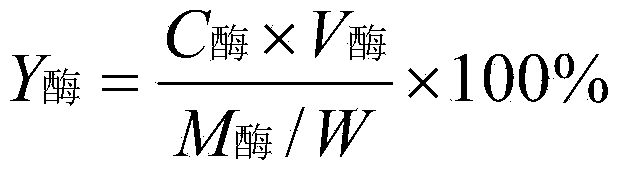

[0040] Take 20 grams of pretreatment r...

Embodiment 3

[0043] Weigh 500 grams of dry bagasse raw material and place it in a closed reactor equipped with a thermocouple, add 4000 mL of water / ethanol solution (60 / 40, v / v), and add 25 grams of acetic acid, open the stirring and heating system, and make the temperature Rapidly rise to 190°C and start timing, when the reaction time reaches 45 minutes, stop heating, and immediately cool the reaction to room temperature with condensed water, and separate the pretreatment liquid and the pretreatment residue by filtration.

[0044] Take 1000 mL of ethanol pretreatment solution, add 2000 mL of deionized water, and then the solvent lignin begins to precipitate, and the solvent lignin is separated from the diluted pretreatment solution by centrifugation. Add 50 mL of diluted pretreatment solution to 250 mL of 3% (w / w) H 2 SO4 and boiled for 4h to hydrolyze the xylo-oligosaccharides into xylose, and determine the xylose content by ion chromatography.

[0045] Take 20 grams of pretreatment res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com