A method and device for recovering ti and w from waste flue gas denitrification catalyst

A denitration catalyst and waste flue gas technology, applied in chemical recovery, titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of reagent waste, low extraction purity and extraction efficiency, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

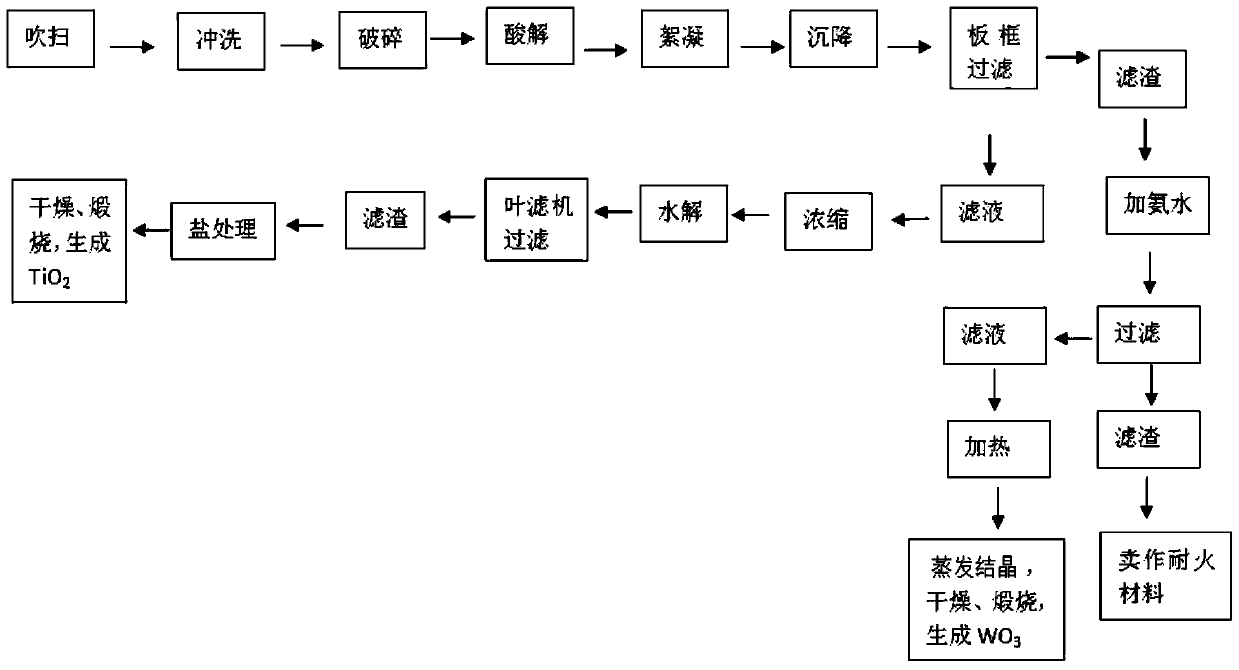

[0048] Embodiment 1 of the present invention: a method for recovering Ti and W from waste flue gas denitrification catalyst, such as figure 1 shown, including the following steps:

[0049] S01, blow the waste flue gas denitrification catalyst with compressed air for 20-23 minutes for each module to remove the dust in the channel;

[0050] S02, use a high-pressure water gun to flush the catalyst after dust removal, the flushing time of each module is 15-20min, and the pressure is 8-12Mpa, to further remove the dust in the channel;

[0051] S03, drying the washed catalyst;

[0052] S1, pulverizing the catalyst and adding concentrated sulfuric acid for acidolysis, adding water after acidolysis to obtain a titanyl sulfate solution, which specifically includes the following steps:

[0053] S11, crushing the catalyst into catalyst powder of 160-180 mesh;

[0054] S12, put the catalyst powder into the acid hydrolysis tank made of lead, add 88%-90% concentrated sulfuric acid accord...

Embodiment 2

[0066]Embodiment 2: a kind of method that reclaims Ti and W from waste flue gas denitrification catalyst, such as figure 1 shown, including the following steps:

[0067] S01, blow the waste flue gas denitrification catalyst with compressed air, and blow each module for 15-20 minutes to remove the dust in the channel;

[0068] S02, use a high-pressure water gun to flush the catalyst after dust removal, the flushing time of each module is 20-25min, and the pressure is 5-8Mpa, to further remove the dust in the channel;

[0069] S03, drying the washed catalyst;

[0070] S1, pulverizing the catalyst and adding concentrated sulfuric acid for acidolysis, adding water after acidolysis to obtain a titanyl sulfate solution, which specifically includes the following steps:

[0071] S11, crushing the catalyst into 180-200 mesh catalyst powder;

[0072] S12, put the catalyst powder into a lead-made acidolysis tank, add 85% to 88% concentrated sulfuric acid according to the weight ratio ...

Embodiment 3

[0084] Embodiment 3: a kind of method that reclaims Ti and W from waste flue gas denitrification catalyst, such as figure 1 shown, including the following steps:

[0085] S01, blow the waste flue gas denitrification catalyst with compressed air for 23 to 30 minutes for each module to remove the dust in the tunnel;

[0086] S02, use a high-pressure water gun to flush the catalyst after dust removal. The flushing time of each module is 25-30min, and the pressure is 7-10Mpa to further remove the dust in the channel;

[0087] S03, drying the washed catalyst;

[0088] S1, pulverizing the catalyst and adding concentrated sulfuric acid for acidolysis, adding water after acidolysis to obtain a titanyl sulfate solution, which specifically includes the following steps:

[0089] S11, pulverizing the catalyst into 190 mesh catalyst powder;

[0090] S12, put the catalyst powder into a lead-made acidolysis tank, add 90% to 92% concentrated sulfuric acid according to the weight ratio of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com