Solar-driven lignite multi-generation power generation system and operation method

A power generation system and solar energy technology, applied in solar thermal power generation, mechanical power generation with solar energy, and mechanisms for generating mechanical power, etc., can solve the problems of high-grade heat waste, incompatible energy cascade utilization, and excessive extraction of flue gas. , to achieve clean utilization, improve energy utilization efficiency, and avoid environmental pollution and energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

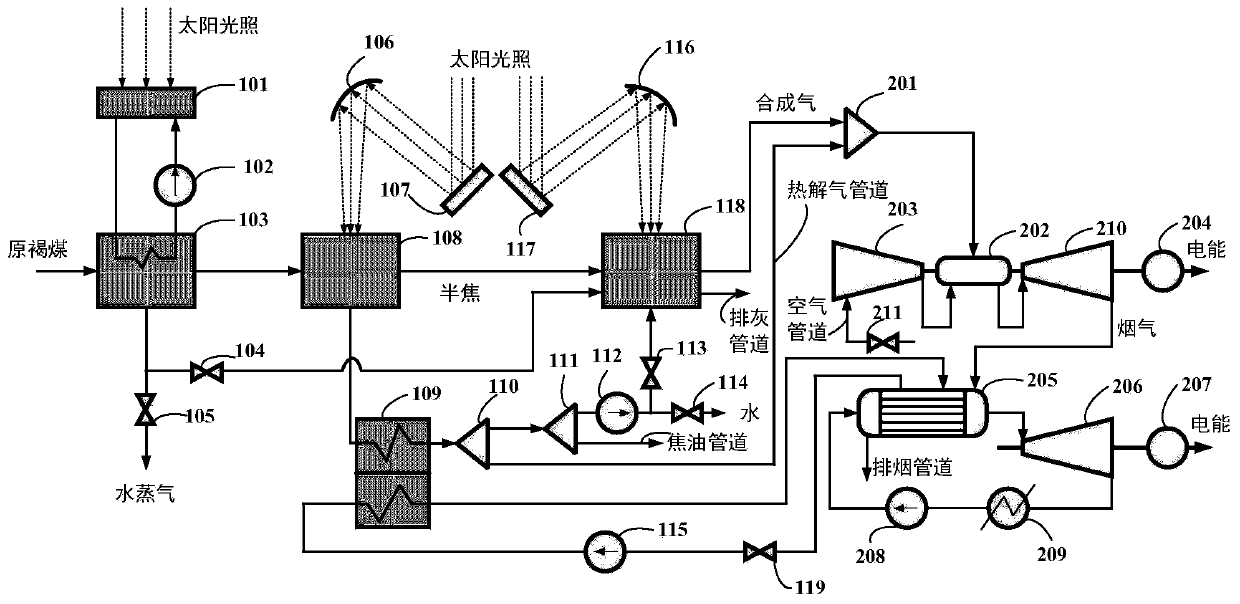

[0019] Such as figure 1 As shown, a solar-driven lignite polygeneration power generation system of the present invention includes a steam dryer 103, a tower solar pyrolyzer 108, a tower solar gasifier 118, a mixer 201, and a combustion chamber 202 connected in sequence , gas turbine 210 and waste heat boiler 205, gas turbine 210 is connected to generator A 204; also includes steam turbine 206, condenser 209 and feed water pump 208, steam turbine 206 connected in sequence with the steam outlet of waste heat boiler 205 The rotating shaft of the steam dryer 103 is connected to the generator second 207; the heat source pipeline of the steam dryer 103 is connected with the trough solar collector 101 through the dry water pump 102; the exhaust steam pipeline of the steam dryer 103 is passed through the pipeline of the steam valve first 104 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com