A method for processing organic waste by coupling hydrogenation fermentation with microalgae cultivation

A technology for organic waste and organic matter, which is applied in the field of hydrino fermentation coupled with microalgae cultivation to treat organic waste, can solve the problems of low energy recovery rate, eutrophication, low removal rate of organic pollutants, etc. The effect of increasing conversion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

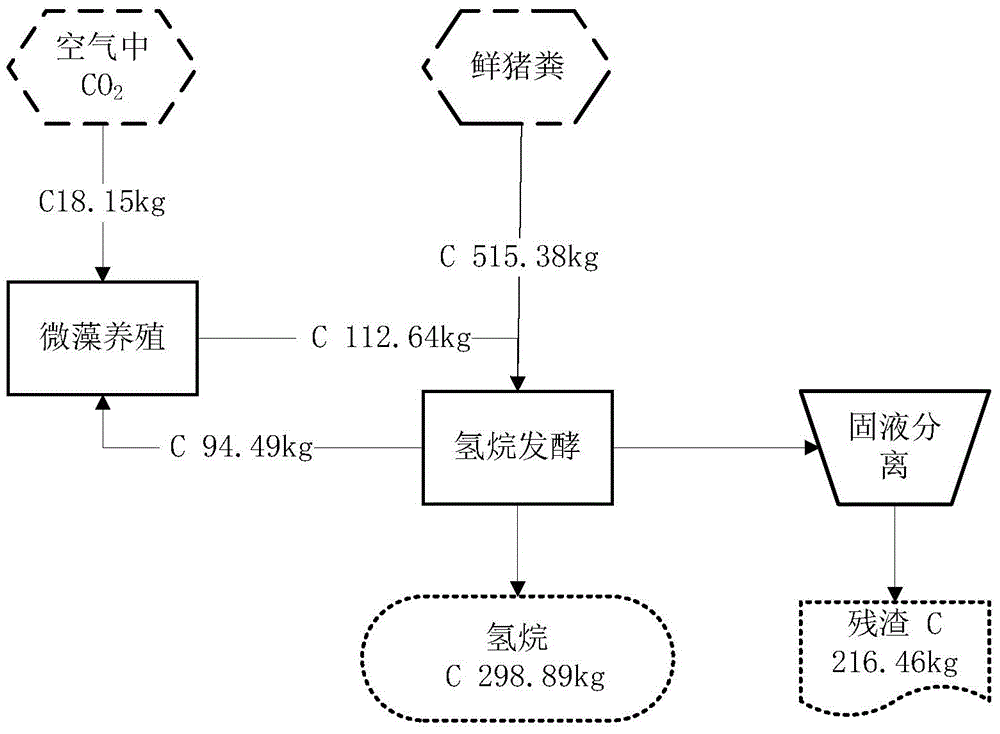

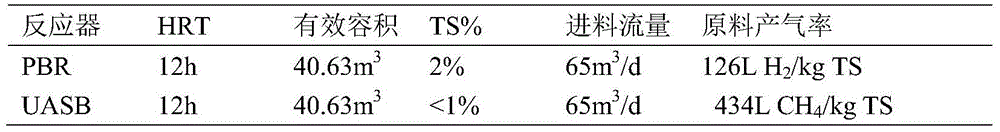

Embodiment 1

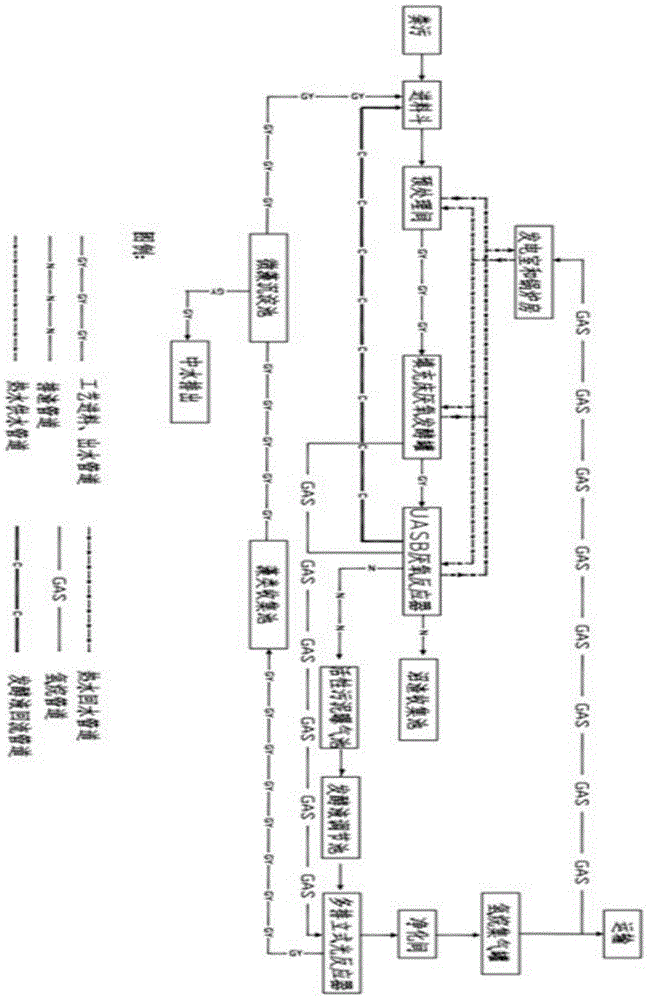

[0032] Method of the present invention is as follows:

[0033] (1) Hydrogen fermentation: the raw materials are removed from mechanical impurities and sanded, then enter the adjustment tank, adjust the initial pH and water content, and then enter the hydrogen fermentation reactor. After fermentation, hydrolysis and acidification, they are converted into small molecular organic substances. The fermentation gas products are mainly hydrogen and carbon dioxide. ;

[0034] (2) Residue methane fermentation: adjust the pH value of the fermented liquid discharged after hydrogen fermentation, enter the methanogenic fermentation reactor, and convert small molecular organic matter into methane and carbon dioxide by methanogenic microorganisms;

[0035](3) Pretreatment of methane-producing fermentation broth: the fermented fermentation broth after precipitation is used as fertilizer, and the liquid part is pretreated by aerobic treatment, physical adsorption or electrochemistry, thereby r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com