Novel environment-protecting and energy-saving industrial boiler system

An environmental protection and energy-saving industrial boiler technology, applied in the direction of combustion method, indirect carbon dioxide emission reduction, solid fuel combustion, etc., can solve the problems of low thermal efficiency, high emission of smoke, sulfur dioxide and nitrogen oxides, so as to improve thermal efficiency, realize clean utilization and save energy energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

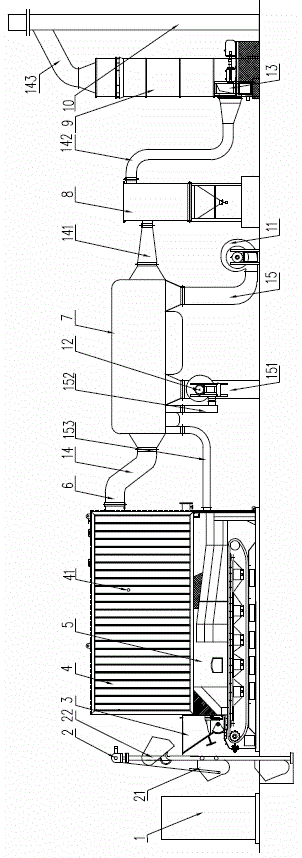

[0013] refer to figure 1 A new type of environmental protection and energy-saving industrial boiler system, mainly composed of an electrical control cabinet 1, a coal loading machine 2, a combustion chamber 5, a furnace body 4, an air preheater 7, a multi-tube dust collector 8, a water film dust collector 9 and a chimney 10 The coal loading machine 1 is composed of a coal hopper 21 and a guide rail 22. The coal hopper 21 can run up and down along the guide rail 22. The lower part of the furnace body 4 is a combustion chamber 5. The furnace body 4 has a furnace temperature measuring port 41 and a flue gas outlet 6 at the rear. , the front of the combustion chamber 5 has a coal hopper 3 and the rear has a secondary air outlet 51; the flue gas outlet 6 is connected to the air preheater 7 through the flue I14, and the air preheater 7 is connected to the multi-pipe dust collector 8 through the flue II141 , the multi-tube dust collector 8 is connected to the lower part of the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com