Catalyst for rapid pyrolysis and liquefaction of biomass as well as preparation method and application thereof

A catalyst and biomass technology, used in physical/chemical process catalysts, preparation of liquid hydrocarbon mixtures, metal/metal oxide/metal hydroxide catalysts, etc. The problems of weak carbon deposition ability and poor comprehensive catalytic effect can achieve the effect of easy modulation, low cost and special electronic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

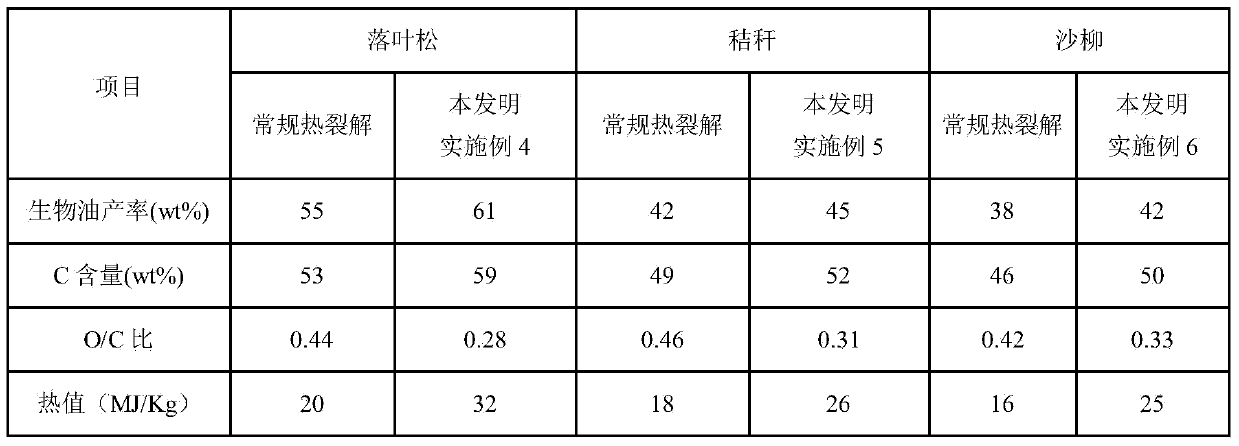

Examples

preparation example Construction

[0022] The preparation method of the catalyst that the present invention proposes is used for biomass rapid pyrolysis liquefaction, comprises the following steps:

[0023] (1) Make the biomass particles react in nitrogen atmosphere at 450-600°C for 0.5-1.5 seconds to generate a mixture of fast pyrolytic charcoal and pyrolytic steam, and make the mixture of fast pyrolytic charcoal and pyrolytic steam undergo gas-solid separation , to obtain fast pyrolysis carbon and pyrolysis steam, and condense the pyrolysis steam at 0-10°C to obtain bio-oil and reducing non-condensable gas;

[0024] (2) Using the Soxhlet extraction method, extract the above-mentioned fast pyrolytic carbon with an organic solvent for 5 to 8 hours to remove the residual bio-oil in the fast pyrolytic carbon. The organic solvent is toluene, dichloromethane, anhydrous Any of diethyl ether or petroleum ether;

[0025] (3) Soak the fast pyrolytic carbon treated in step (2) in an alkaline solution with a molar conce...

Embodiment 1

[0034] (1) Catalyst carrier preparation process

[0035] The larch particles are reacted at 500°C for 1 second in a nitrogen atmosphere to generate a mixture of larch fast pyrolysis charcoal and larch pyrolysis vapor, and the mixture of larch fast pyrolysis charcoal and larch pyrolysis vapor is subjected to gas-solid separation , to obtain larch fast pyrolysis charcoal and larch pyrolysis vapor, and condense the larch pyrolysis vapor at 5° C. to obtain larch bio-oil and larch reducing non-condensable gas;

[0036] (2) Catalyst carrier pretreatment process

[0037] Using the Soxhlet extraction method, the larch fast pyrolytic charcoal was extracted with toluene for 5 hours to remove the larch bio-oil remaining in the larch fast pyrolytic charcoal; then soaked in a KOH solution with a molar concentration of 2mol / L for 0.5 hours , the weight ratio of fast pyrolytic carbon to KOH solution is 1:1, then washed with deionized water to pH = 7, and dried at 105°C for 3 hours; the trea...

Embodiment 2

[0041] (1) Catalyst carrier preparation process

[0042] The straw particles are reacted at 450°C for 0.5 seconds under a nitrogen atmosphere to generate a mixture of straw rapid pyrolysis charcoal and straw pyrolysis steam, and the mixture of straw rapid pyrolysis charcoal and straw pyrolysis vapor is subjected to gas-solid separation to obtain straw rapid pyrolysis Decomposing charcoal and straw pyrolysis steam, condensing the straw pyrolysis steam at 0-2°C to obtain straw bio-oil and straw reducing non-condensable gas;

[0043] (2) Catalyst carrier pretreatment process

[0044] Using the Soxhlet extraction method, the straw rapid pyrolysis carbon was extracted with anhydrous ether for 6 hours to remove the residual straw bio-oil in the straw rapid pyrolysis carbon; then soaked in NaOH solution with a molar concentration of 4mol / L for 2 hours, The weight ratio of fast pyrolytic carbon to NaOH solution is 1:0.5, then washed with deionized water to pH = 7, and dried at 120°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com